Here's why you use sizing lube even with carbide dies.

+22

SingleActionAndrew

DA/SA

messenger

mprince

mikemyers

STEVE SAMELAK

Wes Lorenz

SmokinNJokin

SSgtG

PMcfall

jglenn21

NukeMMC

RoyDean

PhotoEscape

Captdave221

rburk

BE Mike

Asa Yam

dannyd93140

Dcforman

troystaten

zanemoseley

26 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Here's why you use sizing lube even with carbide dies.

Here's why you use sizing lube even with carbide dies.

In the past I've always used spray lube but occasionally try without as I really don't love how you end up with tacky ammo after you're done. I stainless pin tumble so the brass is extra clean. Today while loading some 38sp I pulled out the carbide ring on my Dillon die. I noticed the press ran smoother for a couple rounds lol, caught it when I was going to seat the bullet.

Even after getting the ring off the brass and pressed back in it came out with the next piece of brass. Maybe I should try loctite? I really need to give hornady one shot a try.

Even after getting the ring off the brass and pressed back in it came out with the next piece of brass. Maybe I should try loctite? I really need to give hornady one shot a try.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

Even though I have carbide sizing dies for my 38 special and 45 acp reloading I use Hornady one shot case lube, just makes things easier.

troystaten- Posts : 824

Join date : 2012-04-19

jcullen47 likes this post

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

I just dry tumble for about 12 hours with Hornady One Shot metal polish. Brass is super shiny, with enough slickness to load well. I still fail to see the appeal of wet tumbling. Maybe there's something I'm not understanding?

Dave

Dave

Dcforman- Posts : 928

Join date : 2017-11-18

Age : 43

Location : Ohio

jcullen47 likes this post

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

Well it's a no dust method of getting your brass extremely clean in 2hrs. Also no media to buy or sift through. A bottle of Dawn and you're good to go for years. Also very handy to use a magnet transfer to get out the left over pins.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

sayracin likes this post

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

Tumble cleaned with Lyman green for about 25 years then started wet cleaning. Would never go back to dry again. Deprime, armor all wash and wax, lemi shine, pins and water. Clean just like new brass into a gallon baggy couple spays of hornady one shot; shake lit dry about ten minutes and away you go. I get good results. ( disclaimer two hands with red dot)

dannyd93140- Posts : 197

Join date : 2021-07-31

Location : Jacksonville, Florida

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

I just picked up a large can of one shot to give it a try. Now I gotta see if Dillon will replace this die.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

I'm pretty sure dillion will replace the die, but if you find and afford a Redding duel ring die. It saves your brass and photo escape's powder transfer unit makes a world of difference loading full wad cutters.zanemoseley wrote:I just picked up a large can of one shot to give it a try. Now I gotta see if Dillon will replace this die.

dannyd93140- Posts : 197

Join date : 2021-07-31

Location : Jacksonville, Florida

Captdave221 likes this post

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

Cool! Fight to the death between sizing dies, all at 10 paces!dannyd93140 wrote:... but if you find and afford a Redding duel ring die...

Asa Yam- Posts : 197

Join date : 2018-09-15

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

In my reloading room I have gear from almost every reloading manufacturer because If it works I'm there plus I like new stuff.

dannyd93140- Posts : 197

Join date : 2021-07-31

Location : Jacksonville, Florida

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

I've got Hornady, RCBS, Dillon, Lee, Redding and used to have MEC. I like how most of the big companies really stand by their stuff, several good experiences with Hornady and RCBS.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

No long odds here. I'll bet Dillon will make good on that die. As I don't have water and a sink where I load, I don't clean my brass with pins. That being said, I still lube my cases. The older I get, anything that makes things easier is for me. Being cheap, I started making my own spray lube. So far, it does the job for much, much less.

BE Mike- Posts : 2587

Join date : 2011-07-29

Location : Indiana

chopper likes this post

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

Since I started shooting bullseye about 2 yrs ago, I have loaded at least 5,000 45 ACP rounds, and I still have half of a large can of one-shot left. A little goes a long way.

rburk- Posts : 166

Join date : 2019-09-26

Location : SoCal

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

I wish folks recommending Photo Escape transfer tube would mention how to set it up. Very easy to screw up the cases.dannyd93140 wrote:I'm pretty sure dillion will replace the die, but if you find and afford a Redding duel ring die. It saves your brass and photo escape's powder transfer unit makes a world of difference loading full wad cutters.zanemoseley wrote:I just picked up a large can of one shot to give it a try. Now I gotta see if Dillon will replace this die.

Captdave221- Posts : 5

Join date : 2018-08-08

Lowrate likes this post

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

Zane, you will have to ship your die to Dillon, and you'll get it back fixed in a week.

There is a trade off for getting brass sparkling like new after wet tumbling with pins. After such method of cleaning you must use lube, - brass will gull with funnels (I speculate, it is because brass notoriously gulls with stainless steel. So, I think, cleaning with stainless steel pins has something to do with brass subsequently having higher friction with non-stainless steel. Just IMO, there is no scientific support to that), regardless of funnel manufacturer. I previously posted in one thread, that I'm not concerned with my brass not being shiny but rather dull and with patina. I use ultrasonic cleaner without any pins. I use Costco's ultrashine and add liquid soap. Brass gets "coated" with lubricating layer. I do not use additional lubrication after that.

Captdave221, - setting up PTU is somewhat individual process, and depends on brass and bullets you reload. Objective is to setup PTU on such way that you able to push bullet by your thumb to about seating depth minus 1/16" - 1/32". Seating die should finish then. I suggest using this way of setting up for any HBWC, DEWC and HTC bullets in all calibers while using my PTUs. Hope it answers your inquiry. Feel free to contact me if you need help.

AP

There is a trade off for getting brass sparkling like new after wet tumbling with pins. After such method of cleaning you must use lube, - brass will gull with funnels (I speculate, it is because brass notoriously gulls with stainless steel. So, I think, cleaning with stainless steel pins has something to do with brass subsequently having higher friction with non-stainless steel. Just IMO, there is no scientific support to that), regardless of funnel manufacturer. I previously posted in one thread, that I'm not concerned with my brass not being shiny but rather dull and with patina. I use ultrasonic cleaner without any pins. I use Costco's ultrashine and add liquid soap. Brass gets "coated" with lubricating layer. I do not use additional lubrication after that.

Captdave221, - setting up PTU is somewhat individual process, and depends on brass and bullets you reload. Objective is to setup PTU on such way that you able to push bullet by your thumb to about seating depth minus 1/16" - 1/32". Seating die should finish then. I suggest using this way of setting up for any HBWC, DEWC and HTC bullets in all calibers while using my PTUs. Hope it answers your inquiry. Feel free to contact me if you need help.

AP

PhotoEscape- Admin

- Posts : 1542

Join date : 2018-05-15

Location : Northern Illinois, USA

chopper, Lowrate, Captdave221 and dannyd93140 like this post

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

AP of course means "galls", not those annoying seabirds "gulls".

Blame it on that pesky auto spell checker!

Brass certainly is prone to ""galling" when in contact with other metals.

Hornady One Shot is wonderful.

Blame it on that pesky auto spell checker!

Brass certainly is prone to ""galling" when in contact with other metals.

Hornady One Shot is wonderful.

RoyDean- Posts : 989

Join date : 2021-03-31

Age : 68

Location : Oregon

PhotoEscape likes this post

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

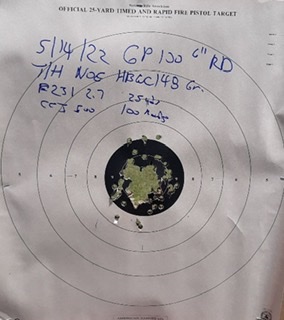

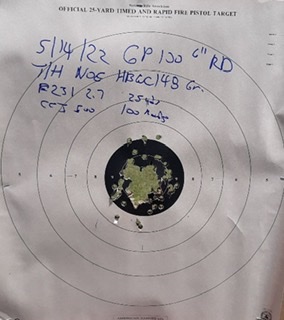

Gotta love SS tumbling though, just takes adding back a bit of lube before sizing. Decap and 2hrs with car wash and pins and it looks close to new. Here's cleaned once fired star line brass next to brand new star. There's a difference but such good results with just water and a nickel of soap with no dust. My allergies and asthma make it the best choice.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

RoyDean and dannyd93140 like this post

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

I knew a fellow once who never tumbled his brass. His cases almost looked black. His ammo shot very nice groups at 50 yards, however.

BE Mike- Posts : 2587

Join date : 2011-07-29

Location : Indiana

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

Bet his hands looked like a coal miner after a match handling that dirty of a case for 180 shots. Seems like it would be rough on your chamber too but who knows.BE Mike wrote:I knew a fellow once who never tumbled his brass. His cases almost looked black. His ammo shot very nice groups at 50 yards, however.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

My dad was like that. I have some (about 1000) WCC-41 45acp brass, twice fired, that looked chocolate brown. My guess is that came because he lubed his brass with 30w motor oil on his fingertips when sizing with old RCBS sizers. I also have some (600+) WRA (undated) once-fired from his stash. I stainless tumbled it all. That old brass was too easy to lose on the range, especially with fall leaves and such, and yes, it shot quite well. Guess what ... it still shoots well.BE Mike wrote:I knew a fellow once who never tumbled his brass. His cases almost looked black. His ammo shot very nice groups at 50 yards, however.

My opinion, for what it's worth, is that wet tumbling the brass gets the brass as consistent in condition as I am able to do. My time is precious and I cannot dedicate time to being overly anal about my brass prep. Wet tumbling cleans the brass inside and out, including primer pockets. When I reload rifle brass I decap, wet tumble, anneal (Giraud), size (Imperial lube), trim (Giraud) then dry tumble to remove the remnant Imperial. Gets it about as consistent as I am willing to spend time making it.

I have never lubed pistol brass since buying carbide dies. To date, I think I have only pulled 1 carbide ring from a sizer die, and that was close to 20 years ago. Before I wet-tumbled my brass, I used to eat a sizer die about every 2 or 3 years with dirt-etching. Since I started wet tumbling, I haven't replaced a sizer die (8 years). I use Lee sizing dies for pistol, even in my 550C. I mean, in 40 years of reloading, I have bought maybe 4 sizing dies for 45acp and only tossed 1 piece of brass for pulling the sizing ring out. I have reloaded tens of thousands of rounds of 45acp. When I was shooting Open Class USPSA, I shot 38 SuperComp and only bought 2 sizing dies. I learned pretty quick to tumble that stuff before sizing after eating the first die. I shot probably 6-8,000 rds a year for 5 years.

Am I the exception to the rule?

NukeMMC- Posts : 564

Join date : 2018-10-12

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

I just have better things to do that be all that concerned about my pistol brass. Come home from a match and dump them i to one or my tumblers with a cap full of Nu Finish. Turn it on and go do other things. Eventually take them out and reload them at some point.. brass is shiny enough and they are slick from the polish. Never had a problem with a carbide die.. I am a bit more serious about my long line ammo. Cases are new or 1-2 fired.

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

DA/SA likes this post

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

I agree with jglenn21. There are two things I'm not going to do. I'm not using case lube and I'm not tumbling ammo. So what if the carbide sizing die fails, I'll just get a new one although that hasn't happened in thousands and thousands in over 30 years.

Phil

Phil

PMcfall- Posts : 395

Join date : 2011-06-16

Location : St. Joseph, MO

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

Couple misconceptions about case lube; I just don't us it for sizing brass but it helps for case expansion too probably more there than any other step. Everyone is going to do it different when I started washing brass didn't think much of it then started getting in the rhythm and takes no time at all. Now I like clean brass.

dannyd93140- Posts : 197

Join date : 2021-07-31

Location : Jacksonville, Florida

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

Clean brass shoots no better than dirty brass. Might extract better...maybe. I use a tablespoon of mineral spirits in my corn cob media about every other load of brass. It's cheaper than one-shot and works well. I've never had an issue.

SSgtG- Posts : 63

Join date : 2012-05-17

Location : Iowa

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

Another easy, cheap technique that will save your arm on the press, buy liquid lanolin and 99% isopropyl, about 1 oz lanolin per 16oz alcohol but its not real critical, spread brass on a towel and give it a few sprays, roll it around a bit and it will be dry in a few minutes. The lanolin is not tacky or sticky like the other stuff. Dries into a very thin, waxy film - you won't even notice its there until you feel the difference. Much smoother press operation. A few seconds of extra effort that is really, really noticeable to the feel of the press operation. My hypothesis (no proof) is that a smoother press operation equates to more consistent, and therefore more accurate ammo. If that isn't true, I would still do it just to avoid the tennis elbow.

SmokinNJokin- Posts : 851

Join date : 2015-07-27

Location : Wisconsin Rapids

Re: Here's why you use sizing lube even with carbide dies.

Re: Here's why you use sizing lube even with carbide dies.

Star reloader base picture of why I switched to wet tumbling. Brass de-primed on the reloader leaves spent primer residue underneath the shellplate which becomes lapping compound.zanemoseley wrote:Gotta love SS tumbling though, just takes adding back a bit of lube before sizing. Decap and 2hrs with car wash and pins and it looks close to new. Here's cleaned once fired star line brass next to brand new star. There's a difference but such good results with just water and a nickel of soap with no dust. My allergies and asthma make it the best choice.

Need to weld this up one day and re-machine to new condition. Wear troughs are .005"-.007" deep in some areas.

Wes Lorenz- Posts : 443

Join date : 2011-06-27

Location : Washington

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Noe sizing dies

» ,45 acp cartridge sizing dies

» Tumble Lube versus Lube Sizer

» 9mm case sizing

» Bullet Sizing

» ,45 acp cartridge sizing dies

» Tumble Lube versus Lube Sizer

» 9mm case sizing

» Bullet Sizing

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum