Marvel Barrel Photos

5 posters

Page 1 of 1

Marvel Barrel Photos

Marvel Barrel Photos

I have Posted a request to buy any cheap Marvel Barrels. I want to disassemble it. As I mentioned one Marvel Barrel I have I can disassemble the other it is a good barrel from my friend for dimensions so that I can make him a one piece from a 2" diameter Lilja tight bore barrel blank.

That being said I want photos of the top and side of various Marvel barrels with info that is on the slide. My friend decided to bring me the entire conversion. His slide does say Marvel on one side and Advantage Arms on the other, I know Frerking purchased Marvel and in making them under FCW

The one I have has 3 rib/scope mount mounting screws, 2 near the Muzzle and one at the end of the barrel but not in the mounting block, the notch for the slide stop pin is square on the bottom. My friend's has 2 screws, one in the barrel and other into the mounting block. The slot is rounded bottom, looks very much like the Nelsons I have!

Please send photos to FSCO@pa.net and information as to the maker FCW, Advantage Arms or other. Plus if you do have a Marvel barrel you want to sell let me know.

That being said I want photos of the top and side of various Marvel barrels with info that is on the slide. My friend decided to bring me the entire conversion. His slide does say Marvel on one side and Advantage Arms on the other, I know Frerking purchased Marvel and in making them under FCW

The one I have has 3 rib/scope mount mounting screws, 2 near the Muzzle and one at the end of the barrel but not in the mounting block, the notch for the slide stop pin is square on the bottom. My friend's has 2 screws, one in the barrel and other into the mounting block. The slot is rounded bottom, looks very much like the Nelsons I have!

Please send photos to FSCO@pa.net and information as to the maker FCW, Advantage Arms or other. Plus if you do have a Marvel barrel you want to sell let me know.

Last edited by Froneck on Wed Aug 07, 2024 6:56 pm; edited 1 time in total

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

Kirk A likes this post

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

Attached is a photo of my friends Advantage Arms Marvel. Notice it has a roll pin inserted slightly below the ejector. slot. I don't see that in the above photos or in the other Marvel I have. As mentioned I can't disassemble my friends barrel so another like it that is in poor cheap condition is desired. Didn't look close at my friend barrel so I didn't see the roll pin before. I have a one piece barrel started that is the same length so all I've done was to measure lengths of it. Kinda wondering why the roll pin was used, is the barrel press fitted and roll pin used to lock it is place, be interesting to find out! If so I would not have used a roll pin, solid or taper pin would be much better!

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

Bob Marvel prepped AA barrel

Jack H- Posts : 2700

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

Looks like the Advantage Arms Marvels have a roll pin, I wonder why? Anyone with a photo of a FCW Marvel barrel? Does it have a roll pin inserted? I'm not familiar with Marvel versions even by Nelsons that have Marvel on the slide.

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

I have another AA barrel. Not a Bob Marvel prepped one. It has the rollpin. I would guess its a lock like on S&W revolver barrels.

Jack H- Posts : 2700

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

I can understand the possible need for the lock but why are other Marvel barrels not locked nor are any of the Nelson barrels locked. However the one rib mount screw is in the mounting block that will prevent rotation,

Jack H is the rib screw near the chamber in the mounting block or in the barrel. The AA I have has the pin and the screw in the mounting block.

Jack H is the rib screw near the chamber in the mounting block or in the barrel. The AA I have has the pin and the screw in the mounting block.

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

I did get a standard length Marvel Barrel, I plan to disassemble it. I know Nelson Barrels are threaded Left Hand, anyone know which way Marvel Barrels are threaded? Will save me time trying to determine the direction if I knew what direction to start with.

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

Took the AA rib off and......Froneck wrote: is the rib screw near the chamber in the mounting block or in the barrel. The AA I have has the pin and the screw in the mounting block.

Jack H- Posts : 2700

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

Hi Frank,

It took me awhile to find the AA barrels so I would be able to take them apart for you.

Picture 1 from top:

Nelson

NW custom with A10 barrel block and tight Lilja barrel

FWC

AA with the worst chamber I have ever came across.

AA with the 2nd worst chamber I have ever came across.

Top View:

Other side:

AA barrels taken apart:

Roll pin barrel is a press fit -going to heat up the block to get it out.

Threaded barrel is a Right Hand 3/8-40tpi w/red locktite.

It took me awhile to find the AA barrels so I would be able to take them apart for you.

Picture 1 from top:

Nelson

NW custom with A10 barrel block and tight Lilja barrel

FWC

AA with the worst chamber I have ever came across.

AA with the 2nd worst chamber I have ever came across.

Top View:

Other side:

AA barrels taken apart:

Roll pin barrel is a press fit -going to heat up the block to get it out.

Threaded barrel is a Right Hand 3/8-40tpi w/red locktite.

Last edited by Wes Lorenz on Sun Aug 11, 2024 5:49 am; edited 1 time in total (Reason for editing : Inserted last photo)

Wes Lorenz- Posts : 443

Join date : 2011-06-27

Location : Washington

jmoore likes this post

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

Thanks Wes! I see differences in AA barrels. Left barrel has larger diameter to fit counter-bore in the block the one on the right looks smaller though not much can be seen. Wonder why one has roll pin? What is the direction of the rifling twist? Right hand on both AA Barrels? How is the NW ejector held in? Who is NW Custom? From what I see the flat where the barrel meets the frame is greater distance on #3 and #5, do they both fit the same slide? I assume the slides are different for the other 2 Marvel barrels. What size group is from Lilja tight bore barrel? Know what chamber type it has, Bentz?

Attached is a photo of how I've attached Nelson extractor

Attached is a photo of how I've attached Nelson extractor

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

<"Thanks Wes! I see differences in AA barrels. Left barrel has larger diameter to fit counter-bore in the block the

1. one on the right looks smaller though not much can be seen.

2. Wonder why one has roll pin?

3. What is the direction of the rifling twist? Right hand on both AA Barrels?

4. How is the NW ejector held in?

5. Who is NW Custom?

6.From what I see the flat where the barrel meets the frame is greater distance on #3 and #5, do they both fit the same slide?

7. I assume the slides are different for the other 2 Marvel barrels. What size group is from Lilja tight bore barrel?

8. Know what chamber type it has, Bentz?">

Hi Frank,

1. The roll pin version is a11/32" (.34375"+/-) thru press (shrink?) fit.

2. Roll pin is to secure the barrel (I guess).

3. Right hand on both.

4. See photo below.

5. -

6. Both blocks are .985" long. Yes, fit both slides.

7. Marvel, AA, NW, and FWC barrels interchange with each of their slides that I have. Never tried the barrels on my Nelson as it shoots wonderfully, so I don't need to.

8. The closest chamber I could find is a Blazer reamer drawing that has a larger diameter and lengthy throat (both were off-center and most likely cut with a dull reamer). No wonder Bob did some with his own barrels.

Hope this helps,

Wes

1. one on the right looks smaller though not much can be seen.

2. Wonder why one has roll pin?

3. What is the direction of the rifling twist? Right hand on both AA Barrels?

4. How is the NW ejector held in?

5. Who is NW Custom?

6.From what I see the flat where the barrel meets the frame is greater distance on #3 and #5, do they both fit the same slide?

7. I assume the slides are different for the other 2 Marvel barrels. What size group is from Lilja tight bore barrel?

8. Know what chamber type it has, Bentz?">

Hi Frank,

1. The roll pin version is a11/32" (.34375"+/-) thru press (shrink?) fit.

2. Roll pin is to secure the barrel (I guess).

3. Right hand on both.

4. See photo below.

5. -

6. Both blocks are .985" long. Yes, fit both slides.

7. Marvel, AA, NW, and FWC barrels interchange with each of their slides that I have. Never tried the barrels on my Nelson as it shoots wonderfully, so I don't need to.

8. The closest chamber I could find is a Blazer reamer drawing that has a larger diameter and lengthy throat (both were off-center and most likely cut with a dull reamer). No wonder Bob did some with his own barrels.

Hope this helps,

Wes

Wes Lorenz- Posts : 443

Join date : 2011-06-27

Location : Washington

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

I see the blocks are different but being the ejector is slightly below the center of the bore it looks as if the top is lowered or barrel diameter changed.

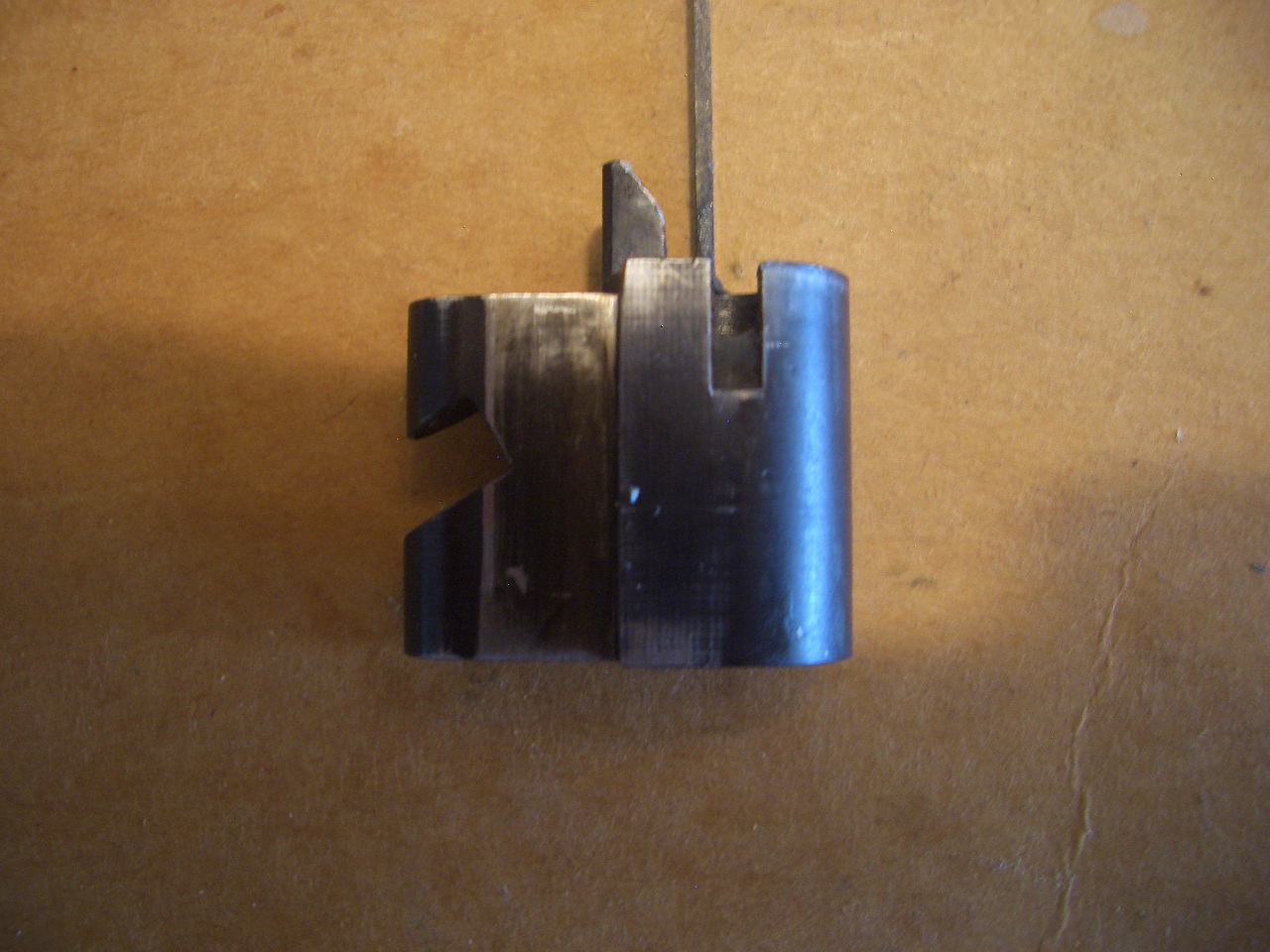

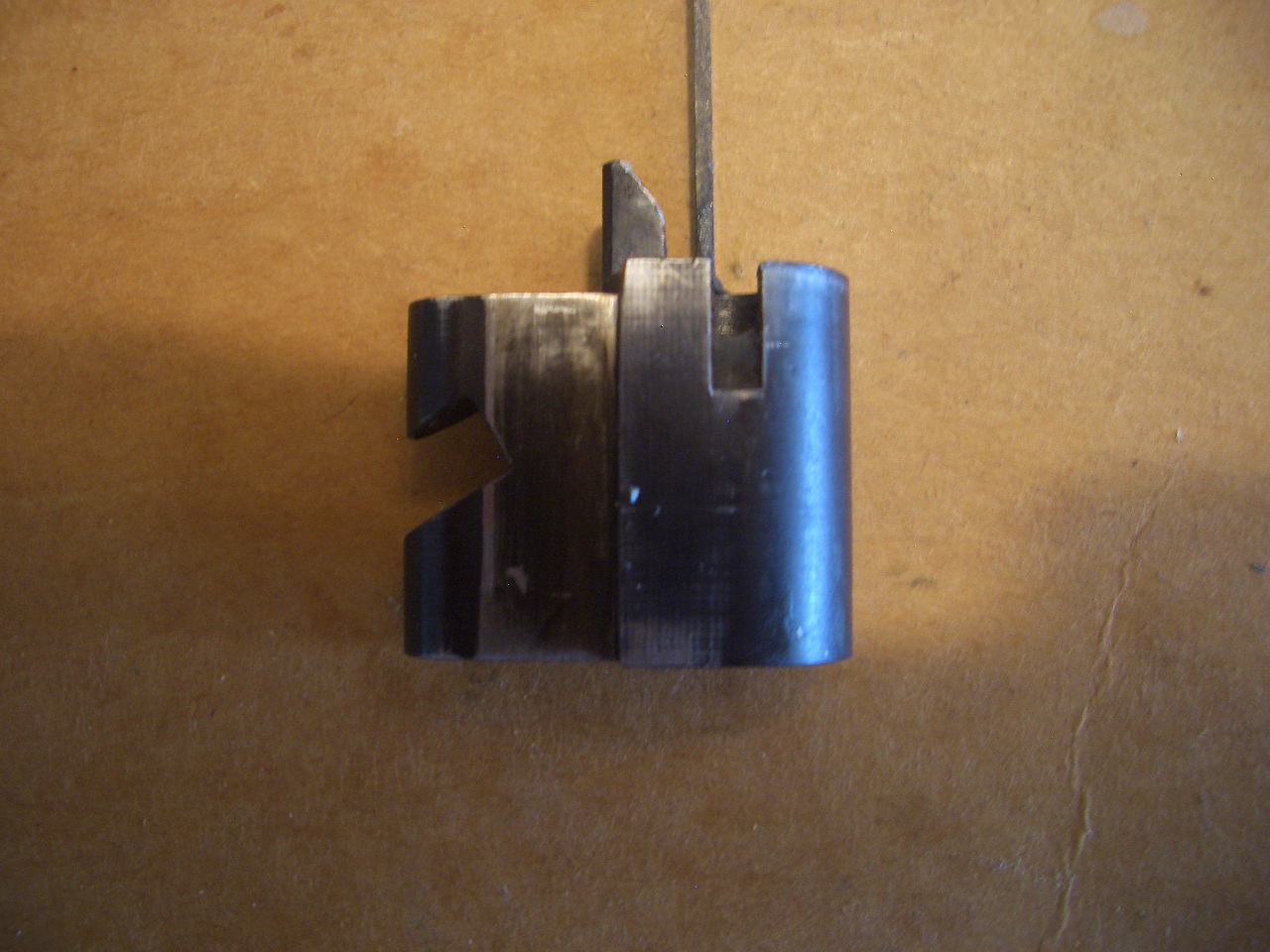

Photos attached is the barrel and block I unscrewed, the Marvel barrel I have is RH thread 3/8-40tpi. Odd barrel diameter .621" X .525" polished muzzle end. .622" x 3.832" with visible tool marks. Block width is .620". Very much extractor slot wear! Nelsons I have are all .625" diameter full length with no tool marks, block width is also .625". Thanks for thread direction Wes, barrels unscrewed with first attempt, didn't need heat! That's also an interesting point, all the well shot Nelsons I unscrewed did so easily without heat yet the one un-shot barrel I almost applied heat, it was at the point I was going to stop and apply heat when it started to turn, was difficult to turn until it was at least 80% out! Seems as though shooting loosens loctite.

I do like that larger diameter where the barrel and block meet as opposed to the undercut of the Nelson barrel but Nelson having more threads. Probably because the Marvel I have threads are probably die cut not lathe single pointed. Nelson as I mentioned is 3/8-40tpi LH so anyone attempting to unscrew a Nelson must turn it right hand or clockwise. Don't understand why Nelson uses LH threads.

Photos attached is the barrel and block I unscrewed, the Marvel barrel I have is RH thread 3/8-40tpi. Odd barrel diameter .621" X .525" polished muzzle end. .622" x 3.832" with visible tool marks. Block width is .620". Very much extractor slot wear! Nelsons I have are all .625" diameter full length with no tool marks, block width is also .625". Thanks for thread direction Wes, barrels unscrewed with first attempt, didn't need heat! That's also an interesting point, all the well shot Nelsons I unscrewed did so easily without heat yet the one un-shot barrel I almost applied heat, it was at the point I was going to stop and apply heat when it started to turn, was difficult to turn until it was at least 80% out! Seems as though shooting loosens loctite.

I do like that larger diameter where the barrel and block meet as opposed to the undercut of the Nelson barrel but Nelson having more threads. Probably because the Marvel I have threads are probably die cut not lathe single pointed. Nelson as I mentioned is 3/8-40tpi LH so anyone attempting to unscrew a Nelson must turn it right hand or clockwise. Don't understand why Nelson uses LH threads.

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

In my memory archives I recall a phone call with Bob Marvel. He did say something of a design change in the barrels. AA I think. Something about the height of the bore or maybe the ejector. That was a long time ago. So, FWIW....

Jack H- Posts : 2700

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

Wes; the barrel that has the roll pin is not threaded? Press or shrink fitted in? Are the heights different or is it because the shorter one (right) in the photo is laying at an angle. Can you provide end views?

Jack; if as Wes stated both could not be used with the same slide if height is different.

I'm making a special depth mic. similar to Starrett 443 half base with a slot in the base so as to measure the flat to bore. I have a Starrett 463 mic. head and 1"wide X 3/4" high X 3" long tool steel base with .380" wide slot in the center to fit the block where it fits into the slide. All sides of the base is surface ground and bottom lapped flat. I need to put the base in my Jig Borer to make the hole for the mic. head. I was that so as to machine th flat on my solid barrel. Photo attached in progress of solid barrel from Lilja tight bore blank. Long one is for my friends AA slide, other is for Adam's Nelson, soon to be third for my home made conversion that is rough cut.

Jack; if as Wes stated both could not be used with the same slide if height is different.

I'm making a special depth mic. similar to Starrett 443 half base with a slot in the base so as to measure the flat to bore. I have a Starrett 463 mic. head and 1"wide X 3/4" high X 3" long tool steel base with .380" wide slot in the center to fit the block where it fits into the slide. All sides of the base is surface ground and bottom lapped flat. I need to put the base in my Jig Borer to make the hole for the mic. head. I was that so as to machine th flat on my solid barrel. Photo attached in progress of solid barrel from Lilja tight bore blank. Long one is for my friends AA slide, other is for Adam's Nelson, soon to be third for my home made conversion that is rough cut.

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

Kirk A likes this post

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

Wes; the barrel that has the roll pin is not threaded? Press or shrink fitted in? Are the heights different or is it because the shorter one (right) in the photo is laying at an angle. Can you provide end views?

Hi Frank,

Yes the roll pin barrel block has a an un-threaded thru bore of 11/32" +/- press or shrink fit.

Laying at angle.

The treaded block extractor slot is .200" from the frame mounting surface (.262" C/L).

The roll pin block is .210".

My guess on the Nelson left hand threads are that you can feed out when cutting them.

Hi Frank,

Yes the roll pin barrel block has a an un-threaded thru bore of 11/32" +/- press or shrink fit.

Laying at angle.

The treaded block extractor slot is .200" from the frame mounting surface (.262" C/L).

The roll pin block is .210".

My guess on the Nelson left hand threads are that you can feed out when cutting them.

Wes Lorenz- Posts : 443

Join date : 2011-06-27

Location : Washington

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

Thanks Wes!

I have Hendey and Pratt&Whitney lathes with lead screw reverse so that thread or feed will stop at preset location. Plus if a lathe without threaded spindle is used turning the tool bit upside down and run the lathe in reverse would work with RH threads. None of my 6 lathes have threaded spindle. LH thread might be done to make it difficult to thread the block, 3/8-40tpi LH tap is like hens teeth to find, I have 2 of them. One is spiral-point plug tap, other is 4 flute bottoming hand tap. I use the bottoming tsp to clean Loctite out of the block. Wouldn't be to difficult to single point the threads in a lathe. However LH threads are wrong direction for RH twist rifling. But .22 bullet might not provide enough inertia to unscrew the barrel. Scope mount screw in the block will help.

Being I am making solid barrels that's not a problem but I'm finding it's more work than I thought.

I have Hendey and Pratt&Whitney lathes with lead screw reverse so that thread or feed will stop at preset location. Plus if a lathe without threaded spindle is used turning the tool bit upside down and run the lathe in reverse would work with RH threads. None of my 6 lathes have threaded spindle. LH thread might be done to make it difficult to thread the block, 3/8-40tpi LH tap is like hens teeth to find, I have 2 of them. One is spiral-point plug tap, other is 4 flute bottoming hand tap. I use the bottoming tsp to clean Loctite out of the block. Wouldn't be to difficult to single point the threads in a lathe. However LH threads are wrong direction for RH twist rifling. But .22 bullet might not provide enough inertia to unscrew the barrel. Scope mount screw in the block will help.

Being I am making solid barrels that's not a problem but I'm finding it's more work than I thought.

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

I made a gauge to measure bore to flat height. I insert gauge pin into the bore (in the photo is .217" gauge pin) Being I'm making a replacement one piece barrel I can use the same micrometer reading as taken from the 22 piece barrel I'm replacing.

I used a Mitutoyo Micrometer Head that is reverse reading because Starrett didn't make one.

See attached photos

I used a Mitutoyo Micrometer Head that is reverse reading because Starrett didn't make one.

See attached photos

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

jmoore likes this post

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

[url=https://servimg.com/view/20577852/8]

[url=https://servimg.com/view/20577852/8] [/url]

[/url]Not sure if this helpful to you at this point in the thread. I'm just a shooter and not much of a machinist or gunsmith. I do live close to FCW and know Travis and Tony...great guys and I understand they're working on an all steel model.

Here are my two older Marvel units:

Huskerhunter- Posts : 7

Join date : 2016-03-06

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

Hi Frank,

I remembered a future project involving the floppy loose ejector on my Kart conversion where I am going to use part of this EGW blank to machine a frame mounted ejector for it.

This may be something that you are interested in too instead of a barrel mounted ejector.

Wes

I remembered a future project involving the floppy loose ejector on my Kart conversion where I am going to use part of this EGW blank to machine a frame mounted ejector for it.

This may be something that you are interested in too instead of a barrel mounted ejector.

Wes

Wes Lorenz- Posts : 443

Join date : 2011-06-27

Location : Washington

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

Wes; Being my homemade conversion is on a dedicated frame. I did make a frame mounted ejector. Simply put I extended the side of the 1911 ejector (made complete ejector) so that it will reach the rim of a .22LR. Works great. I'll make a photos and attach it. Only problem the rear of something like a Nelson slide has to be modified but since I made the slide I simply extended the cut.

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

mbmshooter and Allan Campbell like this post

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

shanneba and jmoore like this post

Re: Marvel Barrel Photos

Re: Marvel Barrel Photos

Update;

Been busy with other projects and getting tooling needed to complete the 3 one piece barrels from 2" diameter Lilja blank. A lilja match reamer was received from Manaon as well as a Bentz reamer. I noticed on the specs that radius of up to .015" was on the reamer at the end just before the rim. I put 50X lens in my Optical Comparator and checked both reamers. Lilja has .011R and Bentz .000R the end is undercut so there will be a sharp corner. Lilja is a tighter bore but I like the radius at the start of the chamber, kinda will guide round into the chamber. I have a few Nelson barrels removed for replacement so my plan is to cut the end off and re-chamber the barrel so as to do the plunk test. I also plan to chamber the Home-made conversion barrel with the Lilja match reamer and test fire it.

Attached photos are progress on 2 of the Nelson Barrels, Adam's Nelson and My Home-made conversion barrel. I also have the AA Marvel about the same except Breach face and ramp not cut yet but soon will be due to machine is set-up to do that. My special Depth Gauge worked great! I ordered 7.5mm carbide reamer to cut the rim radius and the ramp angle though I might use a 9/32" carbide endmill to cut the ramp radius. Reason I'm using the 7.5MM to cut the rim clearance is to prevent any force on the chamber reamers because the rim diameter is listed as .288" I also ordered and have .2150" and .2155" pilots for the reamers (.2155" will not fit, .2152 pin gauge will) required for the tight bore Lilja blank.

Been busy with other projects and getting tooling needed to complete the 3 one piece barrels from 2" diameter Lilja blank. A lilja match reamer was received from Manaon as well as a Bentz reamer. I noticed on the specs that radius of up to .015" was on the reamer at the end just before the rim. I put 50X lens in my Optical Comparator and checked both reamers. Lilja has .011R and Bentz .000R the end is undercut so there will be a sharp corner. Lilja is a tighter bore but I like the radius at the start of the chamber, kinda will guide round into the chamber. I have a few Nelson barrels removed for replacement so my plan is to cut the end off and re-chamber the barrel so as to do the plunk test. I also plan to chamber the Home-made conversion barrel with the Lilja match reamer and test fire it.

Attached photos are progress on 2 of the Nelson Barrels, Adam's Nelson and My Home-made conversion barrel. I also have the AA Marvel about the same except Breach face and ramp not cut yet but soon will be due to machine is set-up to do that. My special Depth Gauge worked great! I ordered 7.5mm carbide reamer to cut the rim radius and the ramp angle though I might use a 9/32" carbide endmill to cut the ramp radius. Reason I'm using the 7.5MM to cut the rim clearance is to prevent any force on the chamber reamers because the rim diameter is listed as .288" I also ordered and have .2150" and .2155" pilots for the reamers (.2155" will not fit, .2152 pin gauge will) required for the tight bore Lilja blank.

Froneck- Posts : 1764

Join date : 2014-04-05

Age : 77

Similar topics

Similar topics» Marvel Conversion Barrel wanted

» Nelson/Marvel barrel upgrade.

» Marvel conversion unit barrel and slide question

» Ranson Rest vs. Linear Slide (Testing)

» .22 Magazine help

» Nelson/Marvel barrel upgrade.

» Marvel conversion unit barrel and slide question

» Ranson Rest vs. Linear Slide (Testing)

» .22 Magazine help

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum