Learning through mistake - Skirt blew off

+8

oldsalt444

CR10X

dlevasse

Wobbley

rburk

john bickar

fc60

beeser

12 posters

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Learning through mistake - Skirt blew off

Learning through mistake - Skirt blew off

First topic message reminder :

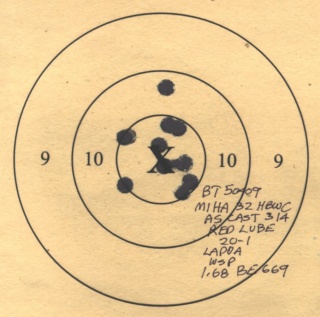

The first time casting and loading a 32 cal. HBWC projectile produced the result shown in pic. below. I'm almost certain it's a situation where the skirt blew off. The 2 through holes above the 2 partials in the black are the result of only 2 shots fired. I casted the projectiles using a new MP mold and probably the culprit 40:1 lead/tin. The load was 1.4 grs. of N310, the same used in a few other 98 gr. HBWCs, which didn't have skirts that separated. And yes, I made sure the barrel was clear before firing the 2nd round. I'll cast a few more except with a harder alloy, a minimum of 20:1. All part of the learning process I guess.

The first time casting and loading a 32 cal. HBWC projectile produced the result shown in pic. below. I'm almost certain it's a situation where the skirt blew off. The 2 through holes above the 2 partials in the black are the result of only 2 shots fired. I casted the projectiles using a new MP mold and probably the culprit 40:1 lead/tin. The load was 1.4 grs. of N310, the same used in a few other 98 gr. HBWCs, which didn't have skirts that separated. And yes, I made sure the barrel was clear before firing the 2nd round. I'll cast a few more except with a harder alloy, a minimum of 20:1. All part of the learning process I guess.

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

While disassembling the remaining unfired bullets that had the skirts blow off I noticed that some of the projectiles were harder to extract than others. Apparently the crimp was not consistent. Is it possible that an aggressive crimp played a role in the skirt coming apart?

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

Sir just barely crimp 32’s just enough to pass the plop test

James Hensler- Posts : 1245

Join date : 2018-01-15

Age : 55

Location : Southwest Florida

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

Alloy not issue. Velocity/pressure is cause.

I keep all HBWC loads to no more the 750 fps and most are 725 or less for 32 and 38. Do not use DEWC data.

I keep all HBWC loads to no more the 750 fps and most are 725 or less for 32 and 38. Do not use DEWC data.

noylj- Posts : 433

Join date : 2012-03-10

Age : 75

Location : SW USA

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

noylj wrote:Alloy not issue. Velocity/pressure is cause.

I keep all HBWC loads to no more the 750 fps and most are 725 or less for 32 and 38. Do not use DEWC data.

As mentioned before the load is the same used with a Bear Creek and Speer HBWC, all being 98 gr. The skirt didn't separate on these. Isn't it possible for the projectile to be so weak near the rear most lube groove that it could separate even with an ordinarily acceptable load, especially if the alloy itself is already tenuous? I may find out further after casting another batch with a stronger lead alloy. Another forum member has used the same MP mold. It would be interesting and instructive if he would chime in.

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

I think your 1.4 gr VV N310 is very mild load. I’ve used it and it’s soft. I doubt it has contributed to the skirt separation. I was thinking that you could have the lube groove depth reduced on the mold and see if that helps. Thanks for sharing...

Jon

Jon

Jon Eulette- Posts : 4399

Join date : 2013-04-15

Location : Southern Kalifornia

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

Just for reference, the depth of the lube grooves is approx. .025", the deepest of any HBWCs that I have including 38s. It's significantly wider too. The good(?) is the grooves hold a lot of lube. I received my Lyman #2 from RotoMetals today and should cast a new batch soon using that alloy. If that doesn't work I may give up on the mold.

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

I cast and lubed another batch of HBWCs today this time using Lyman #2. The ones I didn't reject (about 50%) look good. I plan to use the same load as before. Hopfully firing them in the next few days turns out better than before.

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

Finally got around to fire the newly cast HBWCs using Lyman #2 lead instead of the 40:1 used before. I don't know if it's because of the harder alloy or quality of casting but the bullets remained intact using the same load.

beeser- Posts : 1154

Join date : 2014-06-19

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

That target looks good to me. I thought you mentioned giving up on this mold. Regardless, would you recommend the 20:1 alloy over something harder like Lyman #2?

beeser- Posts : 1154

Join date : 2014-06-19

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

Greetings,

Factory HBWC bullets are softer than Lyman #2. The hardness varies from 6-8 Brinell.

I used 20:1 as I had a potful from my last Black Powder bullet casting session.

Today, I would try out 25:1 or 30:1.

The more Tin in the alloy, the better it flows when casting.

I recall that you have a Bullet Swage. Why monkey with casting HBWC?

Cheers,

Dave

Factory HBWC bullets are softer than Lyman #2. The hardness varies from 6-8 Brinell.

I used 20:1 as I had a potful from my last Black Powder bullet casting session.

Today, I would try out 25:1 or 30:1.

The more Tin in the alloy, the better it flows when casting.

I recall that you have a Bullet Swage. Why monkey with casting HBWC?

Cheers,

Dave

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Learning through mistake - Skirt blew off

Re: Learning through mistake - Skirt blew off

fc60 wrote:Greetings,

Factory HBWC bullets are softer than Lyman #2. The hardness varies from 6-8 Brinell.

I used 20:1 as I had a potful from my last Black Powder bullet casting session.

Today, I would try out 25:1 or 30:1.

The more Tin in the alloy, the better it flows when casting.

I recall that you have a Bullet Swage. Why monkey with casting HBWC?

Cheers,

Dave

Yes, I measured the H&N HBWCs and found them to have a BHN of about 8, which is in the 25:1 and 30:1 area according to the RotoMetal website. But the H&N has a shallower lube groove than the MIHA, which I think contributed to the skirt separation. Using Lyman #2 seemed like a good alternative based on an earlier suggestion that the added antimony would give the alloy more strength. Based on your results it wasn't entirely necessary to add the antimony. Good to know.

I'm still working (struggling) with my swaging efforts. The die making has been slowed by the lack of a proper heat treat oven. I placed an order for a HotShot oven made by Bar Z Industrial but recently learned they ceased production while another company takes over the manufacturing. I'll eventually get one unless something else pops up. I'm also acquiring the motorized swaging press mentioned to you in private correspondence. That should be both fun and interesting. In the meantime, I wanted to make some HBWCs and casting was the only immediate alternative. That's also been a learning experience.

PS I gave up on the swaged .32 SWC bullet I sent samples to you, at least for use with my Pardini HP. Even reducing the weight to 75 grs. produced a bullet that was a little too tight fitting into the Parding magazine. Besides it didn't seem to shoot very well based on your test results.

beeser- Posts : 1154

Join date : 2014-06-19

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» 148g HBWC skirt separation

» UPS mistake SW mistake

» Deleted, my mistake

» NRA vs CMP Range Commands and Rules

» Model 41 S&W Slide Stop Failure Rate

» UPS mistake SW mistake

» Deleted, my mistake

» NRA vs CMP Range Commands and Rules

» Model 41 S&W Slide Stop Failure Rate

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum