Ranson Rest vs. Linear Slide (Testing)

+10

pgg

bruce martindale

Wes Lorenz

fc60

jglenn21

S148

NukeMMC

james r chapman

Jon Eulette

tovaert

14 posters

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Ranson Rest vs. Linear Slide (Testing)

Ranson Rest vs. Linear Slide (Testing)

First topic message reminder :

I read in the past that the design theory behind the RR is that it mimics the shooter's wrist and thus recoils via pivoting, impeded by a spring-loaded torsion-friction plate consisting of some unknown friction material(s) (sensitive to humidity, flatness, trapped wear debris, hysteresis, and temperature, to name a few). My RR is inconsistent in recoil (as measured by a goniometer), despite very precise loads whose MV varies in the single digits (ES), all else remaining the same. I most often get vertical stringing and sometimes wild side-to-side variation, from the same gun, which, tested not long before that, yielded very good groups (all else the same!). The manual offers very few suggestions for "fixes". I've also read about a wide variety of opinions on grip tensioning, or the degree of grip compression as measured by gap thickness between the polymer blocks, whose thickness can vary, which then affects the clamping force for a given gap.

I'm curious if anyone has ever removed the friction material and instead installed a ball or roller thrust bearing creating a frictionless pivot, and braked the device another way (spring/air-damper, etc.)? That removes the variation in friction properties of the pivot material. I thought I read something about a gunsmith with something that functioned like that, but I can't recall who that was.

On the other hand, I was watching a video a while back where Swiss P210s were tested at 50m. They were using a mount attached to a linear ball-bearing slide, impeded by a damping device, with no pivoting recoil. The pistol recoiled straight back. If you tested the same pistol using the two methods, and there was statistically-relevant variation in group size (all else the same), what could cause the variation? Differences in unlocking time? Bushing/barrel friction? Slide/frame friction? I'm referring to 1911s BTW...

I have a linear ball-bearing slide, and it would be easy to fashion something to hold RR grips, a brake, and use a remote trigger mechanism for testing.

I read in the past that the design theory behind the RR is that it mimics the shooter's wrist and thus recoils via pivoting, impeded by a spring-loaded torsion-friction plate consisting of some unknown friction material(s) (sensitive to humidity, flatness, trapped wear debris, hysteresis, and temperature, to name a few). My RR is inconsistent in recoil (as measured by a goniometer), despite very precise loads whose MV varies in the single digits (ES), all else remaining the same. I most often get vertical stringing and sometimes wild side-to-side variation, from the same gun, which, tested not long before that, yielded very good groups (all else the same!). The manual offers very few suggestions for "fixes". I've also read about a wide variety of opinions on grip tensioning, or the degree of grip compression as measured by gap thickness between the polymer blocks, whose thickness can vary, which then affects the clamping force for a given gap.

I'm curious if anyone has ever removed the friction material and instead installed a ball or roller thrust bearing creating a frictionless pivot, and braked the device another way (spring/air-damper, etc.)? That removes the variation in friction properties of the pivot material. I thought I read something about a gunsmith with something that functioned like that, but I can't recall who that was.

On the other hand, I was watching a video a while back where Swiss P210s were tested at 50m. They were using a mount attached to a linear ball-bearing slide, impeded by a damping device, with no pivoting recoil. The pistol recoiled straight back. If you tested the same pistol using the two methods, and there was statistically-relevant variation in group size (all else the same), what could cause the variation? Differences in unlocking time? Bushing/barrel friction? Slide/frame friction? I'm referring to 1911s BTW...

I have a linear ball-bearing slide, and it would be easy to fashion something to hold RR grips, a brake, and use a remote trigger mechanism for testing.

tovaert- Posts : 455

Join date : 2018-11-28

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Definitely follow PGG's sequence..

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Jon Eulette likes this post

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

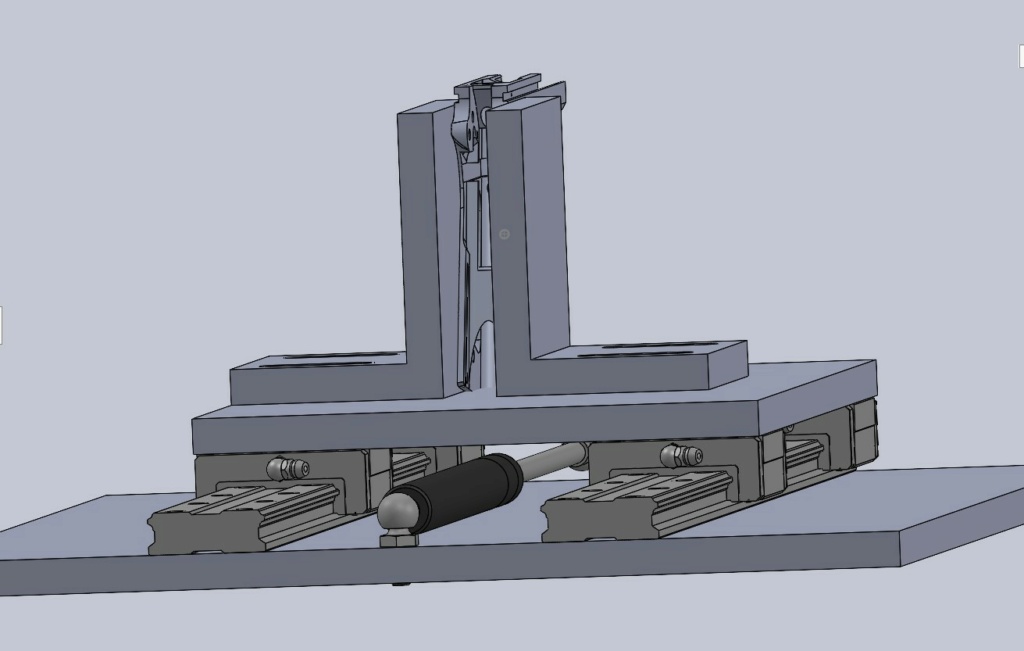

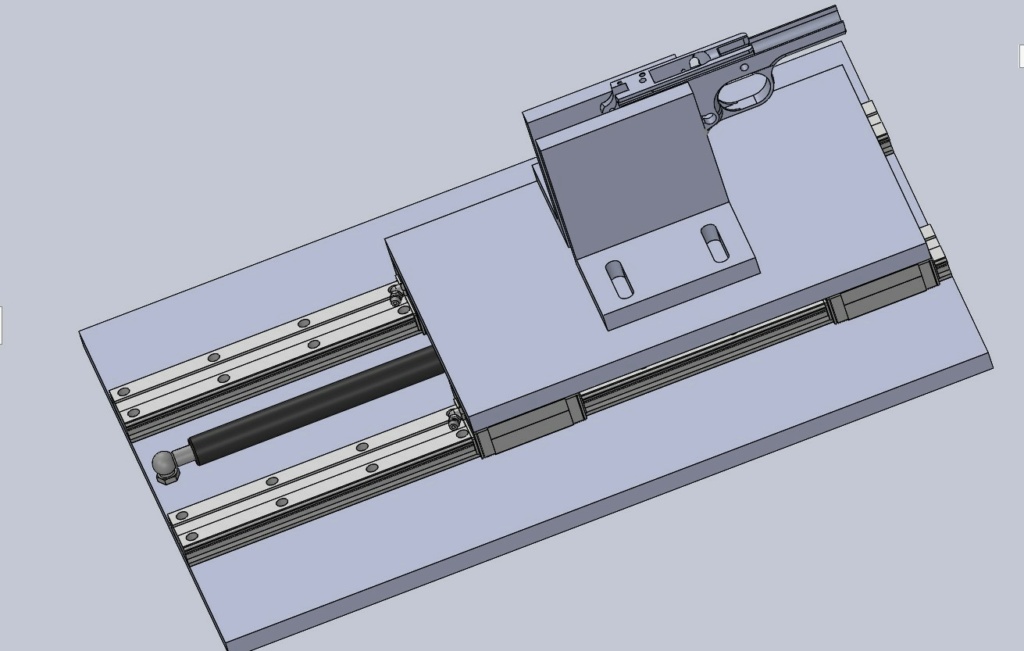

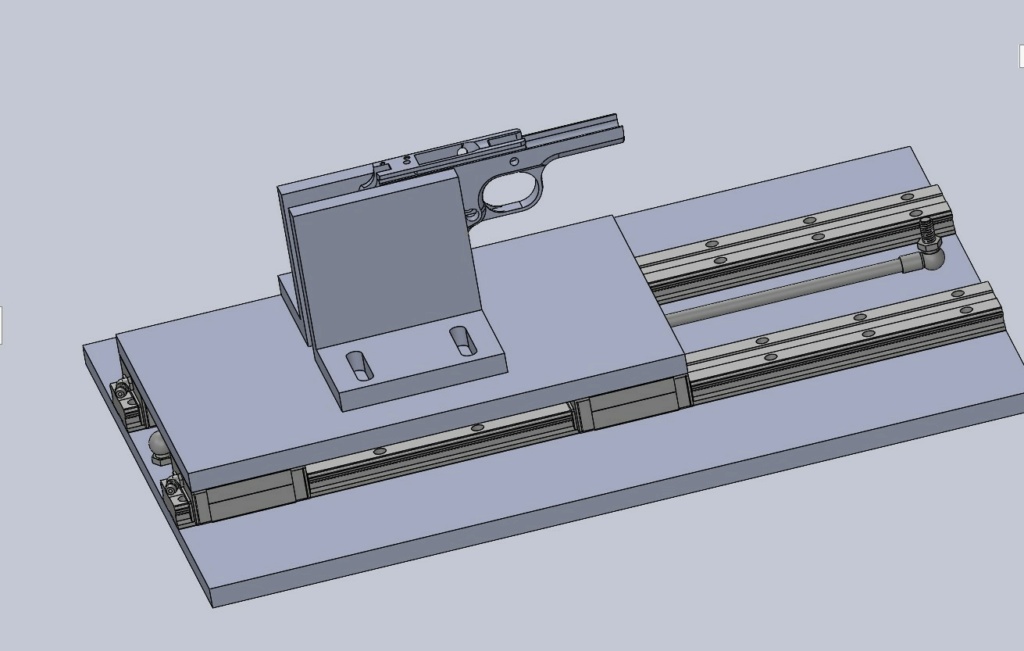

10sandxs wrote:how about this for a linear concept. please, no commentary on the crude drawing and lack of detail, just threw it together this am while waiting for the dr. the gun would probably be held by ransom rest inserts... or not... triggering would be via a small mechanism attached to the front of the trigger guard, like a small air cylinder or similar, I've never liked the trigger mechanism on the RR.

linear rails can be had for reasonable money and a shimmed slot on the base can be used to take out deviation by moving the rails appart and forcing the carrages onto one side of the bearing cage. gas spring to retard recoil and return the assembly forward for next shot.

https://www.amazon.com/CHUANGNENG-Linear-HGH20CA-Carriage-Routers/dp/B08HGZFH8L/ref=sr_1_8?crid=14UL04CW2XGMX&keywords=linear%2Bguide%2Brail&qid=1666705872&qu=eyJxc2MiOiI2Ljg4IiwicXNhIjoiNi4xMSIsInFzcCI6IjUuMTYifQ%3D%3D&sprefix=linear%2Bguide%2Brail%2Caps%2C130&sr=8-8&ufe=app_do%3Aamzn1.fos.f5122f16-c3e8-4386-bf32-63e904010ad0&th=1

these are not the rails used in the drawing, but would work as our forces and reps are relativly low

The thing to be aware of with these rail systems is that the manufacturer of quality parts will specify tolerances. I suspect you're not going to be happy with the slop inherent to a $67 kit that includes both rails and four linear bearing mounts. It'll show up on paper as unacceptable variability.

Just guessing, but I'd be shocked if a fixture made with the rail you linked could hold the 10 ring at 50 yards with a laser gun.

I built a machine rest for AR15s a few years ago. Basically, I machined an AR lower receiver into a big chunk of metal and put it on rails, with a remote trigger. I used four of these on similar precision quality rails.

https://buyrexroth.com/product/R103761620-lsao_a_16_dd

The total cost for the rails and four linear bearings was $907. Each rail was $183.

A photo and video -

As an aside, related to my above post about the RR ... note that the first round (manually chambered) is not part of the group of rounds auto-loaded from the magazine.

When I was ordering parts, I did the math based on the length of the rails, the amount of slop (in micrometers) based on the specified part tolerance. The errors stack up fast. For example, if you put a 12" carriage on those Amazon rails to hold a pistol, slop of just one mm in the bearing would translate into about four inches of potential error on a target 50 yards away. Yeah ... it's that bad. You have to assume the front/rear bearings are maximally off in opposite direction so it's (1mm front bearing slop + 1 mm rear bearing slop) * 50 yards / 12 inches = ~100 mm = ~4 inches.

I don't have my notes handy, but with those parts, that length carriage, and a distance of 100 yards, the error that could be solely attributable to the bearings/rails on my rifle fixture was on the order of 1/4". Which isn't trivial, if you're splitting hairs looking for the best match load. I accepted that, for my purposes, because I was up against practical limits of how long the thing could be, and how much money I wanted to spend.

If you want to make a go of a pistol fixture using bearings and rails, you'll want ones with tolerances measured in micrometers. Not cheap Amazon Chinesium parts intended for hobby 3D printers that don't have to make square parts, that don't even provide tolerance data.

pgg- Posts : 198

Join date : 2015-11-21

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

pgg wrote:

When I was ordering parts, I did the math based on the length of the rails, the amount of slop (in micrometers) based on the specified part tolerance. The errors stack up fast. For example, if you put a 12" carriage on those Amazon rails to hold a pistol, slop of just one mm in the bearing would translate into about four inches of potential error on a target 50 yards away. Yeah ... it's that bad. You have to assume the front/rear bearings are maximally off in opposite direction so it's (1mm front bearing slop + 1 mm rear bearing slop) * 50 yards / 12 inches = ~100 mm = ~4 inches.

I don't have my notes handy, but with those parts, that length carriage, and a distance of 100 yards, the error that could be solely attributable to the bearings/rails on my rifle fixture was on the order of 1/4". Which isn't trivial, if you're splitting hairs looking for the best match load. I accepted that, for my purposes, because I was up against practical limits of how long the thing could be, and how much money I wanted to spend.

If you want to make a go of a pistol fixture using bearings and rails, you'll want ones with tolerances measured in micrometers. Not cheap Amazon Chinesium parts intended for hobby 3D printers that don't have to make square parts, that don't even provide tolerance data.

linear rails can be had for reasonable money and a shimmed slot on the base can be used to take out deviation by moving the rails appart and forcing the carrages onto one side of the bearing cage.

Completely agree with tollerance/error stack. this is why I propose cutting a slot in the base, setting the rail into it, and using set screws or shims to drive the rails together/appart to force all the "gaps" in opposite directions for the two rails. See picture below for example. yes, the other side of each block is not load bearing but based on relativly small loads I don't see that as a big deal. in reality, you only need it to return to the same place and travel accuratly for a very short time when the gun is fired as the bullet will be gone before the carrrage moves much.

yes amazon rails/bearings aren't great, but they're certainly not "mm" tollerance either. I think I may have some laying arround from student projects, I'll see if I can grab one and get some slop measurements.

my thought was to make it cost effective so people could make thier own but still have the precision needed. I'd supply drawings if I make one and it works.

10sandxs- Posts : 972

Join date : 2016-01-29

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

To me, linear rails make sense for a barrel test fixture and probably for a rifle tester, but not for a whole pistol.

We see differences between shooting from the hand and in a ransom rest because the pistol reacts and moves differently during those few milliseconds of transit time. The differences would be even bigger if the pistol does not rotate and the unlocking time would probably be different if the pistol moves back linearly.

We see differences between shooting from the hand and in a ransom rest because the pistol reacts and moves differently during those few milliseconds of transit time. The differences would be even bigger if the pistol does not rotate and the unlocking time would probably be different if the pistol moves back linearly.

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

As has been said before, the differences in the dynamics of shot execution make a Ransom Rest or the linear rifle rest I saw in use at Quantico range 1 more an indicator of what a rifle or pistol CAN do with a given load.

Similar to the recoil spring discussion, I saw an M14 go from shooting a donut-shaped 2moa group at 300yds to a sub-moa knot by simply changing the gas piston. Same ammo, same rifle in the test sled at Q-co.

I use my RR to test loads. I get an idea of what seems to group best for a pistol, then I can tweak it from there to figure out reliability and what shoots best IN MY HAND.

Similar to the recoil spring discussion, I saw an M14 go from shooting a donut-shaped 2moa group at 300yds to a sub-moa knot by simply changing the gas piston. Same ammo, same rifle in the test sled at Q-co.

I use my RR to test loads. I get an idea of what seems to group best for a pistol, then I can tweak it from there to figure out reliability and what shoots best IN MY HAND.

NukeMMC- Posts : 564

Join date : 2018-10-12

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

I think the first question I posed to the list was about using a RR. I am still learning. A main issue to me, which none of the above addresses, is that the RR orients (repeatably, hopefully) the frame to the target - not the barrel, which has a variable relationship to the frame and possibly the sights, e.g. especially the 1911. One solution would be to use a scope, and confirm aimpoint on the target. But again, that orients the slide and not necessarily the barrel in a 1911.

How about cutting to the chase, and determining exactly where the barrel is pointed before firing? This could be done with a laser sighting tool with appropriate precision spud for the barrel, to ensure POA hasn't changed. Anyone try that? I don't have one, or I would. On the other hand, I want to know how the gun shoots from the hand. A first shot that goes out of group should be known, if it happens, and not discarded from the group. We then must understand why. We don't get mulligans on the line.

Just another sometimes frustrated RR user.

How about cutting to the chase, and determining exactly where the barrel is pointed before firing? This could be done with a laser sighting tool with appropriate precision spud for the barrel, to ensure POA hasn't changed. Anyone try that? I don't have one, or I would. On the other hand, I want to know how the gun shoots from the hand. A first shot that goes out of group should be known, if it happens, and not discarded from the group. We then must understand why. We don't get mulligans on the line.

Just another sometimes frustrated RR user.

sharkdoctor- Posts : 179

Join date : 2014-10-16

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

I think some are expecting more out of a RR than it's designed and intended to give. One certainly shouldn't expect a RR to prove a gun/load will perform to any given level when fired from one's hand. But that's not what it's for. It's just a tool for evaluating ammo and barrels with as much human factor removed as possible.

It can certainly identify BAD loads that you shouldn't waste components and range time testing in your hand. Just because it can't prove a load will shoot well and have a tolerable degree/quality of recoil in your hand doesn't mean that valuable information isn't there for the taking.

It can certainly identify BAD loads that you shouldn't waste components and range time testing in your hand. Just because it can't prove a load will shoot well and have a tolerable degree/quality of recoil in your hand doesn't mean that valuable information isn't there for the taking.

pgg- Posts : 198

Join date : 2015-11-21

Photos

Photos

The second photo I posted above: the lower right shot was my fault, I knew it when the gun went off (verified it in the scope). The 11:00 flyer...not sure why. The other eight look good (@50 yards). When testing I keep my POI right of center to preserve the orange paster. I'm going to try to improve that under the same conditions (single load, two hands, pistol rest, etc.) when I get back next week, weather permitting. I'm also going to change the recoil spring from 8 to 9# (a 9mm SA RO).

I agree with pgg that the RR gives some useful information, at least L-R variation.

Don't buy a linear slide...I have one that is an integral base/saddle setup. There is a leadscrew in it now, but that's easily removed. It's about 6" wide and 14" long. It has seen almost no use so it's in EC. It is aluminum (sorry not the super-cool cast iron ones), but it's very tight and I think it's tight enough to use as a test platform. I'm happy to ship and *donate* it to someone who has the resources to fashion a linear pistol tester. Maybe there's a gunsmith out there who really like the opportunity to settle the question I posed?

I agree with pgg that the RR gives some useful information, at least L-R variation.

Don't buy a linear slide...I have one that is an integral base/saddle setup. There is a leadscrew in it now, but that's easily removed. It's about 6" wide and 14" long. It has seen almost no use so it's in EC. It is aluminum (sorry not the super-cool cast iron ones), but it's very tight and I think it's tight enough to use as a test platform. I'm happy to ship and *donate* it to someone who has the resources to fashion a linear pistol tester. Maybe there's a gunsmith out there who really like the opportunity to settle the question I posed?

tovaert- Posts : 455

Join date : 2018-11-28

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Having messed with a ransom rest and a Lee rest, if I had the resources to construct such a monstrosity, it would hold the bore in line, and within as much as possible, a large outer steel tube (od 2.5-3" and 2'long or so). Then that tube would rest in a solid V block base, much like the Mann devices or the similar English equivalent. That way the recoil forces, recoil direction, and center of mass would basically be all together on the same line.

My Lee rest screwed directly to the grip escutions and that worked. The ransom rubber clamp isn't horrible, but I think the easiest way would to just use a gun with a picatinny light rail and clamp to that.

And to the original problems with ransom rest recoiling variation; make sure grease from the pivot pin hasn't migrated and contaminated the friction disk.

My Lee rest screwed directly to the grip escutions and that worked. The ransom rubber clamp isn't horrible, but I think the easiest way would to just use a gun with a picatinny light rail and clamp to that.

And to the original problems with ransom rest recoiling variation; make sure grease from the pivot pin hasn't migrated and contaminated the friction disk.

Merick- Posts : 453

Join date : 2015-08-13

Location : Kansas

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Pm sent...tovaert wrote:The second photo I posted above: the lower right shot was my fault, I knew it when the gun went off (verified it in the scope). The 11:00 flyer...not sure why. The other eight look good (@50 yards). When testing I keep my POI right of center to preserve the orange paster. I'm going to try to improve that under the same conditions (single load, two hands, pistol rest, etc.) when I get back next week, weather permitting. I'm also going to change the recoil spring from 8 to 9# (a 9mm SA RO).

I agree with pgg that the RR gives some useful information, at least L-R variation.

Don't buy a linear slide...I have one that is an integral base/saddle setup. There is a leadscrew in it now, but that's easily removed. It's about 6" wide and 14" long. It has seen almost no use so it's in EC. It is aluminum (sorry not the super-cool cast iron ones), but it's very tight and I think it's tight enough to use as a test platform. I'm happy to ship and *donate* it to someone who has the resources to fashion a linear pistol tester. Maybe there's a gunsmith out there who really like the opportunity to settle the question I posed?

10sandxs- Posts : 972

Join date : 2016-01-29

10sandxs- Posts : 972

Join date : 2016-01-29

jglenn21, Merick, pgg and tovaert like this post

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Dealings With Bench Rest Testing a Revolver

» Nelson Conversion

» RANSOM REST TESTING

» Looking for Ransom rest testing

» Ransom Rest Testing

» Nelson Conversion

» RANSOM REST TESTING

» Looking for Ransom rest testing

» Ransom Rest Testing

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum