Speer Plinkers and Starline brass

+3

bruce martindale

jglenn21

fc60

7 posters

Page 1 of 1

Speer Plinkers and Starline brass

Speer Plinkers and Starline brass

Greetings,

Spent a pleasant day behind the Barrel Tester looking to see what results I could get using Speer Plinkers and StarLine brass.

TEST PARAMETERS....

I loaded 100 rounds of Plinkers examined closely by eye for defects in one loading session.

CCI500 Small Pistol primers.

Federal 100 Small Pistol primers used with the 0.314" bumped Plinker bullets.

1.62 grains of Bullseye, Lot #655 using a 0.165cc powder bushing.

0.325" taper crimp.

The StarLine cases were fired, sized to 0.335", and cleaned.

No expander was used, only a flaring plug.

Barrels mounted in a mechanical fixture.

All targets are fired at 50 yards.

Five "fouling" shots were fired prior to the twenty shot record groups.

All barrels machined to the same profile and length as a Pardini HP New barrel.

OBSERVATIONS....

The Speer Plinker HBWC starts easily into the StarLine case sized 0.335". However, the bullet skirt contacts and compresses during seating due to the construction of the brass. Seated diameter of the cartridge was 0.335".

Seating the 0.314" bullets made the loaded diameter of the cartridge 0.336".

The Speer Plinkers are not round nor consistent in diameter bullet to bullet. Remember, they are mass produced. They range from 0.311" to 0.313". Most likely this is caused by the final knurling operation.

HERE ARE MY RESULTS....

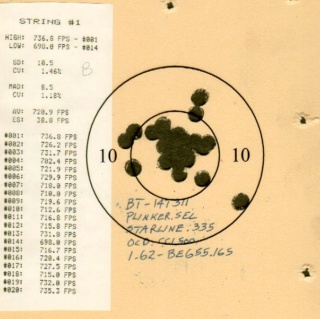

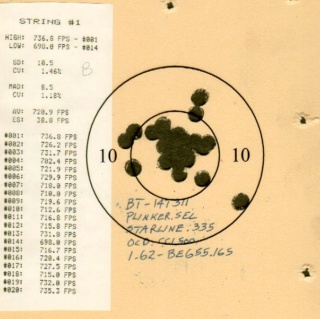

The above is a Factory Pardini HP New barrel with a 0.314" groove diameter and 0.312" choke applied at the muzzle.

Notice how the ammo is trying to shoot X-ring; but the four fliers have ruined the score.

This target is typical of using the Plinkers in factory barrels of all makes with 0.314" groove diameters.

Above shows a Douglas 0.311" 14 twist barrel with the same ammo. The major fliers have gone away.

Still another barrel. A Douglas 0.311 with ten twist. Essentially the same results as the 14 twist.

Barrel 19106 is a prototype. Still a Pardini HP New profile; but, I use a piece of Hart 0.308 stainless with five grooves and 12 twist.

The smaller 0.308 diameter "seems" to suggest accuracy has improved.

Notice the average velocity is not much different that the other barrels tested.

This is the Pardini Factory barrel tested with Plinkers that have been "bumped" to 0.314" diameter.

I have now managed to get the fliers back into the ten ring.

However, due to the thick walls of the StarLine brass the bullet skirt is compressed much smaller than 0.314" swaged diameter.

CONCLUSIONS.....

StarLine brass can be used to produce "good" results. At least ten ring groups.

The Speer Plinkers, culled for minimal defects, also shoot quite well.

Using brass that does not compress the HBWC is a plus. Previous testing has demonstrated this.

Velocity appears to be a result of the chamber size, not the barrel groove diameter.

Brass with thick walls at the midsection produce higher velocities than brass with parallel walls. A smaller combustion chamber increases pressure/velocity.

A barrel groove diameter smaller than the average diameter of a HBWC bullet suggests better groups and fewer fliers.

Barrel twist did not seem to have as much influence on accuracy as the barrel groove diameter.

The less you distort the bullet while loading the better the results.

Cheers,

Dave

Spent a pleasant day behind the Barrel Tester looking to see what results I could get using Speer Plinkers and StarLine brass.

TEST PARAMETERS....

I loaded 100 rounds of Plinkers examined closely by eye for defects in one loading session.

CCI500 Small Pistol primers.

Federal 100 Small Pistol primers used with the 0.314" bumped Plinker bullets.

1.62 grains of Bullseye, Lot #655 using a 0.165cc powder bushing.

0.325" taper crimp.

The StarLine cases were fired, sized to 0.335", and cleaned.

No expander was used, only a flaring plug.

Barrels mounted in a mechanical fixture.

All targets are fired at 50 yards.

Five "fouling" shots were fired prior to the twenty shot record groups.

All barrels machined to the same profile and length as a Pardini HP New barrel.

OBSERVATIONS....

The Speer Plinker HBWC starts easily into the StarLine case sized 0.335". However, the bullet skirt contacts and compresses during seating due to the construction of the brass. Seated diameter of the cartridge was 0.335".

Seating the 0.314" bullets made the loaded diameter of the cartridge 0.336".

The Speer Plinkers are not round nor consistent in diameter bullet to bullet. Remember, they are mass produced. They range from 0.311" to 0.313". Most likely this is caused by the final knurling operation.

HERE ARE MY RESULTS....

The above is a Factory Pardini HP New barrel with a 0.314" groove diameter and 0.312" choke applied at the muzzle.

Notice how the ammo is trying to shoot X-ring; but the four fliers have ruined the score.

This target is typical of using the Plinkers in factory barrels of all makes with 0.314" groove diameters.

Above shows a Douglas 0.311" 14 twist barrel with the same ammo. The major fliers have gone away.

Still another barrel. A Douglas 0.311 with ten twist. Essentially the same results as the 14 twist.

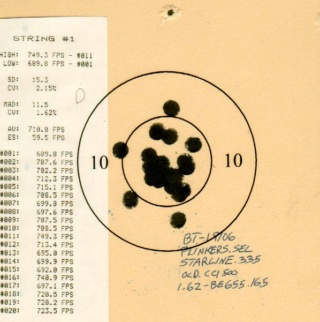

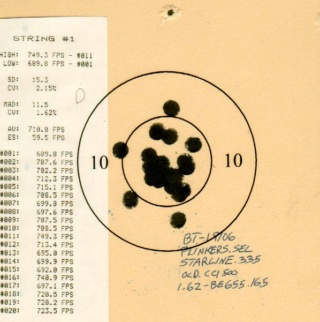

Barrel 19106 is a prototype. Still a Pardini HP New profile; but, I use a piece of Hart 0.308 stainless with five grooves and 12 twist.

The smaller 0.308 diameter "seems" to suggest accuracy has improved.

Notice the average velocity is not much different that the other barrels tested.

This is the Pardini Factory barrel tested with Plinkers that have been "bumped" to 0.314" diameter.

I have now managed to get the fliers back into the ten ring.

However, due to the thick walls of the StarLine brass the bullet skirt is compressed much smaller than 0.314" swaged diameter.

CONCLUSIONS.....

StarLine brass can be used to produce "good" results. At least ten ring groups.

The Speer Plinkers, culled for minimal defects, also shoot quite well.

Using brass that does not compress the HBWC is a plus. Previous testing has demonstrated this.

Velocity appears to be a result of the chamber size, not the barrel groove diameter.

Brass with thick walls at the midsection produce higher velocities than brass with parallel walls. A smaller combustion chamber increases pressure/velocity.

A barrel groove diameter smaller than the average diameter of a HBWC bullet suggests better groups and fewer fliers.

Barrel twist did not seem to have as much influence on accuracy as the barrel groove diameter.

The less you distort the bullet while loading the better the results.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Great.testing as usual Dave !!

Jimmy

Jimmy

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Does the smaller groove dia offset induced skirt dent from +p brass?

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Dave, I’m a little confused by a couple of your comments, not sure if you are referring to the bumped or stock Plinkers. Initially it seems clear you are using bumped Plimkers, but when you mention the inconsistency in sizes I presume you are referring to the stock Plinkers?

Then, in the last pic you indicate that with bumped Plimkers you have managed to eliminate the fliers? Wasn’t sure what had changed from the initial pics with the fliers, which also used the bumped Plinkers in a Pardini barrel?

Then, in the last pic you indicate that with bumped Plimkers you have managed to eliminate the fliers? Wasn’t sure what had changed from the initial pics with the fliers, which also used the bumped Plinkers in a Pardini barrel?

gregbenner- Posts : 738

Join date : 2016-10-29

Location : San Diego area

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Greetings,

Bruce....

Never encountered +P brass in 32 S&W Long. Not sure why the 0.308" barrels offer better results.

Greg....

All tests, except the last image, were Speer Plinkers out of the box examined visually for defects.

The last image shows the improvement by "bumping" the plinkers to 0.314" diameter. However, the thick midsection walls of the StarLine cases severely collapse the HBWC skirts and I suspect that is why the group is not very good. Although, the group is much better than using out of the box Plinkers.

The goal of the test was to evaluate components available to shooters that do not swage bullets.

Cheers,

Dave

Bruce....

Never encountered +P brass in 32 S&W Long. Not sure why the 0.308" barrels offer better results.

Greg....

All tests, except the last image, were Speer Plinkers out of the box examined visually for defects.

The last image shows the improvement by "bumping" the plinkers to 0.314" diameter. However, the thick midsection walls of the StarLine cases severely collapse the HBWC skirts and I suspect that is why the group is not very good. Although, the group is much better than using out of the box Plinkers.

The goal of the test was to evaluate components available to shooters that do not swage bullets.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Dave, your testing is always first rate and a joy to receive/absorb.

It was interesting to me that the last test with the bumped plinkers in the Pardini factory barrel seems to show many more holes with a "precession smudge" than some of the other groups. Even some of the shots near center show a healthy smudge. Any thoughts as to why this might be? Of course it really doesn't matter if they group well.

It was interesting to me that the last test with the bumped plinkers in the Pardini factory barrel seems to show many more holes with a "precession smudge" than some of the other groups. Even some of the shots near center show a healthy smudge. Any thoughts as to why this might be? Of course it really doesn't matter if they group well.

Dr.Don- Posts : 816

Join date : 2012-10-31

Location : Cedar Park, TX

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Greetings Don,

I do not have enough ballistic knowledge to account for the smudges.

The faster twist barrels tend to reduce the smudges, which I attribute to the bullets spinning faster maintaining stability.

Earlier tests show that increasing the velocity (more powder) reduces the destabilization. However, more velocity equals more recoil and wear and tear on the guns leading to damage in some circumstances.

Cheers,

Dave

I do not have enough ballistic knowledge to account for the smudges.

The faster twist barrels tend to reduce the smudges, which I attribute to the bullets spinning faster maintaining stability.

Earlier tests show that increasing the velocity (more powder) reduces the destabilization. However, more velocity equals more recoil and wear and tear on the guns leading to damage in some circumstances.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Ah I think what confused me your comment re: Test Paramtersfc60 wrote:Greetings,

Greg....

All tests, except the last image, were Speer Plinkers out of the box examined visually for defects.

The last image shows the improvement by "bumping" the plinkers to 0.314" diameter. However, the thick midsection walls of the StarLine cases severely collapse the HBWC skirts and I suspect that is why the group is not very good. Although, the group is much better than using out of the box Plinkers.

The goal of the test was to evaluate components available to shooters that do not swage bullets.

Cheers,

Dave

“Federal 100 Small Pistol primers used with the 0.314" bumped Plinker bullets.”

gregbenner- Posts : 738

Join date : 2016-10-29

Location : San Diego area

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Dave, I have also noticed much better results with the standard Plinkers in tighter barrels. In my case both of them .308 barrels made by you, in my GSP.

I am surprised that your test targets with the standard Plinkers in the tighter barrels are better than the last group with bumped Plinkers in the larger .314 Pardini barrel.

I am surprised that your test targets with the standard Plinkers in the tighter barrels are better than the last group with bumped Plinkers in the larger .314 Pardini barrel.

gregbenner- Posts : 738

Join date : 2016-10-29

Location : San Diego area

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Greetings Greg,gregbenner wrote:

I am surprised that your test targets with the standard Plinkers in the tighter barrels are better than the last group with bumped Plinkers in the larger .314 Pardini barrel.

The bumped bullets were forced into the StarLine cases where the HBWC skirts were collapsed. In Lapua cases the groups are much smaller as the bullet base is not distorted when loading.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Hmm, is the Starline brass thicker than Lapua, perhaps thicker in the middle? Recently photo escape started making all links PTU dies for Dillon reloaders. It is intended to eliminate the issue of compressing the base of the wadcutter.fc60 wrote:Greetings Greg,gregbenner wrote:

I am surprised that your test targets with the standard Plinkers in the tighter barrels are better than the last group with bumped Plinkers in the larger .314 Pardini barrel.

The bumped bullets were forced into the StarLine cases where the HBWC skirts were collapsed. In Lapua cases the groups are much smaller as the bullet base is not distorted when loading.

Cheers,

Dave

gregbenner- Posts : 738

Join date : 2016-10-29

Location : San Diego area

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Doc Young used to shoot a .32 S&W Long back in the day. I do remember that he had a custom barrel made for his pistol (maybe an Erma). The bore was .308". Looks like what's old is new again.

BE Mike- Posts : 2589

Join date : 2011-07-29

Location : Indiana

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Greetings BE Mike,

Yes, Doc Young did shoot the 32 a lot. I shot along side of him in the NorthWest and he encouraged me to continue testing with the 32.

Cheers,

Dave

Yes, Doc Young did shoot the 32 a lot. I shot along side of him in the NorthWest and he encouraged me to continue testing with the 32.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Greetings Greg,

If one uses an full length expander for wadcutters on brass with a heavy mid-section, a pronounced bulge will occur.

Quite often, this will enlarge the loaded round so much that chambering will become difficult in custom chambered barrels.

Cheers,

Dave

If one uses an full length expander for wadcutters on brass with a heavy mid-section, a pronounced bulge will occur.

Quite often, this will enlarge the loaded round so much that chambering will become difficult in custom chambered barrels.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Dave,

Greetings from Camp Perry!

Would not it be accurate that 32 Long brass cases that aren't straight walled for the length of projectile in one or another way would compromise accuracy of the resulting round? Bulging case will not fit correctly in the custom chambers after being expanded for the full length of the bullet. However if bulge is fixed with Lee FCD, then bullet's lower part will be disturbed?

Regards,

AP

Greetings from Camp Perry!

Would not it be accurate that 32 Long brass cases that aren't straight walled for the length of projectile in one or another way would compromise accuracy of the resulting round? Bulging case will not fit correctly in the custom chambers after being expanded for the full length of the bullet. However if bulge is fixed with Lee FCD, then bullet's lower part will be disturbed?

Regards,

AP

PhotoEscape- Admin

- Posts : 1543

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Speer Plinkers and Starline brass

Re: Speer Plinkers and Starline brass

Greetings AP,

Yes, the Lee Factory Crimp Die does straighten out the loaded cartridge.

It will compress the skirt of the bullet and with the brass spring back, it will now be loose inside a wee bit.

If one sizes the cases to equal the outside diameter of a loaded round, the skirt of the bullet is compressed tightly inside the case at the mid section.

I have tried the above method in the barrel tester and get good results, about X-ring, however there are two or three shots that exit the X-ring.

I strongly believe the less the bullet is distorted during loading, the better the end results.

Cheers,

Dave

Yes, the Lee Factory Crimp Die does straighten out the loaded cartridge.

It will compress the skirt of the bullet and with the brass spring back, it will now be loose inside a wee bit.

If one sizes the cases to equal the outside diameter of a loaded round, the skirt of the bullet is compressed tightly inside the case at the mid section.

I have tried the above method in the barrel tester and get good results, about X-ring, however there are two or three shots that exit the X-ring.

I strongly believe the less the bullet is distorted during loading, the better the end results.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Similar topics

Similar topics» S&W 32 Long HBWC - loading ammo with 98 gr. Speer Plinkers.

» Speer or Blazer SPP brass

» Best place to buy Starline Brass

» .32 ACP brass available from Starline

» Starline Brass Available?

» Speer or Blazer SPP brass

» Best place to buy Starline Brass

» .32 ACP brass available from Starline

» Starline Brass Available?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum