Learning through mistake - Skirt blew off

+8

oldsalt444

CR10X

dlevasse

Wobbley

rburk

john bickar

fc60

beeser

12 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Learning through mistake - Skirt blew off

Learning through mistake - Skirt blew off

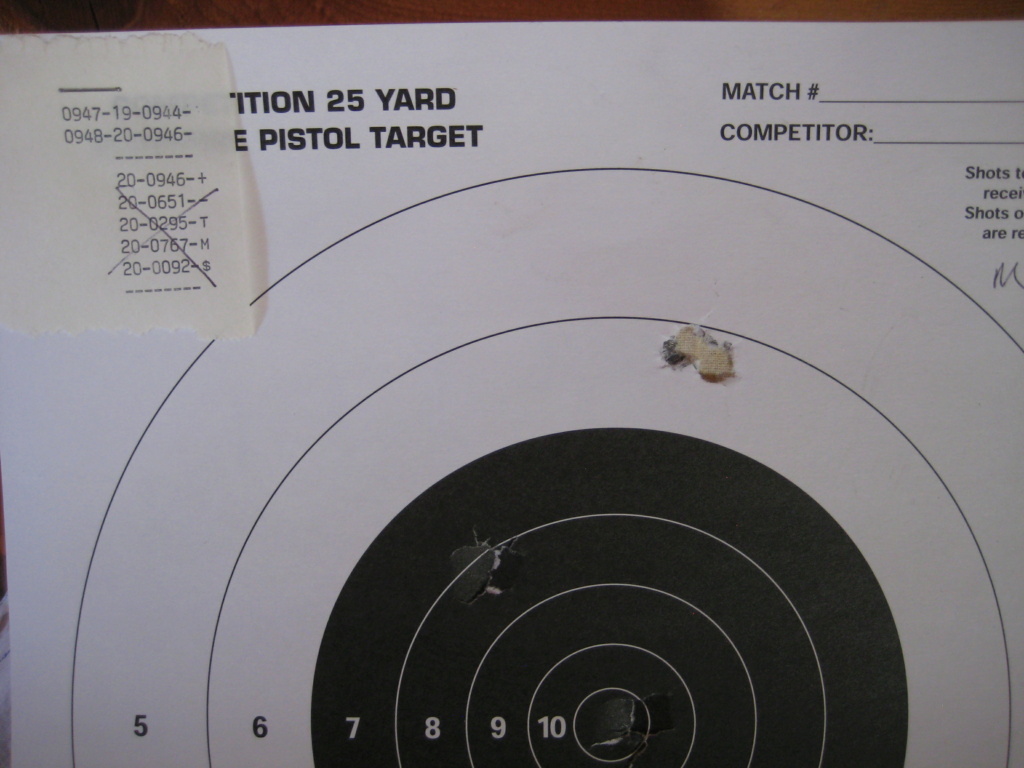

The first time casting and loading a 32 cal. HBWC projectile produced the result shown in pic. below. I'm almost certain it's a situation where the skirt blew off. The 2 through holes above the 2 partials in the black are the result of only 2 shots fired. I casted the projectiles using a new MP mold and probably the culprit 40:1 lead/tin. The load was 1.4 grs. of N310, the same used in a few other 98 gr. HBWCs, which didn't have skirts that separated. And yes, I made sure the barrel was clear before firing the 2nd round. I'll cast a few more except with a harder alloy, a minimum of 20:1. All part of the learning process I guess.

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

What method are you lubing the bullets?

Also, unable to enlarge the thumbnail image.

Cheers,

Dave

Also, unable to enlarge the thumbnail image.

Cheers,

Dave

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

I remember the last time I went to the range and my skirt blew off.

The Cub Scouts in attendance sure learned some things that day.

The Cub Scouts in attendance sure learned some things that day.

john bickar- Posts : 2280

Join date : 2011-07-09

Age : 100

Location : Menlo Park, CA

jwax, james r chapman, Allen Barnett, Outthere, Wobbley, R*P*DR*, Larryb and like this post

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

I used a Star Lubesizer and RCBS lube, beeswax and Alox I believe. The sizing die was the same diameter as cast, .314".fc60 wrote:What method are you lubing the bullets?

Also, unable to enlarge the thumbnail image.

Cheers,

Dave

Edit: The RCBS lube is paraffin and beeswax.

Last edited by beeser on Sat Feb 13, 2021 12:00 pm; edited 1 time in total

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

What's additionally strange is the velocities of 944 and 946. The same weight Speers using the same N310 load averaged about 760. Is it because of the skirt coming off? I wonder if my Oehler chrono even picked up the correct verlocities with separate pieces passing through the gates.

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

If you want to cast harder, throw in some antimony.

rburk- Posts : 166

Join date : 2019-09-26

Location : SoCal

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

I'm trying to stay away from antimony for hardening. If it can't be accomplished with tin alone I may give it a try.rburk wrote:If you want to cast harder, throw in some antimony.

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

beeser wrote:I'm trying to stay away from antimony for hardening. If it can't be accomplished with tin alone I may give it a try.rburk wrote:If you want to cast harder, throw in some antimony.

Tinhardening toos out at about BHN 12-15 or so. 6% antimony and 2% tin gets you 18 or so. Antimony also increases tensile strength, tho it isn’t high to begin with.

That said, blowing the skirt off is usually from too high of a muzzle pressure. The load maybe too hot.

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-13

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

Can this bullets be cold upset form lead wire ?

dlevasse- Posts : 37

Join date : 2021-01-13

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

Are you sure your molds were hot enough to get a full fill without flaws? That skirt area is pretty thin. As this is a HBWC, any minor casting flaws in the skirt area could cause some weakness.

Otherwise, adding some additional tin (your second choice alloy 20:1 might help if its a filling issue. Sometimes new molds can have issues depending on the surface protectants used.

Otherwise, adding some additional tin (your second choice alloy 20:1 might help if its a filling issue. Sometimes new molds can have issues depending on the surface protectants used.

CR10X- Posts : 1777

Join date : 2011-06-17

Location : NC

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

There could've been flaws in the casting as this was among the first of my castings. I didn't realize until later that pure lead and alloys with a greater lead content require higher temperatures. The new mold was thoroughly cleaned with brake cleaner before use. I believe that was the recommendation from MP.CR10X wrote:Are you sure your molds were hot enough to get a full fill without flaws? That skirt area is pretty thin. As this is a HBWC, any minor casting flaws in the skirt area could cause some weakness.

Otherwise, adding some additional tin (your second choice alloy 20:1 might help if its a filling issue. Sometimes new molds can have issues depending on the surface protectants used.

The next attempt at casting this projectile will be with 20:1. Hopefully that produces better results.

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

dlevasse wrote:Can this bullets be cold upset form lead wire ?

If by "cold upset" you mean swaged, the answer is yes. I'm working on making the dies for it now. Swaging is also a task that is new to me.

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

I've seen this before with 32's. Usually it means the load is just a bit too hot. Maybe try 0.2 gr less.

Your 40:1 alloy is about 8 BHN which is relatively soft. 20:1 is about 10 BHN. That might do the trick, but you can still get good obturation with 12-13 BHN. Tin decreases surface tension so the mold fills out better, but it doesn't add a lot of strength. Antimony is what toughens up the alloy.

Have you tried Roto-Metals?

https://www.rotometals.com/bullet-casting-alloys/?sort=bestselling&limit=100&mode=1

Your 40:1 alloy is about 8 BHN which is relatively soft. 20:1 is about 10 BHN. That might do the trick, but you can still get good obturation with 12-13 BHN. Tin decreases surface tension so the mold fills out better, but it doesn't add a lot of strength. Antimony is what toughens up the alloy.

Have you tried Roto-Metals?

https://www.rotometals.com/bullet-casting-alloys/?sort=bestselling&limit=100&mode=1

oldsalt444- Posts : 288

Join date : 2011-10-27

Location : Commiefornia

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

I have no idea if this link will work. I read a article a while back said some brake cleaners could kill you if heated. My under standing is it takes very little residue to be very harm full "hydrogen chloride and possibly phosgene". Look for articles on TIG welding aluminum.

https://www.brewracingframes.com/safety-alert-brake-cleaner--phosgene-gas.html

https://www.brewracingframes.com/safety-alert-brake-cleaner--phosgene-gas.html

dlevasse- Posts : 37

Join date : 2021-01-13

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

I'm ordering all of my lead rom RotoMetals and just placed another one for some harder lead/tin and Lyman #2, which has some antimony in it. Hopefully I have better results with my second batch of HBWCs. I plan to dial down the powder charge a little too.oldsalt444 wrote:I've seen this before with 32's. Usually it means the load is just a bit too hot. Maybe try 0.2 gr less.

Your 40:1 alloy is about 8 BHN which is relatively soft. 20:1 is about 10 BHN. That might do the trick, but you can still get good obturation with 12-13 BHN. Tin decreases surface tension so the mold fills out better, but it doesn't add a lot of strength. Antimony is what toughens up the alloy.

Have you tried Roto-Metals?

https://www.rotometals.com/bullet-casting-alloys/?sort=bestselling&limit=100&mode=1

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

The brake cleaner I used doesn't contain those chemicals but it's good to know. Thanksdlevasse wrote:I have no idea if this link will work. I read a article a while back said some brake cleaners could kill you if heated. My under standing is it takes very little residue to be very harm full "hydrogen chloride and possibly phosgene". Look for articles on TIG welding aluminum.

https://www.brewracingframes.com/safety-alert-brake-cleaner--phosgene-gas.html

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

Hello beeser,beeser wrote:I'm trying to stay away from antimony for hardening. If it can't be accomplished with tin alone I may give it a try.

I read this thread again and could not see any explanation. Why are you trying to stay away from using any antimony?

Thanks.

Jim

spursnguns- Posts : 611

Join date : 2013-01-04

Age : 66

Location : Nampa, Idaho

Jon Eulette likes this post

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

The reason I had before may no longer be applicable but it was my understanding that lead hardness could be obtained by adding tin only, at least for the hardness I thought was necessary. I'm also swaging projectiles and wanted to keep my lead inventory small. Lead/tin alloys are better suited for swaging based on my reading so I thought of using this for both operations. Again, this may not be applicable anymore especially after casting more projectiles using 25:1 as the quality of bullets hasn't improved. I paid more attention to the finished castings this time and there are imperfections that I can't figure out the cause. I ordered some Lyman #2, which has antimony in it. I'm hoping that will help with at least the castings. I'll still be using lead/tin only for swaging. On that front I'm making good progress.spursnguns wrote:Hello beeser,beeser wrote:I'm trying to stay away from antimony for hardening. If it can't be accomplished with tin alone I may give it a try.

I read this thread again and could not see any explanation. Why are you trying to stay away from using any antimony?

Thanks.

Jim

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

Thank you, beeser.

Keep us posted with your progress.

Jim

Keep us posted with your progress.

Jim

spursnguns- Posts : 611

Join date : 2013-01-04

Age : 66

Location : Nampa, Idaho

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

I took a closer look at the HBWCs used when the skirt blew off (had some left over) and couldn't find the same imperfections in my recent casting using a harder alloy. So, the reason for the skirt failure is probably because of a too hot load or the lead was too soft. I don't understand why the load would be too hot because it's the same used on a similar bullet made by Speers and others. Very confusing.

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

Does the Speer have the same internal profile in the cavity. Some muzzleloader types have found that the internal profile can affect the strength of the skirt.

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-13

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

Wobbley wrote:Does the Speer have the same internal profile in the cavity. Some muzzleloader types have found that the internal profile can affect the strength of the skirt.

Thanks for prompting me to take a closer look at the difference between the Speer and my casted projectile. The internal profile and depth of the hollow base looks very similar. But one difference I noticed with my casting and the MP mold design is the deeper lube groove located near the inner hollow root. If I were to guess that would be the weakest part of the projectile and could be where it separated. Looking at my target, the smaller piece of the projectile that doesn't look like it made a complete hole is still intact, probably caused by the broken off skirt. The grooves on the Speer projectile are much shallower and are more like a light knurl.

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

I found this

https://vulcangms.com/resources/library/ And there’s a pamphlet on the properties of lead alloys....

If you can get past the convoluted numbering...the mechanical properties are somewhere in these ranges:

Lead-Tin (20:1) about 4000 psi

“Bullet”alloy (95/5/5, Lyman #2). 7000 psi

“Linotype” (86/12/6) 10000 psi.

So adding antimony will help. I’d mix 50% lead to 92-6-2 alloy which should give you a BHN of 10-13 And try again.

https://vulcangms.com/resources/library/ And there’s a pamphlet on the properties of lead alloys....

If you can get past the convoluted numbering...the mechanical properties are somewhere in these ranges:

Lead-Tin (20:1) about 4000 psi

“Bullet”alloy (95/5/5, Lyman #2). 7000 psi

“Linotype” (86/12/6) 10000 psi.

So adding antimony will help. I’d mix 50% lead to 92-6-2 alloy which should give you a BHN of 10-13 And try again.

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-13

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

Thanks Wobbley. The projectile was actually cast using 40:1 lead/tin so probably worse than the numbers you posted. I have some Lyman #2 coming from RotoMetals and will give that a try. Hopefully I get better results.Wobbley wrote:I found this

https://vulcangms.com/resources/library/ And there’s a pamphlet on the properties of lead alloys....

If you can get past the convoluted numbering...the mechanical properties are somewhere in these ranges:

Lead-Tin (20:1) about 4000 psi

“Bullet”alloy (95/5/5, Lyman #2). 7000 psi

“Linotype” (86/12/6) 10000 psi.

So adding antimony will help. I’d mix 50% lead to 92-6-2 alloy which should give you a BHN of 10-13 And try again.

beeser- Posts : 1154

Join date : 2014-06-19

Page 1 of 2 • 1, 2

Similar topics

Similar topics» 148g HBWC skirt separation

» UPS mistake SW mistake

» Deleted, my mistake

» NRA vs CMP Range Commands and Rules

» Model 41 S&W Slide Stop Failure Rate

» UPS mistake SW mistake

» Deleted, my mistake

» NRA vs CMP Range Commands and Rules

» Model 41 S&W Slide Stop Failure Rate

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum