38 Special Wadcutter Handloading Problem!

+15

Al W.

james r chapman

PhotoEscape

DA/SA

oldsalt444

Allgoodhits

bruce martindale

LenV

fc60

sharkdoctor

S148

gregbenner

Wobbley

Greg Walloch

Multiracer

19 posters

Page 2 of 3

Page 2 of 3 •  1, 2, 3

1, 2, 3

38 Special Wadcutter Handloading Problem!

38 Special Wadcutter Handloading Problem!

First topic message reminder :

For the first time, I am handloading for my S&W K38(?) with 148 lead wadcutters. Most of the loaded cases will not fully chamber. I am seating the bullets slightly below the mouth with a slight crimp. I am using a mixture of nickel-plated Winchester/RP/Federal brass. The resized cases fit easily into the chambers. Any suggestions on what I am doing wrong.

For the first time, I am handloading for my S&W K38(?) with 148 lead wadcutters. Most of the loaded cases will not fully chamber. I am seating the bullets slightly below the mouth with a slight crimp. I am using a mixture of nickel-plated Winchester/RP/Federal brass. The resized cases fit easily into the chambers. Any suggestions on what I am doing wrong.

steve_podleski- Posts : 40

Join date : 2012-09-01

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Dave, Are there variations of wall thickness and taper profile for non-plus p marked ww or Remington brass? I have ball mikes, should go check...

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

There was a link to a study on 38 special brass wall thickness. Way back in 2016 or so. Link is long since but I suppose it could be found in an archive somewhere. The conclusion is that not all makes had straight brass to the depth of a HBWC. Even some +P brass could accommodate a wadcutter, others could not. Basically the guy found that there was no true “Wadcutter brass”. Which makes sense if you think about it. Why would a manufacturer make special brass? He has to bo for “+P” because the headstamp is different

Wobbley- Admin

- Posts : 4808

Join date : 2015-02-13

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Greetings,

A Ball micrometer might not have enough reach. My micrometer only goes in 0.450". A Remington 38 HBWC is close to 0.600" long.

Lately, I have been sizing the case, flare the mouth (no expanding), and slip a gauge pin in the case until I feel resistance at the end.

Then, with a fine tip Sharpie marker, I draw a line around the pin at the case mouth.

Removing the pin reveals how much depth is available before the wall taper starts.

Most of my 38 brass is from my Father-in-laws estate. He shot with the All Army Team back in the late '50's to early '60's.

There is a mix of Peters, Remington, Federal, Western, and REM-UMC to choose from. All have case walls designed for full length wadcutter bullets.

I do cruise the Goon Shows watching for brass. Sometimes I get lucky.

My friend recently purchased 1,000 pieces of new R-P brass and the gauge pin does not go in as far as the old 38 brass I have.

It is more difficult (costly) to draw the cases with uniform walls suitable for wadcutters. Probably why the manufacturers do not do this for bulk brass sales.

Cheers,

Dave

A Ball micrometer might not have enough reach. My micrometer only goes in 0.450". A Remington 38 HBWC is close to 0.600" long.

Lately, I have been sizing the case, flare the mouth (no expanding), and slip a gauge pin in the case until I feel resistance at the end.

Then, with a fine tip Sharpie marker, I draw a line around the pin at the case mouth.

Removing the pin reveals how much depth is available before the wall taper starts.

Most of my 38 brass is from my Father-in-laws estate. He shot with the All Army Team back in the late '50's to early '60's.

There is a mix of Peters, Remington, Federal, Western, and REM-UMC to choose from. All have case walls designed for full length wadcutter bullets.

I do cruise the Goon Shows watching for brass. Sometimes I get lucky.

My friend recently purchased 1,000 pieces of new R-P brass and the gauge pin does not go in as far as the old 38 brass I have.

It is more difficult (costly) to draw the cases with uniform walls suitable for wadcutters. Probably why the manufacturers do not do this for bulk brass sales.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Several questions.

Will an assortment of fired, unsized cases go into all cylinder charges holes?

Will an assortment of resized cases go into the all cylinder charge holes?

If not make resizing die is threaded down far enough to get as much of a full length resize as possible. Of course make sure they are not .357 mag cases that got mixed in somehow. Is there crud build up in the cylinder?

Is it possible you got a poorly sized batch HBWC that are greater than .358 or so? Measure a few. I think Remington HBWC are close to .360.

Try not seating the bullets quite so deep, and a bit less crimp. I can't imagine that is the problem, but work through things until you find it. I think it is the resizing die adjustment or possibly the die itself.

Will an assortment of fired, unsized cases go into all cylinder charges holes?

Will an assortment of resized cases go into the all cylinder charge holes?

If not make resizing die is threaded down far enough to get as much of a full length resize as possible. Of course make sure they are not .357 mag cases that got mixed in somehow. Is there crud build up in the cylinder?

Is it possible you got a poorly sized batch HBWC that are greater than .358 or so? Measure a few. I think Remington HBWC are close to .360.

Try not seating the bullets quite so deep, and a bit less crimp. I can't imagine that is the problem, but work through things until you find it. I think it is the resizing die adjustment or possibly the die itself.

Allgoodhits- Posts : 901

Join date : 2017-09-17

Location : Southport, NC

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

The resized cases fit into the cylinderAllgoodhits wrote:Several questions.

Will an assortment of fired, unsized cases go into all cylinder charges holes?

Will an assortment of resized cases go into the all cylinder charge holes?

If not make resizing die is threaded down far enough to get as much of a full length resize as possible. Of course make sure they are not .357 mag cases that got mixed in somehow. Is there crud build up in the cylinder?

Is it possible you got a poorly sized batch HBWC that are greater than .358 or so? Measure a few. I think Remington HBWC are close to .360.

Try not seating the bullets quite so deep, and a bit less crimp. I can't imagine that is the problem, but work through things until you find it. I think it is the resizing die adjustment or possibly the die itself.

The diameter of the bullets are .3585

All cylinders holes were cleaned.

I am thinking of seating the bullets halfway out of the case to avoid the thicker walls near the base.

steve_podleski- Posts : 40

Join date : 2012-09-01

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

As Len mentioned, Lee makes a Factory Crimp Die. I am not sure exactly what they do, but they have a sliding collar of some type which resizes the loaded case during the neck crimp phase. I use them for .38 Super, .38 Special and .45 acp. They work.

MJ

MJ

Allgoodhits- Posts : 901

Join date : 2017-09-17

Location : Southport, NC

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

All good hits mentioned sizing. I have factory Winchester hbwc that measure 358 at the head but .362 at the skirt.

It is a squeeze fit even into unresized cases. Wondering if it is worthwhile to resize prior to use in a 52? The 52 has a small diameter groove barrel.

I always used as is in the past.

CORRECTED DIMENSIONS SORRY

It is a squeeze fit even into unresized cases. Wondering if it is worthwhile to resize prior to use in a 52? The 52 has a small diameter groove barrel.

I always used as is in the past.

CORRECTED DIMENSIONS SORRY

Last edited by bruce martindale on 2/13/2019, 4:06 pm; edited 1 time in total

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Brucebruce martindale wrote:All good hits mentioned sizing. I have factory Winchester hbwc that measure 360 at the head but .378 at the skirt.

It is a squeeze fit even into unresized cases. Wondering if it is worthwhile to resize prior to use in a 52? The 52 has a small diameter groove barrel.

I always used as is in the past.

What is the skirt?

steve_podleski- Posts : 40

Join date : 2012-09-01

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Wow.bruce martindale wrote:The bullet is tapered.

Did not know that!

My Penn bullets are .3585 on both ends. Much smaller diameter than your Winchesters!

steve_podleski- Posts : 40

Join date : 2012-09-01

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Ooooh that was dumb, the calipers were not zeroed, must have nudged it going back into the drawer.

That said, it's still a squeeze @0.362 on the skirt, 0.358 @ nose

Thanks

That said, it's still a squeeze @0.362 on the skirt, 0.358 @ nose

Thanks

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

I believe if you take a sample of Remmingtons they will measure .360" at the skirt and .357+- at the top. This is partly why many shooters like the Remmingtons. They are about the only ones left oversize.bruce martindale wrote:All good hits mentioned sizing. I have factory Winchester hbwc that measure 360 at the head but .378 at the skirt.

It is a squeeze fit even into unresized cases. Wondering if it is worthwhile to resize prior to use in a 52? The 52 has a small diameter groove barrel.

I always used as is in the past.

Multiracer- Posts : 1003

Join date : 2017-03-15

Location : North Ohio

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Oh, I see you corrected your measurements.

Ron

Ron

Multiracer- Posts : 1003

Join date : 2017-03-15

Location : North Ohio

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Greetings,

A while back, I tried sizing the Remington bullets down to 0.358".

Compared with unsized bullets, they shot worse.

My best groups have been with the Remington HBWC seated in UNSIZED fired cases and using a Lee Factory Carbide Crimp die as the last operation to ensure the ammo will chamber in an autoloader.

Cheers,

Dave

A while back, I tried sizing the Remington bullets down to 0.358".

Compared with unsized bullets, they shot worse.

My best groups have been with the Remington HBWC seated in UNSIZED fired cases and using a Lee Factory Carbide Crimp die as the last operation to ensure the ammo will chamber in an autoloader.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Ericbc7 likes this post

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

What distance are these targets ? Ransom rested testing ? Are you expanding just not sizing the OD of the case ?

Multiracer- Posts : 1003

Join date : 2017-03-15

Location : North Ohio

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Dave, That's the stuff!

But...you likely had a .357 groove barrel whereas I am looking at a Smith 52 which is smaller and might fare better. We shall see what resized hbwc do for me.

Your suggestion on the pin gage opened my eyes. I used a letter drill T and found tapered brass where not expected. More testing to follow. Thanks

But...you likely had a .357 groove barrel whereas I am looking at a Smith 52 which is smaller and might fare better. We shall see what resized hbwc do for me.

Your suggestion on the pin gage opened my eyes. I used a letter drill T and found tapered brass where not expected. More testing to follow. Thanks

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Greetings,

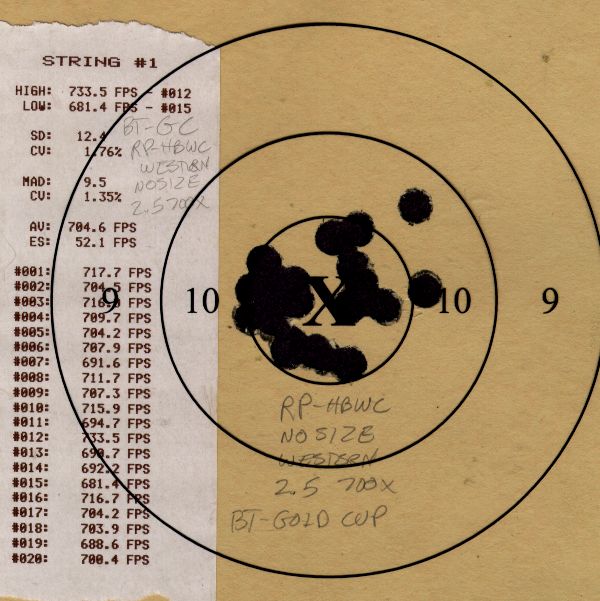

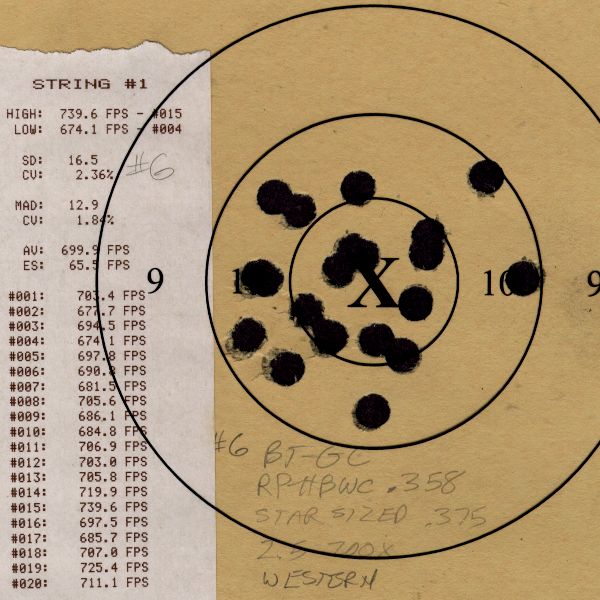

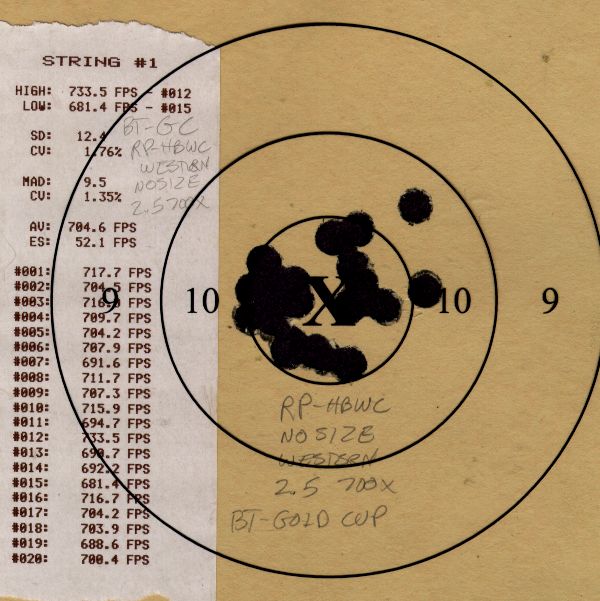

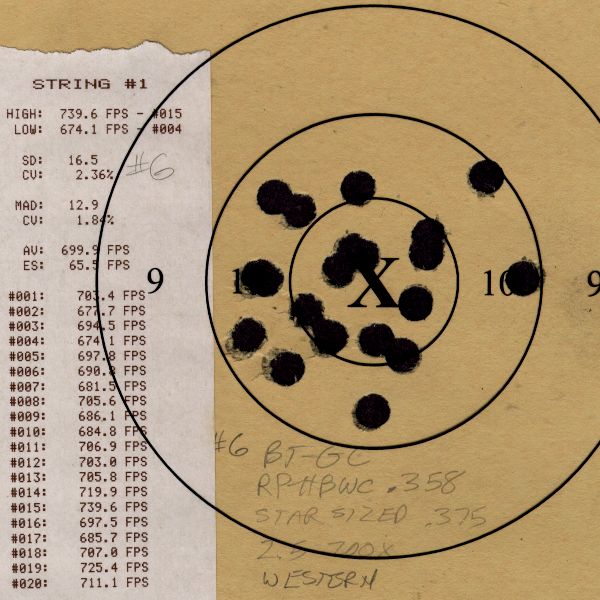

The test targets are fired at 50 yards with a Gold Cup National Match MK III barrel mounted in a machine fixture.

Yes, this barrel does measure 0.357" groove diameter.

I look forward to Bruce's test results with resized bullets. Please do test un-sized and sized bullets with the same setup on the same day.

I miss the H&N bullets. All you had to do was take them out of the box. No bumping, resizing, etc.

Cheers.

Dave

The test targets are fired at 50 yards with a Gold Cup National Match MK III barrel mounted in a machine fixture.

Yes, this barrel does measure 0.357" groove diameter.

I look forward to Bruce's test results with resized bullets. Please do test un-sized and sized bullets with the same setup on the same day.

I miss the H&N bullets. All you had to do was take them out of the box. No bumping, resizing, etc.

Cheers.

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Will do.

My Star loader 3BE bar drops 2.4 700-x or 3.0 wst . The latter are faster. Which would you choose to test?

Will run against factory (old) Remington and Winchester wc loads as well.

...When it warms up. Crappy in NY now.

My Star loader 3BE bar drops 2.4 700-x or 3.0 wst . The latter are faster. Which would you choose to test?

Will run against factory (old) Remington and Winchester wc loads as well.

...When it warms up. Crappy in NY now.

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

2 things - Use a Lee factory crimp die which resizes the loaded round back to factory specs. It has a carbide sizing ring in the bottom like your sizing die. Or you can use a taper crimp die in a separate step after the bullet is seated. Those bullet seater/roll crimper dies that do both in one step are good for bulging out the case mouth and that is likely the cause of your problem.

Crimping the bullet works best when done in a separate step.

Crimping the bullet works best when done in a separate step.

oldsalt444- Posts : 288

Join date : 2011-10-27

Location : Commiefornia

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Greetings Bruce,

I would use neither powder.

Have you access to a lathe?

I have a fixture to machine the bars to 0.501" to accept 1/2" brass bushings. I can modify an old bar for you.

I have bushings bored up in CC (Cubic Centimeter) values. I just swap out the bushing I need. They are marked and I use the Lee VMD method of dispensing powder.

Cheers,

Dave

I would use neither powder.

Have you access to a lathe?

I have a fixture to machine the bars to 0.501" to accept 1/2" brass bushings. I can modify an old bar for you.

I have bushings bored up in CC (Cubic Centimeter) values. I just swap out the bushing I need. They are marked and I use the Lee VMD method of dispensing powder.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

Oldsalt...l found the Lee fcp (for 9 abd 45) was undersize and it swaged the bullet in the case resulting in undersize bullets.

I measured the bullet, seated, fcp'ed it, pulled and re measured.

No Bueno. Shrunk several thou. Have you tested that in 38s?

Thanks

I measured the bullet, seated, fcp'ed it, pulled and re measured.

No Bueno. Shrunk several thou. Have you tested that in 38s?

Thanks

LenV- Posts : 4770

Join date : 2014-01-24

Age : 74

Location : Oregon

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

What is the purpose of using the factory crimp die with no crimp? BTW, what is a factory crimp die?LenV wrote:I use 4 dies. For WC I use a sizing die, powder feed, seat and roll crimp then the factory crimp die with no crimp. Same with LRN and L-SWC. For jacketed bullets I also use 4 but just seat with the third and use the 4th die to crimp also. They all feed, feel and look good

steve_podleski- Posts : 40

Join date : 2012-09-01

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

I had the same issue using a .38/357 FCD with .358"lead projectiles.bruce martindale wrote:Oldsalt...l found the Lee fcp (for 9 abd 45) was undersize and it swaged the bullet in the case resulting in undersize bullets.

I measured the bullet, seated, fcp'ed it, pulled and re measured.

No Bueno. Shrunk several thou. Have you tested that in 38s?

Thanks

It took considerable pressure and made a good "clumk" as it passed over the case where the projectile was seated.

It doesn't live in my tool head any more!

DA/SA- Posts : 1508

Join date : 2017-10-09

Age : 68

Location : Southeast Florida

Re: 38 Special Wadcutter Handloading Problem!

Re: 38 Special Wadcutter Handloading Problem!

I don't use the crimp in the 4th die on lead bullets because I have already given them a heavy roll crimp in the third die. The Factory crimp die is like using a plop test. If it goes thru that die (and it will) then it will run in your pistol. Lee describes it here.steve_podleski wrote:What is the purpose of using the factory crimp die with no crimp? BTW, what is a factory crimp die?LenV wrote:I use 4 dies. For WC I use a sizing die, powder feed, seat and roll crimp then the factory crimp die with no crimp. Same with LRN and L-SWC. For jacketed bullets I also use 4 but just seat with the third and use the 4th die to crimp also. They all feed, feel and look good

https://www.midwayusa.com/product/251707/lee-carbide-factory-crimp-die

LenV- Posts : 4770

Join date : 2014-01-24

Age : 74

Location : Oregon

Page 2 of 3 •  1, 2, 3

1, 2, 3

Similar topics

Similar topics» Leading problem with .38 special

» Potential problem loading .38 Special wadcutters?

» 38 Special Wadcutter

» 38 Special cast wadcutter with less smoke?

» 38 special wadcutter

» Potential problem loading .38 Special wadcutters?

» 38 Special Wadcutter

» 38 Special cast wadcutter with less smoke?

» 38 special wadcutter

Page 2 of 3

Permissions in this forum:

You cannot reply to topics in this forum