Warner Total Radius Sear

+9

jglenn21

Colt711

Jack H

Chuck Warner

Froneck

Jon Eulette

james r chapman

Rob Kovach

Jerry Keefer

13 posters

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Warner Total Radius Sear

Warner Total Radius Sear

First topic message reminder :

This is a reply to a recent request to describe the total radius sear face/trigger job. An innovation of Chuck Warner.. I was fortunate to be on the ground floor of this when Chuck was brain storming it.. It only took 100 years but he figured it out.. Over many years, I had invested heavily into precision measuring equipment and tooling to enable the reproduction of a bullseye trigger job that any HM would appreciate.. Playing the angle game can be very difficult at best. My lady shooter shot the first and only total radius sear at Camp Perry that year.. That same sear is still running with absolutely zero problems, and she has done extremely well with it. .404 is a magic number.. How long is the sear..?? From the pivot pin C/L to the sear face.?? Many sears, that a smith may be struggling with are shorter than the .404 . There also needs to be an accurate way to measure it.. Chuck's Jig/Fixture does all that for the smith.. It works off the sear pin center line, and if it is too short, it will be apparent.

As soon as Chuck mentioned the concept, the Harig fixture, and Suburban Master Grind seemed the logical way to go for me. Below you will see the Master Grind fixtured to grind the sear face. These precision tools are accurate to 5 decimal places.. You can remove the Dykem from from the sear face and not touch the metal..So it will produce a super accurate sear face with minimal material removal.. I have yet to have a sear that did not clean up full face with more than a few tenths of grinding.. Half the battle is won.. Then it is on to the other components of the trigger job, but that sear is as perfect as humanly possible. The sear rotates on the pin, and the radius face neither lifts the hammer nor drops the hammer..Neutral angles can come close.. But it is much tougher to do, especially without the benefit of comparators and or tool maker microscopes.

The Harig and Suburbans can be motor driven.. which I prefer.. Anything to remove human imperfection.

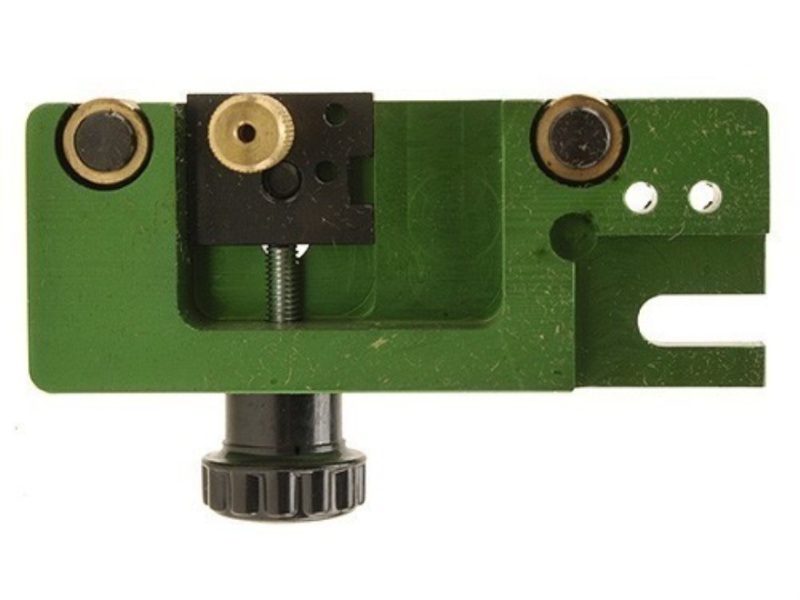

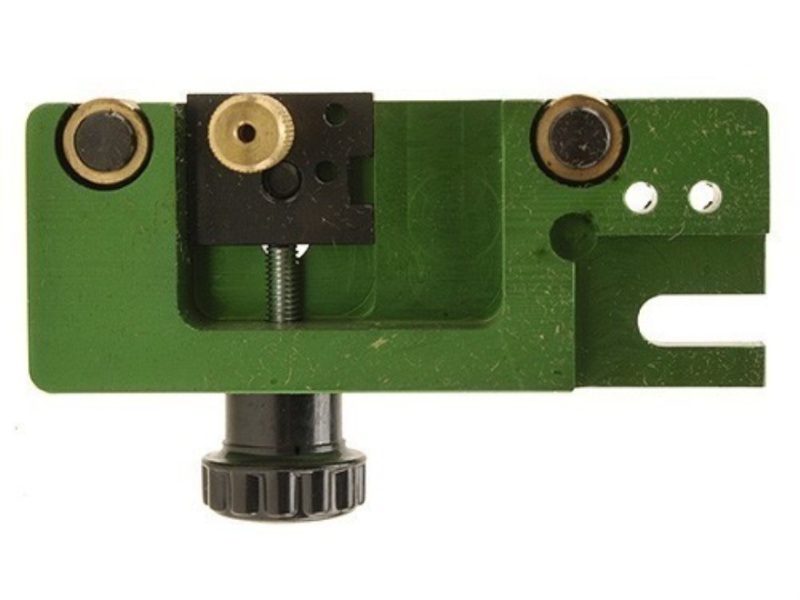

A picture of the sear support fixture ground on the same axis as the tool.

In the grinder

Finished product..

This is a reply to a recent request to describe the total radius sear face/trigger job. An innovation of Chuck Warner.. I was fortunate to be on the ground floor of this when Chuck was brain storming it.. It only took 100 years but he figured it out.. Over many years, I had invested heavily into precision measuring equipment and tooling to enable the reproduction of a bullseye trigger job that any HM would appreciate.. Playing the angle game can be very difficult at best. My lady shooter shot the first and only total radius sear at Camp Perry that year.. That same sear is still running with absolutely zero problems, and she has done extremely well with it. .404 is a magic number.. How long is the sear..?? From the pivot pin C/L to the sear face.?? Many sears, that a smith may be struggling with are shorter than the .404 . There also needs to be an accurate way to measure it.. Chuck's Jig/Fixture does all that for the smith.. It works off the sear pin center line, and if it is too short, it will be apparent.

As soon as Chuck mentioned the concept, the Harig fixture, and Suburban Master Grind seemed the logical way to go for me. Below you will see the Master Grind fixtured to grind the sear face. These precision tools are accurate to 5 decimal places.. You can remove the Dykem from from the sear face and not touch the metal..So it will produce a super accurate sear face with minimal material removal.. I have yet to have a sear that did not clean up full face with more than a few tenths of grinding.. Half the battle is won.. Then it is on to the other components of the trigger job, but that sear is as perfect as humanly possible. The sear rotates on the pin, and the radius face neither lifts the hammer nor drops the hammer..Neutral angles can come close.. But it is much tougher to do, especially without the benefit of comparators and or tool maker microscopes.

The Harig and Suburbans can be motor driven.. which I prefer.. Anything to remove human imperfection.

A picture of the sear support fixture ground on the same axis as the tool.

In the grinder

Finished product..

Jerry Keefer- Posts : 1001

Join date : 2012-01-02

Location : Maidens, VA

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

Does anyone know what to look for that causes and might be fixed on the long roll that starts with a creep in my Ax trigger in the Range Officer?

Jack H- Posts : 2699

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

In my experience, most sear and hammer pin holes are not drilled parallel in frame. As a result it is common for hammer and sear not to be aligned. So one side of the sear hits harder on hammer and it will feel like creep. Also the sear can be rubbing/bearing longer on one side of hammer hooks and it will creep. In my experience drop ins are not 100% going to work. The Ax is one of the nicest I have seen. This description is very basic and generic. Today I saw a pistol with a poorly machined trigger track (trigger yoke) and caused inconsistent creepy feeling. After fixing problem trigger immediately felt better. Also disconnecter can be moving at hole in top of frame and cause creep. Many things can be attributed.

Jon

Jon

Jon Eulette- Posts : 4399

Join date : 2013-04-15

Location : Southern Kalifornia

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

As Jon mentioned many guns do not have the sear and hammer pins parallel and sometime not in exactly the correct location. This is one of the reasons why drop-ins may not work as well in some guns being that they are all set up to the same standard. One location that can feel like a creep is the disconnector rubbing on the slide cut especially if its rough. I like to keep the disconnector short enough so it don't reach the very top of the cut. Another point will be the pins themselves. Either they are smaller than the holes in the frame or the holes in the sear and/or the hammer are larger. Removing the grips and looking at especially the sear pin they should not move! If they don't check their fit in the sear especially and the hammer.

I am not a fan of Austin Behlert, his son is another story. He was a nice guy. He set up at almost all the Police L matches in NJ. I can say more but that's not with in the topic at hand.

I do have one question, I did mention it earlier. With some of the early sear jigs the sear was set in a plate with an opening, pins held the sear at the "correct" angle and the stone on the flat surfaces where the sear protruded. Repeated use eventually wore the surface to cut incorrectly by the cutting action of the stone. Looking at the Radius sear Jig being used on YouTube I see flats being cut by the stone on what looked like a new jig and defiantly a flat cut by the stone when cutting the secondary angle. Is the surface Hard Chromed so that a shine area looks like a flat?

You did mention you had the only radius cutting Jig but as I mentioned earlier the one I seen and did not like was much larger and called the Hockey Puck by few at my club.

I am not a fan of Austin Behlert, his son is another story. He was a nice guy. He set up at almost all the Police L matches in NJ. I can say more but that's not with in the topic at hand.

I do have one question, I did mention it earlier. With some of the early sear jigs the sear was set in a plate with an opening, pins held the sear at the "correct" angle and the stone on the flat surfaces where the sear protruded. Repeated use eventually wore the surface to cut incorrectly by the cutting action of the stone. Looking at the Radius sear Jig being used on YouTube I see flats being cut by the stone on what looked like a new jig and defiantly a flat cut by the stone when cutting the secondary angle. Is the surface Hard Chromed so that a shine area looks like a flat?

You did mention you had the only radius cutting Jig but as I mentioned earlier the one I seen and did not like was much larger and called the Hockey Puck by few at my club.

Last edited by Froneck on Tue Jun 02, 2015 10:52 am; edited 1 time in total

Froneck- Posts : 1763

Join date : 2014-04-05

Age : 77

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

Thanks Jerry and Chuck, was the marvel jig made by bob or al marvel both have current versions of sear jigs on the market. Just for triva Bob and Al Marvel both build great gadgets for gun work but are not related and I asked Al about Bob several years ago and he said he had never met him. As to creep, if you don't have the mega dollar machines you can take a dremel (I know cringe at the word) with a good felt wheel and polishing compound and polish the hammer hooks and sear face and get rid of most felt creep.

DavidR- Admin

- Posts : 3032

Join date : 2011-06-10

Age : 70

Location : NRA:Expert, Georgia

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

....or just use some really nice stones and some kroil instead of the dremel.

Rob Kovach- Admin

- Posts : 2692

Join date : 2011-06-14

Age : 51

Location : Brooklyn, WI

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

Rob Kovach wrote:....or just use some really nice stones and some kroil instead of the dremel.

you cant get a mirror finish with stones but it will get rid of creep in most cases, polishing with a felt wheel is less likely to remove metal like a stone though.

DavidR- Admin

- Posts : 3032

Join date : 2011-06-10

Age : 70

Location : NRA:Expert, Georgia

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

Hmmm I'm wondering what is the difference between creep and roll? On my triggers liked by me and Adam I can feel movement until the hammer falls. I don't like what some call a roll in that when movement starts the pull weight lowers somewhat like a long over travel. To me it feels like a crisp trigger with long over travel whereby the one I like the weight is constantly increasing so I keep the trigger moving until the hammer falls.

Froneck- Posts : 1763

Join date : 2014-04-05

Age : 77

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

What it is imo Creep and Roll is the same thing except for the feel.Creep is a scratchy feel from two rough surfaces sliding on each other. when you smooth those out you get smooth movement which is a smooth Roll.

DavidR- Admin

- Posts : 3032

Join date : 2011-06-10

Age : 70

Location : NRA:Expert, Georgia

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

The trigger creep I refer to feels like a slip on a slick floor, then stop, and finish smoothly

Jack H- Posts : 2699

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

The one I pictured was designed by Al.. They are not produced for sale..DavidR wrote:Thanks Jerry and Chuck, was the marvel jig made by bob or al marvel both have current versions of sear jigs on the market. J.

Jerry Keefer- Posts : 1001

Join date : 2012-01-02

Location : Maidens, VA

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

I thought it looked like what may have been a very nice prototype to the two he now sells. I have the cheaper one that is all aluminum this is the other it is much nicer, has anyone ever used it? Just curios what kind of job it does.... cant ever have enough tools

DavidR- Admin

- Posts : 3032

Join date : 2011-06-10

Age : 70

Location : NRA:Expert, Georgia

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

I mentioned a few possible causes that were in a drop in trigger set in another topic. Another place to look is the disconnector spring ramp. Usually the spring is cut square on the end, most have a sharp corner. When the take-up is completed and the disconnector contacts the sear there is a weight change, now slight "grinds" are notacable, sometimes it's a slip as mentioned by Jack. As the spring slides up the disconnector ramp it may have scraped a little bump. What I do to all my disconnecors is polish that ramp with a smooth stone. Then take the spring and stone a radius on the edge. Most of mine have a radius the thickness of the spring so that no sharp edge contacts the disconnector and it can slide up that ramp smooth as the trigger is pulled.

Froneck- Posts : 1763

Join date : 2014-04-05

Age : 77

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

I am thinking you're referring to this block...I made that block to fixture the sear and the hammer in Al's holding fixture.. Here I am truing the block after it has been heat treated..DavidR wrote:I thought it looked like what may have been a very nice prototype to the two he now sells. I have the cheaper one that is all aluminum this is the other it is much nicer, has anyone ever used it? Just curios what kind of job it does.... cant ever have enough tools

I have both of Bob's fixtures..and one of just about every one ever invented..

Jerry Keefer- Posts : 1001

Join date : 2012-01-02

Location : Maidens, VA

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

thanks Jerry, the TR jig is so much simpler to use looking forward to Chuck telling us exactly how to use it to the best advantage.

DavidR- Admin

- Posts : 3032

Join date : 2011-06-10

Age : 70

Location : NRA:Expert, Georgia

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

DavidR wrote:thanks Jerry, the TR jig is so much simpler to use looking forward to Chuck telling us exactly how to use it to the best advantage.

Until Chuck posts his video here is one I found on YouTube.

- Dave

dronning- Posts : 2581

Join date : 2013-03-20

Age : 71

Location : Lakeville, MN

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

Thanks...That's a good introduction, hopefully Chuck has some of those secret tips that will help us even more!

DavidR- Admin

- Posts : 3032

Join date : 2011-06-10

Age : 70

Location : NRA:Expert, Georgia

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

I really don't want to say much, I did look at that video. First test of the completed gun was initial take-up then broke, second pull same initial take-up then a little more then it broke. Later in his description he mentions the like glass which I associate with crisp triggers.

Frank

Frank

Froneck- Posts : 1763

Join date : 2014-04-05

Age : 77

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

Froneck wrote:I really don't want to say much, I did look at that video. First test of the completed gun was initial take-up then broke, second pull same initial take-up then a little more then it broke. Later in his description he mentions the like glass which I associate with crisp triggers.

Frank

Not sure what Rhode Island Armory is but its not Chucks company so other than seeing the jig in use I don't put much in anything else he had to offer.

DavidR- Admin

- Posts : 3032

Join date : 2011-06-10

Age : 70

Location : NRA:Expert, Georgia

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

Only concern I would have if buying the Jig as shown in the video is what looks like the stone cut into the radius of the Jig. I could be wrong and the Jig Hard Chrome Plated and the wear nothing more that the surface being polished by the stone. Only thing to cut Hard Chrome is Diamond, Possibly Borazon CBN though I haven't tried CBN. If it is being cut then every time the jig is used the radius will change.

Lots of those online instructions are bad. While looking for information I came along a site that showed how to fit a 1911. They were using a drill press with and X-Y table as a milling machine and had a woodruff cutter in the drill chuck! If there is a way to screw-up a good 1911 frame and slide that is definitely the way!

Frank

Lots of those online instructions are bad. While looking for information I came along a site that showed how to fit a 1911. They were using a drill press with and X-Y table as a milling machine and had a woodruff cutter in the drill chuck! If there is a way to screw-up a good 1911 frame and slide that is definitely the way!

Frank

Froneck- Posts : 1763

Join date : 2014-04-05

Age : 77

Re: Warner Total Radius Sear

Re: Warner Total Radius Sear

I used the original jig a lot and it only had minimal wear, so you could do thousands of sears id say before you wore out the jig.

DavidR- Admin

- Posts : 3032

Join date : 2011-06-10

Age : 70

Location : NRA:Expert, Georgia

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Roll trigger for 1911

» Sig P210A - Changing the Trigger Return Spring & Sear Adjustment

» Shorter sight radius

» Total Reloading Equipment Packages

» Total noob regarding upgrades Ruger Mark 2 ( esp grips)

» Sig P210A - Changing the Trigger Return Spring & Sear Adjustment

» Shorter sight radius

» Total Reloading Equipment Packages

» Total noob regarding upgrades Ruger Mark 2 ( esp grips)

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum