Dillon Powder Measure issue

+16

fc60

Richard Ashmore

Rocambole

GrumpyOldMan

Wes Lorenz

Cazmont

spursnguns

mhayford45

chiz1180

STEVE SAMELAK

JKR

james r chapman

Dr.Don

Wobbley

PhotoEscape

CR10X

20 posters

Page 2 of 3

Page 2 of 3 •  1, 2, 3

1, 2, 3

Dillon Powder Measure issue

Dillon Powder Measure issue

First topic message reminder :

I have several toolheads for my Dillon XL650, each with it's own powder measure. Some with X-small bar and others with small bar. One with an Arredondo plastic micrometer bar (no problem with that one).

I've loaded a LOT of 45ACP ammo during these past few weeks. I've settled on two favourite recipes :- Brazos 160LSWC over 4.4 N310 and Nosler/Zero 185JHP over 4.6 WST, I've got a dedicated toolhead for each. In retrospect, I was very foolish to load such a large quantity without thoroughly range testing it batch by batch. I've been practising almost exclusively with the 160 load, I'd kinda got a feeling that the recoil was getting stronger, but that was only brought clearly into focus when I tried some of the newly loaded 185. I then shot some of each batch over the chrono. A lot of variation.

I typically check the powder drop several times at the start of each loading session and then again at the end of each batch of bullets or cases and again at the end. I've been seeing very consistent weight. But, clearly shown by the chrono testing, I'm getting significant inconsistency of powder weight. Been trying to figure out what is going on.

I took the measure that is most suspect to pieces. I notice that there is significant "play" in the bar adjuster - about 0.03" or ~1/32". There is a flat washer between the knob and the end of the bar, the play is similar to the thickness of that washer. The amount of free play is almost the same on all of the measures fitted with standard Dillon bars. Should I put a second washer in there to take out the free play?

I don't yet know whether this is the primary problem, but I want to minimise any variation that I can.

I have several toolheads for my Dillon XL650, each with it's own powder measure. Some with X-small bar and others with small bar. One with an Arredondo plastic micrometer bar (no problem with that one).

I've loaded a LOT of 45ACP ammo during these past few weeks. I've settled on two favourite recipes :- Brazos 160LSWC over 4.4 N310 and Nosler/Zero 185JHP over 4.6 WST, I've got a dedicated toolhead for each. In retrospect, I was very foolish to load such a large quantity without thoroughly range testing it batch by batch. I've been practising almost exclusively with the 160 load, I'd kinda got a feeling that the recoil was getting stronger, but that was only brought clearly into focus when I tried some of the newly loaded 185. I then shot some of each batch over the chrono. A lot of variation.

I typically check the powder drop several times at the start of each loading session and then again at the end of each batch of bullets or cases and again at the end. I've been seeing very consistent weight. But, clearly shown by the chrono testing, I'm getting significant inconsistency of powder weight. Been trying to figure out what is going on.

I took the measure that is most suspect to pieces. I notice that there is significant "play" in the bar adjuster - about 0.03" or ~1/32". There is a flat washer between the knob and the end of the bar, the play is similar to the thickness of that washer. The amount of free play is almost the same on all of the measures fitted with standard Dillon bars. Should I put a second washer in there to take out the free play?

I don't yet know whether this is the primary problem, but I want to minimise any variation that I can.

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

The only other setting change will then be bullet seating - I'm using a Dillon seating die with the two ended seating punch - a clever trick would be to modify the two ends to exactly suit a 185JHP one side and a 160 LSWC the other - then all of the dies can remain in a fixed position

Unless you are very lucky and have enough patience (and length) when milling the insert, you will still wind up having to adjust the seating depth when flipping the seating punch. I just use 2 different complete heads since there is also the powder charge change, some slight belling differences and crimp differences between my jacketed and load loads.

AP: I was lazy and went with the Loctite for just the back and forth play between the insert and the bolt. I like the set screw idea and may do that to also take up any side to side play. (there's not much). Thanks!

CR

CR10X- Posts : 1777

Join date : 2011-06-17

Location : NC

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

I also suffered with inconsistent drops with the Dillon Powder system on my 550. Tried many of the work arounds mentioned. I ultimately settled on the Harrell Schuetzen Pistol powder drop mounted to a custom frame I built for it. It is the most consistent powder drop made.

http://harrellsprec.com/index.php/products/schuetzen-pistol-measure

It is not automatic... but then I have a 550.

http://harrellsprec.com/index.php/products/schuetzen-pistol-measure

It is not automatic... but then I have a 550.

mhayford45- Posts : 259

Join date : 2013-02-21

Location : MI

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

mhayford45 wrote:I also suffered with inconsistent drops with the Dillon Powder system on my 550. Tried many of the work arounds mentioned. I ultimately settled on the Harrell Schuetzen Pistol powder drop mounted to a custom frame I built for it. It is the most consistent powder drop made.

http://harrellsprec.com/index.php/products/schuetzen-pistol-measure

It is not automatic... but then I have a 550.

+1 mhayford45,

I have two and have been using them for years with my 550s. They are the best.

I use a Hornady measure with my 650.

Jim

spursnguns- Posts : 611

Join date : 2013-01-04

Age : 66

Location : Nampa, Idaho

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

But, clearly shown by the chrono testing, I'm getting significant inconsistency of powder

Great thread with lots of useful info but referring to the quote from the original post...is it really clear that the powder weight is at issue? Other factors of the reload could be inconsistent causing the chrono results? Sorry about my lack of thread quoting skill.

Great thread with lots of useful info but referring to the quote from the original post...is it really clear that the powder weight is at issue? Other factors of the reload could be inconsistent causing the chrono results? Sorry about my lack of thread quoting skill.

Cazmont- Posts : 32

Join date : 2020-01-04

Location : NorCal

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Cazmont - your question is a good one.

I discussed my experience with my mentor and now learn that WST powder (originally intended for shotgun) can exhibit inconsistent velocity due to incomplete combustion in a short 1911 barrel. This may be made worse in cold weather. He is also of the opinion that WST is not a good choice with JHP bullets. They do not seal as tightly and might create less resistance in the bore - adding to the inherent incomplete combustion issue.

I had somehow got my recipes "back-to-front" using N310 with my Brazos 160 LSWC and WST with Nosler 185 JHP. When I got my SARO wad gun I had written down the recommended recipes - maybe a dyslexic moment?

But, I am seeing quite a bit of powder around the press and am suspicious of the Dillon measures. I've bought some replacement PhotoEscape adjuster bolts which might help and will make sure that I've got wavy washers. I've also got a Hornady kit on the way. I will now make extra sure that I'm throwing consistent shots of powder. If the Hornady works as suggested by others I may just sell on all of the Dillon measures and upgrade to Hornady's.

But, I'm probably going to switch to all N310 for 45 loads for the rest of this summer - then maybe Bullseye in the winter if I'm shooting in colder weather (not usually the case for me). I've now got a huge stash of WST so I will have to go back to it sooner or later - unless I can sell it to shotgun guys at my local club. Grrrr.....

I discussed my experience with my mentor and now learn that WST powder (originally intended for shotgun) can exhibit inconsistent velocity due to incomplete combustion in a short 1911 barrel. This may be made worse in cold weather. He is also of the opinion that WST is not a good choice with JHP bullets. They do not seal as tightly and might create less resistance in the bore - adding to the inherent incomplete combustion issue.

I had somehow got my recipes "back-to-front" using N310 with my Brazos 160 LSWC and WST with Nosler 185 JHP. When I got my SARO wad gun I had written down the recommended recipes - maybe a dyslexic moment?

But, I am seeing quite a bit of powder around the press and am suspicious of the Dillon measures. I've bought some replacement PhotoEscape adjuster bolts which might help and will make sure that I've got wavy washers. I've also got a Hornady kit on the way. I will now make extra sure that I'm throwing consistent shots of powder. If the Hornady works as suggested by others I may just sell on all of the Dillon measures and upgrade to Hornady's.

But, I'm probably going to switch to all N310 for 45 loads for the rest of this summer - then maybe Bullseye in the winter if I'm shooting in colder weather (not usually the case for me). I've now got a huge stash of WST so I will have to go back to it sooner or later - unless I can sell it to shotgun guys at my local club. Grrrr.....

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Thanks Scott, that is another smart tip.

I fitted the first of Alex's custom adjuster bolts today - makes the powder bar adjustment solid as a rock - excellent. I've just loaded 100 rounds and will run some over the chrono tomorrow to see whether I get better SD results. I will group test at EEGC as soon as it is fully open and can get a decent rest set up.

I fitted the first of Alex's custom adjuster bolts today - makes the powder bar adjustment solid as a rock - excellent. I've just loaded 100 rounds and will run some over the chrono tomorrow to see whether I get better SD results. I will group test at EEGC as soon as it is fully open and can get a decent rest set up.

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

This was my temporary fix when I was loading 32SWL on my 1050. The key to loading this caliber on a Dillon is to carefully stone the interior slide/spacer area on the PM housing, polish the funnel area, and then fit the slide & spacer until you have a nice slip fit with no binding. My high score was an 886/900, so it worked rather well, but still wasn't great. I used the adjustable slide for development and the bushing slide for reloading match ammo (no chance of movement).

I finally listened to my buddy Dave and bought a Star for 32 and have never regretted it. Achieved powder Valhalla.

I finally listened to my buddy Dave and bought a Star for 32 and have never regretted it. Achieved powder Valhalla.

Wes Lorenz- Posts : 443

Join date : 2011-06-27

Location : Washington

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

I want to chime in on couple of topics discussed in this tread.

1. Powder dripping in Dillon's measures and consistencies of powder charges. I believe, I already posted somewhere on the forum. I prepare each new powder measure before first use by sanding and polishing several surfaces including bottom of powder hopper, inside of the powder bar housing, and powder bars and inserts. I replace adjuster bolts and install set screws as I described before in this tread. I have no powder leaks anymore even with finest ball powders. This not to be confused with some powder droplets coming through PTUs/funnels. I want to state for the record that my powder measures easily hold +/-0.04gr powder variations, and a lot of it comes from factors related to powder itself, inconsistencies of dimensions of shell plates, and myself, - inconsistency of stroke and impact at the top & bottom versus no impact will create variables.

2. I also bough Harrell's Schuetzen measure in anticipation of greater accuracy of drop. Contradictory to posted above I didn't experience precision of drops at the same level as described. I ran test with over 400 individual drops of N310 powder, weighted and recorded each drop, and got very mad of myself for spending over $250 for +/- 0.1gr deviation from base charge. I even called to the company and talked to gent there. He confirmed that above mentioned deviation is to be expected. With that said, Brad Miller, PHD published great article on subject of powder charge deviation in handgun ammo. He illustrated that above mentioned variable creates less than an inch difference in impact at 25Y.

3. I've played with Hornady Powder measure as well. Both as a stand alone, and as mounted on Dillon press using native powder through die with my own LNL PTUs, and as well with my Single Stage Die and Dillon PTUs. I didn't observe any improvement in powder drop consistencies over Dillon Powder measure. For that matter it was rather closer to same of the Harrell's and in +/-0.1gr range.

For the sake of discussion, I've tested all of the above with same VV N310 powder. Also, as a side note, Schuetzen doesn't work with charges below 2.0gr, Roy. Something to be aware of if you intend to load for 32 Cal with 1.7gr charges. Same is applicable to Hornady, - you would need a different thimble for such, and on Dillon you would need x-small powder bar or use file to convers small bar into such.

AP

1. Powder dripping in Dillon's measures and consistencies of powder charges. I believe, I already posted somewhere on the forum. I prepare each new powder measure before first use by sanding and polishing several surfaces including bottom of powder hopper, inside of the powder bar housing, and powder bars and inserts. I replace adjuster bolts and install set screws as I described before in this tread. I have no powder leaks anymore even with finest ball powders. This not to be confused with some powder droplets coming through PTUs/funnels. I want to state for the record that my powder measures easily hold +/-0.04gr powder variations, and a lot of it comes from factors related to powder itself, inconsistencies of dimensions of shell plates, and myself, - inconsistency of stroke and impact at the top & bottom versus no impact will create variables.

2. I also bough Harrell's Schuetzen measure in anticipation of greater accuracy of drop. Contradictory to posted above I didn't experience precision of drops at the same level as described. I ran test with over 400 individual drops of N310 powder, weighted and recorded each drop, and got very mad of myself for spending over $250 for +/- 0.1gr deviation from base charge. I even called to the company and talked to gent there. He confirmed that above mentioned deviation is to be expected. With that said, Brad Miller, PHD published great article on subject of powder charge deviation in handgun ammo. He illustrated that above mentioned variable creates less than an inch difference in impact at 25Y.

3. I've played with Hornady Powder measure as well. Both as a stand alone, and as mounted on Dillon press using native powder through die with my own LNL PTUs, and as well with my Single Stage Die and Dillon PTUs. I didn't observe any improvement in powder drop consistencies over Dillon Powder measure. For that matter it was rather closer to same of the Harrell's and in +/-0.1gr range.

For the sake of discussion, I've tested all of the above with same VV N310 powder. Also, as a side note, Schuetzen doesn't work with charges below 2.0gr, Roy. Something to be aware of if you intend to load for 32 Cal with 1.7gr charges. Same is applicable to Hornady, - you would need a different thimble for such, and on Dillon you would need x-small powder bar or use file to convers small bar into such.

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Impressive! Both the slide and score!

It happens that after numerous recommendations from Roddy and others I now own two Star Universals, one for 45ACP and one for 32ACP, but I struggle to operate them. I need to get indexers set-up and have not gotten round to it. In the meantime I persevere with the Dillon 650.

Maybe the Star's are one further step I need to complete if I am to get up to HM Outdoor level.

It happens that after numerous recommendations from Roddy and others I now own two Star Universals, one for 45ACP and one for 32ACP, but I struggle to operate them. I need to get indexers set-up and have not gotten round to it. In the meantime I persevere with the Dillon 650.

Maybe the Star's are one further step I need to complete if I am to get up to HM Outdoor level.

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

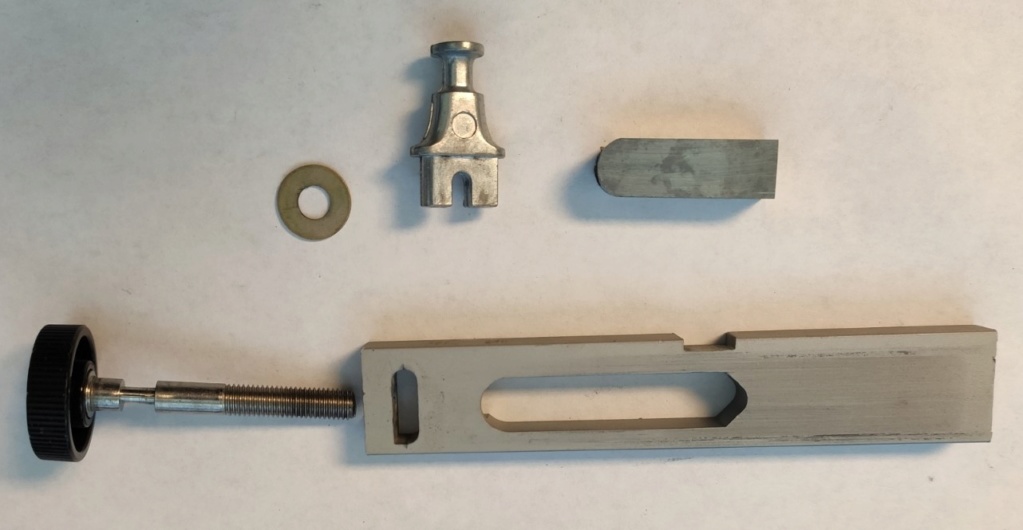

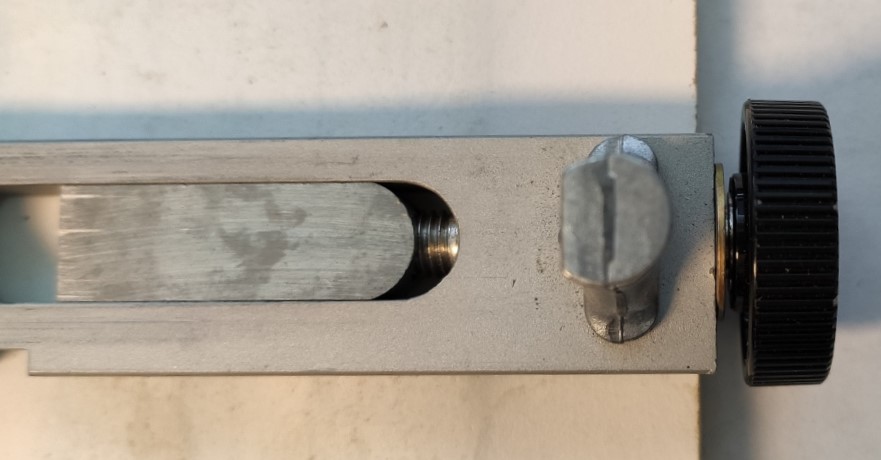

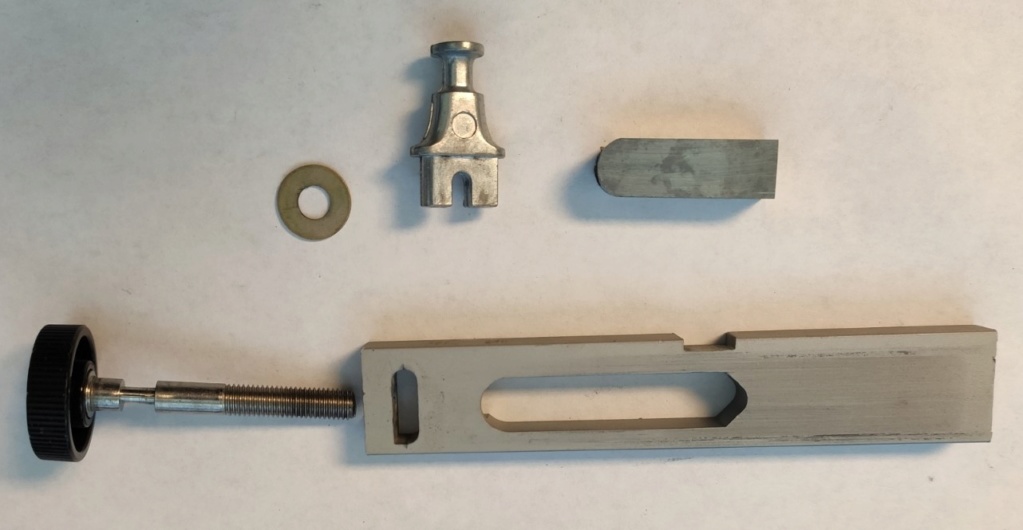

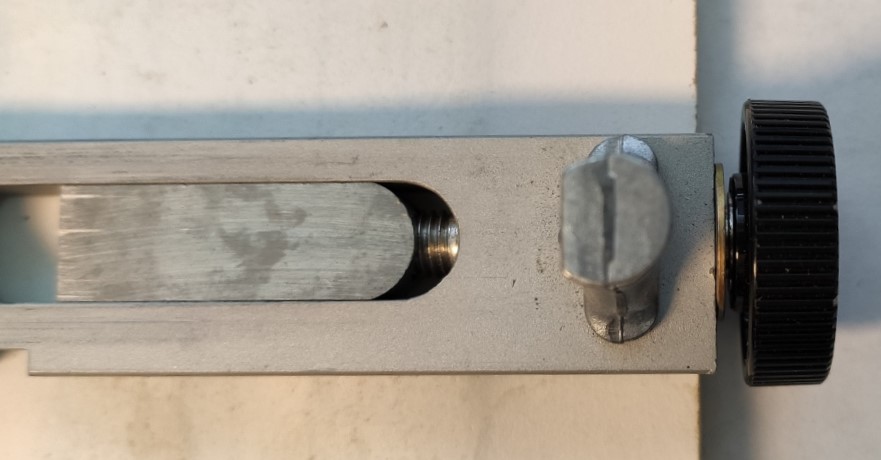

To inspire other tinkerer's:

Here is one of my current projects to mimic a Star Reloader's powder measure cam; which has teeth machined into it that "shake" the powder slide and measure which helps Star's reputation for consistency.

There are two spring loaded ball detents in the aluminum attachment and socket flat head screws in the powder slide which act to shake the assembly as it moves back and forth. Haven't finished it yet, so maybe is will have been a fun waste of time.

Here is one of my current projects to mimic a Star Reloader's powder measure cam; which has teeth machined into it that "shake" the powder slide and measure which helps Star's reputation for consistency.

There are two spring loaded ball detents in the aluminum attachment and socket flat head screws in the powder slide which act to shake the assembly as it moves back and forth. Haven't finished it yet, so maybe is will have been a fun waste of time.

Wes Lorenz- Posts : 443

Join date : 2011-06-27

Location : Washington

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

AP. Interesting - you are another perfectionist like Wes Lorenz!

Yes, 32ACP requires very small powder drops. I have a couple of X-Small bars (and a Micrometer Arredondo) but have found that they all typically will not go down to less than 1.4 N310 without modification. I suspect that they are all not perfect at the bottom end of their adjustment range.

But I'm a sucker for buying stuff and experimenting, so I'll try the Hornady and see how I feel. I have a very good offer to swap it for a Dillon PM + cash from another Forum member if I don't like it.

Yes, 32ACP requires very small powder drops. I have a couple of X-Small bars (and a Micrometer Arredondo) but have found that they all typically will not go down to less than 1.4 N310 without modification. I suspect that they are all not perfect at the bottom end of their adjustment range.

But I'm a sucker for buying stuff and experimenting, so I'll try the Hornady and see how I feel. I have a very good offer to swap it for a Dillon PM + cash from another Forum member if I don't like it.

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

I totally agree with Photo Escape's comments and admire his products workmanship & the thought he puts into each product. I've sent him ideas in the past and am just showing off what has helped me. I'm long past shooting high scores and like to tinker.

In 2007 I loaded over 10,000 rounds of 223 for our State Jr. Service rifle team and used a modified BR-30 PM on my 1050. The set up and linkage works good for rifle loads, but trying to get consistent BE charges would be difficult like Photo Escape states. He is also correct that there is nothing better than the Dillon slide (with his screw set-up). They just work.

my .02

In 2007 I loaded over 10,000 rounds of 223 for our State Jr. Service rifle team and used a modified BR-30 PM on my 1050. The set up and linkage works good for rifle loads, but trying to get consistent BE charges would be difficult like Photo Escape states. He is also correct that there is nothing better than the Dillon slide (with his screw set-up). They just work.

my .02

Wes Lorenz- Posts : 443

Join date : 2011-06-27

Location : Washington

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

I remember this picture, Wes. I think, we both had idea and discussed introduction of vibration to powder measure. Unfortunately in both cases (yours and mine) vibration is introduced while powder bar is out of "zero" position, and powder flow into the cavity of powder bar is cut off. I also experimented and sometimes use weights in the hopper. Improvement is marginal and predominantly with "nasty" flake type powders like Unique. I find, that better consistency is achieved through identifying and maintaining level of the powder in the hopper within certain upper and lower limits. It is rather empirical and different for different powders. On my two Stars, I have marks by Sharpie for upper and lower limits, and refill powder when it reaches lower limit. It also varies from lot to lot.Wes Lorenz wrote:To inspire other tinkerer's:

Here is one of my current projects to mimic a Star Reloader's powder measure cam; which has teeth machined into it that "shake" the powder slide and measure which helps Star's reputation for consistency.

There are two spring loaded ball detents in the aluminum attachment and socket flat head screws in the powder slide which act to shake the assembly as it moves back and forth. Haven't finished it yet, so maybe is will have been a fun waste of time.

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

This made me laugh 'cuz I've done it too!

- you MUST remember that screws have to be released before making any adjustments.

Anyway, what about wrapping Teflon thread tape around the powder slide bolt? I expected the "Nylock" gun screws to become universal waybackwhen they were announced in print advertising for some maker's pistols. The only reason I haven't done it yet is my pistol loading lately has been on a Green Machine or Star, and my rifle stuff has been OCD measure every charge. Gonna get to that high-volume .223 stuff sometime. Soon. Maybe.

- you MUST remember that screws have to be released before making any adjustments.

Anyway, what about wrapping Teflon thread tape around the powder slide bolt? I expected the "Nylock" gun screws to become universal waybackwhen they were announced in print advertising for some maker's pistols. The only reason I haven't done it yet is my pistol loading lately has been on a Green Machine or Star, and my rifle stuff has been OCD measure every charge. Gonna get to that high-volume .223 stuff sometime. Soon. Maybe.

GrumpyOldMan- Posts : 482

Join date : 2013-03-08

Location : High Desert Southwest Red Rock Country

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

I am vaguely surprised at the system of loading 10 charges and if they weigh 10 times as much as the desired charge, you're satisfied. In my opinion, even as a newbie in reloading, that is not a very safe way of doing things. I use a PräziPress and began with the RCBS powder measure with a "micrometer". The thing consistently charges within +/- 0.15 gr, but that's no way good enough for me, so I just weigh every charge, and at times I have had to pour back 6 or 7 charges before I finally got within +/- 0.02 gr, which I wanted for comparison between charge steps. If I allow myself +/- 0.1 gr, I'm already at the next step for 38 Sp, and for 32 S&W Long, it even represents more than a 10 % deviation. I am no pro, and some say that +/- 0.1 gr in 38 Sp makes no difference, but if that's the case, what are we really discussing here? Has anybody else really weighed every load and registered the deviation and what difference it makes on the target? That's really what I'm wondering, just to know if I need to very picky about it. Otherwise, Alex' way gives him +/- 0.04, and I reckon if that's good enough for him, it's certainly good enough for me. (For what it's worth, reading about the Hornady thing here, I also read elsewhere that that one also often deviates to +/- +.1 gr. Meaning it seems we are in Ford vs. Chevy-land, and the only way to truly improve things is the extra tidbits & tips like polishing and using extra springs and set screws, whatever system you are using...)

Rocambole- Posts : 15

Join date : 2019-03-06

Charge Consistency

Charge Consistency

Rocambole wrote:I am vaguely surprised at the system of loading 10 charges and if they weigh 10 times as much as the desired charge, you're satisfied. In my opinion, even as a newbie in reloading, that is not a very safe way of doing things. I use a PräziPress and began with the RCBS powder measure with a "micrometer". The thing consistently charges within +/- 0.15 gr, but that's no way good enough for me, so I just weigh every charge, and at times I have had to pour back 6 or 7 charges before I finally got within +/- 0.02 gr, which I wanted for comparison between charge steps. If I allow myself +/- 0.1 gr, I'm already at the next step for 38 Sp, and for 32 S&W Long, it even represents more than a 10 % deviation. I am no pro, and some say that +/- 0.1 gr in 38 Sp makes no difference, but if that's the case, what are we really discussing here? Has anybody else really weighed every load and registered the deviation and what difference it makes on the target? That's really what I'm wondering, just to know if I need to very picky about it. Otherwise, Alex' way gives him +/- 0.04, and I reckon if that's good enough for him, it's certainly good enough for me. (For what it's worth, reading about the Hornady thing here, I also read elsewhere that that one also often deviates to +/- +.1 gr. Meaning it seems we are in Ford vs. Chevy-land, and the only way to truly improve things is the extra tidbits & tips like polishing and using extra springs and set screws, whatever system you are using...)

I have two relevant anecdotes before I answer the question.

I'll begin by noting that Eley doesn't weigh charges at all on the TENEX line. When I visited the factory, the machine charged five cases at a time and then they were optically scanned. As long as they were within tolerance for height of charge they were good. If the deviation was excessive, all five were dumped and recharged.

In the course of my previous job I wound up talking to a primer chemist at Federal Cartridge Company. I asked him what the factory load was on GM45A and GM45B. The answer surprised me: there isn't one. Federal uses bulk powders not available to handloaders, they are not as consistent as canister powders that we use. They load to a pressure vs time curve that they think is desirable. Obviously they have equipment that we don't have.

My own experiment was this: Using a Dillon RL550B, I dropped and weighed 100 charges each of Bullseye and WST. IIRC the desired charge was 4.5 grains. The Standard Deviation for both powders was about equal to the Probable Error of my scale, a PACT digital scale capable of measuring in 0.1 grain increments, ~0.05 grains.

My conclusion was that, for .45ACP loads, ~66% of the dropped charges would have an undetectable variation, and about 95% would be +/- 0.1 grains.

So I adjust my Dillon powder dispenser so that ten dropped charges weighs ten times what I want each individual charge to be and keep my hands off until I get powder from a different lot. I'm not willing to weigh 100 charges looking for the 5 that are more that 0.1 grains off.

Richard Ashmore- Posts : 156

Join date : 2012-02-17

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Richard Ashmore, very interesting anecdotes.

I started this thread believing that I was experiencing unacceptable variations in powder drops from my Dillon PM and that was causing significant differences in measured velocity of my 45 ammo.

I'm not so sure about all of that now.

I've checked the PM numerous times using my beam scale and seem to get reasonably consistent drops. I've loaded several batches very carefully and am now "just smoothing out the flare" rather than applying a significant taper crimp. The ammo seems to shoot OK. But I'm not yet able to test properly on a 50 yard range using a Ransom Rest and over my chronograph (I also want to check my chrono against another, just to be sure).

But what I have now discovered is that my XL650 toolhead does not remain perpendicular to the ram/shellholder through the stroke. My mentor took a close look at some of my carefully loaded ammo and noticed that there is an eccentric bulge in the brass over the length of the bullet. It seems that as the bullet is being seated the shell is being driven up into the die at a slight angle - hence the slight and eccentric bulge.

I have exchanged opinions about this with several others, notably PhotoEscape, who tells me that he uses shims to square up the toolheads on his Dillons. So, this is a common problem with Dillon presses. Most "run & gun" reloaders would not know or care.

However, whilst this eccentricity of seated bullet could well affect the ultimate accuracy, I doubt that it would have a significant effect on measured velocity. So this is just another step in the learning process and does not get me any closer to a solution to the velocity variation issue.

I have bought a Hornady PM and all necessary bits, but have not yet had time/will to get it set up. The eccentric bulge problem has kind of turned me off altogether - I thought that I'd bought a "precision" press from Dillon.

It looks like I'm just gonna have to get comfortable with my as-yet-unused Star press and switch over to that for long line ammo. Too many presses - not enough time!

Or maybe just shoot factory ammo at the long line - that is my plan for the rest of this year!

Ho hum.

I started this thread believing that I was experiencing unacceptable variations in powder drops from my Dillon PM and that was causing significant differences in measured velocity of my 45 ammo.

I'm not so sure about all of that now.

I've checked the PM numerous times using my beam scale and seem to get reasonably consistent drops. I've loaded several batches very carefully and am now "just smoothing out the flare" rather than applying a significant taper crimp. The ammo seems to shoot OK. But I'm not yet able to test properly on a 50 yard range using a Ransom Rest and over my chronograph (I also want to check my chrono against another, just to be sure).

But what I have now discovered is that my XL650 toolhead does not remain perpendicular to the ram/shellholder through the stroke. My mentor took a close look at some of my carefully loaded ammo and noticed that there is an eccentric bulge in the brass over the length of the bullet. It seems that as the bullet is being seated the shell is being driven up into the die at a slight angle - hence the slight and eccentric bulge.

I have exchanged opinions about this with several others, notably PhotoEscape, who tells me that he uses shims to square up the toolheads on his Dillons. So, this is a common problem with Dillon presses. Most "run & gun" reloaders would not know or care.

However, whilst this eccentricity of seated bullet could well affect the ultimate accuracy, I doubt that it would have a significant effect on measured velocity. So this is just another step in the learning process and does not get me any closer to a solution to the velocity variation issue.

I have bought a Hornady PM and all necessary bits, but have not yet had time/will to get it set up. The eccentric bulge problem has kind of turned me off altogether - I thought that I'd bought a "precision" press from Dillon.

It looks like I'm just gonna have to get comfortable with my as-yet-unused Star press and switch over to that for long line ammo. Too many presses - not enough time!

Or maybe just shoot factory ammo at the long line - that is my plan for the rest of this year!

Ho hum.

Guest- Guest

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

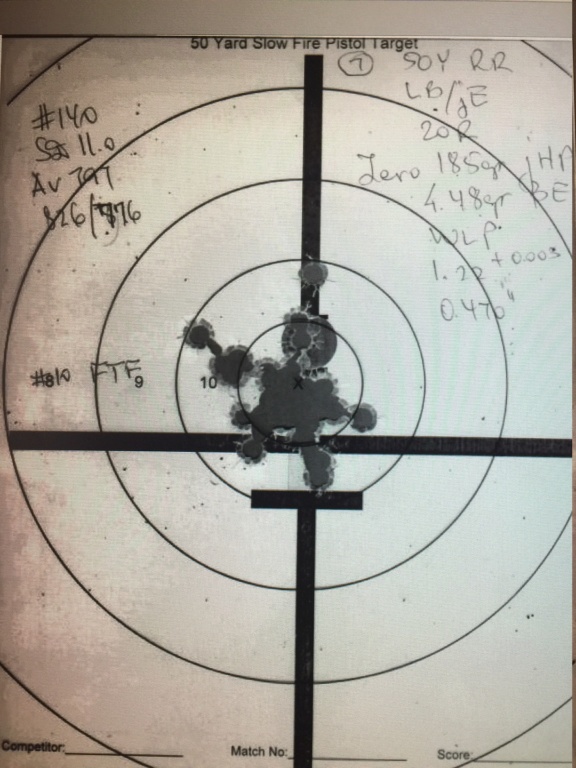

For those who think that thrown charges are inferior, let me first show you

These were two groups fired from the stock S&W 745 shown At 25 yards to use up some ammo left over from a chronograph session. The gun has not been “accurized” in anyway. There were about 12-16 rounds fired Per group and charge weights were 3.8, 4.0 and 4.2 grains. This is not my normal practice I was just shooting up the ammo.

So this tells me that ordinary thrown charges are perfectly fine for 25 yards and very likely acceptable for 50 yards. You have way better things to do to improve your pistol shooting than weighing charges.

These were two groups fired from the stock S&W 745 shown At 25 yards to use up some ammo left over from a chronograph session. The gun has not been “accurized” in anyway. There were about 12-16 rounds fired Per group and charge weights were 3.8, 4.0 and 4.2 grains. This is not my normal practice I was just shooting up the ammo.

So this tells me that ordinary thrown charges are perfectly fine for 25 yards and very likely acceptable for 50 yards. You have way better things to do to improve your pistol shooting than weighing charges.

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Wobbley wrote:These were two groups fired from the stock S&W 745 shown At 25 yards to use up some ammo left over from a chronograph session. The gun has not been “accurized” in anyway. There were about 12-16 rounds fired Per group and charge weights were 3.8, 4.0 and 4.2 grains. This is not my normal practice I was just shooting up the ammo.

So this tells me that ordinary thrown charges are perfectly fine for 25 yards and very likely acceptable for 50 yards.

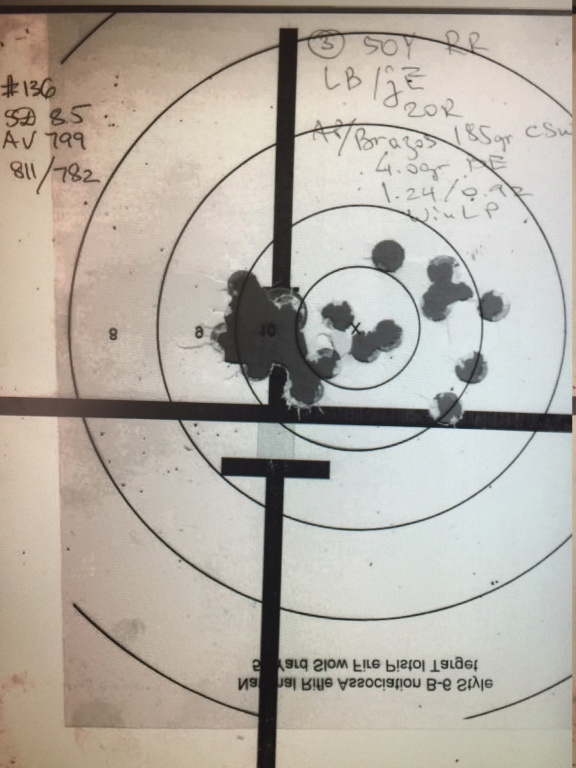

I would be interested in additional details, Ashely, how these groups were produced. If all shots are fired free hand at 25Y - these are awesome targets. However if these were fired from something like Ransom Rest - I would not consider results being that good. I also have rather reversed opinion - if ammo is tested with good results at 50Y, it would definitely do fine at 25Y too. Math / Geometry is quite difficult to overrule, and based on similar tri-angles theory 1" of the center at 25Y shot will be at least 2" of the center at 50Y. Translating this to B6 target it means that it will be in 9 ring at best.

On a flip side 1 3/4" of the center at 50Y will be cutting into X on B8 at 25Y. I recently tested few of my loads in Ransom Rest, - samples are below (sorry about quality - I took pictures of selective targets from the screen rather than attaching file with all scanned targets I shot).

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Greetings,

From many test targets with the 32 S&W Long WadCutter I have learned that 0.1 grains of powder increases/decreases the velocity about 30 FPS.

So, if you accept a charge of +/- 0.1 grain that is a potential 0.2 grain variation. Thus, a 60 FPS variation in velocity.

Cheers,

Dave

From many test targets with the 32 S&W Long WadCutter I have learned that 0.1 grains of powder increases/decreases the velocity about 30 FPS.

So, if you accept a charge of +/- 0.1 grain that is a potential 0.2 grain variation. Thus, a 60 FPS variation in velocity.

Cheers,

Dave

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

They were fired from a rest, my range bag with me aiming and pulling the trigger. I was just checking out the pistol to see if it preferred BE, 452AA, Red Dot, or 700X. Those were the two best using 452 and BE.

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

I concur with that, and would add that 60 FPS variation will translate into about 16.4 in Standard Deviation with 20 shots sample. Correlating to samples of test targets I posted and using suggested "measuring stick" my calculated powder charges variation was +/- 0.083 gr with worth SD, and about half of that with best. My notes in ammo boxes said +/- 0.06gr. I owe you explanation as to how I derive to my numbers when it comes to stating variables. I normally don't set charges when I start loading by throwing x-number of charges. I start loading right away, and adjusting as I go by weighting empty cartridges after priming them on station 2 (XL650/750), then drop charge and weight cartridge again. I trickle in/out powder manually to achieve desired charge with +/-0.02gr on my GemPro 250 electronic scale (side note - scale is always on, and I turn it off only when I feel it needs to be calibrated). Charged case goes back for bullet seating, and crimping whilst (thank you, Roy!) I check next case the same way. I repeat this with about dozen plus cases until I have six consecutive drops without needing to manually adjust powder charge. After I have that I lock powder bar (conditionally to number of total rounds I plan on loading) and go full bore only stopping to refill primers, bullets and cases. I re-check charges every 100-120 rounds by removing 6-7 consecutive charged cases on station 3 while maintaining my normal loading cadence. I then weight each charge by pouring powder in scale's tray. Highest deviation from base earns a label representing such +/- for entire batch, and subsequent designation for training or competition.fc60 wrote:Greetings,

From many test targets with the 32 S&W Long WadCutter I have learned that 0.1 grains of powder increases/decreases the velocity about 30 FPS.

So, if you accept a charge of +/- 0.1 grain that is a potential 0.2 grain variation. Thus, a 60 FPS variation in velocity.

Cheers,

Dave

Ashley,

Not sure if your range bag would be a good substitute the more formal testing device. So those are very good groups, IMHO.

AP

PhotoEscape- Admin

- Posts : 1541

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

Thank you all for great influx on info - it is certainly of great help for me in my learning process. T'would seem that at least for 32 S&W and gentle 38 SP LWC I do need to be extremely careful, as in the field shooting competitions we have here in Norway we sometimes find targets at 70 meters. With a +/- 10% charge deviation giving almost the same speed deviation, I don't believe that the grouping will be satisfactory. Also, I give myself time and kind of appreciate the meditation in taking my time with the reloading. But that's my situation.

If I may: for radjag and others unhappy with Dillon's toolheads not sitting tight, I thought I might suggest you had a look at Armanov's CNC machined toolheads for Dillons which are fastened to the press and cannot move. Otherwise, or in addition, an expander with a second expansion section might be worth trying, as that makes it much easier to have the bullet sit straight.

If I may: for radjag and others unhappy with Dillon's toolheads not sitting tight, I thought I might suggest you had a look at Armanov's CNC machined toolheads for Dillons which are fastened to the press and cannot move. Otherwise, or in addition, an expander with a second expansion section might be worth trying, as that makes it much easier to have the bullet sit straight.

Rocambole- Posts : 15

Join date : 2019-03-06

Re: Dillon Powder Measure issue

Re: Dillon Powder Measure issue

This is worth watching

Bench Report: Powder Measure Accuracy; Dillon, Arredondo, RCBS

https://www.youtube.com/watch?v=arz_AM8K8B8

Bench Report: Powder Measure Accuracy; Dillon, Arredondo, RCBS

https://www.youtube.com/watch?v=arz_AM8K8B8

ASchlem- Posts : 272

Join date : 2014-03-13

Location : IL

Page 2 of 3 •  1, 2, 3

1, 2, 3

Similar topics

Similar topics» Dillon vs Hornady powder measure on Dillon 550

» Help with Dillon powder measure.

» Powder Measure

» Dillon powder measure baffle

» Lee Auto-Drum Powder Measure and CFE Pistol powder metering

» Help with Dillon powder measure.

» Powder Measure

» Dillon powder measure baffle

» Lee Auto-Drum Powder Measure and CFE Pistol powder metering

Page 2 of 3

Permissions in this forum:

You cannot reply to topics in this forum