Larry's Trigger Adjustment Instructions

4 posters

Page 1 of 1

Larry's Trigger Adjustment Instructions

Larry's Trigger Adjustment Instructions

Looking for a copy of Larry/s trigger adjustment for the Hammerli Xesse. Found a link for it but it is broken and will not open. Thanks in advance.

shoot308- Posts : 88

Join date : 2012-08-27

Location : Menomonee Falls, WI

mspingeld- Admin

- Posts : 835

Join date : 2014-04-19

Age : 64

Location : New Jersey

Re: Larry's Trigger Adjustment Instructions

Re: Larry's Trigger Adjustment Instructions

I have a pdf of the whole document. PM your email address.

mspingeld- Admin

- Posts : 835

Join date : 2014-04-19

Age : 64

Location : New Jersey

Re: Larry's Trigger Adjustment Instructions

Re: Larry's Trigger Adjustment Instructions

Thanks PM sent.

shoot308- Posts : 88

Join date : 2012-08-27

Location : Menomonee Falls, WI

Re: Larry's Trigger Adjustment Instructions

Re: Larry's Trigger Adjustment Instructions

Here is a thread on targettalk about the adjustments. I will say i have changed from a single stage to a 2 stage trigger setup and like it better.

http://www.targettalk.org/viewtopic.php?f=10&t=59545&p=286282#p286282

http://www.targettalk.org/viewtopic.php?f=10&t=59545&p=286282#p286282

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Larry's Trigger Adjustment Instructions

Re: Larry's Trigger Adjustment Instructions

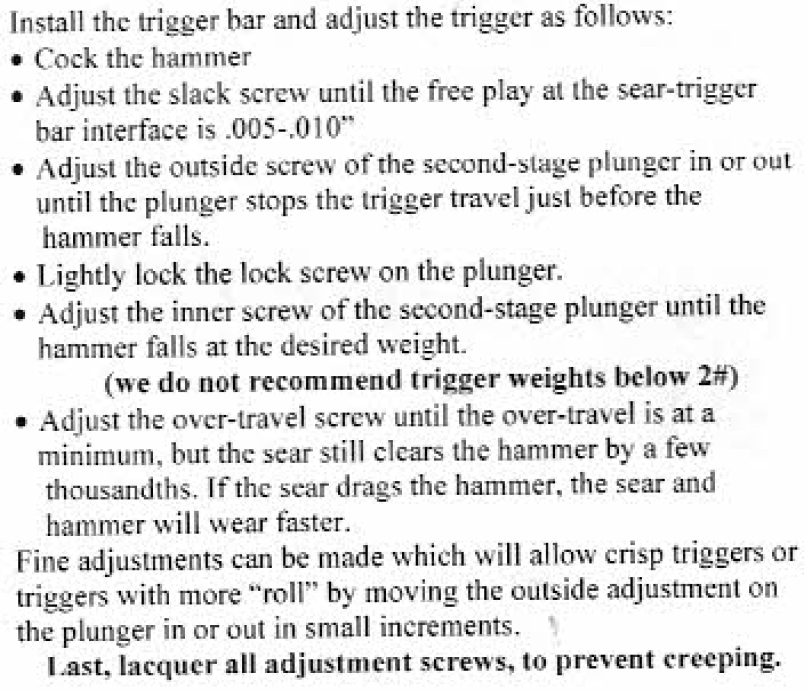

Pay special attention to the "moving the outside adjustment on the plunger in or out in small increments". Once you get the first and second stage weights where you like, this final tweak makes all the difference. Remember to loosen that setscrew on the side when doing this!

If you don't have the "special screwdriver", you can make one from a 4mm hexdrive 100mm long slotted screwdriver bit. It needs to be a 3mm thin shaft, so you can sneak it past the hammer strut and thin enough to turn within the gap, but a 3mm bit is too small to grab both sides of the slot, and the 4mm ones all have 4mm shafts. So to make one you need to grind the sides of a 4mm one flat just behind the blade, and then grind the middle of the shaft all the way around to reduce its diameter. I just chucked it in a power drill and then fed the shaft sideways along a bench grinder. You could probably do the same with a regular screwdriver but it'd be a bit more difficult to reduce it freehand.

If you don't have the "special screwdriver", you can make one from a 4mm hexdrive 100mm long slotted screwdriver bit. It needs to be a 3mm thin shaft, so you can sneak it past the hammer strut and thin enough to turn within the gap, but a 3mm bit is too small to grab both sides of the slot, and the 4mm ones all have 4mm shafts. So to make one you need to grind the sides of a 4mm one flat just behind the blade, and then grind the middle of the shaft all the way around to reduce its diameter. I just chucked it in a power drill and then fed the shaft sideways along a bench grinder. You could probably do the same with a regular screwdriver but it'd be a bit more difficult to reduce it freehand.

-TT-- Posts : 624

Join date : 2016-10-18

Similar topics

Similar topics» Trigger weight adjustment

» Larry's Sig Hammerli X-esse Trigger Kit Instructions

» AW93 Trigger Adjustment

» Sig P210A - Changing the Trigger Return Spring & Sear Adjustment

» S&W M41 Trigger adjustment

» Larry's Sig Hammerli X-esse Trigger Kit Instructions

» AW93 Trigger Adjustment

» Sig P210A - Changing the Trigger Return Spring & Sear Adjustment

» S&W M41 Trigger adjustment

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum