Nelson conversion slide crack

+7

chiz1180

DA/SA

Slamfire

farmboy

rich.tullo

james r chapman

BHeintz

11 posters

Page 1 of 1

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

Email the pics to Nelson.

james r chapman- Admin

- Posts : 6373

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

I sent them a email.

BHeintz- Posts : 82

Join date : 2012-01-19

Age : 38

Location : IL

james r chapman likes this post

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

I had one crack after about +100,000 rounds and dry firing. They replaced the slide no questions asked.

rich.tullo- Posts : 2006

Join date : 2015-03-27

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

I talked to Larry. My conversion is more than 2 years old so it's out of warranty. A new slide would be $110.00

BHeintz- Posts : 82

Join date : 2012-01-19

Age : 38

Location : IL

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

I have had more than one Nelson slide crack.

farmboy- Posts : 295

Join date : 2012-10-04

Location : Wichita, KS

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

Did yours crack in the same spot? Did you just have them replace the slide? Do you know the round count on the cracked slides?

BHeintz- Posts : 82

Join date : 2012-01-19

Age : 38

Location : IL

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

I can't see the cracks in the pictures, maybe an arrow to them would reveal them.

Don't have a Nelson conversion, but based on the pictures, looks like there is a steel breech block held in place by an aluminum slide.

And that is the problem. Aluminum has a finite fatigue lifetime. So does steel if the sections are not thick enough. Make a steel structure thick enough, the load low enough, and you can keep steel below the fatigue limit. If you follow the link, you will see, aluminum will always fail at some fatigue cycle. Make it thicker, it will take longer to fail, but fail it will.

So, what we are seeing are data points for the amount of cycles it takes for a Nelson slide to fail.

I would suggest, buy extra slides and install them when they finally crack. And buy enough so when Nelson stops making the things, you have spares. That's the nature of the beast.

Or, buy a steel pistol, and shoot it forever. Replacing springs as they wear out, of course

Don't have a Nelson conversion, but based on the pictures, looks like there is a steel breech block held in place by an aluminum slide.

And that is the problem. Aluminum has a finite fatigue lifetime. So does steel if the sections are not thick enough. Make a steel structure thick enough, the load low enough, and you can keep steel below the fatigue limit. If you follow the link, you will see, aluminum will always fail at some fatigue cycle. Make it thicker, it will take longer to fail, but fail it will.

So, what we are seeing are data points for the amount of cycles it takes for a Nelson slide to fail.

I would suggest, buy extra slides and install them when they finally crack. And buy enough so when Nelson stops making the things, you have spares. That's the nature of the beast.

Or, buy a steel pistol, and shoot it forever. Replacing springs as they wear out, of course

Slamfire- Posts : 224

Join date : 2016-04-19

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

I believe it is the steel breech block insert that cracked.Slamfire wrote:

Or, buy a steel pistol, and shoot it forever. Replacing springs as they wear out, of course

DA/SA- Posts : 1508

Join date : 2017-10-09

Age : 68

Location : Southeast Florida

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

I have seen Hammerli 208/215's, Model 41's, Rugers, and even 1911s fail all of these are steel guns. Anything mechanical can and will fail at some point.Slamfire wrote:Or, buy a steel pistol, and shoot it forever. Replacing springs as they wear out, of course

chiz1180- Posts : 1510

Join date : 2019-05-29

Location : Ohio

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

I worked for years in a steel mill, and I was the only person there with a Metallurgy degree. I encountered lots of steel parts that had a metallurgical failure because they were the wrong composition, so they did not achieve the right microstructure when the right heat treatment was used, or they were the right material with the wrong or no heat treatment.

Still, give me something made out of steel, if it is cyclically stressed.

Still, give me something made out of steel, if it is cyclically stressed.

NuJudge- Posts : 263

Join date : 2011-09-22

Age : 67

Location : SE Michigan

Richard Ashmore, Jon Eulette and MarkOue like this post

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

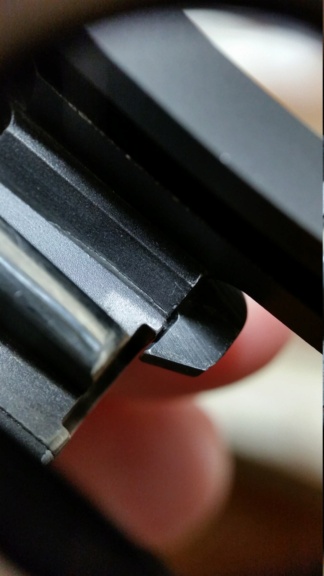

It is the slides that are cracking. On my slide, the crack is under the extractor, running parallel to the breech block. If you click on the picture , it should be easy to see. And for steel guns, I have gone through two Ruger frames, and one upper . Ruger replaced the whole gun the first time. The hammer pin hole in Ruger frames, deforms and opens up. Once the holes get big enough, I started having issues with hammer fallow.Slamfire wrote:I can't see the cracks in the pictures, maybe an arrow to them would reveal them.

Don't have a Nelson conversion, but based on the pictures, looks like there is a steel breech block held in place by an aluminum slide.

And that is the problem. Aluminum has a finite fatigue lifetime. So does steel if the sections are not thick enough. Make a steel structure thick enough, the load low enough, and you can keep steel below the fatigue limit. If you follow the link, you will see, aluminum will always fail at some fatigue cycle. Make it thicker, it will take longer to fail, but fail it will.

So, what we are seeing are data points for the amount of cycles it takes for a Nelson slide to fail.

I would suggest, buy extra slides and install them when they finally crack. And buy enough so when Nelson stops making the things, you have spares. That's the nature of the beast.

Or, buy a steel pistol, and shoot it forever. Replacing springs as they wear out, of course

Last edited by BHeintz on Wed Feb 17, 2021 7:07 am; edited 1 time in total

BHeintz- Posts : 82

Join date : 2012-01-19

Age : 38

Location : IL

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

I also wanted to mention my Nelson was a generation 2, they are now on generation 4. So these issues might not occur in the newest conversions.

BHeintz- Posts : 82

Join date : 2012-01-19

Age : 38

Location : IL

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

what letter is in the SN?BHeintz wrote:I also wanted to mention my Nelson was a generation 2, they are now on generation 4. So these issues might not occur in the newest conversions.

chiz1180- Posts : 1510

Join date : 2019-05-29

Location : Ohio

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

Mine has the letter B. The letters represent each generation. Letter A would be first generation, D would be 4th generation .

BHeintz- Posts : 82

Join date : 2012-01-19

Age : 38

Location : IL

chiz1180 likes this post

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

If you put it in a drill press and put a small drill bit in the chuck, then drill a hole at the end of the crack, will that stop the crack from spreading?

CO1Mtn- Posts : 300

Join date : 2017-06-22

Location : Pennsylvania

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

Perhaps. But the hole has to be big enough. For most cracks that’s usually around .093 maybe as low as .063.CO1Mtn wrote:If you put it in a drill press and put a small drill bit in the chuck, then drill a hole at the end of the crack, will that stop the crack from spreading?

Wobbley- Admin

- Posts : 4808

Join date : 2015-02-13

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

CO1Mtn wrote:If you put it in a drill press and put a small drill bit in the chuck, then drill a hole at the end of the crack, will that stop the crack from spreading?

That is a typical procedure in crack repair/mitigation. However, as a replacement was quoted at $110, from my view that would be the best option. From the perspective of machining and finishing costs, $110 is a good deal.

chiz1180- Posts : 1510

Join date : 2019-05-29

Location : Ohio

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

CO1Mtn wrote:If you put it in a drill press and put a small drill bit in the chuck, then drill a hole at the end of the crack, will that stop the crack from spreading?

That is a typical procedure in crack repair/mitigation. However, as a replacement was quoted at $110, from my view that would be the best option. From the perspective of machining and finishing costs, $110 is a good deal.

chiz1180- Posts : 1510

Join date : 2019-05-29

Location : Ohio

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

After taking the breech block out of the slide I could see how far the crack went. It goes from the front of the slide, to a cut out for the extractor. I don't think the crack will affect anything the way it is now. As far as I can tell the slide cracked because it was making contact with the barrel. If you look at the picture from Farmboy, you can see the black finish warn off from contact with the barrel. My slide looked similar. Im holding off on replacing the slide for now. I just filed down the areas of the slide that were contacting the barrel.

BHeintz- Posts : 82

Join date : 2012-01-19

Age : 38

Location : IL

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

I not sure how you can miss the crack in my photo - it is on the right side of the firing pin block ,as one looks at it in the photo, on top of the slide and runs 3/4 of the length of the slide.Slamfire wrote:I can't see the cracks in the pictures, maybe an arrow to them would reveal them.

farmboy- Posts : 295

Join date : 2012-10-04

Location : Wichita, KS

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

Inside sharp corners are a weak point in any mechanical part.

A .060 inside radius would add enough strength that cracks would be rare or eliminated.

A larger outside radius would need to be added to the breach block to clear.

These small changes would be easy to add and would show that Nelson listens to customers

with cracked slides and other issues if any exist.

If they want $130 for a new slide, $100 with the return of a cracked slide would be a nice gesture.

Larry and Kevin are stand up guys and I'm sure want to produce a problem free unit.

The cost of this unit high and the quality should reflect that.

G

A .060 inside radius would add enough strength that cracks would be rare or eliminated.

A larger outside radius would need to be added to the breach block to clear.

These small changes would be easy to add and would show that Nelson listens to customers

with cracked slides and other issues if any exist.

If they want $130 for a new slide, $100 with the return of a cracked slide would be a nice gesture.

Larry and Kevin are stand up guys and I'm sure want to produce a problem free unit.

The cost of this unit high and the quality should reflect that.

G

Gary Collette- Posts : 124

Join date : 2020-01-21

Re: Nelson conversion slide crack

Re: Nelson conversion slide crack

Not certain if what I see is a crack or a machine tool cut.farmboy wrote:I not sure how you can miss the crack in my photo - it is on the right side of the firing pin block ,as one looks at it in the photo, on top of the slide and runs 3/4 of the length of the slide.Slamfire wrote:I can't see the cracks in the pictures, maybe an arrow to them would reveal them.

It is best to replace any structure that has a crack in the load path.

Slamfire- Posts : 224

Join date : 2016-04-19

Similar topics

Similar topics» Nelson Conversion slide racker?

» Marvel vs. Nelson .22 Conversion Slide

» marvel conversion vs nelson conversion

» Nelson Conversion

» Nelson Conversion Kit

» Marvel vs. Nelson .22 Conversion Slide

» marvel conversion vs nelson conversion

» Nelson Conversion

» Nelson Conversion Kit

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum