Range box from plywood

+13

jjfitch

zanemoseley

GME

cdrt

hg401

LenV

Wobbley

SteveT

243winxb

Jack H

oxbowbob

STEVE SAMELAK

corsara

17 posters

Page 1 of 3

Page 1 of 3 • 1, 2, 3

Range box from plywood

Range box from plywood

Found plans of a simple range pistol box on another site (link), however I don't have tools to cut out proper grooves for sturdy joints. Wondering if I can get away with simply butt joining the plywood by using glue, and maybe some reinforcing brackets on the inside?

corsara- Posts : 34

Join date : 2020-09-07

Re: Range box from plywood

Re: Range box from plywood

As long as you've got good glue and a outhouse load of bar clamps, plus a couple pcs of aluminum angle to use as temporary guides.

Besides adding gluing surface & strength, the grooves (assuming you did them carefully) serve to preserve your sanity while you fit the pieces.

Besides adding gluing surface & strength, the grooves (assuming you did them carefully) serve to preserve your sanity while you fit the pieces.

STEVE SAMELAK- Posts : 958

Join date : 2011-06-10

corsara likes this post

Re: Range box from plywood

Re: Range box from plywood

I would never trust plywood joints simply glued for a gun box. You're using plywood so I assume you have some tools. You need to have the sides securely attached to the top & bottom. You can make some pretty basic finger or even a couple large dovetail joints with minimal tools (check youtube). If that is out of the question, the very least I would do is use 3/4" (plywood or solid) material for the top & bottom (assuming you are using 1/2 for the rest of the box) and glue AND screw the sides to the top & bottom. These screws can be just functional or as decorative as you like. You can also add metal corners to the outside of the box (http://www.woodworkingparts.com/search.php?search_query=metal%20corners§ion=product)

Might sound like overkill, but it's better than a 45 on the ground.

Might sound like overkill, but it's better than a 45 on the ground.

oxbowbob- Posts : 171

Join date : 2016-12-31

Location : South Jersey

corsara likes this post

Re: Range box from plywood

Re: Range box from plywood

I built this old thing in the early 70s. Regular 1/2"plywood, butt joints glue and brads. Front panel and back panel are 1/4".

It has the corner metal bump things.

I don't use it to haul the guns anymore. So the tray has no clamps now.

I made it orange right after a match in Medford where my neighbor had an exact same Pachmyer box as mine and same type High Standards. I came back from targets and moved right in to his place. Not as embarassing as the time I got into the same color Pinto car as mine that my key did not start. I looked down between the seats and said that is not my purse. Then I looked up and saw my twin Pinto to the right. Then I noticed the ladies in the Laundromat with big windows in front laughing their heads off.

It has the corner metal bump things.

I don't use it to haul the guns anymore. So the tray has no clamps now.

I made it orange right after a match in Medford where my neighbor had an exact same Pachmyer box as mine and same type High Standards. I came back from targets and moved right in to his place. Not as embarassing as the time I got into the same color Pinto car as mine that my key did not start. I looked down between the seats and said that is not my purse. Then I looked up and saw my twin Pinto to the right. Then I noticed the ladies in the Laundromat with big windows in front laughing their heads off.

Jack H- Posts : 2699

Join date : 2011-06-10

Age : 75

Location : Oregon

troystaten and corsara like this post

Re: Range box from plywood

Re: Range box from plywood

Mine was made in 1963 @ age 18. Plywood, glue & small nails/brads. Made it a little to big, as i tried to get measurement from Gil Hebert's catalog. . Still works today.

- Attachments

243winxb- Posts : 344

Join date : 2013-12-02

Age : 80

Location : USA

corsara likes this post

Re: Range box from plywood

Re: Range box from plywood

Jack H wrote:Not as embarassing as the time I got into the same color Pinto car as mine that my key did not start.

I once unlocked and sat in a Honda the same color as mine, parked a few spaces closer to the store with a big van blocking the view. My first thought was someone had broken in and taken my stuff and left a bunch of other stuff. Then I noticed said thief had also replaced the stick shift with an automatic.

When I looked it up they claimed that there was about a 1 in 10 Million chance of two keys being the same. I should have bought a lottery ticket that day.

Jon Eulette and corsara like this post

Re: Range box from plywood

Re: Range box from plywood

Where do you live? Many towns have woodworkers clubs and some of these guys will build stuff for you for a fee. If you really want to do it yourself, there are literally hundreds of videos on you tube on building small tote boxes from plywood using various techniques.

One technique I find interesting is the wrap miter joint where the outer

Layer is not cut and the box is literally wrapped around the square bottom.

That said, I’d tend to box join the sides (and bottom) using “finger” joints. Take a look at the bullet boxes from Acme Bullet Company for sizes. I also would tend to use Epoxy glue rather than wood glue...

One technique I find interesting is the wrap miter joint where the outer

Layer is not cut and the box is literally wrapped around the square bottom.

That said, I’d tend to box join the sides (and bottom) using “finger” joints. Take a look at the bullet boxes from Acme Bullet Company for sizes. I also would tend to use Epoxy glue rather than wood glue...

Wobbley- Admin

- Posts : 4805

Join date : 2015-02-13

corsara likes this post

LenV- Posts : 4769

Join date : 2014-01-25

Age : 74

Location : Oregon

bdrake likes this post

Re: Range box from plywood

Re: Range box from plywood

Many places now have a "makersplace" where you can use woodworking and other tools. And often get instruction too.

hg401- Posts : 128

Join date : 2018-02-19

Re: Range box from plywood

Re: Range box from plywood

If I ever get some time, I want to build a new box a little prettier. The guns would lay flat in drawers like a machinists chest. Two guns worth. Maybe 4 in two drawers.

Jack H- Posts : 2699

Join date : 2011-06-10

Age : 75

Location : Oregon

chiz1180 likes this post

Re: Range box from plywood

Re: Range box from plywood

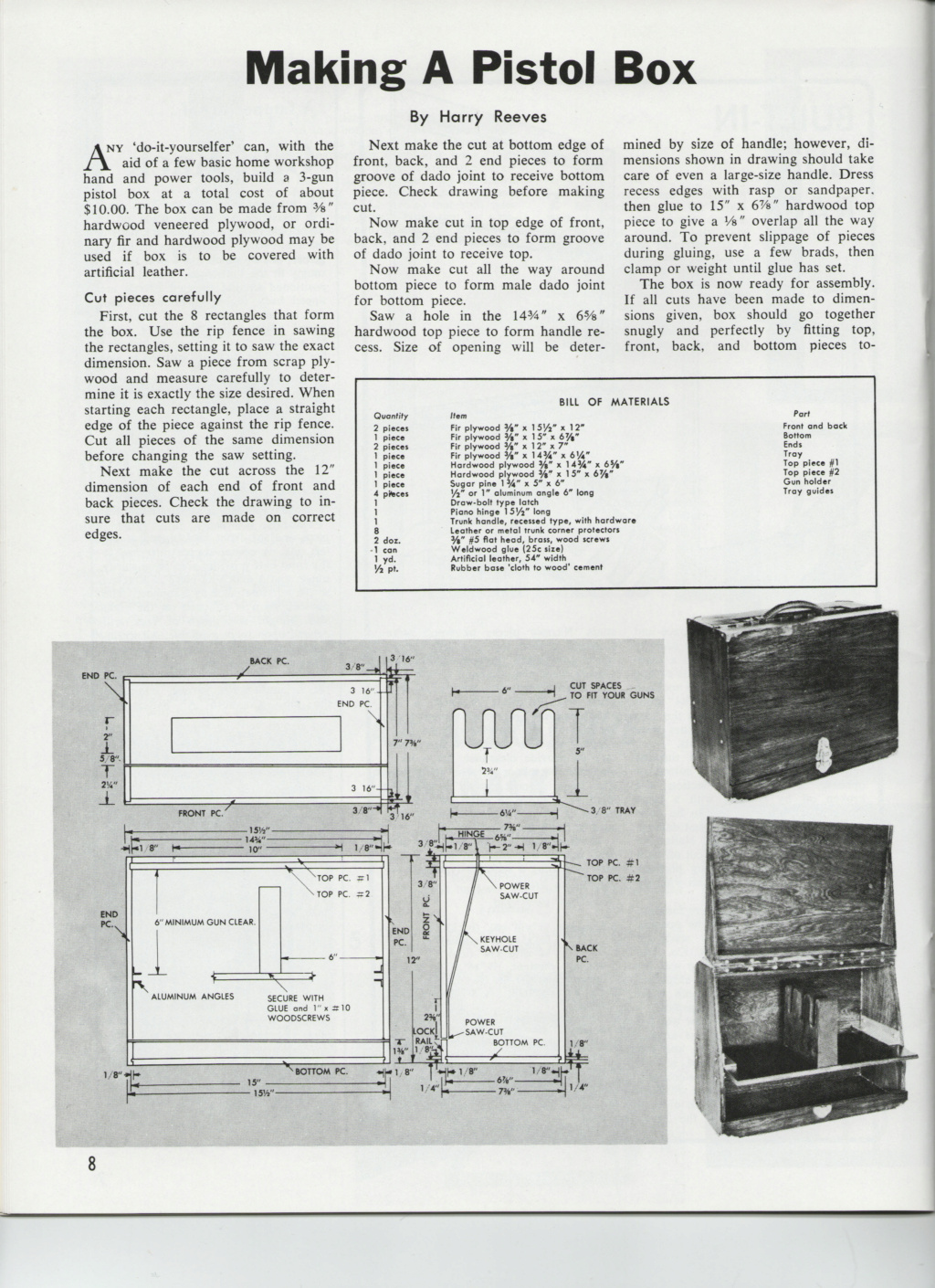

I can email you the plans for a gun box from an old NRA publication. If you want them, send me a PM with your email. I can also email some photos of the one built from the plans that I still have.

cdrt- Posts : 844

Join date : 2016-04-12

Location : Amarillo, Texas

cdrt- Posts : 844

Join date : 2016-04-12

Location : Amarillo, Texas

Re: Range box from plywood

Re: Range box from plywood

When you fasten the back to the top, bottom and sides, you add a great deal of strength. In my experience, you can get by with edge gluing; however, as Steve Samelak alluded to, keeping it all aligned can be an adventure. Speaking from experience, though, it's doable. I did it some 40 years ago with minimal tools. (although I now have a dedicated shop with all the big tools, including a 3 phase CNC router).

IF you want some extra strength, you can add dowels, but not in the conventional way. Glue the top, bottom and sides together an let the glue cure well - wait 24 hours. You'll need to either buy or make a drilling jig, but the idea is to drill holes at the glue joints, add glue to the holes, and drive in dowels. For 3/8" ply, I'd probably use 3/16" dowels. If I wanted to go overboard, I'd use steel dowels cut from some steel rod. For 1/2" ply, I'd go with 1/4" dowels.

For the best results, don't settle for home center plywood. It's junk. If you have a good wood supply nearby, see if they carry Baltic Birch (BB) plywood. Here are the advantages of BB:

More plies for any given thickness - 9mm (3/8") 7 plies; 12mm (1/2") 9 plies, 18mm (3/4'") 13 plies

The face veneer is much thicker than the usually stuff. You can actually sand it without worrying about sanding through.

Few, if any, voids

The plies are all hardwood

Made with exterior glue

As the name suggests, it's made of birch wood

Cut edges are so even

Lighter weight than softwood plywood

holds fasteners better than softwood plywood

Appearance similar to hard maple

Some leave the edges showing, as they can be considered decorative.

Cons: Does not take stain well, especially dark stains. Don't try dark ones.

The standard sizing for BB is a 5' x 5' sheet, which is more than enough for a Bullseye box. If you've every worked with plywood, you'll find BB much nicer than anything else you've ever used. Oh, and it's metric sized for thickness.

Finally, I recommend against using 18mm/3/4" plywood. Too heavy. In my never-to-be-humble opinion, 1/2" is about as thick as you'd want to go keep the weight at bay. If memory serves, most boxes were built of 3/8" ply back in the day. That's what Harry Reeves used in the piece cdrt was thoughtful enough post above.

One final option for adding strength. Get some aluminum angle, drill and countersink for screws and fasten it on the outside. The aluminum will save the wooden edges and reinforce at the same time. One thing, though. Do not get regular 6061 angle. the inside of the profile has a rounded (radiused) corner. To use it, you would need to use a router and a round over bit. You cannot pull that off if you have any metal fasteners in the corners, like brads. You would need an architectural grade of aluminum - 6063-T52, which has a square inside corner.

Sorry to be so long-winded, but there was a lot to cover. I hope this helps.

Gary

IF you want some extra strength, you can add dowels, but not in the conventional way. Glue the top, bottom and sides together an let the glue cure well - wait 24 hours. You'll need to either buy or make a drilling jig, but the idea is to drill holes at the glue joints, add glue to the holes, and drive in dowels. For 3/8" ply, I'd probably use 3/16" dowels. If I wanted to go overboard, I'd use steel dowels cut from some steel rod. For 1/2" ply, I'd go with 1/4" dowels.

For the best results, don't settle for home center plywood. It's junk. If you have a good wood supply nearby, see if they carry Baltic Birch (BB) plywood. Here are the advantages of BB:

More plies for any given thickness - 9mm (3/8") 7 plies; 12mm (1/2") 9 plies, 18mm (3/4'") 13 plies

The face veneer is much thicker than the usually stuff. You can actually sand it without worrying about sanding through.

Few, if any, voids

The plies are all hardwood

Made with exterior glue

As the name suggests, it's made of birch wood

Cut edges are so even

Lighter weight than softwood plywood

holds fasteners better than softwood plywood

Appearance similar to hard maple

Some leave the edges showing, as they can be considered decorative.

Cons: Does not take stain well, especially dark stains. Don't try dark ones.

The standard sizing for BB is a 5' x 5' sheet, which is more than enough for a Bullseye box. If you've every worked with plywood, you'll find BB much nicer than anything else you've ever used. Oh, and it's metric sized for thickness.

Finally, I recommend against using 18mm/3/4" plywood. Too heavy. In my never-to-be-humble opinion, 1/2" is about as thick as you'd want to go keep the weight at bay. If memory serves, most boxes were built of 3/8" ply back in the day. That's what Harry Reeves used in the piece cdrt was thoughtful enough post above.

One final option for adding strength. Get some aluminum angle, drill and countersink for screws and fasten it on the outside. The aluminum will save the wooden edges and reinforce at the same time. One thing, though. Do not get regular 6061 angle. the inside of the profile has a rounded (radiused) corner. To use it, you would need to use a router and a round over bit. You cannot pull that off if you have any metal fasteners in the corners, like brads. You would need an architectural grade of aluminum - 6063-T52, which has a square inside corner.

Sorry to be so long-winded, but there was a lot to cover. I hope this helps.

Gary

GME- Posts : 152

Join date : 2020-09-27

Age : 75

Location : Gig Harbor, WA

bruce martindale, lakemurrayman and corsara like this post

Re: Range box from plywood

Re: Range box from plywood

I can't imagine trying to install several edge dowels in 3/8" ply, that's a good way to ruin your box. Use dovetails, box joints or just be content with glue and brad nails.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Range box from plywood

Re: Range box from plywood

zanemoseley wrote:I can't imagine trying to install several edge dowels in 3/8" ply, that's a good way to ruin your box. Use dovetails, box joints or just be content with glue and brad nails.

Personally, I prefer box joints for plywood. But then, I have a CNC router and joinery jig that allows me to cut them perfectly every time. I also have a Leigh jig, if I want to do it manually. It appears the OP has limited tool resources, so neither box joints nor dovetail appear to be an option.

As far as drilling for dowels is concerned, the the photo below shows a drill jig that goes a long way toward getting a good perpendicular hole. Here's also a link to the product: https://www.amazon.com/Big-Gator-Tools-STD1000DGNP-V-Drill/dp/B0061FY004/ref=sr_1_5?crid=1OLEE4CY854KQ&dchild=1&keywords=drill+guides+for+portable+drills&qid=1603558618&sprefix=drill+guide%2Caps%2C226&sr=8-5

This company also makes guides for thread taps to keep the tap perpendicular. I have sets in both imperial and metric. For me, they were well worth the money.

Take the information/suggestions I've given, or don't. I've used the techniques, so I know they work. I've even done it freehand, but admit freehand is risky.

Sorry I didn't mention the drill guide in my earlier post. IMO, it's an important component.

- Attachments

GME- Posts : 152

Join date : 2020-09-27

Age : 75

Location : Gig Harbor, WA

Re: Range box from plywood

Re: Range box from plywood

I've got 4 CNC routes at work and have worked in engineering for custom cabinetry for 14yrs. I'm just staying if you're drilling 3/8" ply for a 3/16" dowel you have almost no room for error and at risk of blowing out the hole. Also if you squirt glue in your dowel hole then hammer in the dowel the hydraulic pressure can bulge or even blow out the thin wall left.

What's even better than brads for strength is narrow crown staples but leaves more damage to the wood face but can be filled.

You could also cut rabbets and dados for joinery if you have a table saw, best results with a dado blade.

What's even better than brads for strength is narrow crown staples but leaves more damage to the wood face but can be filled.

You could also cut rabbets and dados for joinery if you have a table saw, best results with a dado blade.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Butt joints!

Butt joints!

corsara wrote:Found plans of a simple range pistol box on another site (link), however I don't have tools to cut out proper grooves for sturdy joints. Wondering if I can get away with simply butt joining the plywood by using glue, and maybe some reinforcing brackets on the inside?

Butt joints can be reinforced by cutting 3/4 X 3/4 inch square stock glued into the corners to add strength! Smiles

jjfitch- Posts : 142

Join date : 2012-09-01

Age : 77

Location : The Beautiful Pacific Northwest

chopper likes this post

Re: Range box from plywood

Re: Range box from plywood

This video shows a technique using large “box joints” and dowels to build a sturdy box from birch plywood. In this he uses ordinary wood glue and I don’t believe there is much clamping. He’s only using hand tools and no power tool joinery is used. But he likely has a few decades of skills and experience.

https://youtu.be/lMH5WX7gYME

If I were building a box I would use a good clear 24 hour cure epoxy to get the added strength over ordinary wood glue.

https://youtu.be/lMH5WX7gYME

If I were building a box I would use a good clear 24 hour cure epoxy to get the added strength over ordinary wood glue.

Wobbley- Admin

- Posts : 4805

Join date : 2015-02-13

Re: Range box from plywood

Re: Range box from plywood

You could also cut rabbets and dados for joinery if you have a table saw, best results with a dado blade.

True, or cut them on a router table. If you've got a table saw, you can buy or make a jig for cutting box joints.

Butt joints can be reinforced by cutting 3/4 X 3/4 inch square stock glued into the corners to add strength!

Yup. A time honored method. It's all face grain and pretty darned strong.

This video shows a technique using large “box joints” and dowels to build a sturdy box from birch plywood. In this he uses ordinary wood glue and I don’t believe there is much clamping. He’s only using hand tools and no power tool joinery is used. But he likely has a few decades of skills and experience.

https://youtu.be/lMH5WX7gYME

If I were building a box I would use a good clear 24 hour cure epoxy to get the added strength over ordinary wood glue.

The guy in the video is skilled with a Japanese saw. I can't pull it off. I can't keep a straight enough line, even clamping on a cutting guide help.

Good call on the epoxy, Wobbley. While epoxy is a reasonable choice, it sure can be messy, though. It's not like PVA where you can wipe the excess off with a damp cloth, or fairly easily remove excess dried glue with a cabinet scraper.

On the other hand epoxy is heads and shoulders above PVA for gap filling properties. The lack of gap filling properties a, if not the, major reason for PVA being a less than ideal choice for gluing end grain. If the OP is going to paint the box, epoxy messiness may not be an issue. Sand off the messy parts and paint them over.

A tip. If using a 1:1 mix ratio epoxy, weigh the resin and hardener vs measuring by volume - at least for smaller batches. I have difficulty getting the proper mix by volume on small batches, which is mostly what I use it for. You need an accurate scale for this to work, but with one, you get a perfect ratio every time. I recently used a scale with West System epoxy, which does not use a 1:1 ratio - one of my pumps broke. Worked great.

Here's another thought. Finish the box with something like truck bed liner spray. You can get it at home centers in spray cans. It will cover up most any cosmetic issues and be pretty darned durable to boot. I think your are limited to black, so that's a consideration. I think most, if not all, of the old school commercial boxes were black, but they were covered with a thin, black synthetic fabric. Might want to keep the interior natural, or paint it white. Black makes it harder to see inside.

True, or cut them on a router table. If you've got a table saw, you can buy or make a jig for cutting box joints.

Butt joints can be reinforced by cutting 3/4 X 3/4 inch square stock glued into the corners to add strength!

Yup. A time honored method. It's all face grain and pretty darned strong.

This video shows a technique using large “box joints” and dowels to build a sturdy box from birch plywood. In this he uses ordinary wood glue and I don’t believe there is much clamping. He’s only using hand tools and no power tool joinery is used. But he likely has a few decades of skills and experience.

https://youtu.be/lMH5WX7gYME

If I were building a box I would use a good clear 24 hour cure epoxy to get the added strength over ordinary wood glue.

The guy in the video is skilled with a Japanese saw. I can't pull it off. I can't keep a straight enough line, even clamping on a cutting guide help.

Good call on the epoxy, Wobbley. While epoxy is a reasonable choice, it sure can be messy, though. It's not like PVA where you can wipe the excess off with a damp cloth, or fairly easily remove excess dried glue with a cabinet scraper.

On the other hand epoxy is heads and shoulders above PVA for gap filling properties. The lack of gap filling properties a, if not the, major reason for PVA being a less than ideal choice for gluing end grain. If the OP is going to paint the box, epoxy messiness may not be an issue. Sand off the messy parts and paint them over.

A tip. If using a 1:1 mix ratio epoxy, weigh the resin and hardener vs measuring by volume - at least for smaller batches. I have difficulty getting the proper mix by volume on small batches, which is mostly what I use it for. You need an accurate scale for this to work, but with one, you get a perfect ratio every time. I recently used a scale with West System epoxy, which does not use a 1:1 ratio - one of my pumps broke. Worked great.

Here's another thought. Finish the box with something like truck bed liner spray. You can get it at home centers in spray cans. It will cover up most any cosmetic issues and be pretty darned durable to boot. I think your are limited to black, so that's a consideration. I think most, if not all, of the old school commercial boxes were black, but they were covered with a thin, black synthetic fabric. Might want to keep the interior natural, or paint it white. Black makes it harder to see inside.

GME- Posts : 152

Join date : 2020-09-27

Age : 75

Location : Gig Harbor, WA

Re: Range box from plywood

Re: Range box from plywood

It's hard to beat good old Titebond wood glue. Epoxy is a mess to deal with. The 3/4"x3/4" reinforcement blocks are a decent idea and would be easy to do.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

cdrt- Posts : 844

Join date : 2016-04-12

Location : Amarillo, Texas

Re: Range box from plywood

Re: Range box from plywood

The way to beat the epoxy mess is to not let it stick where you don’t want it to stick. So masking tape covered with clear plastic shipping tape works well.

Wobbley- Admin

- Posts : 4805

Join date : 2015-02-13

Re: Range box from plywood

Re: Range box from plywood

The top and bottom can be made from thicker ply (3/4") if you want to use dowels, screws or similar type device. I have done this on plywood cases with good success in the past. Aluminum angle would also make a good reinforcing bracket as well. I built my gun box with an aluminum angle flat bar frame, aluminum sheet top and bottom with composite sides.

As far as adhesive, assuming your joint fitment is good PVA (Titebond) is more than adequate, the biggest issue with epoxy is higher cost and the need for experience to have proper mixing. An alternative could be a polyurethane construction adhesive (e.g. liquid nails, or loctite power grab), but more expensive than a PVA. The key to any adhesive method is good joint fitment and good clamping.

As far as adhesive, assuming your joint fitment is good PVA (Titebond) is more than adequate, the biggest issue with epoxy is higher cost and the need for experience to have proper mixing. An alternative could be a polyurethane construction adhesive (e.g. liquid nails, or loctite power grab), but more expensive than a PVA. The key to any adhesive method is good joint fitment and good clamping.

chiz1180- Posts : 1507

Join date : 2019-05-29

Location : Ohio

Re: Range box from plywood

Re: Range box from plywood

Hey guys, I'm the OP. Thank you so much for all the suggestions and advice, I really appreciate it and learned a lot! Some of you guessed right---I have a very limited set of tools. Also, I'm in Canada, and there is no woodworking lab / carpentry shop that I can get access to. So, here is what I did today, followed by photos:

1) Revised the original schematic a little bit, added a bit more length and a little more headroom.

2) Bought two sheets of baltic birch plywood. One 1/2 and one 1/4 thickness. I decided to go with 1/2 for top and bottom as opposed to the suggested 3/4, because the wood shop I went to didn't have any in stock. Also bought Titebond Original wood glue, and #6 screws.

3) I only used a Jigsaw and a bit driver for everything. Other tools that I have are a reciprocating saw and a small miter saw, both of which did not participate in the task for obvious reasons. I struggled a lot with the Jigsaw, my cuts are not perfect, but will do.

4) As you can see in the pics below, I went with simple butt joints, supported by screws and glue. I drilled pilot holes, countersank, #6 screws and glue. Since the sides and back are 1/4, I put the two vertical extra pieces in the inside corners, because without them I couldn't really screw the back to the sides. I used nails. Everything test-fitted, then glued and all screws put in. Honestly, I think it's plenty strong!

NEXT: when glue dries, sand really well and paint. I'll also put corners. Didn't have a chance to do the door today, but will probably tomorrow. It will be attached with a piano hinge, which I bought from Home Depot today along with the screws (baltic birch from another place). Then I'm yet to figure out what to do inside. One thing at a time I'll keep the thread updated! Keep the suggestions coming---I may not be replying, but I'm reading carefully every single comment!

I'll keep the thread updated! Keep the suggestions coming---I may not be replying, but I'm reading carefully every single comment!

1) Revised the original schematic a little bit, added a bit more length and a little more headroom.

2) Bought two sheets of baltic birch plywood. One 1/2 and one 1/4 thickness. I decided to go with 1/2 for top and bottom as opposed to the suggested 3/4, because the wood shop I went to didn't have any in stock. Also bought Titebond Original wood glue, and #6 screws.

3) I only used a Jigsaw and a bit driver for everything. Other tools that I have are a reciprocating saw and a small miter saw, both of which did not participate in the task for obvious reasons. I struggled a lot with the Jigsaw, my cuts are not perfect, but will do.

4) As you can see in the pics below, I went with simple butt joints, supported by screws and glue. I drilled pilot holes, countersank, #6 screws and glue. Since the sides and back are 1/4, I put the two vertical extra pieces in the inside corners, because without them I couldn't really screw the back to the sides. I used nails. Everything test-fitted, then glued and all screws put in. Honestly, I think it's plenty strong!

NEXT: when glue dries, sand really well and paint. I'll also put corners. Didn't have a chance to do the door today, but will probably tomorrow. It will be attached with a piano hinge, which I bought from Home Depot today along with the screws (baltic birch from another place). Then I'm yet to figure out what to do inside. One thing at a time

Last edited by corsara on Thu Nov 12, 2020 11:15 am; edited 1 time in total

corsara- Posts : 34

Join date : 2020-09-07

243winxb and chiz1180 like this post

Page 1 of 3 • 1, 2, 3

Similar topics

Similar topics» Range Review - On Target Range - Crystal Lake IL

» Stock Range Officer Range Report

» Another ( !)Question on “Range Officer” and “Range Officer Target”

» Need a new range box

» Looking for a range box

» Stock Range Officer Range Report

» Another ( !)Question on “Range Officer” and “Range Officer Target”

» Need a new range box

» Looking for a range box

Page 1 of 3

Permissions in this forum:

You cannot reply to topics in this forum