Dillon Powder Measure issue

+16

fc60

Richard Ashmore

Rocambole

GrumpyOldMan

Wes Lorenz

Cazmont

spursnguns

mhayford45

chiz1180

STEVE SAMELAK

JKR

james r chapman

Dr.Don

Wobbley

PhotoEscape

CR10X

20 posters

Page 1 of 3

Page 1 of 3 • 1, 2, 3

Dillon Powder Measure issue

Dillon Powder Measure issue

I have several toolheads for my Dillon XL650, each with it's own powder measure. Some with X-small bar and others with small bar. One with an Arredondo plastic micrometer bar (no problem with that one).

I've loaded a LOT of 45ACP ammo during these past few weeks. I've settled on two favourite recipes :- Brazos 160LSWC over 4.4 N310 and Nosler/Zero 185JHP over 4.6 WST, I've got a dedicated toolhead for each. In retrospect, I was very foolish to load such a large quantity without thoroughly range testing it batch by batch. I've been practising almost exclusively with the 160 load, I'd kinda got a feeling that the recoil was getting stronger, but that was only brought clearly into focus when I tried some of the newly loaded 185. I then shot some of each batch over the chrono. A lot of variation.

I typically check the powder drop several times at the start of each loading session and then again at the end of each batch of bullets or cases and again at the end. I've been seeing very consistent weight. But, clearly shown by the chrono testing, I'm getting significant inconsistency of powder weight. Been trying to figure out what is going on.

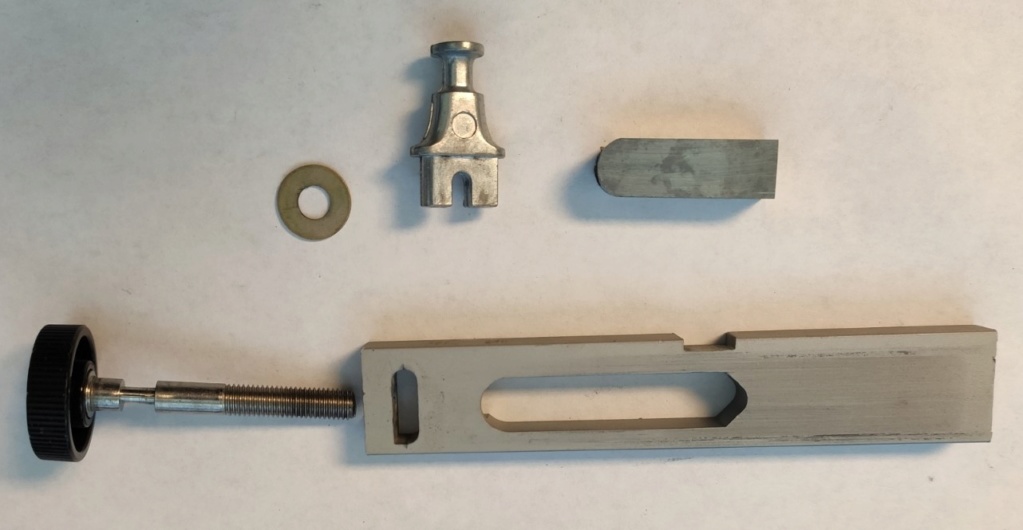

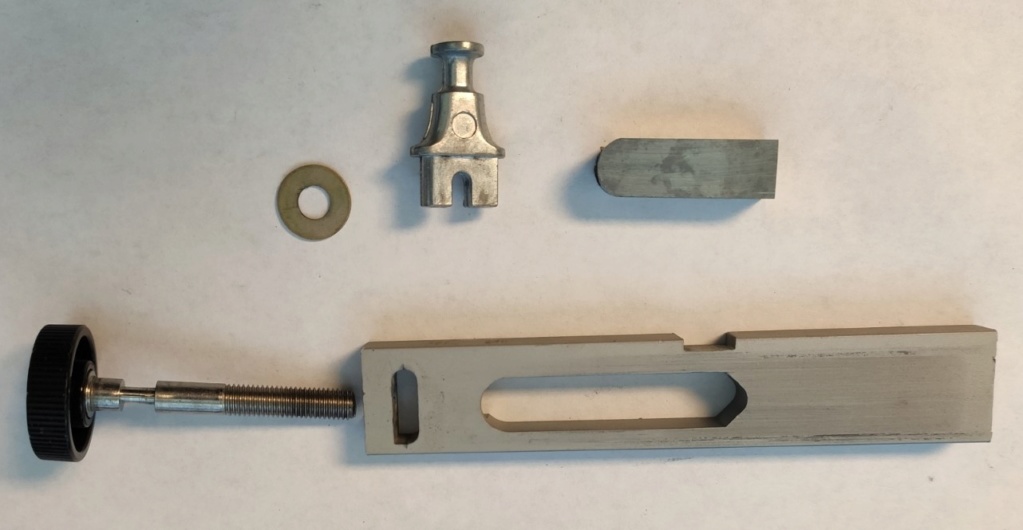

I took the measure that is most suspect to pieces. I notice that there is significant "play" in the bar adjuster - about 0.03" or ~1/32". There is a flat washer between the knob and the end of the bar, the play is similar to the thickness of that washer. The amount of free play is almost the same on all of the measures fitted with standard Dillon bars. Should I put a second washer in there to take out the free play?

I don't yet know whether this is the primary problem, but I want to minimise any variation that I can.

I've loaded a LOT of 45ACP ammo during these past few weeks. I've settled on two favourite recipes :- Brazos 160LSWC over 4.4 N310 and Nosler/Zero 185JHP over 4.6 WST, I've got a dedicated toolhead for each. In retrospect, I was very foolish to load such a large quantity without thoroughly range testing it batch by batch. I've been practising almost exclusively with the 160 load, I'd kinda got a feeling that the recoil was getting stronger, but that was only brought clearly into focus when I tried some of the newly loaded 185. I then shot some of each batch over the chrono. A lot of variation.

I typically check the powder drop several times at the start of each loading session and then again at the end of each batch of bullets or cases and again at the end. I've been seeing very consistent weight. But, clearly shown by the chrono testing, I'm getting significant inconsistency of powder weight. Been trying to figure out what is going on.

I took the measure that is most suspect to pieces. I notice that there is significant "play" in the bar adjuster - about 0.03" or ~1/32". There is a flat washer between the knob and the end of the bar, the play is similar to the thickness of that washer. The amount of free play is almost the same on all of the measures fitted with standard Dillon bars. Should I put a second washer in there to take out the free play?

I don't yet know whether this is the primary problem, but I want to minimise any variation that I can.

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

First off, replace that flat washer with a wavey washer (or 2).

CR

CR

CR10X- Posts : 1777

Join date : 2011-06-17

Location : NC

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Thank you CR10X. Yes, spot on, wavy washer missing on one measure. Found the Large bars in my parts box, which I never use, and took a wavy washer from one of them. Perfect, slack removed. Now on to some more loading and testing to try to eliminate any other issues.

Thanks again.

Thanks again.

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

A lot of aftermarket dillon powder measure bolts, bars and dials / knobs don't include a wavey washer. Even the Arrendondo powder bar / bolt needs some help to keep from creeping. Mark the dials / bolts well with a Sharpie and keep an eye on it.

CR10X- Posts : 1777

Join date : 2011-06-17

Location : NC

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

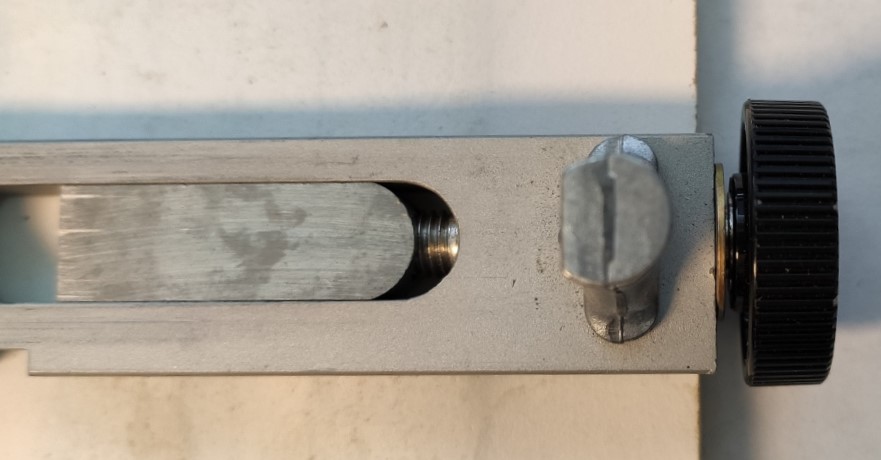

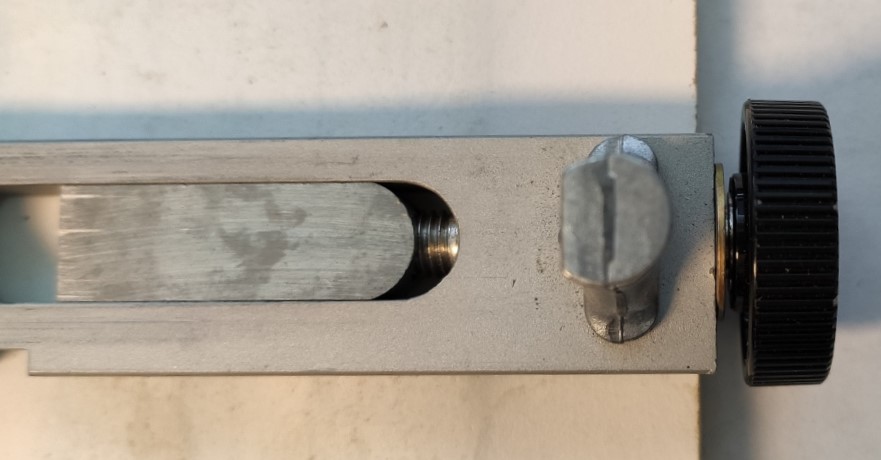

If you are using stock adjustment bolt, there is natural backlash between bolt and insert. That is because thread on OEM bold is not cut but rather stamped. If you hold insert with your fingers above and below the bar, and move it along bolt's axial, you can feel it. Adding wave washer removed backlash in area, that has some but lesser effect on the charge variations. That is because bolt is locked in place with that thing on top of the bar (where springs used to be wrapped up on older measures). Majority of powder variation comes from insert moving over bolt's thread.

Cecil,

As funny as it is, - you have one of mine heading your way >

>

AP

Cecil,

As funny as it is, - you have one of mine heading your way

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

OK. So, an unbiased opinion please. Which is the absolute best aftermarket upgrade for a Dillon measure?

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Years ago I bought two of these - http://www.uniquetek.com/product/T1231. Still have them, one on 45 toolhead, and one on 38WC toolhead. It is very good option! Since then I added three more 45 toolheads (and about a dozen and a half of others), and all have my own bolts - http://www.photoescapeinc.com/products/bolt-screw.html One of the part on drawing board is replacement insert.

Advantage of UniqueTek's over mine: UniqueTek's MicroMeter bolt's body is glued by locktite to the powder bar, and its tip locktited to the bar's insert. This way backlash in both places is totally eliminated, and insert adjustment is being done by precision screw. Mine bolts have full threads so backlash is minimized. Advantage of mine over UniqueTek's is the cost / performance balance.

Between these two options you have the two best, IMHO.

AP

Advantage of UniqueTek's over mine: UniqueTek's MicroMeter bolt's body is glued by locktite to the powder bar, and its tip locktited to the bar's insert. This way backlash in both places is totally eliminated, and insert adjustment is being done by precision screw. Mine bolts have full threads so backlash is minimized. Advantage of mine over UniqueTek's is the cost / performance balance.

Between these two options you have the two best, IMHO.

AP

Last edited by PhotoEscape on Mon May 18, 2020 4:53 pm; edited 1 time in total (Reason for editing : added information)

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Swapping it out for a Hornady Case activated powder measure...radjag wrote:OK. So, an unbiased opinion please. Which is the absolute best aftermarket upgrade for a Dillon measure?

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

AP, I thought I ordered only the Aimpoint Shade kit? I was thinking about trying the bolt sometime.

As for the other options. Here's some more of my experience / comments.

The micrometer powder bar adjustment is one of the products that I had some issue with it "creeping" some during reloading sessions. Don't get me wrong, its a good product for its intended used (changing a lot). But there is still just a little bit of "back and forth" pressure during the measuring cycle and the resistance on the adjustment dial is not very much so it would creep a little over time (and its very easy to move if something brushes up against it when you're working around the press). And the material for their powder bar (if you get the whole kit) is a little flexible so it can bind on the older Dillon measures with the two return springs (pre measure failsafe return update).

I generally stick to the crude dillon bars and make sure they are hard to move when I finally get a load. I have actually used some Loctite (removable) on the interior threads at the adjustment block to also take up the backlash issue. Most of my reloading is done for very specific loads that have been developed over they years. I use multiple heads (complete with powder measures) for my 5 usual loads for (2) for .45, (1) 9mm and (2) .38. Eventually I'll get a another set up for 9mm 147 gr when I find a really consistent / good load for the new gun; and I'll really can't see buying that many micrometer bars / slides.

Someone should make some "blank" Dillon powder bars for those of us that don't change loads very much. That way I can drill out exactly what I want. I got one from somewhere for 5.0 gr WSF for my 9 mm reloading (at least you know it can't change when you're not looking.)

CR

As for the other options. Here's some more of my experience / comments.

The micrometer powder bar adjustment is one of the products that I had some issue with it "creeping" some during reloading sessions. Don't get me wrong, its a good product for its intended used (changing a lot). But there is still just a little bit of "back and forth" pressure during the measuring cycle and the resistance on the adjustment dial is not very much so it would creep a little over time (and its very easy to move if something brushes up against it when you're working around the press). And the material for their powder bar (if you get the whole kit) is a little flexible so it can bind on the older Dillon measures with the two return springs (pre measure failsafe return update).

I generally stick to the crude dillon bars and make sure they are hard to move when I finally get a load. I have actually used some Loctite (removable) on the interior threads at the adjustment block to also take up the backlash issue. Most of my reloading is done for very specific loads that have been developed over they years. I use multiple heads (complete with powder measures) for my 5 usual loads for (2) for .45, (1) 9mm and (2) .38. Eventually I'll get a another set up for 9mm 147 gr when I find a really consistent / good load for the new gun; and I'll really can't see buying that many micrometer bars / slides.

Someone should make some "blank" Dillon powder bars for those of us that don't change loads very much. That way I can drill out exactly what I want. I got one from somewhere for 5.0 gr WSF for my 9 mm reloading (at least you know it can't change when you're not looking.)

CR

CR10X- Posts : 1777

Join date : 2011-06-17

Location : NC

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

+1 on Uniquetek.

Dr.Don- Posts : 816

Join date : 2012-10-31

Location : Cedar Park, TX

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

I’ve had good luck with the Prairie Dog micro adjustment bar on Amazon

https://www.amazon.com/Prairie-Dog-6-120-Perfect-Control/dp/B01AM3ZBBC/ref=mp_s_a_1_13?dchild=1&keywords=dillon+powder+bars&qid=1589895852&sr=8-13

https://www.amazon.com/Prairie-Dog-6-120-Perfect-Control/dp/B01AM3ZBBC/ref=mp_s_a_1_13?dchild=1&keywords=dillon+powder+bars&qid=1589895852&sr=8-13

james r chapman- Admin

- Posts : 6370

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Cecil,CR10X wrote:AP, I thought I ordered only the Aimpoint Shade kit? I was thinking about trying the bolt sometime.

As for the other options. Here's some more of my experience / comments.

The micrometer powder bar adjustment is one of the products that I had some issue with it "creeping" some during reloading sessions. Don't get me wrong, its a good product for its intended used (changing a lot). But there is still just a little bit of "back and forth" pressure during the measuring cycle and the resistance on the adjustment dial is not very much so it would creep a little over time (and its very easy to move if something brushes up against it when you're working around the press). And the material for their powder bar (if you get the whole kit) is a little flexible so it can bind on the older Dillon measures with the two return springs (pre measure failsafe return update).

I generally stick to the crude dillon bars and make sure they are hard to move when I finally get a load. I have actually used some Loctite (removable) on the interior threads at the adjustment block to also take up the backlash issue. Most of my reloading is done for very specific loads that have been developed over they years. I use multiple heads (complete with powder measures) for my 5 usual loads for (2) for .45, (1) 9mm and (2) .38. Eventually I'll get a another set up for 9mm 147 gr when I find a really consistent / good load for the new gun; and I'll really can't see buying that many micrometer bars / slides.

Someone should make some "blank" Dillon powder bars for those of us that don't change loads very much. That way I can drill out exactly what I want. I got one from somewhere for 5.0 gr WSF for my 9 mm reloading (at least you know it can't change when you're not looking.)

CR

My full time job is being mind reader

Everything in CR's post is absolutely correct. I've never used Arredondo bars, so I can't say anything about. And issue with drifting on Micrometer adjuster is also correct, - it uses 40TPI, and there is no locking like on real micrometers. That was the driving factor for my bolts (and of course cost, - it adds up when one has as many toolheads as I do!). I would argue that "fixed" bars would not work though, - I thought about doing just that, but rejected idea. In essence it is same volumetric approach as being used on Star slides with different bushings for different powders and charges. Issue is that powder consistency changes from lot to lot. Same powder would provide for different charge per same volume. In reality, there is a much simpler solution. Look at the picture below, then look at your press. Then go to local hardware store and buy 8-32 tap with appropriate drill bit, and two 8-32x1/8 socket set screws per powder bar. Obviously some mechanical aptitude for drilling and threading is necessary, and it is better to do on drill press. Please be cognoscente of the one big problem (might be specific to myself) with this solution though - you MUST remember that screws have to be released before making any adjustments.

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

So, Ashley, interesting alternative. Don't know anything about the Hornady stuff. Am I correct in understanding that it would require all of these items plus a suitable die (and the additional micrometer if desired)?Wobbley wrote:Swapping it out for a Hornady Case activated powder measure...radjag wrote:OK. So, an unbiased opinion please. Which is the absolute best aftermarket upgrade for a Dillon measure?

Wow! - probably $250 per measure in total.

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Alex,

Looks like a great idea to use set screws in powder bar. But is it really necessary to use two?

JKR

Looks like a great idea to use set screws in powder bar. But is it really necessary to use two?

JKR

JKR- Posts : 763

Join date : 2015-01-13

Location : Northern Wisconsin

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

I would use two to make sure everything stays parallel & would probably use nylon tipped set screws to minimize damaging the sides of the bar. But then again I've been told that I have some strange ideas.

STEVE SAMELAK- Posts : 958

Join date : 2011-06-10

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Jim,

Just to clarify, I'm using two screws piggy backed to each other. First one locks insert in the bar, second one locks the first one. This is just in case in order to avoid first screw getting lose from vibration during long reloads. Also, I'm using 1/8, because wall thickness on small bar is about 0.2550", and close to 0.220" of large bar.

Otherwise, you are absolutely correct, single screw would do the job! I use one on short reloads, and until I'm set on charge. Only after that, and if I'm for a long run, I add 2nd one.

Steve,

There is no need to worry about keeping parallel (for that matter only one side of the bar is exposed) or damaging the insert. Set screw is only to prevent drifting. However your idea about using nylon tipped screw is a good one! I have to get such screws, and replace ones on all my drilled bars. I just have ample of 8-32x1/8s as I'm using same on my 650 Fail Safety Brackets.

AP

Just to clarify, I'm using two screws piggy backed to each other. First one locks insert in the bar, second one locks the first one. This is just in case in order to avoid first screw getting lose from vibration during long reloads. Also, I'm using 1/8, because wall thickness on small bar is about 0.2550", and close to 0.220" of large bar.

Otherwise, you are absolutely correct, single screw would do the job! I use one on short reloads, and until I'm set on charge. Only after that, and if I'm for a long run, I add 2nd one.

Steve,

There is no need to worry about keeping parallel (for that matter only one side of the bar is exposed) or damaging the insert. Set screw is only to prevent drifting. However your idea about using nylon tipped screw is a good one! I have to get such screws, and replace ones on all my drilled bars. I just have ample of 8-32x1/8s as I'm using same on my 650 Fail Safety Brackets.

AP

Last edited by PhotoEscape on Tue May 19, 2020 2:37 pm; edited 1 time in total (Reason for editing : additional information.)

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Perhaps...

Or you can spend $ on taps & setscrews, new metering screws, new metering bars etc. and you still have a powder measure that won’t be consistent or, worse, leaks powder and has a return mechanism that is a kludge.

The Hornady with the small insert can be quickly changed over by swapping out the metering assembly. And the expanders don’t require adjusting the 7/8-14 die body to change the expansion. You can literally dial it in.

Or you can spend $ on taps & setscrews, new metering screws, new metering bars etc. and you still have a powder measure that won’t be consistent or, worse, leaks powder and has a return mechanism that is a kludge.

The Hornady with the small insert can be quickly changed over by swapping out the metering assembly. And the expanders don’t require adjusting the 7/8-14 die body to change the expansion. You can literally dial it in.

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Wobbley wrote:Perhaps... And the expanders don’t require adjusting the 7/8-14 die body to change the expansion. You can literally dial it in.

You've kinda got me interested, but, so far, I find the Hornady descriptions of their products to be very difficult to understand.

Buy the measure, buy a pistol rotor, buy the case activated powder drop (and that appears to come with a 7/8-14 die), buy the micrometer pistol insert.

But does it also come with an expander and, if so, for what caliber?

I need to be able to expand and drop powder at station 2 (like a standard Dillon XL650 does), cause I've got a bullet feeder at station 3.

Which expander or PTU fits the Hornady die.

Or do I have to buy yet another expensive part?

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

I do not have a Dillion press but I have two Hornady LNL The case activated powder drop assembly is 7/8-14 like a regular die, it comes with a universal tube that activates the powder drop. If you want to expand while dropping powder a Hornady ptx expander is ~$10 per caliber. The micrometer insert is only beneficial if you change your powder charges a lot, definitely not a needed item but nice to have.

chiz1180- Posts : 1507

Join date : 2019-05-29

Location : Ohio

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

chiz1180. Thanks - got it. I'll order a kit to test - on the basis that if I don't like it I can always sell it on.

Cheers.

Cheers.

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

If you get the Hornady ptx expanders (some aftermarket options exist, I have not played with them, I use a lyman M die for 45) you can get .451 and .452 options. Fair warning the instructions are not the best, but once you figure it out it is not that hard to make desired adjustments.

chiz1180- Posts : 1507

Join date : 2019-05-29

Location : Ohio

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Roy

This is the item that allows you to dial in the expansion.

The spring you see is the return spring. It is very positive because the powder doesn’t get between the sliding and the stationary. The RCBS is very similar.

This is the item that allows you to dial in the expansion.

The spring you see is the return spring. It is very positive because the powder doesn’t get between the sliding and the stationary. The RCBS is very similar.

radjag wrote:Wobbley wrote:Perhaps... And the expanders don’t require adjusting the 7/8-14 die body to change the expansion. You can literally dial it in.

You've kinda got me interested, but, so far, I find the Hornady descriptions of their products to be very difficult to understand.

Buy the measure, buy a pistol rotor, buy the case activated powder drop (and that appears to come with a 7/8-14 die), buy the micrometer pistol insert.

But does it also come with an expander and, if so, for what caliber?

I need to be able to expand and drop powder at station 2 (like a standard Dillon XL650 does), cause I've got a bullet feeder at station 3.

Which expander or PTU fits the Hornady die.

Or do I have to buy yet another expensive part?

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Ashley, OK, good explanatory photo - does this work with the PTX expander?

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

OK, I've ordered a set - did not get the micrometer - I will try it all on my 45ACP 185JHP toolhead first. If I find that I can get more consistent powder throws (and no spillage) then I will consider getting a second pistol insert and set them to the two drops I use for short/long line loads. The only other setting change will then be bullet seating - I'm using a Dillon seating die with the two ended seating punch - a clever trick would be to modify the two ends to exactly suit a 185JHP one side and a 160 LSWC the other - then all of the dies can remain in a fixed position - just swap powder rotor insert and flip the seating punch. I can standardise on VV N310 powder for both loads to make it all even easier. Or, I can populate my second 45ACP LSWC toolhead with another Hornady powder measure kit and sell on the surplus Dillon measures.

If this all works well then there could be a lot of expensive Dillon parts for sale on Commercial Row soon (not to mention a couple of Star presses that I'm struggling to come to terms with). Grrr.............

If this all works well then there could be a lot of expensive Dillon parts for sale on Commercial Row soon (not to mention a couple of Star presses that I'm struggling to come to terms with). Grrr.............

Guest- Guest

Page 1 of 3 • 1, 2, 3

Similar topics

Similar topics» Dillon vs Hornady powder measure on Dillon 550

» Help with Dillon powder measure.

» Powder Measure

» Dillon powder measure baffle

» Lee Auto-Drum Powder Measure and CFE Pistol powder metering

» Help with Dillon powder measure.

» Powder Measure

» Dillon powder measure baffle

» Lee Auto-Drum Powder Measure and CFE Pistol powder metering

Page 1 of 3

Permissions in this forum:

You cannot reply to topics in this forum