Reloading 148 HBWC

+12

mikemyers

Dr.Don

shoot308

Kp321

fc60

Wobbley

mspingeld

dannyd93140

PhotoEscape

Dcforman

DA/SA

Foundryratjim

16 posters

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Reloading 148 HBWC

Reloading 148 HBWC

First topic message reminder :

I am using a Dillon press. I have just got and set up one of photo escape's PTU for this bullet. I am using zero bullets. I have the press set up so that I can push the bullet into the case by hand. The finished round will only go about 1/3 of it's length into my gage, about halfway into my GP100 cylinder and odly enough drops into my Model 52's chamber. I set up a Lee factory crimp die on another press and ran the rounds through it but nothing changed. What am I missing or doing wrong??

I am using a Dillon press. I have just got and set up one of photo escape's PTU for this bullet. I am using zero bullets. I have the press set up so that I can push the bullet into the case by hand. The finished round will only go about 1/3 of it's length into my gage, about halfway into my GP100 cylinder and odly enough drops into my Model 52's chamber. I set up a Lee factory crimp die on another press and ran the rounds through it but nothing changed. What am I missing or doing wrong??

Foundryratjim- Posts : 243

Join date : 2018-08-01

Age : 66

Location : michigan

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

What I am finding in my mixed brass matches your data in your chart.Wobbley wrote:What you have is a Western Cartridge Company “military” case. There were a LOT of these sold as “USA” branded ammunition back then which became “Winchester White box”. Just because it said “WCC” doesn’t necessarily mean it was military issue. But it WAS from the military production tooling.Foundryratjim wrote:I have adjusted the PTU so that I can insert the bullet by my finger and it stops perfectly flush with the top of the case. So far only Remington and Federal have passed the test. Most of what I have so far are these and they don't. Who makes these?PhotoEscape wrote:Watching! The point is, James, - you can check cases with 0.355"+ plug, and if plug doesn't go to about 0.625" depth without obstruction you can safely relegate those cases to loading your DR ammo. Also, check wall thickness of the cases, - if case has wall thickness is over 0.009" (i.e. 0.011"), same as above. FCD with such cases will swag the squirt of HBWC bullet, and hence accuracy will be dismal. If you do not have proper tools, PTU can be used for identifying cases that are not suited for loading HBWC. If you can setup toolhead that will just do sizing and then powder drop WITHOUT actually dropping powder, but just expanding cases, any case that has bulge - relegate to DR ammo.

AP

All that said, I don’t have enough of these to get meaningful data, but I do have enough WCC +P+, Winchester, W-W, and Winchester +P headstamps that I have measured. The case wall thickness at the mouth is .0105 for +P compared to .0096 for non-+P. The difference is in the length of the “cylinder” portion of the case wall. 38 Special cases vary a lot between headstamps. The major difference is between +P and non-+P. Winchester from Wadcutter ammo had an average cylinder of .61 whereas the +P and +P+ was .4.

Remington brass from Wadcutter ammo measured .56. From non-Wadcutter ammo measured .55. Essentially no difference. This is pretty much across the brands. There is no difference between 38 special brass from non-Wadcutter ammo and Wadcutter ammo. Let me repeat that THERE IS NO DIFFERENCE BETWEEN BRASS FOR REGULAR 38 SPECIAL AMMUNITION AND WADCUTTER AMMUNITION IN ANY PARTICULAR BRAND.

There IS a difference between brands. I’ve attached a summary chart.

Foundryratjim- Posts : 243

Join date : 2018-08-01

Age : 66

Location : michigan

PacFltShooter and sayracin like this post

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

For those worried about not having a set of gage plugs, you can buy individual plugs from mscdirect.com and they aren't very expensive.

Dr.Don- Posts : 816

Join date : 2012-10-31

Location : Cedar Park, TX

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

$3.55 from Travers Tool.

https://www.travers.com/product/vermont-gage-111235500-class-zz-pin-gage-58-203-550

...or just look at Wobbley's chart!

https://www.travers.com/product/vermont-gage-111235500-class-zz-pin-gage-58-203-550

...or just look at Wobbley's chart!

DA/SA- Posts : 1506

Join date : 2017-10-09

Age : 68

Location : Southeast Florida

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

Greetings,

In my limited testing of Speer 98 HBWC 0.313" bullets in StarLine cases do collapse the bullet skirt slightly although accuracy was acceptable.

I DO NOT use an expander plug. I size the brass to the needed diameter prior to loading.

In the case of StarLine, and Federal, brass, sizing to 0.334"-0.335" works well.

I merely flare the case mouth to accept the bullet.

The Speer bullets vary in diameter; but, most measure 0.313".

You should be able to start the bullet into the case with finger pressure and be able to push it down into the case about half way. This aligns the bullet as an added bonus.

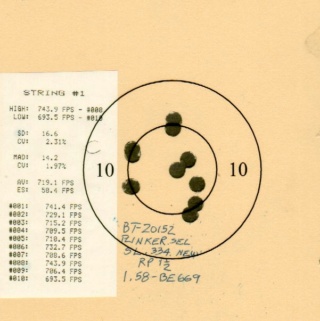

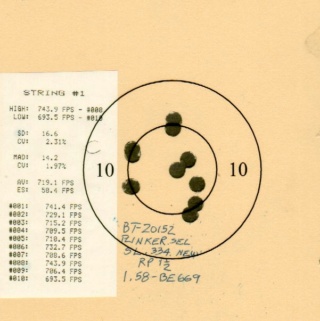

The target below is a custom Pardini Barrel fired at 50 yards in a mechanical fixture. I used new StarLine brass that measured 0.334" diameter. I loaded culled (reject any with visual defects) Speer HBWC "Plinkers".

Cheers,

Dave

In my limited testing of Speer 98 HBWC 0.313" bullets in StarLine cases do collapse the bullet skirt slightly although accuracy was acceptable.

I DO NOT use an expander plug. I size the brass to the needed diameter prior to loading.

In the case of StarLine, and Federal, brass, sizing to 0.334"-0.335" works well.

I merely flare the case mouth to accept the bullet.

The Speer bullets vary in diameter; but, most measure 0.313".

You should be able to start the bullet into the case with finger pressure and be able to push it down into the case about half way. This aligns the bullet as an added bonus.

The target below is a custom Pardini Barrel fired at 50 yards in a mechanical fixture. I used new StarLine brass that measured 0.334" diameter. I loaded culled (reject any with visual defects) Speer HBWC "Plinkers".

Cheers,

Dave

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

Since Remington for many years was producing 38WC ammo, and used Holy Grail of all HBWC bullets, here are few pictures for the reference.

Here are three different types of Remington Brass. On the left is older double canelure used for loading HBWC p/n: R38S3 In the middle newer double canelure used for loading same HBWC bullet p/n: RTG38S3. Lastly on the right is no canelure brass used for loading 38 SPL, the regular one, not the +p.

This picture represents 355 + pin gauge inserted into regular 38 SPL Brass.

Same for newer 38WC brass.

Lastly - 355+ pin gauge inserted in old WC brass.

Now pictures of measurements for reference point:

Apparently there is a difference in the brass from the same manufacturer. Side note, - testing done with old and new WC ammo shows stark difference as well. Old Remington WC ammo holds 10 ring or better at 50Y, while RTG38S3 Wadcautter Match Target Master doesn't come even close to that.

AP

Here are three different types of Remington Brass. On the left is older double canelure used for loading HBWC p/n: R38S3 In the middle newer double canelure used for loading same HBWC bullet p/n: RTG38S3. Lastly on the right is no canelure brass used for loading 38 SPL, the regular one, not the +p.

This picture represents 355 + pin gauge inserted into regular 38 SPL Brass.

Same for newer 38WC brass.

Lastly - 355+ pin gauge inserted in old WC brass.

Now pictures of measurements for reference point:

Apparently there is a difference in the brass from the same manufacturer. Side note, - testing done with old and new WC ammo shows stark difference as well. Old Remington WC ammo holds 10 ring or better at 50Y, while RTG38S3 Wadcautter Match Target Master doesn't come even close to that.

AP

PhotoEscape- Admin

- Posts : 1542

Join date : 2018-05-15

Location : Northern Illinois, USA

Foundryratjim likes this post

dannyd93140- Posts : 197

Join date : 2021-07-31

Location : Jacksonville, Florida

Foundryratjim likes this post

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

A couple of issues with these photos. In the new case the lower cannelure is still present. In the much older case the cannelure seems to be almost gone. Does the pin go past this cannelure? I bet it does. Also, while the pin method is good for comparisons, I’m not sure I’d try to defend it as a true measurement. This was my method:PhotoEscape wrote:

Same for newer 38WC brass.

Lastly - 355+ pin gauge inserted in old WC brass.

Now pictures of measurements for reference point:

Apparently there is a difference in the brass from the same manufacturer. Side note, - testing done with old and new WC ammo shows stark difference as well. Old Remington WC ammo holds 10 ring or better at 50Y, while RTG38S3 Wadcautter Match Target Master doesn't come even close to that.

AP

The case mouth distance from the black frame was measured at the point where the case wall increased by .001 inch, then when the case mouth and plunger were coincident. Here also were some of the cases I measured and they were in the data chart published. As you can see from the old op index of “6138” they are very old and I fired them from factory ammo.

Wobbley- Admin

- Posts : 4805

Join date : 2015-02-12

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

Wobbley wrote:A couple of issues with these photos. In the new case the lower cannelure is still present. In the much older case the cannelure seems to be almost gone. Does the pin go past this cannelure? I bet it does. Also, while the pin method is good for comparisons, I’m not sure I’d try to defend it as a true measurement.

Really!???

Fine, let's discard newer double cannelure case, consider that older double cannelure case has both cannelures gone and obstruct from method of measuring and accuracy of it. The point that there is the difference in the brass from the same manufacturer stands. And that is first fact.

The second fact is that OP experienced bulging in some of the cases exactly in the area where pin gage stops in regular Remington case, and that points that some of the brass isn't suitable for loading long HBWC bullets. Once bulge is flattened with FCD, bullet's skirt will be swaged. Accuracy will be affected.

Third fact is that there is brass specifically stamped for loading wadcutter bullets (which you, Wobbley, wasn't aware exists!) as I posted on another thread - https://www.bullseyeforum.net/t19139-cannelure-or-not And that brass has no cannelures to begin with. Coincidentally pin gage goes into such case(s) to the same depth as in Remington old double cannelure case. I have ammo loaded in such cases with Remington 148gr HBWC holding X-ring at 50Y, - tested out of machine fixture. Hence importance of cannelures pertaining to accuracy of the ammo is questionable. However importance of using proper cases is indisputable.

With that said, what to use and how to load is up to each of us.

AP

PhotoEscape- Admin

- Posts : 1542

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

So, one obscure maker headstamps ammo with “38 Spl Wad” and then you jump to a conclusion that all ammunition companies “make (or made) Wadcutter brass”? That’s supposition. There’s no clear evidence of that.

It also doesn’t make ANY sense from a manufacturing perspective. If you’ve ever seen case production at an ammunition plant you’d perhaps get an idea. Brass is drawn on large presses at 100 strokes per minute. The tools used are precision made and expensive. The individual pieces are collated and fed from bulk hoppers. The machine discharges into bulk hoppers. From there they go on to loading and assembly. So, under your scheme, the ammo maker has to have separate tools to make 38 Wadcutter brass yet the case has no marks to differentiate it until it get assembled into a loaded round?

But, even if they DID do that, they most CERTAINLY do not now. So rather than telling folks to search for unicorns perhaps it’s better to go in with data that allows shooters today to make selections from what is available today.

It also doesn’t make ANY sense from a manufacturing perspective. If you’ve ever seen case production at an ammunition plant you’d perhaps get an idea. Brass is drawn on large presses at 100 strokes per minute. The tools used are precision made and expensive. The individual pieces are collated and fed from bulk hoppers. The machine discharges into bulk hoppers. From there they go on to loading and assembly. So, under your scheme, the ammo maker has to have separate tools to make 38 Wadcutter brass yet the case has no marks to differentiate it until it get assembled into a loaded round?

But, even if they DID do that, they most CERTAINLY do not now. So rather than telling folks to search for unicorns perhaps it’s better to go in with data that allows shooters today to make selections from what is available today.

Wobbley- Admin

- Posts : 4805

Join date : 2015-02-12

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

It is a deviation from the subject of the thread as it was posted by OP. I believe, I provided factual answers and illustrated facts with details. I can provide more details and more illustrations. I agree that past time (made) is more indicative of manufacturers producing cases specific to WC ammo. I know for sure that Remington is no longer does, and it is reflective in the accuracy of latest WC ammo I have. I also know that Remington is no longer manufactures 148gr HBWC bullets for retail sale. With that said, and as I stated in my previous post, it is up to each individual to decide whether to accept compromise, and "make selections from what is available today" or seek proper components for the subject ammo. In order to do that one must know what it is he / she is looking for. And as of today there are many occasions when someone, who is retiring from the sport, offers WC related components or even older ammo here in Commercial Row. I was lucky enough to purchase 3500 of Federal GM38A WC ammo, and several thousands of Remington 148gr HBWC bullets here on the forum. And it happened very recently. Zero's HBWC bullets are good substitute for Remington's, and WC specific cases can last for very long time, - with proper technique multiple dozens of reloads. I have cases that have head stamps faded to the extent of not being readable, and they are still usable.Wobbley wrote:So, one obscure maker headstamps ammo with “38 Spl Wad” and then you jump to a conclusion that all ammunition companies “make (or made) Wadcutter brass”? That’s supposition. There’s no clear evidence of that.

It also doesn’t make ANY sense from a manufacturing perspective. If you’ve ever seen case production at an ammunition plant you’d perhaps get an idea. Brass is drawn on large presses at 100 strokes per minute. The tools used are precision made and expensive. The individual pieces are collated and fed from bulk hoppers. The machine discharges into bulk hoppers. From there they go on to loading and assembly. So, under your scheme, the ammo maker has to have separate tools to make 38 Wadcutter brass yet the case has no marks to differentiate it until it get assembled into a loaded round?

But, even if they DID do that, they most CERTAINLY do not now. So rather than telling folks to search for unicorns perhaps it’s better to go in with data that allows shooters today to make selections from what is available today.

"Obscure" manufacturer is a Fiocchi Munizioni, one of the largest and oldest ammo manufacturers in the world. BTW - original GFI ammo I purchased, is designed for revolver shooting. It is too light for semi-auto. I had to go with lowest strength recoil spring available for M52, and then trim couple of coils from it in order to cycle pistol. However 2000 rounds I bought originally about half a dozen years ago provided me with cases I use today.

AP

PhotoEscape- Admin

- Posts : 1542

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

I appreciate all who have taken time to reply to this thread. Being new to shooting centerfire in bullseye, all the information has helped me tremendously. I had no idea that there would be so much variation in the cases. The photo escape PTU works as it was designed to do once I learned what was going on. I would have never know this if it wasn't for this forum. I am hoping to get enough practice in to be able to shoot well enough in our summer league without hurting my average too much!

Foundryratjim- Posts : 243

Join date : 2018-08-01

Age : 66

Location : michigan

troystaten likes this post

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

Based mostly on recommendations here, I purchased "enough" cases in 38 and 45.

For 38, the only bullets I use are Magnus #514, again as recommended here many, many years ago.

I use an RCBS Pro2000 5-station press, and after discussing reloading with the two tech people I've come to know at Redding, I bought their custom dies for both 38 and 45.

Bullets press in easily to about half their length, meaning they are going straight in.

I can take photos, but my 38 rounds work in both my Model 52, and in my S&W Model 14 revolver.

I still have extra bags of new cases for both 38 and 45, all Starline.

As far as I know, everything is working fine.

As to loads, for 38 I only use 2.8 grains of WST. I bought four one-pound bottles.

(in the 1970's I was using Unique, but when I got the Pro2000 press I switched to Bullseye. Then people told me of the advantages of using WST, which "flows" more easily into my cases, and I think my loads are now more consistent.)

I'm curious as to why Starline cases were said to be the best a few years ago, and I'm reading here about potential problems??

For 38, the only bullets I use are Magnus #514, again as recommended here many, many years ago.

I use an RCBS Pro2000 5-station press, and after discussing reloading with the two tech people I've come to know at Redding, I bought their custom dies for both 38 and 45.

Bullets press in easily to about half their length, meaning they are going straight in.

I can take photos, but my 38 rounds work in both my Model 52, and in my S&W Model 14 revolver.

I still have extra bags of new cases for both 38 and 45, all Starline.

As far as I know, everything is working fine.

As to loads, for 38 I only use 2.8 grains of WST. I bought four one-pound bottles.

(in the 1970's I was using Unique, but when I got the Pro2000 press I switched to Bullseye. Then people told me of the advantages of using WST, which "flows" more easily into my cases, and I think my loads are now more consistent.)

I'm curious as to why Starline cases were said to be the best a few years ago, and I'm reading here about potential problems??

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

Foundryratjim wrote:I am using a Dillon press. I have just got and set up one of photo escape's PTU for this bullet. I am using zero bullets. I have the press set up so that I can push the bullet into the case by hand. The finished round will only go about 1/3 of it's length into my gage, about halfway into my GP100 cylinder and odly enough drops into my Model 52's chamber. I set up a Lee factory crimp die on another press and ran the rounds through it but nothing changed. What am I missing or doing wrong??

Reading this through a few months late. Curious as to how the OP still ended up with his reloaded HBWC's coming out at .391 after running them through a Lee Factory carbide crimp die. Mine sizes to a max of .377-.378 which supposedly ensures the round will drop into any 38 special chamber.

Does lee also make a non carbide factory crimp die that doesn't size an oversize case?

Last edited by PeteG on 8/28/2022, 7:27 pm; edited 2 times in total

PeteG- Posts : 2

Join date : 2021-04-24

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

...all fascinating.

I have learned that when I pay closer attention to the sights, and jerk the trigger less, my ammo is more accurate.

I have learned that when I pay closer attention to the sights, and jerk the trigger less, my ammo is more accurate.

Allgoodhits- Posts : 901

Join date : 2017-09-17

Location : Southport, NC

robert84010, troystaten, chiz1180 and dannyd93140 like this post

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

fc60 wrote:Greetings,

Try using a 38 Super Carbide Sizing die. Your sized cases should measure about 0.377".

Then, just flare the case mouth.

The bullet should start and press in with finger pressure about half way.

Cycle the press to finish seating.

The bulge should not appear; but, with thick walled cases the hollow base will collapse slightly.

It is difficult to find 38 Special brass that is uniform in wall thickness the entire length of the HBWC bullet.

Use PhotoEscape's pin check to gauge your brass. Slip it in until it stops and with a fine Sharpie pen mark a ring around the case mouth.

Next, compare the Zero bullet to the pin observing where the Sharpie line is in relation to the bullet.

It also helps to sort your cases by head stamp.

Cheers,

Dave

Dave is correct about the 38 Super die. That really works slick.

Bill

messenger- Posts : 1035

Join date : 2011-06-18

Location : North Carolina

Re: Reloading 148 HBWC

Re: Reloading 148 HBWC

here is a single pin gauge you can buy

https://www.mscdirect.com/browse/tn?searchterm=pin%20gage&navid=2107890&refinements=Diameter%20of%20Measurement%20(Decimal%20Inch)%3A0.3550

msc sells pretty much any pin/plug gauge you would need.

https://www.mscdirect.com/browse/tn?searchterm=pin%20gage&navid=2107890&refinements=Diameter%20of%20Measurement%20(Decimal%20Inch)%3A0.3550

msc sells pretty much any pin/plug gauge you would need.

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Dillon 38 HBWC Reloading

» S&W 32Long Copying the H&N .314 HBWC for Reloading

» Reloading 38 special cases.....fit help please

» Reloading HBWC on a progressive press question

» Zero 38 cal HBWC

» S&W 32Long Copying the H&N .314 HBWC for Reloading

» Reloading 38 special cases.....fit help please

» Reloading HBWC on a progressive press question

» Zero 38 cal HBWC

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum