Case gauge check not working

+3

Kp321

JIMPGOV

hengehold

7 posters

Page 1 of 1

Case gauge check not working

Case gauge check not working

I am making pistol ammo (45acp w/ coated lead SWC, dia=.452, Federal brass) for the first time. My loaded cartridge does not fit all the way into my cartridge gauge. The rim of the case sticks out about 0.050-0.100” or so. I can fit a case all the way into the gauge immediately after resizing but after loading and applying a taper crimp I can not fit it in all the way. I started with a .472” crimp and have incrementally made it tighter down to .465”. The tighter the crimp gets, the more of the cartridge I can fit into the gauge. I put factory ammo into the gauge, mag tech went all the way in and the PMC ammo did not. PMC ammo stuck out about the same as my hand loads do now (~0.100”).

Here is a link to the gauge I have.

https://www.theshootersbox.com/45-ACP-Case-Ammunition-Gauge--All-New-Patented-Tri-Step-Face-Design_p_24105.html

Should I keep tightening the crimp?

If so, how much crimp is too much?

There is a lot of resistance when I pull the case out of the crimp die, it almost seems excessive. But since I am new to pistol loading I don’t have a frame of reference to compare it to.

I am not using lube on the cases because I have a carbide sizing die. Maybe I need to lube cases to assist with the crimping?

Here is a link to the gauge I have.

https://www.theshootersbox.com/45-ACP-Case-Ammunition-Gauge--All-New-Patented-Tri-Step-Face-Design_p_24105.html

Should I keep tightening the crimp?

If so, how much crimp is too much?

There is a lot of resistance when I pull the case out of the crimp die, it almost seems excessive. But since I am new to pistol loading I don’t have a frame of reference to compare it to.

I am not using lube on the cases because I have a carbide sizing die. Maybe I need to lube cases to assist with the crimping?

Last edited by hengehold on Wed Jul 28, 2021 11:49 am; edited 1 time in total

hengehold- Posts : 424

Join date : 2017-11-26

Location : VA

Re: Case gauge check not working

Re: Case gauge check not working

WHAT BRAND OF CARTRIDGE GAUGE ARE YOU USING ?

HAVE YOU MEASURED THE DIAMETER OF THE BULLETS ?

PLENTY OF PEOPLE HERE TO HELP, BUT LETS GIVE THEM A BETTER VIEW OF WHAT YOUR WORKING WITH. JP

HAVE YOU MEASURED THE DIAMETER OF THE BULLETS ?

PLENTY OF PEOPLE HERE TO HELP, BUT LETS GIVE THEM A BETTER VIEW OF WHAT YOUR WORKING WITH. JP

JIMPGOV- Posts : 657

Join date : 2011-09-27

Re: Case gauge check not working

Re: Case gauge check not working

The ultimate case gauge is the barrel itself. See if your ammo plunks in the barrel, if so you are good to go.

If not, take a look at seating depth. The shoulder of the bullet should be a “fingernail thickness” above the case mouth when seated.

Check the diameter of the unseated bullets, if they are oversized, they could be swelling the brass and causing problems.

You should not have to taper crimp past .470. Excess taper crimping with coated bullets can damage the coating.

If not, take a look at seating depth. The shoulder of the bullet should be a “fingernail thickness” above the case mouth when seated.

Check the diameter of the unseated bullets, if they are oversized, they could be swelling the brass and causing problems.

You should not have to taper crimp past .470. Excess taper crimping with coated bullets can damage the coating.

Kp321- Posts : 237

Join date : 2019-06-17

Re: Case gauge check not working

Re: Case gauge check not working

Use a magic marker to determine exactly where/why they don't fit, as described in the link below. Then you'll know how to fix it.

https://www.shootingtimes.com/editorial/reloading-tips-the-plunk-test/99389

https://www.shootingtimes.com/editorial/reloading-tips-the-plunk-test/99389

S148- Posts : 319

Join date : 2017-07-04

Re: Case gauge check not working

Re: Case gauge check not working

We often taper crimp to .463 without issues, but, more likely base to shoulder should be around .920

james r chapman- Admin

- Posts : 6372

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

Re: Case gauge check not working

Re: Case gauge check not working

SOON AS I SAW THIS , IT CLICKED. IF YOU USED THE STANDARD O.A.L. MEASURING TO THE TOP OF THE BULLET YOU WOULD ENCOUNTER YOUR PROBLEM. MEASURING FROM THE BASE TO THE SHOULDER (AS CHAPMAN STATED) FOR .920 SHOULD, COULD ELIMINATE YOUR PROBLEM. JPjames r chapman wrote:We often taper crimp to .463 without issues, but, more likely base to shoulder should be around .920

JIMPGOV- Posts : 657

Join date : 2011-09-27

hengehold likes this post

Re: Case gauge check not working

Re: Case gauge check not working

hengehold, do your handloads fit your barrel chamber? If they do, ignore your case gauge.

S148- Posts : 319

Join date : 2017-07-04

Re: Case gauge check not working

Re: Case gauge check not working

Here is the gauge I am using

https://www.theshootersbox.com/45-ACP-Case-Ammunition-Gauge--All-New-Patented-Tri-Step-Face-Design_p_24105.html

Bullets used are the Brazo 185gr coated SWC, diameter measured .452 I believe. Using Federal brass.

https://www.theshootersbox.com/45-ACP-Case-Ammunition-Gauge--All-New-Patented-Tri-Step-Face-Design_p_24105.html

Bullets used are the Brazo 185gr coated SWC, diameter measured .452 I believe. Using Federal brass.

hengehold- Posts : 424

Join date : 2017-11-26

Location : VA

Re: Case gauge check not working

Re: Case gauge check not working

Case lube makes the loading process take less effort, especially expanding and crimping, well worth it in my opinion. Somethings that I would check, are you expanding the case correctly, seating the bullet square, and are you seating from the nose or shoulder of the bullet?

chiz1180- Posts : 1509

Join date : 2019-05-29

Location : Ohio

Re: Case gauge check not working

Re: Case gauge check not working

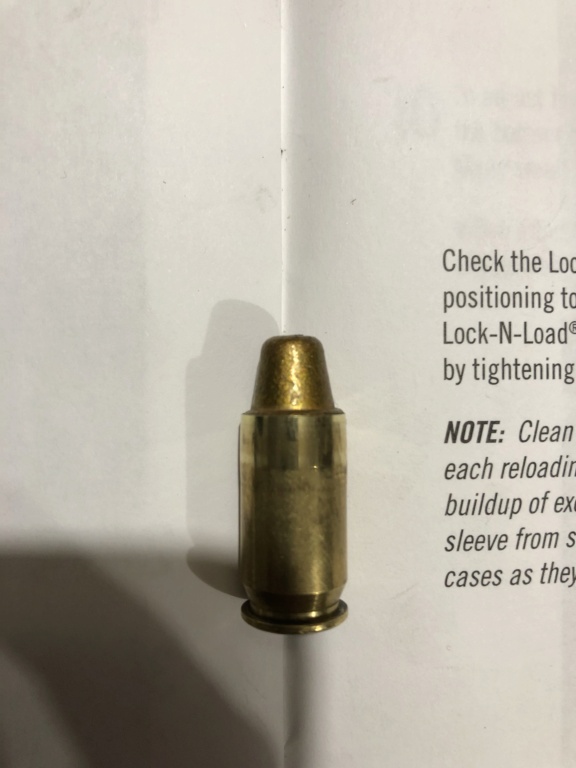

Let’s see a pic of your loaded cartridge

james r chapman- Admin

- Posts : 6372

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

Re: Case gauge check not working

Re: Case gauge check not working

I tried a plunk test in the actual chamber and it appears that it fits the chamber but not the gauge I was using. I guess I am good to go. Thanks for all the input.

P.s. base to shoulder measurement is .911. Any reason why that may be considered too short or is COAL based on reliable feeding?

P.s. base to shoulder measurement is .911. Any reason why that may be considered too short or is COAL based on reliable feeding?

hengehold- Posts : 424

Join date : 2017-11-26

Location : VA

Re: Case gauge check not working

Re: Case gauge check not working

COAL is based on

1. Must fit in the Magazine

2: must chamber (.920 Max to the shoulder)

3. Must feed.

It’s a balancing act.

1. Must fit in the Magazine

2: must chamber (.920 Max to the shoulder)

3. Must feed.

It’s a balancing act.

Wobbley- Admin

- Posts : 4805

Join date : 2015-02-13

hengehold likes this post

Similar topics

Similar topics» Case gauge for 38sp

» Rimfire case gauge?

» Strong Case Aluminum gauge/thickness

» gauge cleaning

» Check your stuff, then check it again.

» Rimfire case gauge?

» Strong Case Aluminum gauge/thickness

» gauge cleaning

» Check your stuff, then check it again.

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum