SOLUTION to Hornady AP “Last Primer” that does not feed properly

+5

71firebird400

RodJ

messenger

zanemoseley

AJ

9 posters

Page 1 of 1

SOLUTION to Hornady AP “Last Primer” that does not feed properly

SOLUTION to Hornady AP “Last Primer” that does not feed properly

Hi All,

I posted this thread on another forum and though it may be interesting for reloaders with Hornady AP press on this forum.

I finally found an easy solution for “last primer not feeding / seating sideways upside down”. Though I would share a fix anyone can do in just a few minutes with electrical tape and scissors.

I have had this issue since day one with Large & Small primers. Tried every possible idea one can find on Youtube, this forum and others which never fixes this “last primer” issue.

I would think a 3/16 rode may work but I did not have one on hand at the time so had to think outside the box.

The solution is actually simple:

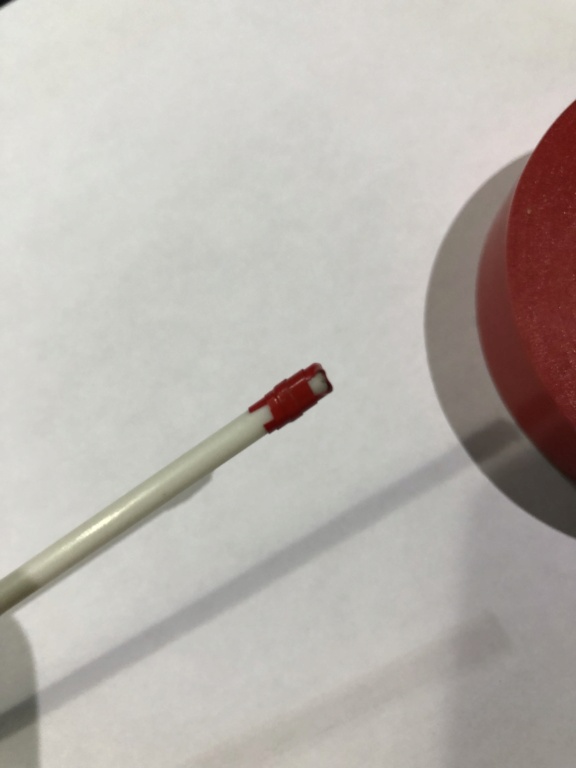

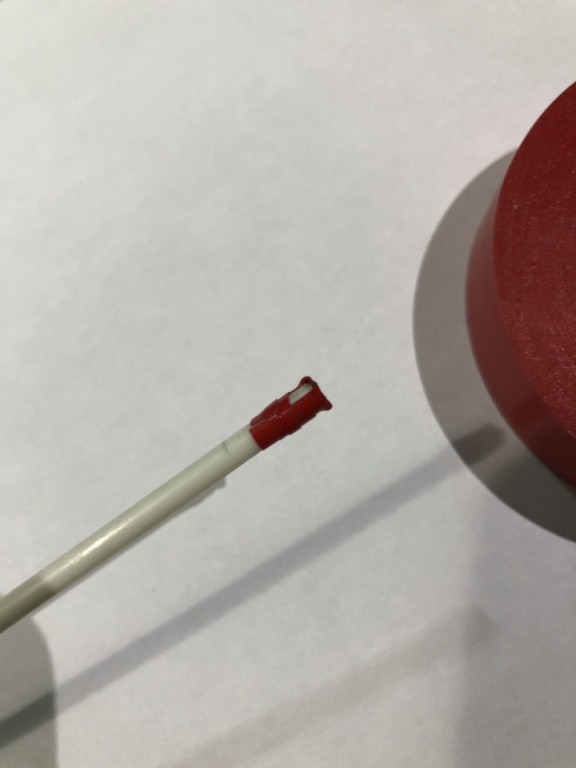

At the end of the Hornady primer rode, add a small piece of electrical tape to cover the tip of the rode. I used 3/4” strip, width of the electrical tape roll. The electrical tape should not be larger than the rode. A little larger will still work as long as the rode still slides freely inside the primer tube with the electrical tape.

From there use another piece of electrical tape around the rode and over the initial piece of tape to lock everything in place. The electrical tape makes it just large enough to address the “last primer not feeding properly”!!!

On a side note I added a 45ACP brass at the upper extremity of the Hornady primer rode. It adds a little bit of weight, not sure this actually helps but it cannot hurt.

I also do use Braggin Rights Precision’s Slide Alignment Tools, which have not solved the “last prime issue” but his tools are inexpensive, easy to use and allow everything on AP press to ligne-up properly in 30 seconds without having to use a flashlight and trying to look down the hole, which is not easy when dies and powder hopper are installed.

I tested with 100 primers, 20, 10, 5, 3 and only 1 many times without any hiccups.

This solution is KISS easy…

Photos attached…

Enjoy !

PS: This works for Small and Large primers

I posted this thread on another forum and though it may be interesting for reloaders with Hornady AP press on this forum.

I finally found an easy solution for “last primer not feeding / seating sideways upside down”. Though I would share a fix anyone can do in just a few minutes with electrical tape and scissors.

I have had this issue since day one with Large & Small primers. Tried every possible idea one can find on Youtube, this forum and others which never fixes this “last primer” issue.

I would think a 3/16 rode may work but I did not have one on hand at the time so had to think outside the box.

The solution is actually simple:

At the end of the Hornady primer rode, add a small piece of electrical tape to cover the tip of the rode. I used 3/4” strip, width of the electrical tape roll. The electrical tape should not be larger than the rode. A little larger will still work as long as the rode still slides freely inside the primer tube with the electrical tape.

From there use another piece of electrical tape around the rode and over the initial piece of tape to lock everything in place. The electrical tape makes it just large enough to address the “last primer not feeding properly”!!!

On a side note I added a 45ACP brass at the upper extremity of the Hornady primer rode. It adds a little bit of weight, not sure this actually helps but it cannot hurt.

I also do use Braggin Rights Precision’s Slide Alignment Tools, which have not solved the “last prime issue” but his tools are inexpensive, easy to use and allow everything on AP press to ligne-up properly in 30 seconds without having to use a flashlight and trying to look down the hole, which is not easy when dies and powder hopper are installed.

I tested with 100 primers, 20, 10, 5, 3 and only 1 many times without any hiccups.

This solution is KISS easy…

Photos attached…

Enjoy !

PS: This works for Small and Large primers

Last edited by AJ on 12/31/2021, 2:25 pm; edited 2 times in total

AJ- Posts : 52

Join date : 2021-10-17

AJ- Posts : 52

Join date : 2021-10-17

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

I hate to say this but this is a bad idea. The fiberglass ROD also drops into the primer hole in the primer shuttle after the last primer has been fed, that pinching is going to wear away the tape and you're gonna get sticky tape residue in your primer tube and slide mechanism, might not be immediate but is sure to happen.

Another tip, when the primer shuttle has locked back on the rod never just pull the rod out and let the shuttle fly forward, it hits the primer insertion ram and will damage the bottom edge of the slide which is an MIM part and eventually will cause issues and will need to be replaced. Hornady has replaced 2-3 shuttles for me over time. I now manually hold the shuttle while I remove the rod and gently let it close.

I've loaded probably 20k rounds out of my 2 LNL AP's with very few primer related issues. I would suggest you email Hornady and ask what they suggest. Their customer service is very good.

Another tip, when the primer shuttle has locked back on the rod never just pull the rod out and let the shuttle fly forward, it hits the primer insertion ram and will damage the bottom edge of the slide which is an MIM part and eventually will cause issues and will need to be replaced. Hornady has replaced 2-3 shuttles for me over time. I now manually hold the shuttle while I remove the rod and gently let it close.

I've loaded probably 20k rounds out of my 2 LNL AP's with very few primer related issues. I would suggest you email Hornady and ask what they suggest. Their customer service is very good.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Love people who start with a negative!

You may have your own more complicated way of solving this inherent Hornady issue but do not negate someone's idea until you have tried it yourself..

I reloaded over 3000 rounds with no issue. Yes, maybe the tape will come off one day but nothing in the press stays clean for very long. After 3000 reloads tests this solution may not be for you but certainly for others looking for a solution.

Respectfully,

AJ

PS: I contacted Hornady several times. The only solution is a larger rode. I wonder why they do not have one with new presses as solution above works for both Large and Small primers. This solution is free and does not require any handy skills.

You may have your own more complicated way of solving this inherent Hornady issue but do not negate someone's idea until you have tried it yourself..

I reloaded over 3000 rounds with no issue. Yes, maybe the tape will come off one day but nothing in the press stays clean for very long. After 3000 reloads tests this solution may not be for you but certainly for others looking for a solution.

Respectfully,

AJ

PS: I contacted Hornady several times. The only solution is a larger rode. I wonder why they do not have one with new presses as solution above works for both Large and Small primers. This solution is free and does not require any handy skills.

Last edited by AJ on 12/31/2021, 6:54 pm; edited 1 time in total

AJ- Posts : 52

Join date : 2021-10-17

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

I have two lock n load progressives. Like most, one set up for large and one set up for small primer. I have never had the "last primer issue." I have, from my model airplane days, use a wheel collar. I dropped the composite rod into the empty primer tower then slide the wheel collar down to rest on the primer tower, tighten the set screw, done. I did this to let me know when I was getting low on primers.

Bill

Bill

- Attachments

messenger- Posts : 1035

Join date : 2011-06-18

Location : North Carolina

RodJ likes this post

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

My LNL AP did not come with any rod. I found that a 3/16” wood dowel, with the lower tip slightly sanded to a taper to fit the small primer slide hole, works fine.

I also wrap a piece of electrical tape, like a flag, to the upper end of the dowel, such that when the lower dowel tip drops into the hole, the flag has dropped to just touch the black primer tube support. That flag tells me whether the primer tube is truly empty or there’s a last primer that doesn’t want to feed. The flag will be just about an 1/8” above the primer tube support if “sump’in ain’t right.”

Fiberglass should work a bit better, being more dense.

I also wrap a piece of electrical tape, like a flag, to the upper end of the dowel, such that when the lower dowel tip drops into the hole, the flag has dropped to just touch the black primer tube support. That flag tells me whether the primer tube is truly empty or there’s a last primer that doesn’t want to feed. The flag will be just about an 1/8” above the primer tube support if “sump’in ain’t right.”

Fiberglass should work a bit better, being more dense.

RodJ- Posts : 921

Join date : 2021-06-26

Location : TX

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

RodJ wrote:My LNL AP did not come with any rod. I found that a 3/16” wood dowel

Mine didn't come with one either. I'm in the telecommunications industry. I splice fiberoptic cable. My rod is the strength member that runs down the center of the cable. If anyone needs some I throw away a lot of it.

Bill

messenger- Posts : 1035

Join date : 2011-06-18

Location : North Carolina

RodJ likes this post

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Bill, I’m sure I can find a piece of f’glass rod but that’s a great source. If I can’t I may hit you up.

And btw, more importantly, I love your dinosaur cartoon. Hits my funny bone and makes me laugh every time.

And btw, more importantly, I love your dinosaur cartoon. Hits my funny bone and makes me laugh every time.

RodJ- Posts : 921

Join date : 2021-06-26

Location : TX

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

From my experience, Hornady has very good customer service. Call them and they will send you Fiberglass rode free of charge.

AJ

AJ

AJ- Posts : 52

Join date : 2021-10-17

dannyd93140 likes this post

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Glad it worked for you. I guess I'm lucky, I've been using a random wood dowel since the day I got my LNL AP 10 or 11 years ago. I found that timing the primer shuttle properly seems to resolve any sort of priming issues. My press has been remarkably reliable but I do have a Dillon 750 beside it- variety is the spice of life.

71firebird400- Posts : 33

Join date : 2014-04-18

Location : Bellingham WA

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

I think it has to do with manufacturing tolerances.

You did not get lucky, you got what you paid for, a good working press. Users like me got unlucky and what a PITA.

Yes, timing primer shuttle properly solves lots of issues, Braggin Rights Precision tool does just that very easily. But it did not solve the the “last primer” feeding issue.

Had similar issue with a Lee Factory Crimp Die, one had the carbide ring tighter than the other which created unpleasant reloading experience. Lee confirmed some FCD carbide rings are made tighter than others, but all within SAMMI specs.

The real solution would be to find a fiberglass 3/16” dowel as it seats flat on primers. Maybe a 5mm will work as well.

For now, just happy to feed all my primers correctly without having to disassemble anything ))

))

Thank you for feedback

You did not get lucky, you got what you paid for, a good working press. Users like me got unlucky and what a PITA.

Yes, timing primer shuttle properly solves lots of issues, Braggin Rights Precision tool does just that very easily. But it did not solve the the “last primer” feeding issue.

Had similar issue with a Lee Factory Crimp Die, one had the carbide ring tighter than the other which created unpleasant reloading experience. Lee confirmed some FCD carbide rings are made tighter than others, but all within SAMMI specs.

The real solution would be to find a fiberglass 3/16” dowel as it seats flat on primers. Maybe a 5mm will work as well.

For now, just happy to feed all my primers correctly without having to disassemble anything

Thank you for feedback

AJ- Posts : 52

Join date : 2021-10-17

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Would a brass rod and a stop at the top of the tube work? Isn't that what the Star machines use?

8eightring- Posts : 193

Join date : 2011-06-16

Location : Ohio

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Yes, I would think a 3/16 brass rode would work as well. From what I read, Hornady wants reloaders to stay away from heavy dowels on the primers. It may be a safety and liability issue.

Actually, any 3/16 rode would work if one has it available or buys it online.

The initial point I was trying to make, electrical tape works when one does not have anything else available, easy and free!

Even though it works well I will personally look for a more elegant solutions and find a dowel that fits and works as well.

For those that have this “last primer issue”, the electrical tape quick fix is a relief and it works!

Actually, any 3/16 rode would work if one has it available or buys it online.

The initial point I was trying to make, electrical tape works when one does not have anything else available, easy and free!

Even though it works well I will personally look for a more elegant solutions and find a dowel that fits and works as well.

For those that have this “last primer issue”, the electrical tape quick fix is a relief and it works!

AJ- Posts : 52

Join date : 2021-10-17

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

A solution (BUT NOT THE ONLY ONE) is to get a piece of small piece of Delrin and affix it to the end of your rod. The dimensions are up to you. Delrin is plastic and relatively light,

Wobbley- Admin

- Posts : 4805

Join date : 2015-02-12

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

In my opinion; you need to stay away from a heavy rod ( no matter what it is made) because if the primers detonated the blast would go out the top. I have two LNL and between them 100,298 rounds; the last primer not feeding is annoying but nothing a person can't live with.

But you need one of these if your old.

But you need one of these if your old.

- Attachments

dannyd93140- Posts : 197

Join date : 2021-07-31

Location : Jacksonville, Florida

dieselguy624 likes this post

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

The AP is meant to send the blast upward regardless in the case of a primer stack detonation, that's the intention behind the secondary steel protective sleeve. I suppose if you go too heavy on the rod it could possibly make the blast go outward and possibly rupture the sleeve.

I still feel like I got either extremely lucky on my 2 presses bought a couple years apart or there's something wrong with with your press setup or a defective part.

I still feel like I got either extremely lucky on my 2 presses bought a couple years apart or there's something wrong with with your press setup or a defective part.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

primer follower rod

primer follower rod

This works for me. I drilled and installed a small control knob to use as a stop. And then added a dummy round to use for extra weight.

- Attachments

8eightring- Posts : 193

Join date : 2011-06-16

Location : Ohio

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

AJ,

I have a question - when you install the primer magazine tube, have you noticed that one end of the tube is slightly different than the other end? One end has a slight “step”, no more than 1/32”, at the tip. Hard to describe without a photo, but the last 1/32” of the tube is slight smidge smaller in the outside diameter. That end must be at the bottom, because that slight step inserts the tube a hair bit further.

This isn’t mentioned in my manual nor the one that I just pulled up (unless I missed it). If the tube is upside down, then you will experience frustrating primer problems.

I have a question - when you install the primer magazine tube, have you noticed that one end of the tube is slightly different than the other end? One end has a slight “step”, no more than 1/32”, at the tip. Hard to describe without a photo, but the last 1/32” of the tube is slight smidge smaller in the outside diameter. That end must be at the bottom, because that slight step inserts the tube a hair bit further.

This isn’t mentioned in my manual nor the one that I just pulled up (unless I missed it). If the tube is upside down, then you will experience frustrating primer problems.

RodJ- Posts : 921

Join date : 2021-06-26

Location : TX

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Rodj,

I appreciate the idea and yes I have noticed. If you browse around you will find “last primer not feeding” reports. I think it has to do with manufacturer’s tolerances.

The problem is fixed though! It works for small and large primers.

Solution is free and easy for those who have been fighting with this issue.

I appreciate the idea and yes I have noticed. If you browse around you will find “last primer not feeding” reports. I think it has to do with manufacturer’s tolerances.

The problem is fixed though! It works for small and large primers.

Solution is free and easy for those who have been fighting with this issue.

AJ- Posts : 52

Join date : 2021-10-17

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

My "fix" was popping the anvil out of a fired primer, tapping the FP indent flat with a punch then epoxy the primer cup on the follower rod. rough up the rod a bit. That works like another primer on top of the last one and will lock the slide back as normal.

Don't forget to clean the primer tubes. I think the aluminum oxidizes some making for a "stickier" interior surface.

I started using a bit of floor wax after cleaning the tubes. Use just a bit on a small patch, let it dry then try to buff it all out. That seems to keep things sliding along.

I popped a LP primer last fall in my 1050. I had backed the swage rod down a bit to use a M die for a "pre" flair in that station as I have no crimped .45 cases. Well that setup allowed a small primer case to slip by.

Bang.

Got my attention. Changed the setup back to the normal swage with the hold down in place. Trying to do a better job of inspecting brass. That was my first experience with that since I started loading around 1976. I want it to be the last...

I can't imagine a whole magazine going off. I've seen pics. Don't want to go there.

I'm thinking that if that were to happen a brass follower might turn into a long bullet or cause the blast tube to fail.

So I'm in the make it work without so much weight on the follower camp. I do have a empty .45 case on the 1050.

Good luck.

Don't forget to clean the primer tubes. I think the aluminum oxidizes some making for a "stickier" interior surface.

I started using a bit of floor wax after cleaning the tubes. Use just a bit on a small patch, let it dry then try to buff it all out. That seems to keep things sliding along.

I popped a LP primer last fall in my 1050. I had backed the swage rod down a bit to use a M die for a "pre" flair in that station as I have no crimped .45 cases. Well that setup allowed a small primer case to slip by.

Bang.

Got my attention. Changed the setup back to the normal swage with the hold down in place. Trying to do a better job of inspecting brass. That was my first experience with that since I started loading around 1976. I want it to be the last...

I can't imagine a whole magazine going off. I've seen pics. Don't want to go there.

I'm thinking that if that were to happen a brass follower might turn into a long bullet or cause the blast tube to fail.

So I'm in the make it work without so much weight on the follower camp. I do have a empty .45 case on the 1050.

Good luck.

blindshooter- Posts : 122

Join date : 2016-03-15

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

Re: SOLUTION to Hornady AP “Last Primer” that does not feed properly

I load everyday, so I also don't put a 100 primers in the tube. Winchester and CCI 50 and Federal 25 takes a little more work and time but I don't want 100 primers detention.

dannyd93140- Posts : 197

Join date : 2021-07-31

Location : Jacksonville, Florida

Similar topics

Similar topics» 45 colt not cycling properly

» Root cause help, Ruger Mark III FTF

» High Standard replacement barrels

» Model 52-2 Won't Eject properly

» Rust Blue solution

» Root cause help, Ruger Mark III FTF

» High Standard replacement barrels

» Model 52-2 Won't Eject properly

» Rust Blue solution

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum