Photo Escape FailSafe Bracket for the Dillon 650 Review

+4

Ed Hall

mikehoma

Wobbley

JayhawkNavy02

8 posters

Page 1 of 1

Photo Escape FailSafe Bracket for the Dillon 650 Review

Photo Escape FailSafe Bracket for the Dillon 650 Review

I enjoy working on my Dillon 650 and in search of the ever elusive and impossible powder throw. After borrowing Greg's Ransom Rest for a prolific period of time, powder amount is the greatest single contributor to the group size I see. Crimp and OAL get adjusted after. That drove me to try and get as consistent of throws as possible. This is a mental game, and I appreciate knowing that the ammunition is good.

http://www.photoescapeinc.com/products/failsafe-bracket.html

http://uniquetek.com/product/T1677

So, what's the setup?

Dillon 650 secured to a grounded massive bench that is horribly heavy and bolted to the frame of my home. The press itself is grounded, and has been modified with a Dillon roller handle to smooth things out, modified powder through expander as the stock Dillon tends to "stick" on new starline brass and causes "issues" with precise powder dispensing, Hit Factor shellplate bearing kit, Entirely Crimson Index Bearing Cam Block, Entirely Crimson Roller Cam Follower/Camming Pin, and prairie dog powder baffle. This powder dispenser and expander (internally) I used were not polished, unlike my normal funnel. I will pick up some Flitz and get things in order and post an update as I think there will be some gains, but that should apply to both equally regardless. All powder was filled to the same level to start after verifying charges. I used new starline brass at the beginning of each to ensure no grains stuck to the side. The scale is a lab grade, accurate to .02 grains and was left on for 30 minutes to minimize drift and I used batteries to isolate from the home's relatively noisy power.

I selected 3 common powders and threw 20 each. WST, Bullseye and Titegroup. VVN310 to follow once I polish the funnel and get ready to load for some matches and Varget as I want to see how it handles extruded powders for those of us who shoot rifle. Apologies in advance for the incomplete data. So the question I was trying to answer, was, with only modifying one component of my press, the bracket, could I improve my consistency across various powders. The answer is, yes. The data in the table below highlights any charge over .06 gr from the base 4.6 gr charge in yellow and the charges above .08 from the base in red. I then did some basic looks at the information and as you can see the Photo Escape outperformed the Dillon OEM in 13 of 18, tied in 4 and lost in only 1 by a very small margin. Pretty good. I did notice more variation than normal, which may be due to the weather. One surprise was the 4.82 gr throw of WST using the Dillon FailSafe bracket. I've never seen that before, but I measured twice, on two separate scales, so the data stays.

All of this is a little difficult to see, so some graphs to help. Charge amount in the vertical (Y-Axis) and the charge number in the horizontal (X-Axis). Ideally you'll want this perfectly level. So flatter is better. Dillon is in blue and Photo Escape in Orange. These graphs are specific to each powder test.

Not sure if this helps, but I wanted a consolidated view. Again, flatter is better. Same X/Y axis used. When you lay all 60 charges down and compare between the Dillon OEM and the Photo Escape in my view it stands alone. An already very good press is significantly better. No charge was over +/- .06 after installing the Photo Escape FailSafe Bracket Kit across 3 powders.

The Photo Escape FailSafe Bracket Kit for the Dillon 650 is significantly stronger and more well made. It uses forgoes the plastic shoulder washer and has an adjustable machine screw vice the stamped projection in the OEM. The only down side is that I can remove the powder funnel very quickly to dump and with the Photo Escape as well, there are two set screws, one of which that you need to loosen as the other just holds it in place. No big deal, I'll take the very small delay to gain reliability. The washer/bushing is very nicely captures via the set screws and seems to be aligned better than the plastic, which has significantly more play, but I doubt there is any effect. Cosmetic, but the nice stainless finish also goes well with the press.

http://www.photoescapeinc.com/products/failsafe-bracket.html

http://uniquetek.com/product/T1677

So, what's the setup?

Dillon 650 secured to a grounded massive bench that is horribly heavy and bolted to the frame of my home. The press itself is grounded, and has been modified with a Dillon roller handle to smooth things out, modified powder through expander as the stock Dillon tends to "stick" on new starline brass and causes "issues" with precise powder dispensing, Hit Factor shellplate bearing kit, Entirely Crimson Index Bearing Cam Block, Entirely Crimson Roller Cam Follower/Camming Pin, and prairie dog powder baffle. This powder dispenser and expander (internally) I used were not polished, unlike my normal funnel. I will pick up some Flitz and get things in order and post an update as I think there will be some gains, but that should apply to both equally regardless. All powder was filled to the same level to start after verifying charges. I used new starline brass at the beginning of each to ensure no grains stuck to the side. The scale is a lab grade, accurate to .02 grains and was left on for 30 minutes to minimize drift and I used batteries to isolate from the home's relatively noisy power.

I selected 3 common powders and threw 20 each. WST, Bullseye and Titegroup. VVN310 to follow once I polish the funnel and get ready to load for some matches and Varget as I want to see how it handles extruded powders for those of us who shoot rifle. Apologies in advance for the incomplete data. So the question I was trying to answer, was, with only modifying one component of my press, the bracket, could I improve my consistency across various powders. The answer is, yes. The data in the table below highlights any charge over .06 gr from the base 4.6 gr charge in yellow and the charges above .08 from the base in red. I then did some basic looks at the information and as you can see the Photo Escape outperformed the Dillon OEM in 13 of 18, tied in 4 and lost in only 1 by a very small margin. Pretty good. I did notice more variation than normal, which may be due to the weather. One surprise was the 4.82 gr throw of WST using the Dillon FailSafe bracket. I've never seen that before, but I measured twice, on two separate scales, so the data stays.

All of this is a little difficult to see, so some graphs to help. Charge amount in the vertical (Y-Axis) and the charge number in the horizontal (X-Axis). Ideally you'll want this perfectly level. So flatter is better. Dillon is in blue and Photo Escape in Orange. These graphs are specific to each powder test.

Not sure if this helps, but I wanted a consolidated view. Again, flatter is better. Same X/Y axis used. When you lay all 60 charges down and compare between the Dillon OEM and the Photo Escape in my view it stands alone. An already very good press is significantly better. No charge was over +/- .06 after installing the Photo Escape FailSafe Bracket Kit across 3 powders.

The Photo Escape FailSafe Bracket Kit for the Dillon 650 is significantly stronger and more well made. It uses forgoes the plastic shoulder washer and has an adjustable machine screw vice the stamped projection in the OEM. The only down side is that I can remove the powder funnel very quickly to dump and with the Photo Escape as well, there are two set screws, one of which that you need to loosen as the other just holds it in place. No big deal, I'll take the very small delay to gain reliability. The washer/bushing is very nicely captures via the set screws and seems to be aligned better than the plastic, which has significantly more play, but I doubt there is any effect. Cosmetic, but the nice stainless finish also goes well with the press.

Last edited by JayhawkNavy02 on Sat Feb 01, 2020 9:07 am; edited 1 time in total

JayhawkNavy02- Posts : 821

Join date : 2014-03-01

Age : 45

Location : San Diego

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

Interesting. Dunno how it might compare to a drum measure. My experience with the Hornady measure is positive compared to the Dillons I have.

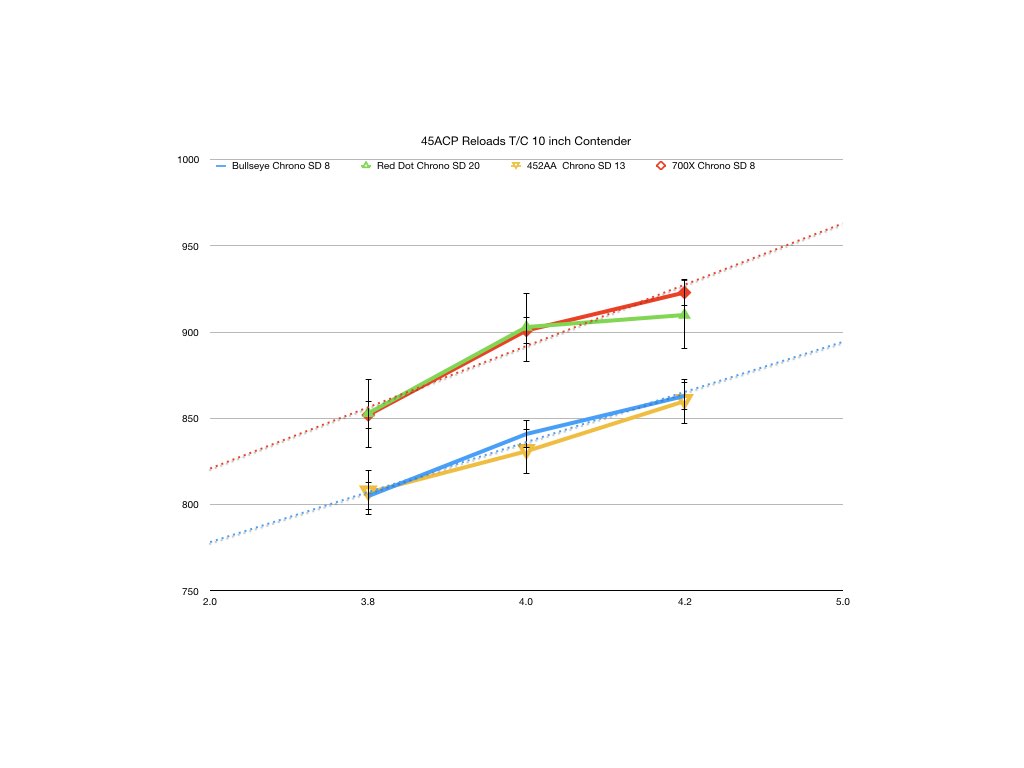

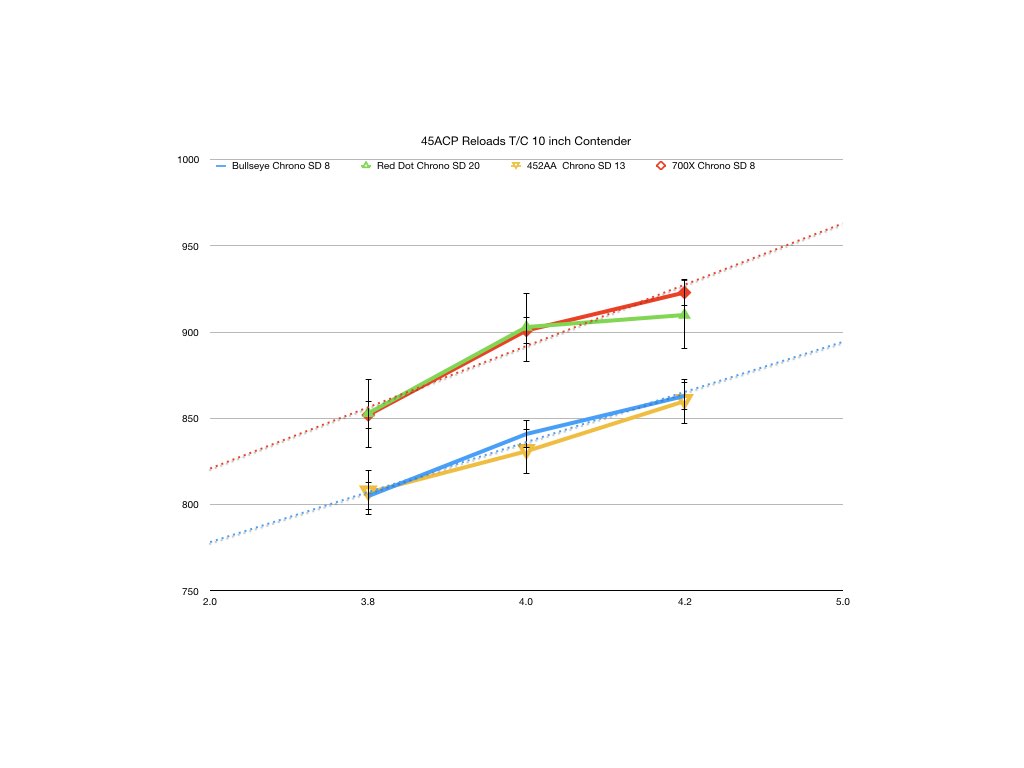

In any event this graph shows the importance of powder charge variance may have on typical bullseye charges. This was a result of some chrono work done using a 10 inch Contender barrel. A typical 5 inch barrel will lose about 70-90 fps. Note the large SD with Red Dot. These SD numbers are consistent with those in 38 Special with the same powders. The error bars graphed are the SD numbers. A Linear trend line has been added for convenience.

In any event this graph shows the importance of powder charge variance may have on typical bullseye charges. This was a result of some chrono work done using a 10 inch Contender barrel. A typical 5 inch barrel will lose about 70-90 fps. Note the large SD with Red Dot. These SD numbers are consistent with those in 38 Special with the same powders. The error bars graphed are the SD numbers. A Linear trend line has been added for convenience.

Wobbley- Admin

- Posts : 4805

Join date : 2015-02-12

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

Wobbley wrote:Interesting. Dunno how it might compare to a drum measure. My experience with the Hornady measure is positive compared to the Dillons I have.

In any event this graph shows the importance of powder charge variance may have on typical bullseye charges. This was a result of some chrono work done using a 10 inch Contender barrel. A typical 5 inch barrel will lose about 70-90 fps. Note the large SD with Red Dot. These SD numbers are consistent with those in 38 Special with the same powders. The error bars graphed are the SD numbers. A Linear trend line has been added for convenience.

I like the powder measure as well. When I can slime my wave over I want to run the same powder through a buddies Hornady LNL. If it wasn’t for the bushing system and case feeder I would have gone with the Hornady.

I didn’t do a terrific job summarizing the results. I did this on the phone so the arithmetic is in question

If we look at eliminating outliers, charges at or over .06 gr. Which is my “goal” again I need to polish this funnel and I think I’ll be there, then we go from 11 to 5 or roughly a 45.45 % improvement in consistency. If we look at throws greater than .06 grains, we go from OEM Dillon at 3 to 0.

Now if we look at averages, the Median across all 3 powders with the OEM is 4.61 and PhotoEscape is 4.59. That results in a 5% improvement in the median charge. Regarding the less important Mean, the OEM is 4.61 and Photo Escape 4.60, again about a 5% benefit. Very close and I attribute that to a press already modified and a large number of throws.

Average Standard Deviation with the OEM Dillon is .005 compared to Photo Escape at .003. You reduce standard deviation by roughly 60%.

JayhawkNavy02- Posts : 821

Join date : 2014-03-01

Age : 45

Location : San Diego

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

This product may be the cat's meow for a Dillon press, but I doubt that you can legitimately claim that there is a significant statistical difference between the two. With small sample sizes you can't assume that because the average of the test samples is "different" by .01 to .03 grains, that the measurements actually represent different distributions. To determine if the data represents two different distributions, you need to do a comparison of the means, a T-test (and probably a lot more sampling). With the measurements you have reported, +/- 3 standard deviations is prertty darn close to the scale resolution. The scale has a resolution of 0.02 grains; but accuracy is typically specified as +/- percentage.

mikehoma- Posts : 1

Join date : 2016-09-20

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

I had an email with this topic subject, although I have not posted within this thread. I deleted it thinking it was the standard thread activity notice. If someone tried to contact me directly, please try again.

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

I found the Dillon powder bar adjustment, fit and finish to be less than desirable for consistent and repeatable powder drops. So I took it off and machined a mount for a Harrell Schuetzen Pistol powder drop for my BL550. It defeats the automatic nature of the Dillon powder drop, but the Harrell sure is consistent.

mhayford45- Posts : 259

Join date : 2013-02-21

Location : MI

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

mikehoma wrote:This product may be the cat's meow for a Dillon press, but I doubt that you can legitimately claim that there is a significant statistical difference between the two. With small sample sizes you can't assume that because the average of the test samples is "different" by .01 to .03 grains, that the measurements actually represent different distributions. To determine if the data represents two different distributions, you need to do a comparison of the means, a T-test (and probably a lot more sampling). With the measurements you have reported, +/- 3 standard deviations is prertty darn close to the scale resolution. The scale has a resolution of 0.02 grains; but accuracy is typically specified as +/- percentage.

Absolutely agreed. There are a couple other items that need to be highlighted/addressed.

I introduced some error, and thanks to some other forums and owner of Photo Escape I probably need to re-run this. It appears that case position on the shell plate may affect the charge amount. If you look i.e. at Dillon’s shell plate for 45 ACP you’ll see a 1 with a circle around it. The owner of Photo Escape and others have nticed that certain positions on the shell plate would give base charge +, while another would give base charge -. Platforms on the presses were verified with the Dillon alignment tool, and the shell plate bolt checked for concentricity, etc. It is suspected that Dillon shell plates have excessive variations in dimensions in each cell or the center isn’t straight. I did a quick test, using Bullseye and 10 charges specific to each shellplate position. This is the result with the same metrics as above. I'm not sure I'm ready to confirm the above, based on the sample and scale precision as you mentioned, but it would be interesting to investigate further. Without a machined precision shell plate I don’t think there’s anything you can do to rectify it anyway and the way that the 650 operates (opposite of the 1050 and star) is probably a major limiter regardless. What I can do, is use the same position on each shell plate to limit the amount of variance. I'll probably use position 4 or 5. I need to do more throws to see which is best of the two, but I'm reaching the limits of my scale as mentioned earlier in your post. Regardless, I think taking out the variance of position will help.

You will have similar issues with the metrics below, but that was what I had time for previous to some excitement at work. The near future is pretty tough from a schedule stand point. But I intend to re-attack this as well with the parts installed and a ideally a new scale. All charges are with BE and the Photo Escape bracket testing each shell plate position using the previous scale mentioned.

mhayford45 wrote:I found the Dillon powder bar adjustment, fit and finish to be less than desirable for consistent and repeatable powder drops. So I took it off and machined a mount for a Harrell Schuetzen Pistol powder drop for my BL550. It defeats the automatic nature of the Dillon powder drop, but the Harrell sure is consistent.

Agreed. The second item I need to address in this is the powder bar itself. I now have an oversized powder bar and the regular. I"m going to compare both and see which is more consistent and use the best of the two for the re-test. Fundamentally, I'm not sure the Dillon measure is ideal, but I would like to stay with the OEM to maintain the progressive/automated nature. In the future if I plan to pick up a 550 and do something similar for rifle as the precision requirements for pistol aren't as demanding.

The third item is the Dillon Failsafe Bracket itself. Mine is warped. I didn't notice it originally, and I think some of the variance is due to that. I have a new one on hand and I'll match that with a new bushing.

Regarding the scale, I'm on the hunt. The A&D FX-120i, Intell-Lab PM-100 look like great scales, but you're still facing .002 g (.003 gr) repeatability and that seems to be the standard in the upper end non-strain type precision scales. Getting inside that is interesting. The only scale I've found so far, and still searching is the Ohaus Pioneer PX163/E Precision Balance 160 g x .001 g. Long name. That gets down to .001 g repeatability or about .002 gr and within reason, that appears to be the limit of reason in cost, unless we want to do a GoFundMe for a 5k+ scale for this and I doubt it....lol. I'm sure there are others, but still hunting for something less expensive and ideally, one I can simply borrow as this is outside my normal need/use case. If anyone has one their aware of please let me know. The other option is to have Scott Parker tune my Lyman-Ohaus M5, but that wouldn't give a specific measurement although it would be more accurate. IMO, better suited to trickling than comparison.

What I suspect will happen is that when I have as many controls as I can in place, a new, perfectly formed OEM bracket will perform roughly the same as the Photo Escape. However, that is contingent on the OEM staying perfectly shaped, which I've already seen can fail to happen even when adjusted properly over time. The risk of loosing the proper return is mitigated by the photo escape product which is made out of stainless and won't deform like the OEM with proper use/setup so I'm very happy to remove a possible (and past) contributor to error. That remains enough to make the change for me and in line with the photo escape product description.

"As a continuation of my pursuit of more accurate charge drops, I felt, that having FailSafe Brackets that fits two of my Dillon XL650 presses, and provides for consistent return of the powder bars, is a necessity. OEM bracket easily bent when something goes wrong during bar return, i.e. worn white plastic insert (shoulder washer, per Dillon's manual) drops down, and then catches bracket by its top, instead of sliding all way in, or simply wing nut being over tightened. Once OEM bracket bent / unbent couple times, it starts flexing, which in turn creates inconsistencies on powder bar return. This in turn necessitates further tightening of wing nut, and ultimately call to Dillon, requesting replacement. I have clear understanding, that with Dillon's EXCELLENT warranty on XL650, the need for part proposed here for many of reloaders would be non-existent. I, by myself, always keep kit of spare parts, and failsafe bracket is in it. However every time I had to replace it in the middle of loading of the batch of few hundred rounds (that is when it happens most of the time, because I'm going at the "max" speed), I would lose quite a bit of time on unscrewing, unbending, resetting, re-measuring, etc. But most importantly, I would have a doubt in the back of my mind - "do I have undercharged cases"! That is right, - bent safety bracket means insufficient powder bar return, subsequent undercharge, and subsequent potential squib. Obviously squib is an extreme case, however accuracy would be definitely affected. So I decided and manufactured a batch of about dozen brackets made of stainless steel, complemented it with shoulder washer made out of brass, installed and tested on both of my presses. I'm much happier now, - I can go full speed without worrying that bracket would bend, flex, or else. Set screw prevents from washer drops, and powder bar returns to the same spot every time. Resulting rounds produce more accurate imprints on targets, standard deviation is lower by 4-6 in comparison with previously loaded same charge rounds."

Last edited by JayhawkNavy02 on Sat Feb 01, 2020 11:57 am; edited 6 times in total

JayhawkNavy02- Posts : 821

Join date : 2014-03-01

Age : 45

Location : San Diego

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

I totally agree with this post. This is where my quest for better accuracy started about dozen years ago when I got my first 650. Having more than a tens (+/-0.1) variation was less than appealing. So I polished all surfaces of the powder bars, and bottom surface of the bar housing on the powder measure (this also eliminated pretty mush all of the powder spillage). I also polished cone portion of powder measure itself so there is no resistance to powder flow. That gave me a bit of improvement. While polishing bars, I noticed that inserts have substantial backlash. I determined that the culprit is OEM stamped bolt with incomplete thread. I then purchased replacement micro adjuter manufactured by Uniquetek. Everything is great with this product........., except at $65/pc. and my growing collection of calibers I reload it would be too costly. So I machined my own adjusters. These are CNC machined, so threads are precise, almost micrometer grade. That gave me noticeable improvement. Then came my PTUs - I noticed that OEM funnels have ID with substantial machine marks, that lid to few particles of powder here and there dropped on shellplate during rotation. My PTUs are polished on ID, so there is no abstraction to powder flow. Fail Safety bracket so far is the last piece in the list of improvements, - OEM one flexes during operation and produces sufficient variances to be concerned about. Plus during long loads (I frequently load 1000+ rounds in one sit down) delrin washer can slip out on the upstroke and then bend OEM bracket on the down stroke. With all improvements above, plus locking toolheads so there is no play in them, both of my 650s produce consistent +/-0.04 grain drops with powders like BullsEye, N310, N340, HP38, etc.mhayford45 wrote:I found the Dillon powder bar adjustment, fit and finish to be less than desirable for consistent and repeatable powder drops. So I took it off and machined a mount for a Harrell Schuetzen Pistol powder drop for my BL550. It defeats the automatic nature of the Dillon powder drop, but the Harrell sure is consistent.

My dreams are to re-design platform to incorporate support for the shellplate (i.e. needle bearing), and find means of manufacturing better shellplates.

Thank you to JayhawkNavy02 for the time spent on testing and writing such comprehensive review.

AP

PhotoEscape- Admin

- Posts : 1542

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

I don't use the failsafe on my 1050. Went back to the spring return on the measure and got better results. BE and WST are my go to powders. I don't have the means or the mental equipment to make nice graphs but a lot of weighing and scribbling proved it to me. I do use a powder check to catch gross errors. I have polished the inside of the measure and treated it to a graphite run. Also use a ground wire on the press. It makes sense that anything you do to smooth up the whole process can't hurt and I have to admit Hornady one shot lube has made the most improvement in that area for me.

It is most interesting to read these threads, there's a lot to gained from the accomplished folks that contribute.

Thanks much.

It is most interesting to read these threads, there's a lot to gained from the accomplished folks that contribute.

Thanks much.

blindshooter- Posts : 122

Join date : 2016-03-15

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

AP how about a new failsafe bracket for the 750..

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

Re: Photo Escape FailSafe Bracket for the Dillon 650 Review

jglenn21 wrote:AP how about a new failsafe bracket for the 750..

I'm planning to order 750 shortly. Rick Koskela, Mr. BulletFeeder also asked me to work on re-designing this bracket, as it interferes with installing droppers. So it is on my list of future projects.

AP

PhotoEscape- Admin

- Posts : 1542

Join date : 2018-05-15

Location : Northern Illinois, USA

Similar topics

Similar topics» Photo escape phone number

» Smallest Photo Escape aperture?

» Photo Escape Aperture suggestion

» CMM Brass Catcher Pistol Box Bracket

» Dillon vs Hornady powder measure on Dillon 550

» Smallest Photo Escape aperture?

» Photo Escape Aperture suggestion

» CMM Brass Catcher Pistol Box Bracket

» Dillon vs Hornady powder measure on Dillon 550

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum