Seating Die/Stem for 38 Wadcutter

+3

shanneba

NuJudge

mutley

7 posters

Page 1 of 1

Seating Die/Stem for 38 Wadcutter

Seating Die/Stem for 38 Wadcutter

Here shortly I'm going to load 38 wadcutters for the first time, for a new SW Model 52. I'm using 148r Zero wadcutters. I already have a Redding die with a round nose bullet seater. Any potential issues with using that type of seating stem on a wadcutter?

I ask because my first foray into lead pistols bullets involved using a 45 ACP round nose bullet stem in the seating die and I had issues with ejecting cases. The forum here suggested I switch to a Dillon die with a UnqueTek LSWC stem and that cleared up all the ejecting issues.

I want to get ahead of any of the same type of issues as I start loading wadcutters.

I ask because my first foray into lead pistols bullets involved using a 45 ACP round nose bullet stem in the seating die and I had issues with ejecting cases. The forum here suggested I switch to a Dillon die with a UnqueTek LSWC stem and that cleared up all the ejecting issues.

I want to get ahead of any of the same type of issues as I start loading wadcutters.

mutley- Posts : 52

Join date : 2022-03-28

Re: Seating Die/Stem for 38 Wadcutter

Re: Seating Die/Stem for 38 Wadcutter

You will probably need a different seater stem, but I do not see die parts for sale from Redding.

Answers to related matters:

Zero makes two types of wadcutters: a true wadcutter that they call a double ended wadcutter, and a hollow based wadcutter. They would require some different tooling, but probably not as to the seating stem in the seating die.

For soft Lead bullets, most of the people here will tell you that you want the belled, primed, powder charged case to have an ID at or very slightly smaller than the bullet OD. Having the case ID smaller than the bullet gives you good neck tension, which will prevent the bullet falling down in the case, but it will also probably swage your bullet smaller, which may give you Leading but it will give you poor accuracy, in my experience fliers. I try to achieve the case ID being the same as the bullet, down to the bottom of the bullet, but case ID being smaller than the bullet below the bullet, to prevent the bullet from being forced deeper into th case. The bullet being forced even a little deeper in the case could raise pressures a lot. A lot of us here use first a full length sizer die, then a Dillon expander die with an expander stem which I believe is made by UniqueTek. I believe UniqueTek makes three such expander stems, and here's where it gets confusing.

A wadcutter bullet is frequently not just a cylinder of Lead. They vary in length because some of them have features such as a hollow base (longer) or a button on the nose, or more/deeper grooves. They also vary in diameter slightly. All of these variables may change the depth of expansion you want. Lately, I have been shooting the double ended wadcutter with the expander for such simple wadcutters, with good groups at 50 feet.

Answers to related matters:

Zero makes two types of wadcutters: a true wadcutter that they call a double ended wadcutter, and a hollow based wadcutter. They would require some different tooling, but probably not as to the seating stem in the seating die.

For soft Lead bullets, most of the people here will tell you that you want the belled, primed, powder charged case to have an ID at or very slightly smaller than the bullet OD. Having the case ID smaller than the bullet gives you good neck tension, which will prevent the bullet falling down in the case, but it will also probably swage your bullet smaller, which may give you Leading but it will give you poor accuracy, in my experience fliers. I try to achieve the case ID being the same as the bullet, down to the bottom of the bullet, but case ID being smaller than the bullet below the bullet, to prevent the bullet from being forced deeper into th case. The bullet being forced even a little deeper in the case could raise pressures a lot. A lot of us here use first a full length sizer die, then a Dillon expander die with an expander stem which I believe is made by UniqueTek. I believe UniqueTek makes three such expander stems, and here's where it gets confusing.

A wadcutter bullet is frequently not just a cylinder of Lead. They vary in length because some of them have features such as a hollow base (longer) or a button on the nose, or more/deeper grooves. They also vary in diameter slightly. All of these variables may change the depth of expansion you want. Lately, I have been shooting the double ended wadcutter with the expander for such simple wadcutters, with good groups at 50 feet.

NuJudge- Posts : 263

Join date : 2011-09-22

Age : 67

Location : SE Michigan

chopper likes this post

Re: Seating Die/Stem for 38 Wadcutter

Re: Seating Die/Stem for 38 Wadcutter

Which Redding die set do you have?

Midway lists a wadcutter seater for the Redding Competition seating die for 38/357mag

Redding Competition Seater Die Stem 38 Special 357 Mag Wadcutter (midwayusa.com)

Midway lists a wadcutter seater for the Redding Competition seating die for 38/357mag

Redding Competition Seater Die Stem 38 Special 357 Mag Wadcutter (midwayusa.com)

shanneba- Posts : 344

Join date : 2021-10-16

Age : 68

Location : Indiana

mspingeld- Admin

- Posts : 835

Join date : 2014-04-19

Age : 64

Location : New Jersey

Re: Seating Die/Stem for 38 Wadcutter

Re: Seating Die/Stem for 38 Wadcutter

Thanks everyone for the replies. To add a bit more color...

1) I have a set of these Redding dies: https://www.midwayusa.com/product/1012552259?pid=569544

2) But using this Redding stem: https://www.midwayusa.com/product/101263582?pid=136611

3) Using a Hornady powder measure with PTX Expander

4) Bullets are the double ended wadcutters

Sounds like I might need to buy a new seating die. Doesn't look like the stem shanneba linked to will fit in my dies. Any other seating dies I should consider aside from the Redding comp die?

Anyone have luck using the factory Hornady PTX expander?

1) I have a set of these Redding dies: https://www.midwayusa.com/product/1012552259?pid=569544

2) But using this Redding stem: https://www.midwayusa.com/product/101263582?pid=136611

3) Using a Hornady powder measure with PTX Expander

4) Bullets are the double ended wadcutters

Sounds like I might need to buy a new seating die. Doesn't look like the stem shanneba linked to will fit in my dies. Any other seating dies I should consider aside from the Redding comp die?

Anyone have luck using the factory Hornady PTX expander?

mutley- Posts : 52

Join date : 2022-03-28

Re: Seating Die/Stem for 38 Wadcutter

Re: Seating Die/Stem for 38 Wadcutter

This may work in your original dies,

More info fron Redding-

Bullet Seating Micrometers - Redding Reloading Equipment: reloading equipment for rifles, handguns, pistols, revolvers and SAECO bullet casting equipment (redding-reloading.com)

Redding Flat Bullet Seating Micrometer #9471 (38 Special 357 Mag) (midwayusa.com)

More info fron Redding-

Bullet Seating Micrometers - Redding Reloading Equipment: reloading equipment for rifles, handguns, pistols, revolvers and SAECO bullet casting equipment (redding-reloading.com)

Redding Flat Bullet Seating Micrometer #9471 (38 Special 357 Mag) (midwayusa.com)

shanneba- Posts : 344

Join date : 2021-10-16

Age : 68

Location : Indiana

Re: Seating Die/Stem for 38 Wadcutter

Re: Seating Die/Stem for 38 Wadcutter

I have Redding Dies even the Duel Ring Sizing Dies, but this die works great for lead or hollow base WC's.

https://www.midwayusa.com/product/1011107963?pid=875929

https://www.midwayusa.com/product/1011107963?pid=875929

dannyd93140- Posts : 197

Join date : 2021-07-31

Location : Jacksonville, Florida

Foundryratjim- Posts : 243

Join date : 2018-08-01

Age : 66

Location : michigan

samtoast likes this post

Re: Seating Die/Stem for 38 Wadcutter

Re: Seating Die/Stem for 38 Wadcutter

Foundryratjim wrote:https://www.bullseyeforum.net/t19125-reloading-148-hbwc

You may find some useful info here.

Good thread, thanks for sharing!

What are the pin gauges used for? Are they used to detect how far down the case the wall thickness becomes too much to realistically expand? In example, you take the .355 gauge, and so long as it can inset further down the case then the length of your wadcutter bullet, the bullet should seat ok?

mutley- Posts : 52

Join date : 2022-03-28

Re: Seating Die/Stem for 38 Wadcutter

Re: Seating Die/Stem for 38 Wadcutter

The pin gauges are a way of measuring the case ‘cylindrical’ wall depth. There are other methods, but it is reasonably priced to get into. That said, I’ve loaded accurate 38 HBWC reloads in some “+P+” brass that has very thick walls that really squeeze the HB bullets.

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

Re: Seating Die/Stem for 38 Wadcutter

Re: Seating Die/Stem for 38 Wadcutter

Wobbley wrote:The pin gauges are a way of measuring the case ‘cylindrical’ wall depth. There are other methods, but it is reasonably priced to get into. That said, I’ve loaded accurate 38 HBWC reloads in some “+P+” brass that has very thick walls that really squeeze the HB bullets.

For someone trying to get into 38 wadcutter reloading, how should I use a pin gauge? (i.e. is it for the reasons I noted earlier or something different)

Hopefully my questions don't come across as snide. 100% sincerity, I'm not even sure what I should ask to help me. Just seems like there is something here that will provide value in the reloading room, but I'm a bit lost in understanding it.

mutley- Posts : 52

Join date : 2022-03-28

Re: Seating Die/Stem for 38 Wadcutter

Re: Seating Die/Stem for 38 Wadcutter

38 special brass is not all the same dimensions. In the thread from the link I posted it explains how to use a pin gauge to sort your brass. If you are using a hollow base wadcutter, the idea is to not deform the bullet skirt when reloading them for better accuracy. In my Model 52,from I learned in that thread tightened my groups up considerably.

Foundryratjim- Posts : 243

Join date : 2018-08-01

Age : 66

Location : michigan

Re: Seating Die/Stem for 38 Wadcutter

Re: Seating Die/Stem for 38 Wadcutter

mutley wrote:

For someone trying to get into 38 wadcutter reloading, how should I use a pin gauge? (i.e. is it for the reasons I noted earlier or something different)

Hopefully my questions don't come across as snide. 100% sincerity, I'm not even sure what I should ask to help me. Just seems like there is something here that will provide value in the reloading room, but I'm a bit lost in understanding it.

Measure the pin gauge length, measure the case length, insert the pin gauge into the case until it stops, then measure the length of the whole shebang. This will give you a number that is relatable to the cylindrical length where the bullet is seated. All that said, I have found that this varies from manufacturer to manufacturer. I did discover that most manufacturers do NOT make “special” “ Wadcutter brass”. They just DON’T. At the very least not now and any you do find are decades old. It is true that Wadcutters usually have two cannelures pressed into the side of the case but that is an artifact of the loading process used at the factory. I believe that the second cannelure is used to help the ammo to shoot better but is not an indicator of anything else. The only thing I do now is sort out any marked as “+P”.

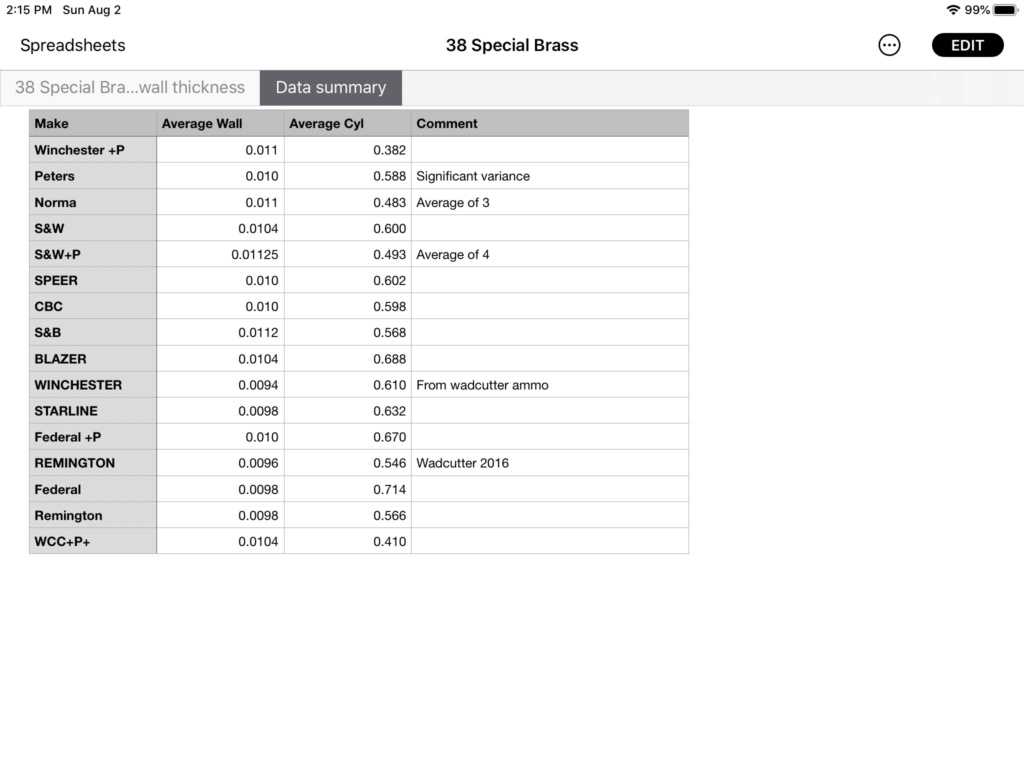

Here is the data I found.

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

samtoast likes this post

Similar topics

Similar topics» seating stem for JHP

» Seating 9mm

» Hornady seating problems

» Redding 32ACP seating die stem is too short?

» .45ACP Wadcutter seating with Swaged SWC's vs. Hard Cast

» Seating 9mm

» Hornady seating problems

» Redding 32ACP seating die stem is too short?

» .45ACP Wadcutter seating with Swaged SWC's vs. Hard Cast

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum