Adventures In Swaging

+9

PhotoEscape

gregbenner

BE Mike

Dr.Don

joy2shoot

zanemoseley

Greg Walloch

Multiracer

fc60

13 posters

Page 1 of 1

Adventures In Swaging

Adventures In Swaging

Greetings All,

I was recently gifted some 200 grain 45 ACP SWC Moly coated Swaged bullets to play with.

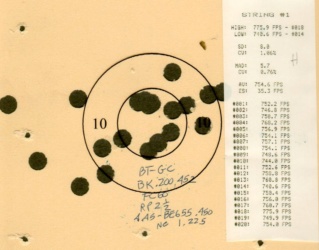

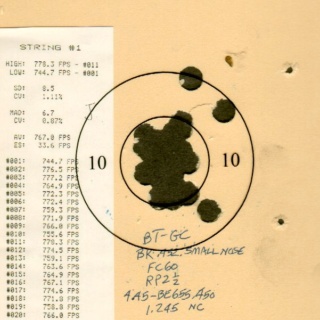

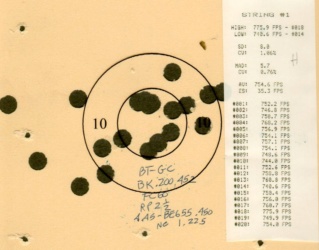

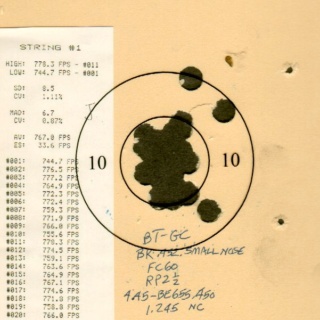

I tested three different sets of twenty shots at 50 yards.

One target is with the 'as received' bullets.

The second target is with bullets I 'bumped' to true up the edges.

The third target is the same as #2 with a slightly different nose punch profile.

All targets fired at 50 yards with a Colt Gold Cup barrel mounted in a mechanical fixture.

No need to mention the Brand. The point here is that the bullet needs to be as near perfect as possible.

Cheers,

Dave

I was recently gifted some 200 grain 45 ACP SWC Moly coated Swaged bullets to play with.

I tested three different sets of twenty shots at 50 yards.

One target is with the 'as received' bullets.

The second target is with bullets I 'bumped' to true up the edges.

The third target is the same as #2 with a slightly different nose punch profile.

All targets fired at 50 yards with a Colt Gold Cup barrel mounted in a mechanical fixture.

No need to mention the Brand. The point here is that the bullet needs to be as near perfect as possible.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Adventures In Swaging

Re: Adventures In Swaging

Please define "bumped"

Multiracer- Posts : 1002

Join date : 2017-03-15

Location : North Ohio

Re: Adventures In Swaging

Re: Adventures In Swaging

Take my money....are the bump dies 7/8-14?

Greg Walloch- Posts : 183

Join date : 2011-06-11

Re: Adventures In Swaging

Re: Adventures In Swaging

What was the starting and ending OD of the bullets? If you increased the OD maybe you weren't getting a good seal in the bore with the factory bullets. Either way the last 2 targets are great.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Adventures In Swaging

Re: Adventures In Swaging

Dave, apologies for my ignorance of the lingo, but are you saying you used a resizing press and nose punch to increase the diameter of the bullet? Or did you ‘just’ use the resizing press to round out the bullet, while keeping the factory diameter?

joy2shoot- Posts : 570

Join date : 2014-08-02

Location : North Carolina

Re: Adventures In Swaging

Re: Adventures In Swaging

Dave,

Your pictures are the best example I've ever seen of the importance of a "perfect" bullet base to accuracy. The nose shape affected things some, but the squaring up of the "edges" is glaring. That is the reason, in my opinion, that jacketed JHPs are often more accurate than jacketed SWCs (think Nosler, XTP, etc). The cup forming process for a JHP gives a better opportunity for a truly perfect base than the equivalent process for a SWC or other "open base" bullet.

Your pictures are the best example I've ever seen of the importance of a "perfect" bullet base to accuracy. The nose shape affected things some, but the squaring up of the "edges" is glaring. That is the reason, in my opinion, that jacketed JHPs are often more accurate than jacketed SWCs (think Nosler, XTP, etc). The cup forming process for a JHP gives a better opportunity for a truly perfect base than the equivalent process for a SWC or other "open base" bullet.

Dr.Don- Posts : 816

Join date : 2012-10-31

Location : Cedar Park, TX

Re: Adventures In Swaging

Re: Adventures In Swaging

I like the end result, but am unfamiliar with the bumping process and equipment used. Could you please explain in detail?

BE Mike- Posts : 2589

Join date : 2011-07-29

Location : Indiana

Re: Adventures In Swaging

Re: Adventures In Swaging

Dave, I have limited experience with 45, but would I assume the process you have used is similar to the “bumping” process that some of us use for accurrizing the 32 S&W long Speer Plinker? I.e. inserting the bullet in a swaging tool, and using pressure to reform the bullet very slightly larger, and, more consistent?

Since I have never RR tested 45, I was a little surprised by your results. I only say this since I seem to read about 45s with 1” groups, guns with 1 1/2” guarantees, etc? Having some idea of how meticulous you reload, and test, I would expect your results to represent the best of the best?

Alternatively, are these less than great bullets, made a bit better with bumping, but still not a great bullet?

Since I have never RR tested 45, I was a little surprised by your results. I only say this since I seem to read about 45s with 1” groups, guns with 1 1/2” guarantees, etc? Having some idea of how meticulous you reload, and test, I would expect your results to represent the best of the best?

Alternatively, are these less than great bullets, made a bit better with bumping, but still not a great bullet?

gregbenner- Posts : 738

Join date : 2016-10-29

Location : San Diego area

Re: Adventures In Swaging

Re: Adventures In Swaging

Greetings All,

I use a Corbin CSP-1 swage press I bought in the mid 90's. It is designed for swaging.

'Bumping' is a term I plagiarized from the Cast Bullet Rifle guys. You take a cast bullet and swage (bump) it slightly to fit the rifle chamber in a special made die. Swaging and Bumping are essentially the same process only no metal is bled off. The bullet slug is already to weight. The swage press merely uniforms it.

The 'as received' bullets were probably swaged from cast slugs to true up the features. Sadly, they were tumbled after swaging damaging all the previously swaged edges.

Speer 32 HBWC Plinkers experience a similar trip to the tumbler.

The as received bullets measured 0.452". My swage dies form a bullet of 0.452". Please note, in order to get the as received bullet to fit into my swage die, I ran them through my Star Greaser with a 0.450" die.

I machine my own dies and punches. The Base Punch is a copy of the Winchester 185 Jacketed WadCutter. It has a large dimple.

One Nose Punch is a reverse engineered copy of the nose profile of the old Western 210 grain Lead SWC bullet sold in the 1960's.

The second nose punch was made to 'bump' plated bullets manufactured locally in an effort to get them to group at 50 yards.

For my good friend, Laughing Bear, I plan to machine wadcutter nose punches and a hollow base punch for his 625 revolver. If I start today, I should be done in about two years.

Cheers,

Dave

I use a Corbin CSP-1 swage press I bought in the mid 90's. It is designed for swaging.

'Bumping' is a term I plagiarized from the Cast Bullet Rifle guys. You take a cast bullet and swage (bump) it slightly to fit the rifle chamber in a special made die. Swaging and Bumping are essentially the same process only no metal is bled off. The bullet slug is already to weight. The swage press merely uniforms it.

The 'as received' bullets were probably swaged from cast slugs to true up the features. Sadly, they were tumbled after swaging damaging all the previously swaged edges.

Speer 32 HBWC Plinkers experience a similar trip to the tumbler.

The as received bullets measured 0.452". My swage dies form a bullet of 0.452". Please note, in order to get the as received bullet to fit into my swage die, I ran them through my Star Greaser with a 0.450" die.

I machine my own dies and punches. The Base Punch is a copy of the Winchester 185 Jacketed WadCutter. It has a large dimple.

One Nose Punch is a reverse engineered copy of the nose profile of the old Western 210 grain Lead SWC bullet sold in the 1960's.

The second nose punch was made to 'bump' plated bullets manufactured locally in an effort to get them to group at 50 yards.

For my good friend, Laughing Bear, I plan to machine wadcutter nose punches and a hollow base punch for his 625 revolver. If I start today, I should be done in about two years.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Adventures In Swaging

Re: Adventures In Swaging

Thank you, Dave, for sharing the information. As you know, I admire your encyclopedic knowledge and readiness to share it.

For those interested, Corbin as a company is still in business, and CSP-1 press is available, - http://www.corbins.com/presses.htm. Please keep in mind though a key element from Dave's post - swaging dies and punches. Corbin manufactures both, but..............

AP

For those interested, Corbin as a company is still in business, and CSP-1 press is available, - http://www.corbins.com/presses.htm. Please keep in mind though a key element from Dave's post - swaging dies and punches. Corbin manufactures both, but..............

AP

PhotoEscape- Admin

- Posts : 1543

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Adventures In Swaging

Re: Adventures In Swaging

fc60 wrote:Greetings All,

The as received bullets measured 0.452". My swage dies form a bullet of 0.452". Please note, in order to get the as received bullet to fit into my swage die, I ran them through my Star Greaser with a 0.450" die

Dave

Dave, I googled “Star Greaser”, got John Travilta

Does this tool shave bullets down, or more like the bumping in reverse? Does this also lubricate thr bullet for the swager?

gregbenner- Posts : 738

Join date : 2016-10-29

Location : San Diego area

Re: Adventures In Swaging

Re: Adventures In Swaging

Very good point AP. Dave recently brought this to my attention re: the swaging dies I purchased last year for bumping 32 wadcuttersPhotoEscape wrote:Thank you, Dave, for sharing the information. As you know, I admire your encyclopedic knowledge and readiness to share it. Please keep in mind though a key element from Dave's post - swaging dies and punches. Corbin manufactures both, but..............

AP

gregbenner- Posts : 738

Join date : 2016-10-29

Location : San Diego area

Re: Adventures In Swaging

Re: Adventures In Swaging

Dave, hopefully you do not regret making this post. But if you could, can you post a pic of the damaged edges and another pic of the fixed edges? I have been known to say 'thats horrible' while others say 'nothing wrong with that'. So I wanted to get the perspective of a more experienced person.fc60 wrote:... Sadly, they were tumbled after swaging damaging all the previously swaged edges.

Thank you,

Thomas

joy2shoot- Posts : 570

Join date : 2014-08-02

Location : North Carolina

Re: Adventures In Swaging

Re: Adventures In Swaging

Greg and all,

This might be an interesting information to read through. Star Greaser or rather Sizer is included in the article. I presume, name is interchangeable.

http://www.castpics.net/subsite2/HowTo/Choosing%20a%20Sizer.pdf

AP

This might be an interesting information to read through. Star Greaser or rather Sizer is included in the article. I presume, name is interchangeable.

http://www.castpics.net/subsite2/HowTo/Choosing%20a%20Sizer.pdf

AP

PhotoEscape- Admin

- Posts : 1543

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Adventures In Swaging

Re: Adventures In Swaging

Greetings,

More details...

The Star Greaser has been around since the 1940's. I have been shooting 40+ years and 'in the old days' shooters cast and greased their own bullets.

The Star was the go to machine to buy.

Star greaser dies have a long gentle taper that does not shave metal from the bullet.

I did not apply grease to the bullets as they were already lubricated with the Moly. I just had to make them slightly smaller to slip into my swage die without scraping metal.

Actually, grease gums up the swaging dies to the point where no progress can be made.

It is just good fortune that Speer and other bullet companies are using this Moly lube on their bullets.

It, the Moly, has a dual purpose. It eliminates having to lube the bullet during swaging. After swaging, the Moly is pressed into the bullet retaining it's lubricity for clean shooting.

Do not think you can swage/bump the mass produced cast bullets you buy. The metal is too hard and the grease distorts the bullet and makes a mess. I speak from experience.

I did look at the Corbin website. A press and dies will cost upward of $1000.00!!!

Cheers,

Dave

More details...

The Star Greaser has been around since the 1940's. I have been shooting 40+ years and 'in the old days' shooters cast and greased their own bullets.

The Star was the go to machine to buy.

Star greaser dies have a long gentle taper that does not shave metal from the bullet.

I did not apply grease to the bullets as they were already lubricated with the Moly. I just had to make them slightly smaller to slip into my swage die without scraping metal.

Actually, grease gums up the swaging dies to the point where no progress can be made.

It is just good fortune that Speer and other bullet companies are using this Moly lube on their bullets.

It, the Moly, has a dual purpose. It eliminates having to lube the bullet during swaging. After swaging, the Moly is pressed into the bullet retaining it's lubricity for clean shooting.

Do not think you can swage/bump the mass produced cast bullets you buy. The metal is too hard and the grease distorts the bullet and makes a mess. I speak from experience.

I did look at the Corbin website. A press and dies will cost upward of $1000.00!!!

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Adventures In Swaging

Re: Adventures In Swaging

Corbin makes nice stuff. Back in my youth i had a corbin mini mite that i swaged 30 cal. Match bullet for a while. Really makes you appreciate Sierra...

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Adventures In Swaging

Re: Adventures In Swaging

Thx Dave and AP. So much to learn, and so little time. No memory doesn’t help.

Dave, conceptually could the correct “greaser” dies work in a swaging tool like mine, to reduce the Speer Plinker bullet before bumping? The idea would be to make smaller H&N copies for tighter chambered barrels, e.g .312? Not at all sure I would try it, but......

Another thought would be bumping 38 wadcutters. Again, issue would be getting dies, but I wouldn’t it help here as well?

Dave, conceptually could the correct “greaser” dies work in a swaging tool like mine, to reduce the Speer Plinker bullet before bumping? The idea would be to make smaller H&N copies for tighter chambered barrels, e.g .312? Not at all sure I would try it, but......

Another thought would be bumping 38 wadcutters. Again, issue would be getting dies, but I wouldn’t it help here as well?

gregbenner- Posts : 738

Join date : 2016-10-29

Location : San Diego area

Re: Adventures In Swaging

Re: Adventures In Swaging

Greetings,

I have, in the past, used a Lee 0.311" push through sizing die kit to reduce the diameter of the Speer Plinkers prior to swaging them back up to 0.312".

I believe you will find that the 0.314" bullets will shoot as good as the 0.312" bullets in the smaller diameter barrels.

The only caveat is the chamber size. You need to measure the diameter of your chamber to be sure your loaded cartridges chamber freely.

If your swage dies were made by the same shop that did Zane's, they are most likely not H&N clones and should not be referred to as such. A more accurate description would be "bumped Speer Plinkers".

I have dies to swage 38 HBWC; but, have not had the time to experiment further. I still have several cases of Remington HBWC to consume.

Cheers,

Dave

I have, in the past, used a Lee 0.311" push through sizing die kit to reduce the diameter of the Speer Plinkers prior to swaging them back up to 0.312".

I believe you will find that the 0.314" bullets will shoot as good as the 0.312" bullets in the smaller diameter barrels.

The only caveat is the chamber size. You need to measure the diameter of your chamber to be sure your loaded cartridges chamber freely.

If your swage dies were made by the same shop that did Zane's, they are most likely not H&N clones and should not be referred to as such. A more accurate description would be "bumped Speer Plinkers".

I have dies to swage 38 HBWC; but, have not had the time to experiment further. I still have several cases of Remington HBWC to consume.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Adventures In Swaging

Re: Adventures In Swaging

Side note: Is there any safety hazard in handling moly coated bullets with your fingers or should gloves always be worn?

I used to have a set of swaging dies for turning scrap 22 rf cases into 22 cf bullets . That got old fast. I recall slugs had to be undersize to get them into the die. No reswaging without damage

I used to have a set of swaging dies for turning scrap 22 rf cases into 22 cf bullets . That got old fast. I recall slugs had to be undersize to get them into the die. No reswaging without damage

Re: Adventures In Swaging

Re: Adventures In Swaging

bruce martindale wrote:Side note: Is there any safety hazard in handling moly coated bullets with your fingers or should gloves always be worn?

I used to have a set of swaging dies for turning scrap 22 rf cases into 22 cf bullets . That got old fast. I recall slugs had to be undersize to get them into the die. No reswaging without damage

For the most part no hazard in handling the cured dry film lube. There have been a lot of these films developed over the years and one of the most common was MIL-PRF-46010. Is is basically fine Moly Disulfide in a resin binder that is heat cured. http://everyspec.com/MIL-PRF/MIL-PRF-030000-79999/download.php?spec=MIL-PRF-46010H.052119.pdf. There are some that are air dried that meet an earlier spec MIL-L-23398. This one is air cured. The 23398 one can rub off sometimes and this is the one most likely to be used as the curing temp for 46010 may soften lead alloys, But in reality, I don’t know which dry film is used specifically. Graphite is specifically prohibited in these milspec lubes.

Even still I’d wash my hands before eating after handling these bullets.

Wobbley- Admin

- Posts : 4808

Join date : 2015-02-12

Re: Adventures In Swaging

Re: Adventures In Swaging

Thanks Dave, very helpful and informative. Gives me something to ponder

gregbenner- Posts : 738

Join date : 2016-10-29

Location : San Diego area

Re: Adventures In Swaging

Re: Adventures In Swaging

fc60 wrote:Greetings,

The Star Greaser has been around since the 1940's. I have been shooting 40+ years and 'in the old days' shooters cast and greased their own bullets.

The Star was the go to machine to buy.

Assuming you mean the venerable Star luber/sizer with the optional heating block, I kick myself for giving one away about 15 years ago. Same with a Phelps reloading press.

I recall giving them to a 2650 shooter. Haven't seen nor heard from that guy in many years.

"plop, plop, plop"

john bickar- Posts : 2280

Join date : 2011-07-09

Age : 100

Location : Menlo Park, CA

Similar topics

Similar topics» New shooter's adventures with MK III

» Swaging First Attempt - How to load?

» New Toy - Swaging Machine Video

» Swaging - Still a few bugs in the system

» Bullet's base swaging

» Swaging First Attempt - How to load?

» New Toy - Swaging Machine Video

» Swaging - Still a few bugs in the system

» Bullet's base swaging

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum