Eccentric Dillon owner

+3

PhotoEscape

SteveT

Schaumannk

7 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Eccentric Dillon owner

Eccentric Dillon owner

I was eccentric, but got some therapy and now I'm good

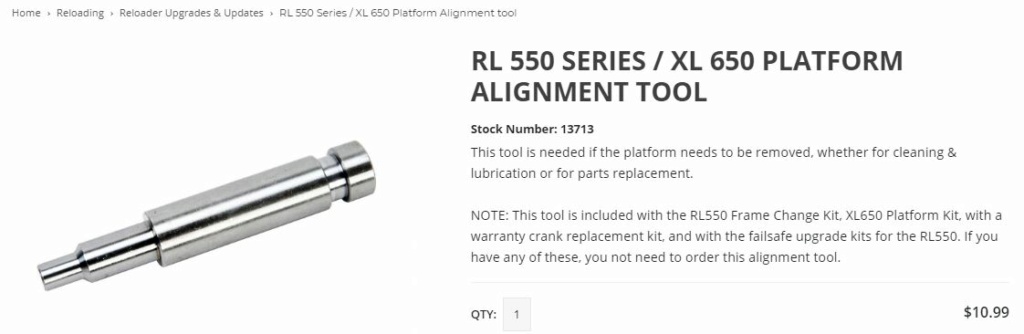

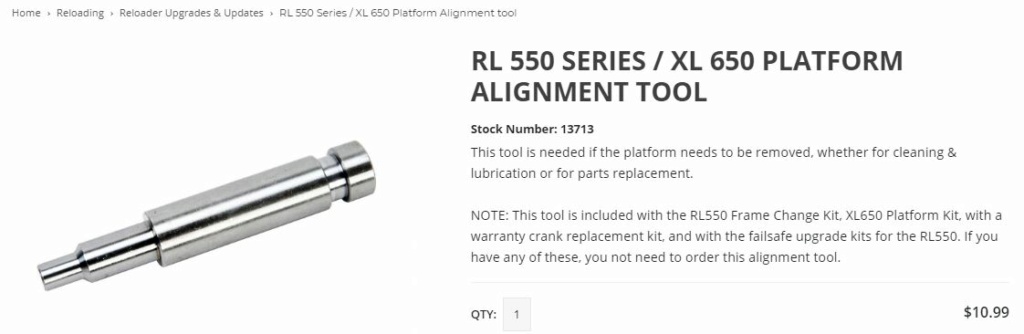

I got a new XL650 about one year ago direct from Dillon. I then proceeded to acquire all of the custom add-ons, extra tool-heads, etc., etc. But I was never able to produce really good looking ammo and struggled to achieve the level of consistency and accuracy that I expected. I found that almost all of my reloads had a noticeable bulge in the brass on one side only. Folks here in Oregon told me that "Dillon's don't produce good ammo" or "you need to improve your technique" and similar less than useful comments. When I was on my Ohio Swing I showed some of my reloads to a few folks. Alex (Photoescape) immediately told me that I needed to check the alignment of my press using one of these:-

Dillon ought to include this simple steel rod with the press (but I guess that there is a reason they don't ). It comes with very detailed instructions which I followed carefully - requires a lot of dis-assembly. My press was significantly out of alignment.

). It comes with very detailed instructions which I followed carefully - requires a lot of dis-assembly. My press was significantly out of alignment.

Very long call to Dillon Tech Support with me answering questions and doing further checks to the instructions of the techie. He talked about "tolerance stacks" and made a lot of excuses - then put me on hold whilst he discussed with their repair shop. It seems that in 2019 they had some "out of spec" platforms and I must have got one. Promised to immediately mail a new one to me free of charge.

I estimate that my old platform was at least 0.025" out of spec. Does not sound much, but more than enough to create a problem.

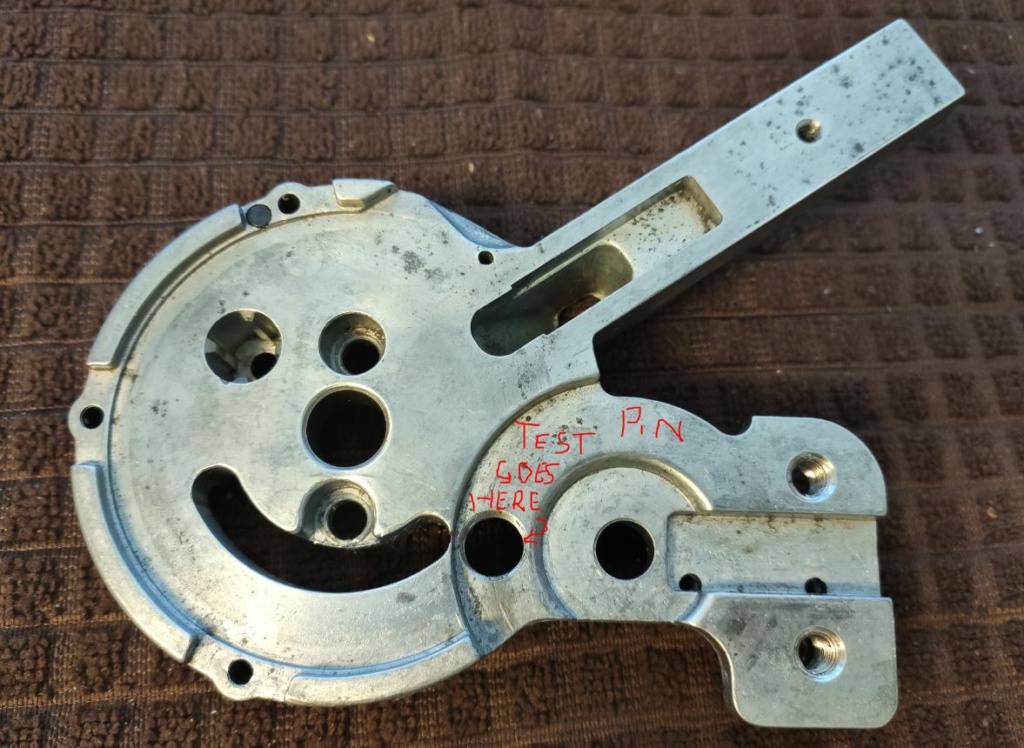

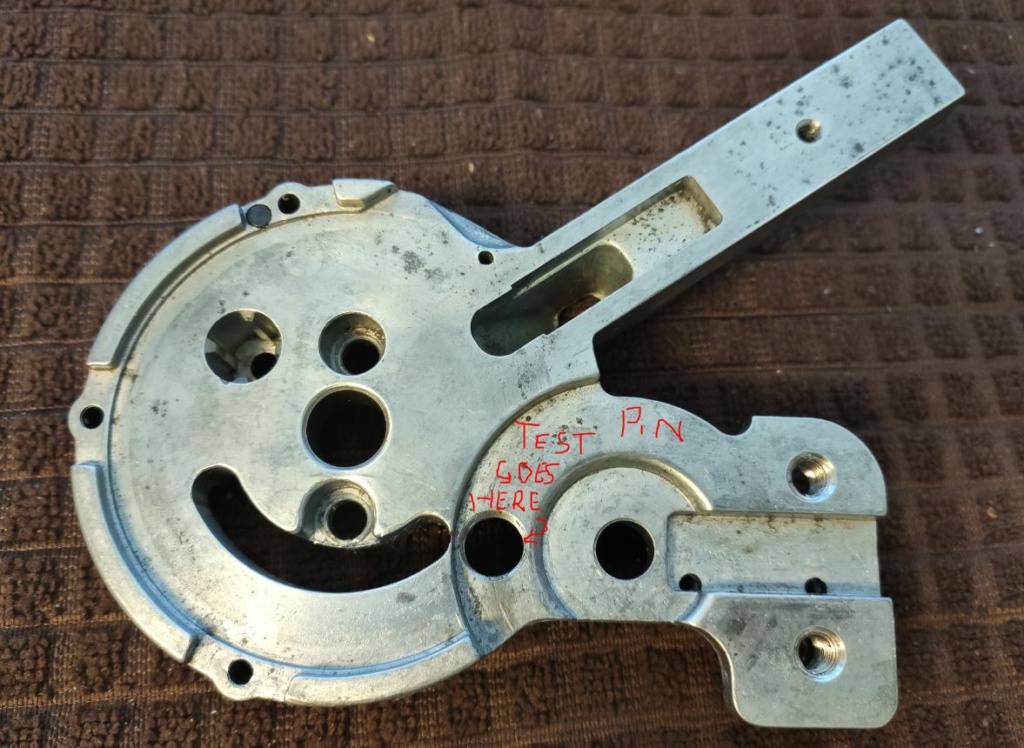

The new one did not get shipped as promised, then after several unanswered emails and two more lengthy phone-calls, eventually it arrived. The new platform was not perfect - took a lot of jiggling and tighten/undo the bolts that retain the platform on the ram, but eventually I got it so that the pin would clear the hole without catching. Put everything back together and - perfectly round ammo - Yay!

I have no evidence, but I suspect that "some" out-of spec platforms might well actually mean ALL of the platforms installed in end 2018, early 2019 XL650's. I guess that almost all "run & gun" and other bulk ammo shooters probably don't know or care about a little eccentricity. Dillon phased out the XL650 just after I bought mine and replaced it with the XL750. Grrr...

Anyhow. I now have a Dillon XL650 that runs smoothly and I am relatively happy. The Dillon case feeder still chokes on 32ACP brass (but I am going to use another press for that caliber soon), but for 45ACP it can churn out decent ammo at a good rate. OK.

I'm no longer eccentric

I got a new XL650 about one year ago direct from Dillon. I then proceeded to acquire all of the custom add-ons, extra tool-heads, etc., etc. But I was never able to produce really good looking ammo and struggled to achieve the level of consistency and accuracy that I expected. I found that almost all of my reloads had a noticeable bulge in the brass on one side only. Folks here in Oregon told me that "Dillon's don't produce good ammo" or "you need to improve your technique" and similar less than useful comments. When I was on my Ohio Swing I showed some of my reloads to a few folks. Alex (Photoescape) immediately told me that I needed to check the alignment of my press using one of these:-

Dillon ought to include this simple steel rod with the press (but I guess that there is a reason they don't

Very long call to Dillon Tech Support with me answering questions and doing further checks to the instructions of the techie. He talked about "tolerance stacks" and made a lot of excuses - then put me on hold whilst he discussed with their repair shop. It seems that in 2019 they had some "out of spec" platforms and I must have got one. Promised to immediately mail a new one to me free of charge.

I estimate that my old platform was at least 0.025" out of spec. Does not sound much, but more than enough to create a problem.

The new one did not get shipped as promised, then after several unanswered emails and two more lengthy phone-calls, eventually it arrived. The new platform was not perfect - took a lot of jiggling and tighten/undo the bolts that retain the platform on the ram, but eventually I got it so that the pin would clear the hole without catching. Put everything back together and - perfectly round ammo - Yay!

I have no evidence, but I suspect that "some" out-of spec platforms might well actually mean ALL of the platforms installed in end 2018, early 2019 XL650's. I guess that almost all "run & gun" and other bulk ammo shooters probably don't know or care about a little eccentricity. Dillon phased out the XL650 just after I bought mine and replaced it with the XL750. Grrr...

Anyhow. I now have a Dillon XL650 that runs smoothly and I am relatively happy. The Dillon case feeder still chokes on 32ACP brass (but I am going to use another press for that caliber soon), but for 45ACP it can churn out decent ammo at a good rate. OK.

I'm no longer eccentric

Guest- Guest

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

The micro switch went out on my case feeder about five weeks ago. Called Dillon, they sent a new one. New one didn’t fit, because the case feeder was an older model. I can run the case feeder without the micro switch that stops the brass from jamming up when the tube is full, but left the housing off while I called Dillon to explain the problem. They said they were sending out the entire housing. That was three weeks ago. Still no sign. I will call again in the morning and reluctantly then I guess, put the housing back on so I can at least load some more 45 without hand feeding all the cases.

What does your case feeder do with the 32 ACP brass? Now I am a bit worried. Haven’t tackled reloading the 32 ACP yet because I don’t want to switch my small primer press over until I have some more 9mm stock piled.

My opinion of Dillon is that it can be very expensive to add all the upgrades to a 550 or a 650 or a 750 to try and get it to perform like a 1050. I was never satisfied with the product until I finally opted for a 1050. Not really that much more, and holds its value extremely well. Was lucky enough to buy one of them used.

What does your case feeder do with the 32 ACP brass? Now I am a bit worried. Haven’t tackled reloading the 32 ACP yet because I don’t want to switch my small primer press over until I have some more 9mm stock piled.

My opinion of Dillon is that it can be very expensive to add all the upgrades to a 550 or a 650 or a 750 to try and get it to perform like a 1050. I was never satisfied with the product until I finally opted for a 1050. Not really that much more, and holds its value extremely well. Was lucky enough to buy one of them used.

Last edited by Schaumannk on Mon Aug 31, 2020 9:07 am; edited 1 time in total (Reason for editing : Spelling)

Schaumannk- Posts : 614

Join date : 2011-06-11

Location : Cheyenne, WY

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

Interesting. They sent me an Alignment tool and instruction when my Ring Indexer broke a couple of weeks ago. My press was in alignment, but I thought that was strange.

I'm surprised at the poor service you got from them. I've never had a bad experience with their customer service. I've needed repairs more often than I'd like, but they've always been knowledgeable and send everything I need right away.

I'm surprised at the poor service you got from them. I've never had a bad experience with their customer service. I've needed repairs more often than I'd like, but they've always been knowledgeable and send everything I need right away.

Plunker likes this post

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

In their defense, I think lately they have been busier than a one legged man in the proverbial butt kicking contest. On the other, this is about the fifth time I have gotten blown off by tech support.SteveT wrote:Interesting. They sent me an Alignment tool and instruction when my Ring Indexer broke a couple of weeks ago. My press was in alignment, but I thought that was strange.

I'm surprised at the poor service you got from them. I've never had a bad experience with their customer service. I've needed repairs more often than I'd like, but they've always been knowledgeable and send everything I need right away.

Strangely enough, this doesn’t happen when I have my son call for me. For the amount of money I have put into Dillon products, you would think I might get a bit more respect. Have been treated ok, actually in their store, but am always with my fellow shooters from Colorado.

Schaumannk- Posts : 614

Join date : 2011-06-11

Location : Cheyenne, WY

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

Roy,radjag wrote:

Dillon phased out the XL650 just after I bought mine and replaced it with the XL750. Grrr...

Don't be upset with not getting XL750! I put over 30 hours of my time to make it work as I deem acceptable, with multiple calls to Dillon and several replacement parts shipped, made several small modifications and designed and machined some of the replacement parts, with one more (replacement safety bracket kit about to be delivered to UniqueTek) on the way! Yet, two of my XL650s run smoother even after more than 50000 rounds through on each. The good thing, Dillon guys don't argue when I call, - probably my account is marked somehow, and send me what I ask for. There are several good techs in service department, that are very knowledgeable and helpful (Sam, Mike). I normally call and ask for specific parts providing part numbers. This would be a good entry point when you need to find replacement part of component - https://www.dillonprecision.com/xl650-parts_8_45.html and then drill down to particular part.

AP

PhotoEscape- Admin

- Posts : 1539

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

My experience with both Dillon products and their customer service was always positive. I got 650 with all the upgrades, yes, expensive, but buy once, cry once. I have a case feeder and switching it from .45ACP to .32 ACP takes a little bit of tinkering. Aside from changing the plate, there are two screw in front which hold the piece called "deflector block" inside the bowl. So if you change to a different caliber, you need to loose these screws and tweak the deflector block a little bit. Takes some trial and error but it can be done.

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

Is that you Alex? If so, PM me so we can stay in touch. Your friend, Kate from the Cardinal center match.PhotoEscape wrote:Roy,radjag wrote:

Dillon phased out the XL650 just after I bought mine and replaced it with the XL750. Grrr...

Don't be upset with not getting XL750! I put over 30 hours of my time to make it work as I deem acceptable, with multiple calls to Dillon and several replacement parts shipped, made several small modifications and designed and machined some of the replacement parts, with one more (replacement safety bracket kit about to be delivered to UniqueTek) on the way! Yet, two of my XL650s run smoother even after more than 50000 rounds through on each. The good thing, Dillon guys don't argue when I call, - probably my account is marked somehow, and send me what I ask for. There are several good techs in service department, that are very knowledgeable and helpful (Sam, Mike). I normally call and ask for specific parts providing part numbers. This would be a good entry point when you need to find replacement part of component - https://www.dillonprecision.com/xl650-parts_8_45.html and then drill down to particular part.

AP

Schaumannk- Posts : 614

Join date : 2011-06-11

Location : Cheyenne, WY

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

I currently have a 1050 Super set up for 9mm. Is there a different plate for 32ACP?javaduke wrote:My experience with both Dillon products and their customer service was always positive. I got 650 with all the upgrades, yes, expensive, but buy once, cry once. I have a case feeder and switching it from .45ACP to .32 ACP takes a little bit of tinkering. Aside from changing the plate, there are two screw in front which hold the piece called "deflector block" inside the bowl. So if you change to a different caliber, you need to loose these screws and tweak the deflector block a little bit. Takes some trial and error but it can be done.

BTW I just got a call from a Dillon. Steve was very nice. Said I was the victim of the Corona virus. Back ordered part which could be coming in any day now.

Schaumannk- Posts : 614

Join date : 2011-06-11

Location : Cheyenne, WY

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

There are two plates for pistol cases, part 21072 is for large pistol cases, 21073 is for small pistol cases. I think both 9mm and .32ACP require the 21073 plate.

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

Yep. That is what I found as well. Thanks.javaduke wrote:There are two plates for pistol cases, part 21072 is for large pistol cases, 21073 is for small pistol cases. I think both 9mm and .32ACP require the 21073 plate.

Schaumannk- Posts : 614

Join date : 2011-06-11

Location : Cheyenne, WY

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

I have both plates and have "tweaked the Deflector Block" and even tried the short plastic tube "whip" mentioned in another thread. But I have not been able to solve the problem of 32ACP cases jamming up against the deflector block. If I do decide to continue using the Dillon case feeder with 32ACP (in order to feed my Lee APP or my new 32ACP press) then my next move will be to fabricate a larger deflector block specifically for 32.

In the meantime I've got some 3D printer guys up in Canada working on both case and bullet feeder prototypes specifically for the very small 32ACP components, but that is taking much longer than I hoped. Almost as bad as waiting for Bullseye gunsmiths to get projects done!

In the meantime I've got some 3D printer guys up in Canada working on both case and bullet feeder prototypes specifically for the very small 32ACP components, but that is taking much longer than I hoped. Almost as bad as waiting for Bullseye gunsmiths to get projects done!

Guest- Guest

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

Schaumannk wrote:

Is that you Alex? If so, PM me so we can stay in touch. Your friend, Kate from the Cardinal center match.

Yeah, Kate, it is me. I'll PM later, you can PM me as well.

Super 1050 is not very conducive platform for changing calibers very often. I would get something else to load 32 ACP.

Roy,

(and others)

Please send me picture(s) of "Deflector Block" and detailed description of the problem. There are several versions of Dillon's Case feeder (I have 3), so I'm not sure what exactly you experience. Since I don't load 32 ACP nor 32 Long, I can't relate to the problem you experience.

AP

PhotoEscape- Admin

- Posts : 1539

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

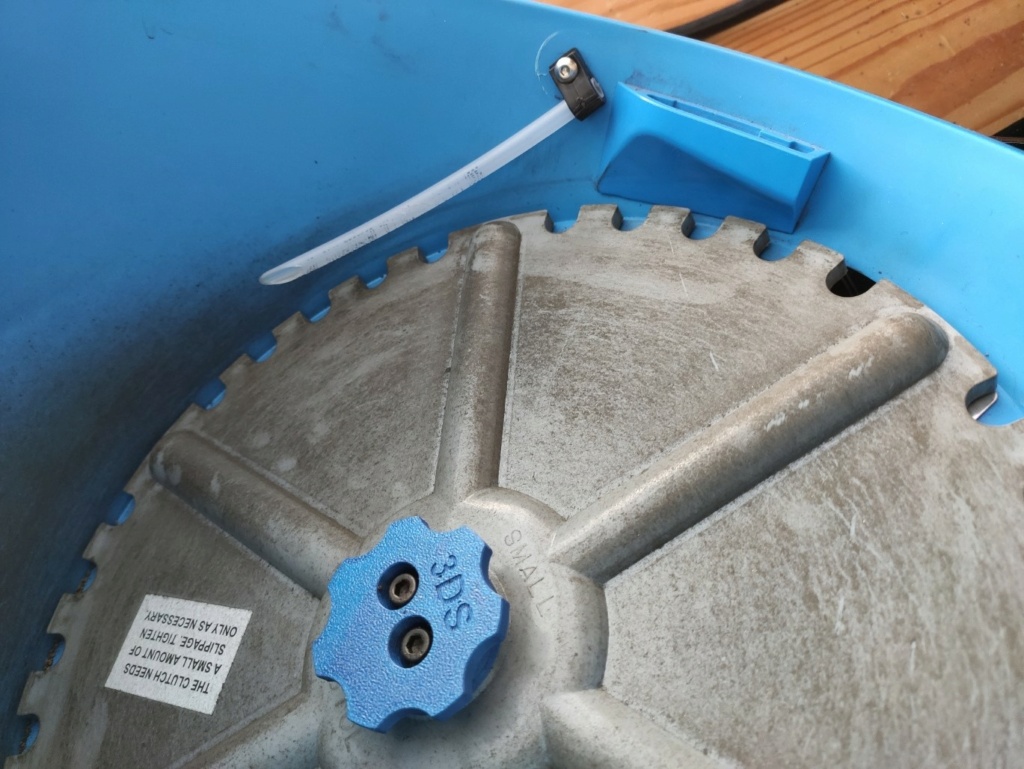

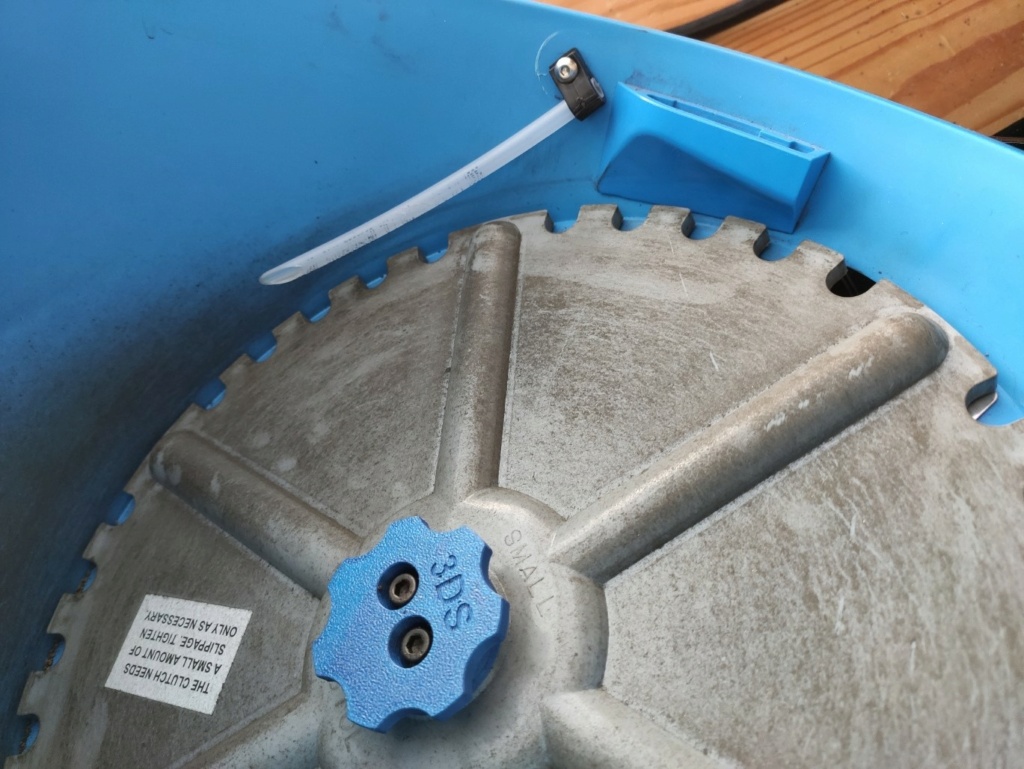

This is the standard Dillon "Deflector Block" inside the drum of the case feeder, together with the aftermarket "whip" which others have found useful, but not me.

The block can be adjusted via these two screws on the outside of the drum.

I also have problems (with both 32 and 45 shells) catching in the mouth of the dropper tube caused by the micro-switch arm pushing the brass across to the left side. One of the clever 3D printer geeks on this forum ought to come up with an improved funnel please.

The problem with 32ACP is that the brass is so short. The notches in the Small Plate are a bit too wide (cause it is a universal plate for everything smaller than 40cal). I believe that a plate with smaller notches and a little wider spacing between notches would help (another 3D printer project?), but the Deflector Plate design is too crude to deal with those tiny 32ACP cases which tend to sit horizontally on top of the rotating plate and then jam under the deflector. The challenge is to knock the brass that is not ready to be seated in a notch away whilst still causing some brass to rotate and drop rim down in an empty notch - not easy.

The block can be adjusted via these two screws on the outside of the drum.

I also have problems (with both 32 and 45 shells) catching in the mouth of the dropper tube caused by the micro-switch arm pushing the brass across to the left side. One of the clever 3D printer geeks on this forum ought to come up with an improved funnel please.

The problem with 32ACP is that the brass is so short. The notches in the Small Plate are a bit too wide (cause it is a universal plate for everything smaller than 40cal). I believe that a plate with smaller notches and a little wider spacing between notches would help (another 3D printer project?), but the Deflector Plate design is too crude to deal with those tiny 32ACP cases which tend to sit horizontally on top of the rotating plate and then jam under the deflector. The challenge is to knock the brass that is not ready to be seated in a notch away whilst still causing some brass to rotate and drop rim down in an empty notch - not easy.

Last edited by radjag on Mon Aug 31, 2020 2:04 pm; edited 2 times in total (Reason for editing : Added words)

Guest- Guest

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

Let's look into case feeder deflector first. As I mentioned I have three different ones. Here is the one I like the most:

It is older style one. As you can see there is no deflector of any kind, but rather little "tong" of metal. I don't think it does anything, but it also doesn't obstruct anything. One on the Roy's picture is the latest version with variable speed, - I hate this model, not so much because of the deflector but rather because of the noise it make. So, if you have this model, my suggestion would be to take deflector out completely, and see what happens. If you see any kind of deficiencies, take piece of galvanized steel (sold in hardware stores) cut appropriate piece, drill two holes (must measure and drill in same spots as on the deflector) and bend one end of it slightly. Bolt it to the body of the case feeder. You most definitely will be able to use same screws that came with deflector, but will need to find two nuts with appropriate threads. Nuts should be placed outside of the feeder. Onto brass being caught issue - see next post.

AP

It is older style one. As you can see there is no deflector of any kind, but rather little "tong" of metal. I don't think it does anything, but it also doesn't obstruct anything. One on the Roy's picture is the latest version with variable speed, - I hate this model, not so much because of the deflector but rather because of the noise it make. So, if you have this model, my suggestion would be to take deflector out completely, and see what happens. If you see any kind of deficiencies, take piece of galvanized steel (sold in hardware stores) cut appropriate piece, drill two holes (must measure and drill in same spots as on the deflector) and bend one end of it slightly. Bolt it to the body of the case feeder. You most definitely will be able to use same screws that came with deflector, but will need to find two nuts with appropriate threads. Nuts should be placed outside of the feeder. Onto brass being caught issue - see next post.

AP

PhotoEscape- Admin

- Posts : 1539

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

I had problem with brass being caught as well. Once again, my solution was to use piece of galvanized steel inserted in the case feeder's output funnel and using chamfer tools (as shown on the picture). I bent and inserted piece of steel as shown on another picture, - one detail here, insert should be long enough to have bottom below the switch's arm

. I think, both are self explanatory, but if additional information is needed, please contact me. AP

. I think, both are self explanatory, but if additional information is needed, please contact me. AP

. I think, both are self explanatory, but if additional information is needed, please contact me. AP

. I think, both are self explanatory, but if additional information is needed, please contact me. AP

PhotoEscape- Admin

- Posts : 1539

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

I have the Dillon case feeder that Alex posted a picture of and have had zero issues with .32 acp brass. Think I bought it 20+ years ago.

What very rare issue I do have is the plastic funnel before the drop tube gets a few jams. Those tiny .32 cases sometimes log jam. It’s very rare and I didn’t see a need to try and remedy it. Now with Roy’s 3D comment I may have to!

Roy, have you started loading .32 with the Lee yet? I’ve been on the prowl for one as they are pretty inexpensive but waiting to hear how your quest goes first...hahaha.

What very rare issue I do have is the plastic funnel before the drop tube gets a few jams. Those tiny .32 cases sometimes log jam. It’s very rare and I didn’t see a need to try and remedy it. Now with Roy’s 3D comment I may have to!

Roy, have you started loading .32 with the Lee yet? I’ve been on the prowl for one as they are pretty inexpensive but waiting to hear how your quest goes first...hahaha.

lablover- Posts : 1275

Join date : 2015-07-30

Location : Michigan

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

Alex, thanks for the useful tips - I will test all of those soon.

Joe, get that 3D printer warmed up please! No, I have not yet got the Lee 32 loader fired up yet, been trying to perfect the Lee APP (which I REALLY like, I will post that story later) and get a decent stash of sized and primed 32ACP brass before I move on. Jim Hensler has very kindly given me loads of advice and I am trying to follow that to the letter first. Story to follow.

Joe, get that 3D printer warmed up please! No, I have not yet got the Lee 32 loader fired up yet, been trying to perfect the Lee APP (which I REALLY like, I will post that story later) and get a decent stash of sized and primed 32ACP brass before I move on. Jim Hensler has very kindly given me loads of advice and I am trying to follow that to the letter first. Story to follow.

Guest- Guest

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

Will do buddy.radjag wrote:Alex, thanks for the useful tips - I will test all of those soon.

Joe, get that 3D printer warmed up please! No, I have not yet got the Lee 32 loader fired up yet, been trying to perfect the Lee APP (which I REALLY like, I will post that story later) and get a decent stash of sized and primed 32ACP brass before I move on. Jim Hensler has very kindly given me loads of advice and I am trying to follow that to the letter first. Story to follow.

I’m healing right now from Achilles Tendon surgery but I’ll get on it soon enough. I also got a a APP and love that little thing!

lablover- Posts : 1275

Join date : 2015-07-30

Location : Michigan

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

The gimpy one has other friends with 3D printers....and APP'slablover wrote:Will do buddy.radjag wrote:Alex, thanks for the useful tips - I will test all of those soon.

Joe, get that 3D printer warmed up please! No, I have not yet got the Lee 32 loader fired up yet, been trying to perfect the Lee APP (which I REALLY like, I will post that story later) and get a decent stash of sized and primed 32ACP brass before I move on. Jim Hensler has very kindly given me loads of advice and I am trying to follow that to the letter first. Story to follow.

I’m healing right now from Achilles Tendon surgery but I’ll get on it soon enough. I also got a a APP and love that little thing!

TonyH- Posts : 802

Join date : 2018-08-06

Location : Utah's Dixie

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

Tony, don't just brag about having a friend

Fire up that 3D printer and make something useful - I mean something that I can use

Fire up that 3D printer and make something useful - I mean something that I can use

Guest- Guest

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

Roy,

I dont have all those fancy reloading tools like a 650, 750 or 1050, just a 550 that I started with some 40 years ago. If you give me either some dimensional drawings, or the measurements of what you have now, and what you would like altered, I can certainly do that.

Oh, and I don't have any friends.....just enemies that I like to keep pretty close!

I dont have all those fancy reloading tools like a 650, 750 or 1050, just a 550 that I started with some 40 years ago. If you give me either some dimensional drawings, or the measurements of what you have now, and what you would like altered, I can certainly do that.

Oh, and I don't have any friends.....just enemies that I like to keep pretty close!

Last edited by TonyH on Mon Aug 31, 2020 5:21 pm; edited 1 time in total

TonyH- Posts : 802

Join date : 2018-08-06

Location : Utah's Dixie

lablover likes this post

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

Tony, he needs a funnel reducer for the 650 case feeder. I can’t get downstairs to measure but maybe Roy can get you the dimensions. You’d probably get it done faster than I could right now. I actually think Dillon sells something like that as well.

lablover- Posts : 1275

Join date : 2015-07-30

Location : Michigan

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

Tony, just kidding.

Alex has made some suggestions which I want to test first, but I may take you up on that offer later.

Thanks.

P.S. After extolling the greatness of the APP, mine just broke. The little plastic hook on the sliding feeder which the return spring attaches to just came off. I was intending to order a spare set of all those plastic parts, now I shall order 2 sets!

Just when I'd got it all set up how I want it and working smoothly. Grrrrr....

Alex has made some suggestions which I want to test first, but I may take you up on that offer later.

Thanks.

P.S. After extolling the greatness of the APP, mine just broke. The little plastic hook on the sliding feeder which the return spring attaches to just came off. I was intending to order a spare set of all those plastic parts, now I shall order 2 sets!

Just when I'd got it all set up how I want it and working smoothly. Grrrrr....

Guest- Guest

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

See Roy, if you broke down and got a 3d printer you could make your own replacement parts! Few designs already out there to do away with the flimsy lee parts

lablover- Posts : 1275

Join date : 2015-07-30

Location : Michigan

Re: Eccentric Dillon owner

Re: Eccentric Dillon owner

I got one of these UFO LED light kits for my Dillon press and it makes a world of difference in being able to see all the details.

https://kmssquared.com/ufo650.html

They make them for the different models. No affiliation with the company.

https://kmssquared.com/ufo650.html

They make them for the different models. No affiliation with the company.

Domino1- Posts : 81

Join date : 2019-04-05

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Eccentric Dillon with a feeding problem and a bad attitude!

» Les Baer 1911 Bullseye OR Rock River Arms 1911 Bullseye

» Looking for the owner of Hammerli 208 # 44411

» Dillon vs Hornady powder measure on Dillon 550

» Looking for owner of a trigger I didn't return

» Les Baer 1911 Bullseye OR Rock River Arms 1911 Bullseye

» Looking for the owner of Hammerli 208 # 44411

» Dillon vs Hornady powder measure on Dillon 550

» Looking for owner of a trigger I didn't return

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum