Dillon XL750 First impressions / First modifications

+11

Carbide

Jack H

Wes Lorenz

blindshooter

bullseyebill

Arthur

DA/SA

Pat Clarkson

jglenn21

Plunker

PhotoEscape

15 posters

Page 2 of 4

Page 2 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Dillon XL750 First impressions / First modifications

Dillon XL750 First impressions / First modifications

First topic message reminder :

I ordered one locally about 10 days ago. Installed and started testing last Friday.

Needless to say, my primary interest was in new indexing system, new priming and fail safety mechanisms.

Initial observation is that engineering level is of typical Dillon. It is very raw, without much attention to technical details, too much reliance on free hanging self adjusting parts, and cutting corners for the benefit of production cost. The best example are primer feeding tubes that are installed into primer magazine. Plastic ends on tubes do not provide for consistent feeding. Out of 15 primers I loaded in my first trial, only 13 were loaded. I had to fish for two remaining with low primer rod. I then reamed plastic end with standard 0.175"+ reamer, and loaded another 10 - this time 9 made through. Called to Dillon technical support yesterday yelled suggestion by support tech that my primers might of been out of roundness, and then suggestion to cut off plastic end and install spare one included in package.

I also observed more disturbing thing, - couple of primers got flipped over. I'm interested to learn if any of the early adopters of the 750 had this happening! I also am not happy that during return primer bar crosses open area exactly where particles of powder can drop right into the primer holding cup.

Unfortunately older style tubes with brass ends would not work. So that is the first part I measured, drew and am getting turned out of brass.

Needless to say, I was disappointed that I cannot transfer tool head, that was setup on 650, to 750 without needing to make changes. However the good news here is that releasing two screws holding Powder Measure and rotating it enough to install tool head, was sufficient, and no additional changes to any of the dies was needed. That brings me to that fail safety rod and bracket. Latter seam to be a little bit off dimension wise (2mm, IMO) for the rod to drop down vertically as outlined in manual. And of course, bracket is sized the way, that if anyone wants to use Mr. Bulletfeeder's dropper installed on station 4 (while using station 3 for powder check), it is impossible! Powder measure with current bracket is seating about 10 degrees too far to the right, - this is the issue that Rick Koskela, The Mr. Bulletfeeder asked me to look into. The simplest solution to this problem is using fail safety rod assembly from Super 1050, p/n. 16811. I FaceTimed how it works to Rick, and he will take it to Dillon's folks. However I'm still going to re-design entire bracket for better overall functionality.

I implemented first modification on Sunday. I installed springs on both primer bars between body of the bar and plastic roller, so roller doesn't get stuck at the back corner of the housing. If anyone interested - in my local True Value it is Spring #9 ($0.59), and then cut to the proper size. Or in simpler terms, spring with ID 0.1875" and smallest wire diameter you can find.

I proposed this tread as a means of exchanging experience and ideas regarding this new press. I understand that there might be other forums, that are more specific to Dillon's equipment. I simply don't have time to follow up all of them. Feel free to propagate information.

AP

I ordered one locally about 10 days ago. Installed and started testing last Friday.

Needless to say, my primary interest was in new indexing system, new priming and fail safety mechanisms.

Initial observation is that engineering level is of typical Dillon. It is very raw, without much attention to technical details, too much reliance on free hanging self adjusting parts, and cutting corners for the benefit of production cost. The best example are primer feeding tubes that are installed into primer magazine. Plastic ends on tubes do not provide for consistent feeding. Out of 15 primers I loaded in my first trial, only 13 were loaded. I had to fish for two remaining with low primer rod. I then reamed plastic end with standard 0.175"+ reamer, and loaded another 10 - this time 9 made through. Called to Dillon technical support yesterday yelled suggestion by support tech that my primers might of been out of roundness, and then suggestion to cut off plastic end and install spare one included in package.

I also observed more disturbing thing, - couple of primers got flipped over. I'm interested to learn if any of the early adopters of the 750 had this happening! I also am not happy that during return primer bar crosses open area exactly where particles of powder can drop right into the primer holding cup.

Unfortunately older style tubes with brass ends would not work. So that is the first part I measured, drew and am getting turned out of brass.

Needless to say, I was disappointed that I cannot transfer tool head, that was setup on 650, to 750 without needing to make changes. However the good news here is that releasing two screws holding Powder Measure and rotating it enough to install tool head, was sufficient, and no additional changes to any of the dies was needed. That brings me to that fail safety rod and bracket. Latter seam to be a little bit off dimension wise (2mm, IMO) for the rod to drop down vertically as outlined in manual. And of course, bracket is sized the way, that if anyone wants to use Mr. Bulletfeeder's dropper installed on station 4 (while using station 3 for powder check), it is impossible! Powder measure with current bracket is seating about 10 degrees too far to the right, - this is the issue that Rick Koskela, The Mr. Bulletfeeder asked me to look into. The simplest solution to this problem is using fail safety rod assembly from Super 1050, p/n. 16811. I FaceTimed how it works to Rick, and he will take it to Dillon's folks. However I'm still going to re-design entire bracket for better overall functionality.

I implemented first modification on Sunday. I installed springs on both primer bars between body of the bar and plastic roller, so roller doesn't get stuck at the back corner of the housing. If anyone interested - in my local True Value it is Spring #9 ($0.59), and then cut to the proper size. Or in simpler terms, spring with ID 0.1875" and smallest wire diameter you can find.

I proposed this tread as a means of exchanging experience and ideas regarding this new press. I understand that there might be other forums, that are more specific to Dillon's equipment. I simply don't have time to follow up all of them. Feel free to propagate information.

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

I've spent a little bit of time working on priming system of XL750. Here are couple mods I implemented.

1. I replaced plastic ends on primer magazine tubes with brass ones similar to what Dillon's EOM on XL650.

2. I replaced plastic primer pushing rod with brass one threaded on the top so it allows for adjusting length and hence number of primers left before low primer buzzer goes off.

If anyone interested in details, I'll be happy to post information.

AP

1. I replaced plastic ends on primer magazine tubes with brass ones similar to what Dillon's EOM on XL650.

2. I replaced plastic primer pushing rod with brass one threaded on the top so it allows for adjusting length and hence number of primers left before low primer buzzer goes off.

If anyone interested in details, I'll be happy to post information.

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

another modification

another modification

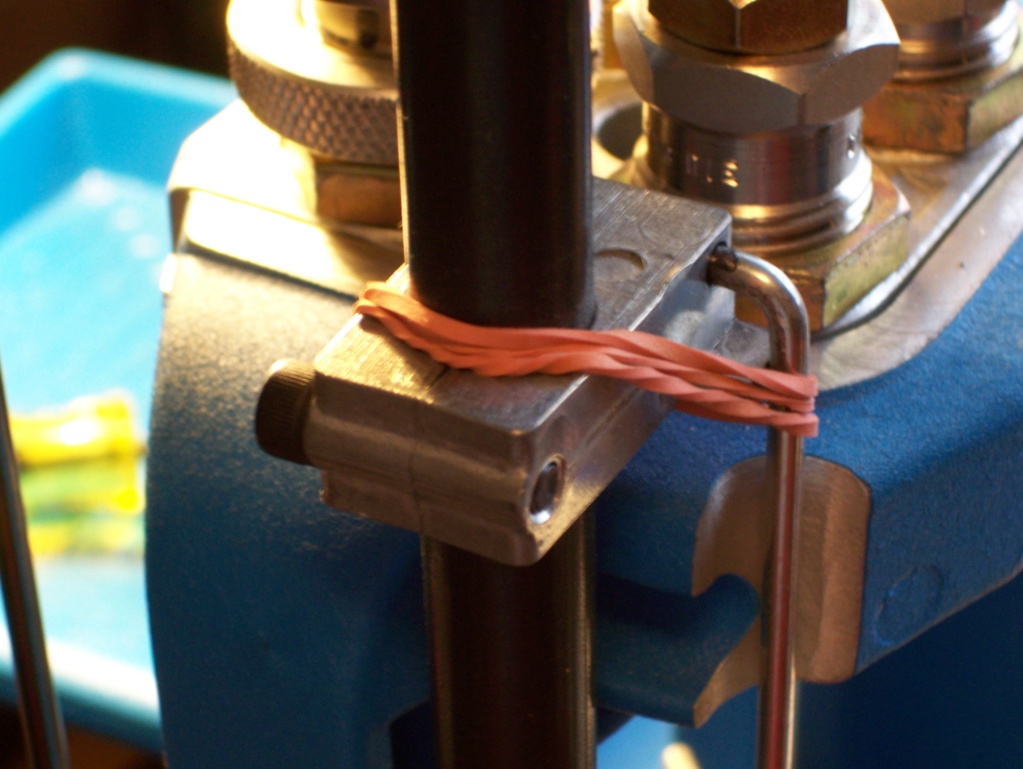

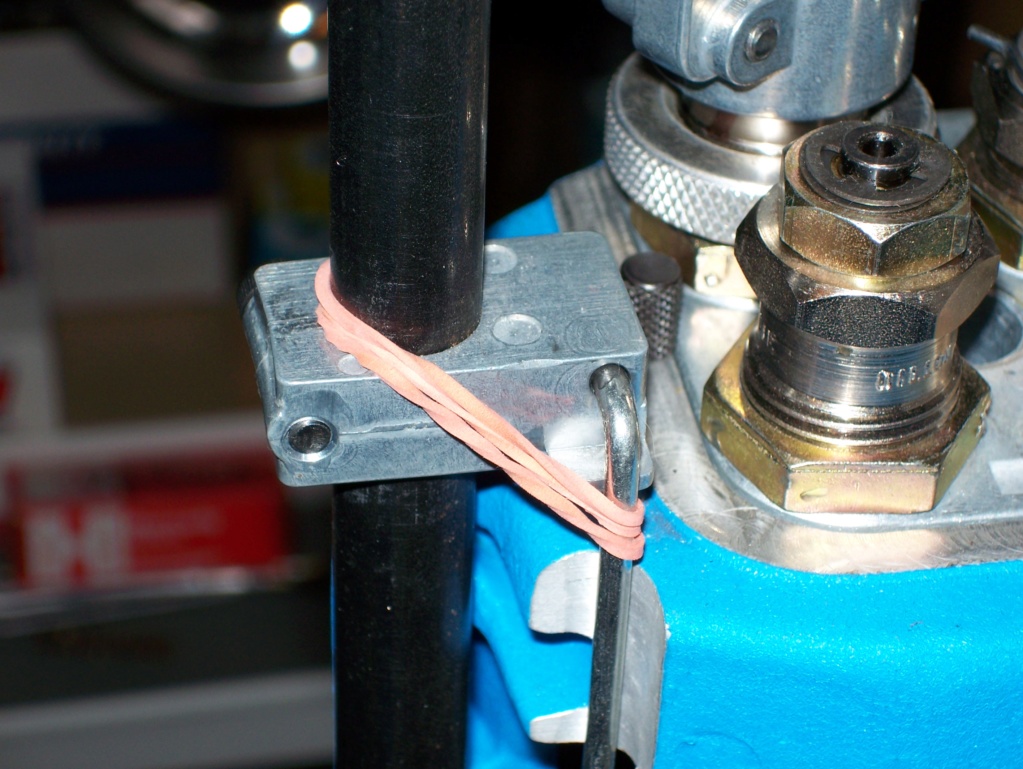

I'm almost at full speed on 750 now. Came across of annoying issue with Operating Rod sliding towards right in the Operating Rod Bracket and then pops-out from the rollers. Looks as RL550C (judging by drawings, I personally don't have any experience with this model) and XL750 have same or similar Priming System. I wonder if any of the 550 users experienced something like this. Picture below represents my solution.  Word of caution though. Material this part is made off is quite hard (tool / spring steel probably, and threated). So drilling hole without appropriate tools would be quite difficult.

Word of caution though. Material this part is made off is quite hard (tool / spring steel probably, and threated). So drilling hole without appropriate tools would be quite difficult.

AP

Word of caution though. Material this part is made off is quite hard (tool / spring steel probably, and threated). So drilling hole without appropriate tools would be quite difficult.

Word of caution though. Material this part is made off is quite hard (tool / spring steel probably, and threated). So drilling hole without appropriate tools would be quite difficult. AP

Last edited by PhotoEscape on 4/10/2020, 1:58 pm; edited 1 time in total (Reason for editing : spelling)

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

Instead of a hairpin, maybe cut groove with a Dremel and use a C clip.

bullseyebill- Posts : 16

Join date : 2012-03-31

Location : N. IL

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

On the 550, putting grease on the short end of the rod or in the hole is one fix. Also many people simply put a rubber band around the rod and bracket to hold the end in as it swivels. Peening the end of the short arm is a temporary fix.

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

Jimmy,

If I read you correctly, this is known problem since 550 press was released, and Dillon in almost 40 years of production did nothing?!! I've never had 550, so only with purchase of 750 I realized there is an issue. I'm very surprised as Dillon uses very same approach with 1050 safety rod (p/n: 16811 - BTW, I replaced original 650/750 rod on my 750 with this part. And for the record this addresses issue that many folks are crying about - ability to install Mr. Bulletfeeder dropper on station 4, - when I talked to one of the supervisors at Dillon recently, I pointed at this possibility.) Anyway, I'm itching to order truck load of part in question, setup Bridgeport with carbide end mill, and have it available to all in need. I'm not a fan of temporary solutions. It is waste of time, and I have less and less of it left with every day going by.

AP

If I read you correctly, this is known problem since 550 press was released, and Dillon in almost 40 years of production did nothing?!! I've never had 550, so only with purchase of 750 I realized there is an issue. I'm very surprised as Dillon uses very same approach with 1050 safety rod (p/n: 16811 - BTW, I replaced original 650/750 rod on my 750 with this part. And for the record this addresses issue that many folks are crying about - ability to install Mr. Bulletfeeder dropper on station 4, - when I talked to one of the supervisors at Dillon recently, I pointed at this possibility.) Anyway, I'm itching to order truck load of part in question, setup Bridgeport with carbide end mill, and have it available to all in need. I'm not a fan of temporary solutions. It is waste of time, and I have less and less of it left with every day going by.

AP

Last edited by PhotoEscape on 4/11/2020, 9:19 am; edited 1 time in total (Reason for editing : spelling)

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

I've always been nervous about using metal primer follower. Not so sure what would be the results of a magazine explosion?

blindshooter- Posts : 122

Join date : 2016-03-15

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

from personal experience they stick really well in the ceiling. my dad launched one somehow on a old Cougar and Hunter inline press back in the 80s.. Never would tell me what he did..

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

Always looked at that brass rod as a squib

I popped a few on my 1050 but not the whole tube, try to remember to blow off the slide every couple hundred.

I popped a few on my 1050 but not the whole tube, try to remember to blow off the slide every couple hundred.

blindshooter- Posts : 122

Join date : 2016-03-15

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

Reloading in general requires attention and exercising extreme caution. Piece of cellulose under the primer when latter gets seated has better chance to going off then anything else on the press. I personally can attest to that. Technically primer can be ignited by plastic rod as well. My follower is flattened out for the entire OD, which is 0.125". While I agree, that metal on metal is not a good idea (and that is the reason I'm not going to offer this to anyone) when it comes to primers, I'm hoping my son will not have to post any time soon, that there is a hole in the sealing above one of the presses.

But..... only GOD knows if that will ever happen!

Be safe everyone!

AP

But..... only GOD knows if that will ever happen!

Be safe everyone!

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

Here's what I did on my 550 case feeder which had the same problem.PhotoEscape wrote:I'm almost at full speed on 750 now. Came across of annoying issue with Operating Rod sliding towards right in the Operating Rod Bracket and then pops-out from the rollers. Looks as RL550C (judging by drawings, I personally don't have any experience with this model) and XL750 have same or similar Priming System. I wonder if any of the 550 users experienced something like this. Picture below represents my solution.Word of caution though. Material this part is made off is quite hard (tool / spring steel probably, and threated). So drilling hole without appropriate tools would be quite difficult.

AP

I'm a Tig welder, so I just used some 1/8" diameter ER80 or ER90 (I forget) Tig Rod and bent my own rod to duplicate the Dillon rod. I left the section that goes into the block extra long, like you, then filed a little groove in the rod and used a clip like this to hold it in place.

Wes Lorenz- Posts : 443

Join date : 2011-06-27

Location : Washington

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

That is one of the issues with the 550 primer operating rod. the small end is too short to go thru the holder clamped on the primer tube.. nothing sticks out the backside..

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

Great idea Wes. This spring washer is as easily removable as my pin solution. And it is easier then drilling as it is hard material. The rod I have came with XL750, so I just needed to drill it. I'm just surprised that Dillon has done nothing in all these years.Wes Lorenz wrote:

Here's what I did on my 550 case feeder which had the same problem.

I'm a Tig welder, so I just used some 1/8" diameter ER80 or ER90 (I forget) Tig Rod and bent my own rod to duplicate the Dillon rod. I left the section that goes into the block extra long, like you, then filed a little groove in the rod and used a clip like this to hold it in place.

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Jack H- Posts : 2698

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

blindshooter wrote:I've always been nervous about using metal primer follower. Not so sure what would be the results of a magazine explosion?

Yeah, I thought the same thing the second I saw it.

Carbide- Posts : 13

Join date : 2012-06-25

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

Update on the brass tip for the 750 primer tube:

AP was kind enough to get me some to test on my 750 which is setup for 45.

Installation was a breeze.. I knocked the plastic end off my LP tube and fit the brass end on easily. On my tube the brass end was press fit. I simply heated it a bit and pressed it right on. Installed the tube and began to run Winchester LP primers thru the loader. I ran a test of 20 using the primer rod with a 45 case on the end. All primers ran perfectly.. then I ran the same 20 back thru the primer feed without the rod. Again it ran perfectly including the last primer.

My impression is this is a perfect long term solution for the plastic tips Dillon uses.. while my 750 has been very good with the plastic tip installed at the factory. I have enough 550 experience(30 years or so) to know the plastic will wear/warp and induce issues..replaced a few over the years on my 550s..

Very well done solution

I'll update this with real volume results after I load quantity of ammo

AP was kind enough to get me some to test on my 750 which is setup for 45.

Installation was a breeze.. I knocked the plastic end off my LP tube and fit the brass end on easily. On my tube the brass end was press fit. I simply heated it a bit and pressed it right on. Installed the tube and began to run Winchester LP primers thru the loader. I ran a test of 20 using the primer rod with a 45 case on the end. All primers ran perfectly.. then I ran the same 20 back thru the primer feed without the rod. Again it ran perfectly including the last primer.

My impression is this is a perfect long term solution for the plastic tips Dillon uses.. while my 750 has been very good with the plastic tip installed at the factory. I have enough 550 experience(30 years or so) to know the plastic will wear/warp and induce issues..replaced a few over the years on my 550s..

Very well done solution

I'll update this with real volume results after I load quantity of ammo

Last edited by jglenn21 on 4/11/2020, 4:45 pm; edited 1 time in total

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

Carbide wrote:blindshooter wrote:I've always been nervous about using metal primer follower. Not so sure what would be the results of a magazine explosion?

Yeah, I thought the same thing the second I saw it.

This concern is easily addressable for those who have such concern. Piece of properly sized plastic straw or plastic isolation cover from electrical wire warmed up for flexibility fit over the metal is all it takes. There is enough of space between 0.125" OD of rod and 0.180" ID of small primer tube. Star presses used to come with steel rods coupled on the bottom with piece of plastic rod.

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

jglenn21 wrote:Glad to see this thread as I have a new 750 myself.. factory setup for a 45 has been near perfect for me.. no primer issues at all. I did have to slightly adjust the case feeder to get it to work perfectly but no big deal.. I'm thinking of getting the mini bullet feeder and installing it in station 3. station 4 is my bullet seater and 5 is my crimp die. I don't use a powder check..

BTW I use Winchester primers exclusively

I also normally install one of the old style powder bar return springs just to help with smoothness..

I bought the mini bullet feeder. I had nothing but problems with 185 lead zeros. Could be the wax. Could be me. YMMV. The belling die is superior to the Dillon one, in my opinion.

Vociferous- Posts : 185

Join date : 2012-02-23

Location : North Carolina

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

pretty typical of std. lead bullets in any bullet feeder.. the Hi=Tek or powder coated bullets work perfectly from all accounts.

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

Phil,Vociferous wrote:

The belling die is superior to the Dillon one, in my opinion.

What is "belling die"?

Thanks,

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

Its the part of the powder drop station that widens the case, or "bells" it so to easier receive the bullet.

What part of N. Illinois are you at? Lived 10 years, in the 90's, in the Libertyville, Buffalo Grove, and Mundelein areas. Competed in disc golf back then.

What part of N. Illinois are you at? Lived 10 years, in the 90's, in the Libertyville, Buffalo Grove, and Mundelein areas. Competed in disc golf back then.

Vociferous- Posts : 185

Join date : 2012-02-23

Location : North Carolina

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

I live in Lake Zurich IL area, and work in Mundelein.

AP

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

So here is what I came across of while getting acclimated with 750. Looks as indexing of the shell plate isn't finished by the time priming stem starts pushing up. Subsequently I must take a momentary pause before back strocking to seat primer. Otherwise I get primers seated sideways. In order to alleviate such behavior I have to have shell plate quite loose, so detent ball forces it to complete indexing faster. Having loose shell plate in combination with higher speed of operating press leads to case shake and powder spillage. Result is lower productivity and I feel more tired in comparison with using 650. At this point I have about 5000-6000 rounds of 9mm ammo loaded on 750, and it took me a. much longer, and b. I had many more rounds I had to fix after QC. Needless to say I had quite a number of crashed primers.

I wonder if anyone has experience working with both 650 and 750 presses, and can share their take.

I understand that this is not an issue on 550, as indexing is done manually and one has to take fingers out before rising ramp. Thus there cannot be incomplete turn of the shell plate, and misalignment of the primer punch with shell plate's cells.

AP

I wonder if anyone has experience working with both 650 and 750 presses, and can share their take.

I understand that this is not an issue on 550, as indexing is done manually and one has to take fingers out before rising ramp. Thus there cannot be incomplete turn of the shell plate, and misalignment of the primer punch with shell plate's cells.

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon XL750 First impressions / First modifications

Re: Dillon XL750 First impressions / First modifications

Guess my cycle time is slower coming from the 550.havent run into that problem yet..

On a happy note, the brass primer tube tips have been working perfectly. Not one issue in around 400 45s loaded..

On a happy note, the brass primer tube tips have been working perfectly. Not one issue in around 400 45s loaded..

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

primer timing

primer timing

Not that I know squat about the 750 press but....I see on page 40 of the owners manual that there is a section talking about adjusting the indexer.PhotoEscape wrote:So here is what I came across of while getting acclimated with 750. Looks as indexing of the shell plate isn't finished by the time priming stem starts pushing up. Subsequently I must take a momentary pause before back strocking to seat primer. Otherwise I get primers seated sideways. In order to alleviate such behavior I have to have shell plate quite loose, so detent ball forces it to complete indexing faster. Having loose shell plate in combination with higher speed of operating press leads to case shake and powder spillage. Result is lower productivity and I feel more tired in comparison with using 650. At this point I have about 5000-6000 rounds of 9mm ammo loaded on 750, and it took me a. much longer, and b. I had many more rounds I had to fix after QC. Needless to say I had quite a number of crashed primers.

I wonder if anyone has experience working with both 650 and 750 presses, and can share their take.

I understand that this is not an issue on 550, as indexing is done manually and one has to take fingers out before rising ramp. Thus there cannot be incomplete turn of the shell plate, and misalignment of the primer punch with shell plate's cells.

AP

It may be that you need a slight adjustment of the indexer timing to get the plate moving slightly sooner, that was something I had to sometimes fool with when I was using Lee Pro 1000 presses.

Different system but similar issue

STEVE SAMELAK- Posts : 958

Join date : 2011-06-10

Page 2 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Similar topics

Similar topics» Dillon XL750 Shaving Brass

» Inexpensive removable Mounting option for Dillon XL750 to bench....suggestions please

» Matchguns MG2 First Impressions

» Holosun 407 C First Impressions

» New Pardini first impressions

» Inexpensive removable Mounting option for Dillon XL750 to bench....suggestions please

» Matchguns MG2 First Impressions

» Holosun 407 C First Impressions

» New Pardini first impressions

Page 2 of 4

Permissions in this forum:

You cannot reply to topics in this forum