Hammerli 208s reliability

+9

BE Mike

CR10X

Steve Brown

Greg Walloch

SW-52

Black_Talon

robert84010

Jon Eulette

joy2shoot

13 posters

Page 1 of 1

Hammerli 208s reliability

Hammerli 208s reliability

I purchased a Hammerli 208s and have had it for about a year. I really like its fit and balance and I seem to shoot it fairly well (see photo 1: a 25 yard slow fire practice session). However, I am having a difficult time making it reliable enough to use in a match.

Before Larry passed away (RIP), he did a total clean and relube of the gun. He also reground and resurfaced the chamber face and bolt face. He also said I needed to replace the tubes on all the magazines, which I have done.

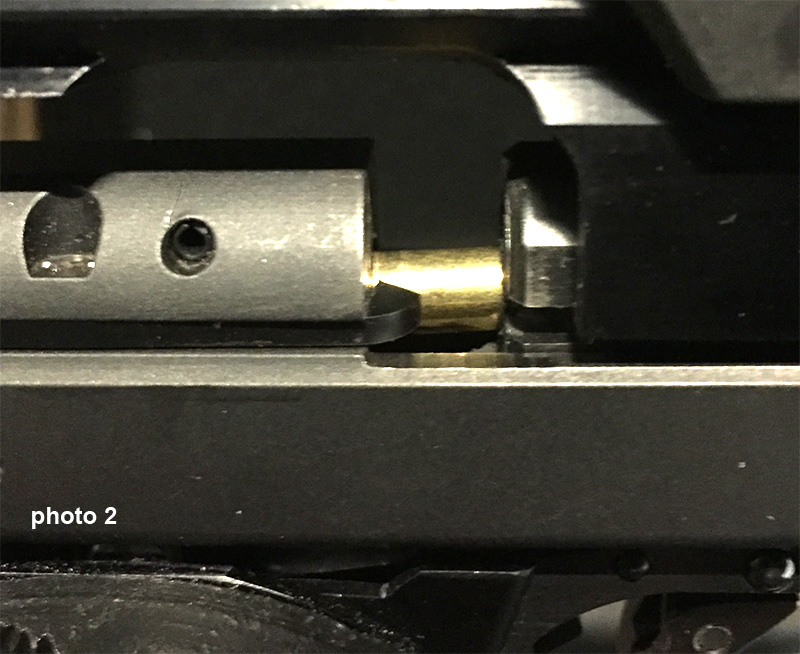

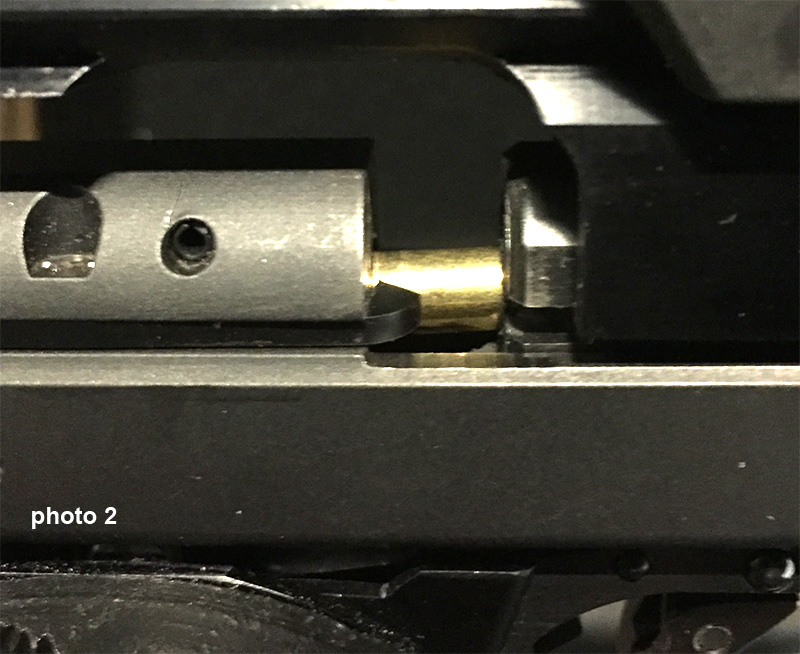

But I am still plagued by failure to chamber (see photo 2) and failure to eject (photo 3). I get about 2 to 3 failures about every 50 rounds. The most common failure is failure to chamber. When I get a FTC, if I gently push on the back of the slide, it chambers the round. Of the four magazines I own, only one does not have an issue.

I am using the same ammo as the previous owner used (Eley Target). But I also get the same issues with S&K Standard Plus. Next time I go to the range, I am going to try CCI Std Velocity. I am also regularly cleaning the chamber with a bent wire brush as Larry suggested.

But at this point, I am just guessing as to the cause of the issues. Any suggestions on how I can properly diagnose what is going on will be appreciated. Thank you.

Before Larry passed away (RIP), he did a total clean and relube of the gun. He also reground and resurfaced the chamber face and bolt face. He also said I needed to replace the tubes on all the magazines, which I have done.

But I am still plagued by failure to chamber (see photo 2) and failure to eject (photo 3). I get about 2 to 3 failures about every 50 rounds. The most common failure is failure to chamber. When I get a FTC, if I gently push on the back of the slide, it chambers the round. Of the four magazines I own, only one does not have an issue.

I am using the same ammo as the previous owner used (Eley Target). But I also get the same issues with S&K Standard Plus. Next time I go to the range, I am going to try CCI Std Velocity. I am also regularly cleaning the chamber with a bent wire brush as Larry suggested.

But at this point, I am just guessing as to the cause of the issues. Any suggestions on how I can properly diagnose what is going on will be appreciated. Thank you.

joy2shoot- Posts : 570

Join date : 2014-08-02

Location : North Carolina

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

Your feeding issue only halfway into the chamber that’s a Bizzarre one. Makes me wonder if something is dragging somewhere. Your extraction stove pipe could be because you’re ejected case is hitting the scope mount and not cleanly ejecting. So maybe you could try shooting it with iron sights to see if the extraction issue goes away. Have you plunk tested rounds into the chamber? I would also check to make sure that the recoil guide rod does not have any burrs and its catching inside of the frame/barrel channel when the slide cycles. This is where I would start

Jon

Jon

Jon Eulette- Posts : 4399

Join date : 2013-04-15

Location : Southern Kalifornia

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

That is good information Jon. Thanks. I will check into each of these. Larry had me do a plunk test (see if the round drops all the way into the chamber all the way to the rim without assistance). Eley Target consistently failed that test. S&K Standard Plus and CCI Std Velocity consistently passed. But I was getting the same failure to chamber with S&K. So my plan was to try CCI next time. But I will checking into the other possible causes you listed.

joy2shoot- Posts : 570

Join date : 2014-08-02

Location : North Carolina

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

I have had similar FTC issues with a Kart conversion. I used a fine india stone to polish most any surface that touches another. The bolt face and breaking the edge at the bottom of the breech face and the bottom of the slide that contacts rounds in the magazine definitely made an immediate improvement. My conversion would start the round just fine but it just seemed to lose the energy to push it in due to friction and it did solve my issues. Somewhat different setup but maybe this gives you an idea of other areas to look at.

robert84010- Posts : 834

Join date : 2011-09-21

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

For your ejection issue, make sure the rim of the extracted round is clearing the top left edge of the magazine lips. If it hits the mag lip instead of the ejector, erratic ejection can result. Cure for this is *carefully* filing the bottom edge of the magazine (where it contacts the mag release lever) to lower the magazine down slightly in the frame, until the extracted rounds fully clear the lip. Somewhere on the forums is a picture that shows how to do this.

Black_Talon- Posts : 214

Join date : 2011-06-10

Location : SoCal

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

Is possible the same Reason Nygord make this cut on this KART conversion.robert84010 wrote:I have had similar FTC issues with a Kart conversion. I used a fine india stone to polish most any surface that touches another. The bolt face and breaking the edge at the bottom of the breech face and the bottom of the slide that contacts rounds in the magazine definitely made an immediate improvement. My conversion would start the round just fine but it just seemed to lose the energy to push it in due to friction and it did solve my issues. Somewhat different setup but maybe this gives you an idea of other areas to look at.

SW-52- Posts : 805

Join date : 2015-07-20

Age : 40

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

sorry but both my 5" Karts eject fine. Only one had inconsistent failure to feed issues. All my other Karts eject fine also.

robert84010- Posts : 834

Join date : 2011-09-21

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

How about lubrication? I don’t see oil dripping off it....

Greg Walloch- Posts : 183

Join date : 2011-06-11

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

While I have heard 1911s like to be wet, I believe (close to) the opposite is true for the 208s. So my 208s would be considered 'dry' compared to my shirt staining 1911.Greg Walloch wrote:How about lubrication? I don’t see oil dripping off it....

joy2shoot- Posts : 570

Join date : 2014-08-02

Location : North Carolina

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

It may be worth a try to lube it up good...

Greg Walloch- Posts : 183

Join date : 2011-06-11

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

When the round doesn't chamber fully, can you easily finish seating it by pushing the slide closed?

If you have another slide (recuperator) spring, I'd be curious if changing that didn't make a difference in both of your malfunctions. Check to make sure the retaining pin for that spring is seated correctly as well. There is a notch the little side pin seats in.

If you have another slide (recuperator) spring, I'd be curious if changing that didn't make a difference in both of your malfunctions. Check to make sure the retaining pin for that spring is seated correctly as well. There is a notch the little side pin seats in.

Steve Brown- Posts : 33

Join date : 2011-06-10

Location : Pacific Northwest

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

Be sure not to "slam" magazines into the gun when loading. Hammerli's don't like that due to the design of the magazine catch and base. Eventually, it will cause problems. Magazines that ride too high will impede the slide and not feed well.

Make sure the magazine catch assemble is properly located in the frame and no problems with the fit or alignment. It is a dual purpose part. Bent or "un-square" catches can cause magazine position problems.

When installing or replacing the CMM grip adapter, make sure the cutout for the slide stop has enough clearance and is not binding or interfering with the slide stop in any position. Usually, stoning of the cutout in the grip adapter is needed. If not enough clearance, the slide stop can ride just high enough to drag on the slide, but still seem to function.

Be sure the little slide stop spring is in the correct position and not damaged.

(Added)

And stick with the scope mount that was cut off at the barrel breech.

Make sure the magazine catch assemble is properly located in the frame and no problems with the fit or alignment. It is a dual purpose part. Bent or "un-square" catches can cause magazine position problems.

When installing or replacing the CMM grip adapter, make sure the cutout for the slide stop has enough clearance and is not binding or interfering with the slide stop in any position. Usually, stoning of the cutout in the grip adapter is needed. If not enough clearance, the slide stop can ride just high enough to drag on the slide, but still seem to function.

Be sure the little slide stop spring is in the correct position and not damaged.

(Added)

And stick with the scope mount that was cut off at the barrel breech.

Last edited by CR10X on 2/21/2019, 3:57 pm; edited 1 time in total

CR10X- Posts : 1777

Join date : 2011-06-17

Location : NC

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

This may sound like blasphemy, but it looks like there is a possibility that the recoil spring is too strong. How about trying 5 rounds of high velocity .22 ammo and see if you have any problems. If it functions fine, I DON'T suggest using high velocity ammo, but you may be able to find a lower powered spring or clip a coil off it, etc.

BE Mike- Posts : 2590

Join date : 2011-07-29

Location : Indiana

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

Do NOT lube it up good. I had to modify my dot mount by cutting away the back end and that stopped the FTC. As Jon said, try shooting it with irons.

Joel

Joel

1joel1- Posts : 401

Join date : 2012-11-09

Location : San Diego, CA

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

First, thanks for all the advice.

To answer a question, Yes, when the round does not fully chamber, a slight push on the back of the slide will chamber the round.

Based on the feedback, this is the course of action I am going to take to see if I can figure this out. Hopefully, I have everyone’s input covered.

Scope mount – The gun came with a scope mount that was cut off in the back sufficiently enough that no part of the scope mount covered the breech. However, it is somewhat difficult to mount the Aimpoint base on it and I cannot install Larry’s barrel weight on it. Hence, why I was using Larry’s scope mount. But for testing purposes, I will remove Larry’s scope mount and use the one that came with the gun to see if that resolves the FTE issue. If it does, I know what I need to do to the LGI mount.

CMM 1911 Adapter – This accessory can cause a variety of issues if installed too tight or improperly. So, I will remove it and put on a grip that does not use the 1911 adapter to test the FTC issue. The gun did come with two ‘European’ style grips, but when I put them on, they appear to push up on the slide release, so I will not test with those. Also, it does appear the slide stop and adapter do make contact (see photo), so I will open that area. However, the modified adapter will not be part of the upcoming test. I want to see how the gun behaves without the adapter first.

Ammo – I don’t like changing too many things at once, so I will stay with Eley Target for the next test.

Magazine lip clearance – On one of the four mags, the extracted case touches the mag lips before it touches the ejector. I will set this mag aside for the upcoming test.

Magazine catch – As best as I can tell, it is properly aligned.

Magazines – I am guilty of giving the magazines a slap once inserted. I will work on not doing that.

Slide stop – As part of Larry’s overhaul, he did replace the slide stop and its spring wire. I checked them and they both seem to function ok.

Recoil guide rod and spring – I will check this part if I continue to get failures during the upcoming test. But I do have a question. After you install the guide rod and spring, do you end up with the guide rod pin in the 12 o’clock position or the 6 o’clock position or does it matter (as long as it is not in the 3 o’clock position)?

Recoil spring clipping – The 208s recoil spring is what I call closed on both ends. Plus, the end diameters are different. With the large end going into the gun to hold the ejector in place and the small end going over the recoil rod. Therefore, I am hesitant to take wire cutters to the spring.

Lubrication – I will continue to lube the way Larry suggests.

In summary, the next test consists of using scope mount that does not cover breech to test for FTE and totally removing the CMM Adapter to test for FTC.

To answer a question, Yes, when the round does not fully chamber, a slight push on the back of the slide will chamber the round.

Based on the feedback, this is the course of action I am going to take to see if I can figure this out. Hopefully, I have everyone’s input covered.

Scope mount – The gun came with a scope mount that was cut off in the back sufficiently enough that no part of the scope mount covered the breech. However, it is somewhat difficult to mount the Aimpoint base on it and I cannot install Larry’s barrel weight on it. Hence, why I was using Larry’s scope mount. But for testing purposes, I will remove Larry’s scope mount and use the one that came with the gun to see if that resolves the FTE issue. If it does, I know what I need to do to the LGI mount.

CMM 1911 Adapter – This accessory can cause a variety of issues if installed too tight or improperly. So, I will remove it and put on a grip that does not use the 1911 adapter to test the FTC issue. The gun did come with two ‘European’ style grips, but when I put them on, they appear to push up on the slide release, so I will not test with those. Also, it does appear the slide stop and adapter do make contact (see photo), so I will open that area. However, the modified adapter will not be part of the upcoming test. I want to see how the gun behaves without the adapter first.

Ammo – I don’t like changing too many things at once, so I will stay with Eley Target for the next test.

Magazine lip clearance – On one of the four mags, the extracted case touches the mag lips before it touches the ejector. I will set this mag aside for the upcoming test.

Magazine catch – As best as I can tell, it is properly aligned.

Magazines – I am guilty of giving the magazines a slap once inserted. I will work on not doing that.

Slide stop – As part of Larry’s overhaul, he did replace the slide stop and its spring wire. I checked them and they both seem to function ok.

Recoil guide rod and spring – I will check this part if I continue to get failures during the upcoming test. But I do have a question. After you install the guide rod and spring, do you end up with the guide rod pin in the 12 o’clock position or the 6 o’clock position or does it matter (as long as it is not in the 3 o’clock position)?

Recoil spring clipping – The 208s recoil spring is what I call closed on both ends. Plus, the end diameters are different. With the large end going into the gun to hold the ejector in place and the small end going over the recoil rod. Therefore, I am hesitant to take wire cutters to the spring.

Lubrication – I will continue to lube the way Larry suggests.

In summary, the next test consists of using scope mount that does not cover breech to test for FTE and totally removing the CMM Adapter to test for FTC.

joy2shoot- Posts : 570

Join date : 2014-08-02

Location : North Carolina

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

You own four magazines and one does not have an issue. That's where I would look, if one works fine try to find out why. Just a thought.

Tom

Tom

thessler- Posts : 149

Join date : 2018-05-14

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

Results of test 1.

Ammo: Eley Target

# rounds fired: 210+ rounds. 120+ at indoor practice followed by 95 at an outdoor 1800 league match (no, not the kind of 1800 the NRA is discussing). The 1800 was a little muddy but the gun shot well (see photos).

FTE

I removed the LGI scope mount, which covers the breech, and used the scope mount that came with the gun, which does not cover the breech. I had to use a little force to get the Aimpoint micro scope base on the mount.

Result: No FTEs.

And the gold star goes to … Jon and Cecil

Next steps: I will be modifying my LGI scope mount since the Aimpoint micro fits it better and the barrel weight that came with the gun and the LGI barrel weight I purchased later both fit the LGI scope mount, but the LGI barrel weight does not fit the other scope mount.

FTC

I removed the CMM 1911 adapter and put on a grip that mounts straight to the frame. And I also stopped slapping the bottom of the mag after inserting it. In addition, I use a bean bag to rest gun and hand when shooting. I noticed that sometimes I was resting the bottom of the mag on the bean bag. So, I reoriented the bag to prevent this.

Result: No FTCs.

Next steps: Either one or both of the changes resulted in the no FTCs. Since the CMM Adapter allows me to get a grip that I prefer, I will file the adapter so it no longer touches the slide stop, reinstall it, and retest.

Ammo: Eley Target

# rounds fired: 210+ rounds. 120+ at indoor practice followed by 95 at an outdoor 1800 league match (no, not the kind of 1800 the NRA is discussing). The 1800 was a little muddy but the gun shot well (see photos).

FTE

I removed the LGI scope mount, which covers the breech, and used the scope mount that came with the gun, which does not cover the breech. I had to use a little force to get the Aimpoint micro scope base on the mount.

Result: No FTEs.

And the gold star goes to … Jon and Cecil

Next steps: I will be modifying my LGI scope mount since the Aimpoint micro fits it better and the barrel weight that came with the gun and the LGI barrel weight I purchased later both fit the LGI scope mount, but the LGI barrel weight does not fit the other scope mount.

FTC

I removed the CMM 1911 adapter and put on a grip that mounts straight to the frame. And I also stopped slapping the bottom of the mag after inserting it. In addition, I use a bean bag to rest gun and hand when shooting. I noticed that sometimes I was resting the bottom of the mag on the bean bag. So, I reoriented the bag to prevent this.

Result: No FTCs.

Next steps: Either one or both of the changes resulted in the no FTCs. Since the CMM Adapter allows me to get a grip that I prefer, I will file the adapter so it no longer touches the slide stop, reinstall it, and retest.

joy2shoot- Posts : 570

Join date : 2014-08-02

Location : North Carolina

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

Yea! Outstanding! Nice target!

Jon

Jon

Jon Eulette- Posts : 4399

Join date : 2013-04-15

Location : Southern Kalifornia

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

Both groups are more right than centered. I’d go at least a click left maybe two.

Wobbley- Admin

- Posts : 4808

Join date : 2015-02-13

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

Thanks Jon. And thanks for your suggestions.Jon Eulette wrote:Yea! Outstanding! Nice target!

Jon

joy2shoot- Posts : 570

Join date : 2014-08-02

Location : North Carolina

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

Wobbley, since the POI pretty much equaled POA when the shot broke, I think no real adjustments are needed (hope that makes sense). But as Bickar would say, I do need to get my X count up! (Actually, I was so cold and wet, I was happy with what I got.) Also, since I will be moving the scope off the 'old' scope mount and putting it back on the LGI mount, I will need to re-zero it. (When I moved the scope from the LGI mount to the 'old' mount, I had to re-zero the scope ... a lot.)Wobbley wrote:Both groups are more right than centered. I’d go at least a click left maybe two.

joy2shoot- Posts : 570

Join date : 2014-08-02

Location : North Carolina

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

The shell has to feed all the wayvup into the extractor hook and breech face, and it needs to stay in control of the extractor on he way back out.

My breach developed a burr at the top as well as an accumulation of junk that prevents full rise. A lathe bit or sharp chisel can be used to clear this burr by approacing from the bottom and while in contact with the face.

The hook can grab above the shell centerline and this can push it down during extraction so the shell hits the lips.

I had to shape the hook to hold it below center.

My breach developed a burr at the top as well as an accumulation of junk that prevents full rise. A lathe bit or sharp chisel can be used to clear this burr by approacing from the bottom and while in contact with the face.

The hook can grab above the shell centerline and this can push it down during extraction so the shell hits the lips.

I had to shape the hook to hold it below center.

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

https://www.starreloaders.com/edhall/hammerli208sca.html

Joel

Joel

1joel1- Posts : 401

Join date : 2012-11-09

Location : San Diego, CA

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

Thank you Joel, I am familiar with that document and the individual who wrote it. It does a good job of describing basic cleaning and trigger adjustments, but does not address the issues I am experiencing.1joel1 wrote:https://www.starreloaders.com/edhall/hammerli208sca.html

Joel

joy2shoot- Posts : 570

Join date : 2014-08-02

Location : North Carolina

Re: Hammerli 208s reliability

Re: Hammerli 208s reliability

Results of test 2.

Ammo: Eley Target

# rounds fire: 150+ at indoor range

Changes:

1. Shortened the LGI scope mount so that none of it hung over the breech face

2. Modifications to the CMM 1911 adapter and how installed.

Results:

No FTEs

No FTCs

Discussion:

I modified the CMM 1911 adapter (and the wooden slab) so that none of it touched the slide stop. I also modified it so that it was not close to the trigger bar even though I did not see the adapter and trigger bar making contact when hand cycled. Per the CMM instructions, I did not install the adapter overly tight. However, when I installed the grips/slabs, I did notice that the top grip screws where protruding through the adapter and making contact with the frame. If these screws were gorilla tightened, it would push in on the frame from both sides, which could result in something dragging somewhere.

Conclusion:

The FTEject was caused by a scope mount overhanging the breech.

The FTChamber was caused by one or more of the following: 1)me slapping the bottom of the mag when inserting the mag, 2)the bottom of the mag resting on the sand bag when I rested hand/gun between shots, 3)the slide stop/trigger arm was dragging on the CMM adapter, 4)the top grip screws were overly tightened.

Some follow up:

Black_Talon – I put one of the mags in time out because as I manually cycled the slide with a spent case and the case was making contact with the mag lips before it contacted the ejector. So, I will have to carefully work on the mag so it does not ride as high in the frame.

Bruce Martindale – I tested how well the extractor was holding a spent case by doing the following. Insert spent case into chamber. Close slide. Slowly open the slide and stop before case meets ejector. Slowly (and I mean slowly) close the slide. Does the case re-enter the chamber without issue? If so, the extractor is doing a good job of holding the case. For this gun, the case re-entered the chamber without any issues.

So again, thanks for the advice and suggestions. Unless something really bizarre happens, this is the last update.

Ammo: Eley Target

# rounds fire: 150+ at indoor range

Changes:

1. Shortened the LGI scope mount so that none of it hung over the breech face

2. Modifications to the CMM 1911 adapter and how installed.

Results:

No FTEs

No FTCs

Discussion:

I modified the CMM 1911 adapter (and the wooden slab) so that none of it touched the slide stop. I also modified it so that it was not close to the trigger bar even though I did not see the adapter and trigger bar making contact when hand cycled. Per the CMM instructions, I did not install the adapter overly tight. However, when I installed the grips/slabs, I did notice that the top grip screws where protruding through the adapter and making contact with the frame. If these screws were gorilla tightened, it would push in on the frame from both sides, which could result in something dragging somewhere.

Conclusion:

The FTEject was caused by a scope mount overhanging the breech.

The FTChamber was caused by one or more of the following: 1)me slapping the bottom of the mag when inserting the mag, 2)the bottom of the mag resting on the sand bag when I rested hand/gun between shots, 3)the slide stop/trigger arm was dragging on the CMM adapter, 4)the top grip screws were overly tightened.

Some follow up:

Black_Talon – I put one of the mags in time out because as I manually cycled the slide with a spent case and the case was making contact with the mag lips before it contacted the ejector. So, I will have to carefully work on the mag so it does not ride as high in the frame.

Bruce Martindale – I tested how well the extractor was holding a spent case by doing the following. Insert spent case into chamber. Close slide. Slowly open the slide and stop before case meets ejector. Slowly (and I mean slowly) close the slide. Does the case re-enter the chamber without issue? If so, the extractor is doing a good job of holding the case. For this gun, the case re-entered the chamber without any issues.

So again, thanks for the advice and suggestions. Unless something really bizarre happens, this is the last update.

joy2shoot- Posts : 570

Join date : 2014-08-02

Location : North Carolina

Similar topics

Similar topics» Larry's Guns/Red Feather Hammerli Scope Mount Reliability issues

» Hammerli 208s

» Hammerli 208s

» Hammerli 208S

» Hammerli 208 vs. 208s

» Hammerli 208s

» Hammerli 208s

» Hammerli 208S

» Hammerli 208 vs. 208s

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum