Reliability test protocol

+5

Jon Eulette

jglenn21

Tripscape

SteveT

Merick

9 posters

Page 1 of 1

Reliability test protocol

Reliability test protocol

My eic gun has problems and it seems the more I work on it the worse it gets.

Ammo conditions being what they are; what is the most concise range test it needs to pass before I blow another two tanks of gas just to watch it lay down in a novel and unprecedented way during a leg match?

Ammo conditions being what they are; what is the most concise range test it needs to pass before I blow another two tanks of gas just to watch it lay down in a novel and unprecedented way during a leg match?

Merick- Posts : 453

Join date : 2015-08-13

Location : Kansas

Re: Reliability test protocol

Re: Reliability test protocol

Also are you asking reliability or safety tests? Safety test can be checked on dry run. Reliability tests are limited on dry run.

Tripscape- Posts : 878

Join date : 2019-03-22

Re: Reliability test protocol

Re: Reliability test protocol

45 range officer and my best effort at the usmc load. Didn't group like I thought it should so I bought a kart barrel and had it installed [by gunsmith #1]. Last round catches nose on barrel ramp. Gs1 recommends different magazines. No resolution.SteveT wrote:What gun? What load? What is the problem?

GS2 recommends more recoil spring (wolff 18.5#). No resolution. GS2 recommends profile barrel feed per Kuhnhausen specs. Tentative success.

Test with old and new mags and old/new springs since I have them all now anyhow. New mags and new spring print an astonishing group. Confirmed with a couple practice sessions.

Get to the match and it suddenly decides to do a new trick where a spent case is holding the slide off the barrel and a live round is in the chamber, but just in the timed and rapid stages.

EDIT FOR CLARIFICATION

I am asking for a reliability of function test. Imagine as if you were repairing your brother-in-law's gun and if it ever jammed you would never hear an end to it. How would you test it before you gave it back to him?

Last edited by Merick on Sun Jul 03, 2022 7:53 pm; edited 2 times in total

Merick- Posts : 453

Join date : 2015-08-13

Location : Kansas

Re: Reliability test protocol

Re: Reliability test protocol

a picture of the current "trick" would help

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Reliability test protocol

Re: Reliability test protocol

Can you provide picture of barrel sitting on receiver all the way to the rear? Need a pic of frame feedramp to barrel ramp/throat.

Also if too much extractor tension, it will cause feeding issues.

What bullet are you using?

Jon

Also if too much extractor tension, it will cause feeding issues.

What bullet are you using?

Jon

Jon Eulette- Posts : 4399

Join date : 2013-04-15

Location : Southern Kalifornia

Re: Reliability test protocol

Re: Reliability test protocol

Always hard to get to the exact problem over the net, but off hand I'd say you have an extrator issue.. too much pressure.. also could be an profile problem.

Set the tension where with a case held by the extrator it will flop up and down but not fall off. If the case noves very little then too much tension.

Also check you ejector with the slide off to be sure it's not loose..SA glued their ejectors in the later models.

Set the tension where with a case held by the extrator it will flop up and down but not fall off. If the case noves very little then too much tension.

Also check you ejector with the slide off to be sure it's not loose..SA glued their ejectors in the later models.

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Reliability test protocol

Re: Reliability test protocol

My first wadgun was a used Les Baer and it had issues stripping the last round of a mag but would feed the rest fine. Why not buy a new quality extractor like EGW and drop it in to see if that helps. You can always use a spare extractor.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Reliability test protocol

Re: Reliability test protocol

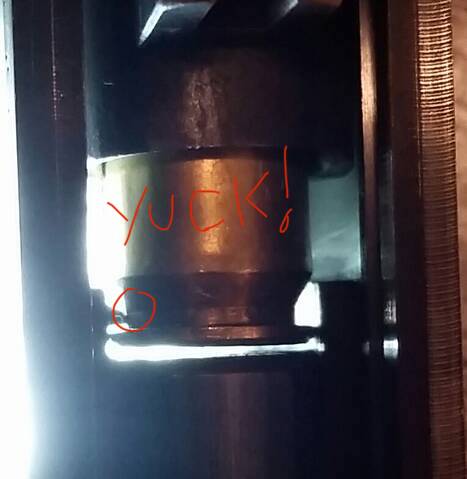

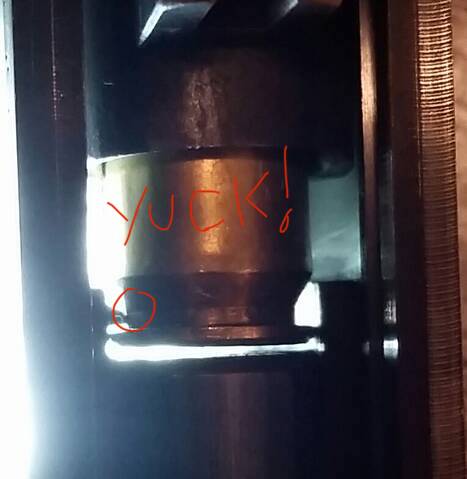

Merick wrote:*Recreation. I did pull the firing pin before I set that up. How this happens I do not understand.

What's happening in the picture is that the expended case is extracted from the chamber but the extractor loses control of it before it is ejected. The fired case then "floats" on or just above the next round in the magazine. The slide comes forward and strips the next round out of the magazine while also pushing the fired case forward until it impacts the barrel hood which brings everything to a screeching halt.

This specific malfunction is caused by an improperly fit extractor.

99.9% of the time you cannot simply drop in a new extractor and have it function properly. It needs to be fit to the pistol. For more than you ever wanted to know about correctly fitting an extractor go to this LINK.

Steve in Allentown- Posts : 49

Join date : 2020-04-24

Location : Allentown, PA

Re: Reliability test protocol

Re: Reliability test protocol

Zero 185 JHPJon Eulette wrote:Can you provide picture of barrel sitting on receiver all the way to the rear? Need a pic of frame feedramp to barrel ramp/throat.

Also if too much extractor tension, it will cause feeding issues.

What bullet are you using?

Jon

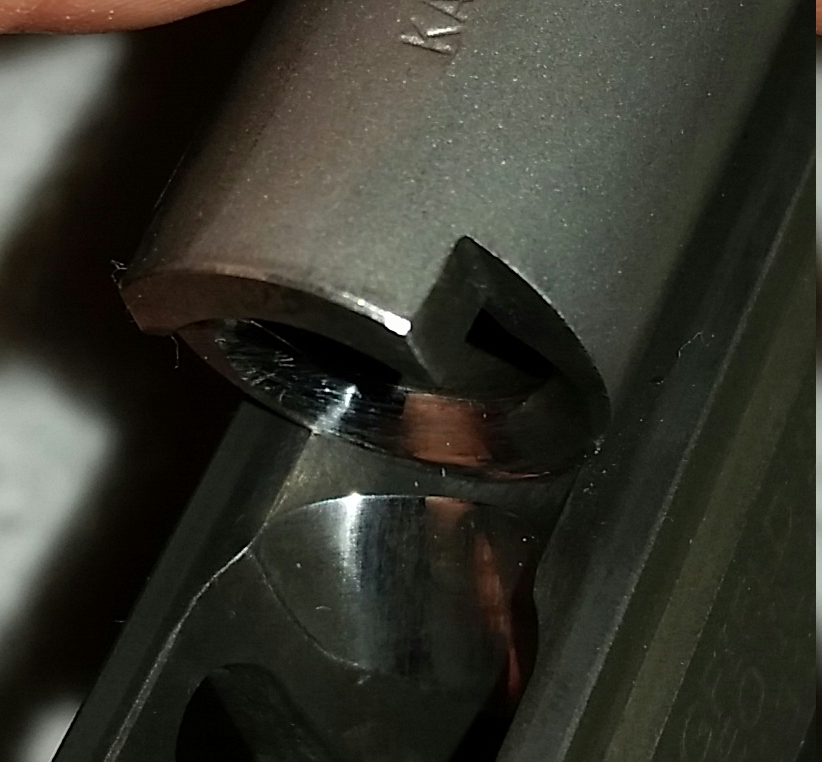

And for fun here's one of the extractor holding a case;

Merick- Posts : 453

Join date : 2015-08-13

Location : Kansas

Re: Reliability test protocol

Re: Reliability test protocol

The extractor look long in that image.

If the case head was against the breech face, the extractor nose looks like it would be against the angled area of the case.

Have you looked at a fired case to see if the extractor left a mark in that area?

Is it just the image?

If the case head was against the breech face, the extractor nose looks like it would be against the angled area of the case.

Have you looked at a fired case to see if the extractor left a mark in that area?

Is it just the image?

DA/SA- Posts : 1506

Join date : 2017-10-09

Age : 68

Location : Southeast Florida

Re: Reliability test protocol

Re: Reliability test protocol

That is indeed the case.DA/SA wrote:The extractor look long in that image.

If the case head was against the breech face, the extractor nose looks like it would be against the angled area of the case.

Have you looked at a fired case to see if the extractor left a mark in that area?

Is it just the image?

Merick- Posts : 453

Join date : 2015-08-13

Location : Kansas

Re: Reliability test protocol

Re: Reliability test protocol

That looks like a pterodactyl beak. Mine was the same on my RO and I did some careful shaping with one of the goals that the case rim contacted the extractor groove and the “beak” was close but not contacting the case. There’s other contours to address as well as tension. Gunsmith should have picked up on that in my humble opinion.

RodJ- Posts : 921

Join date : 2021-06-26

Location : TX

Re: Reliability test protocol

Re: Reliability test protocol

Here's what a perfectly fit should look like. There is no contact between the claw edge and the case and the case rim sits flush against the breechface.

The picture on the left is the common method of fitting a smaller than .45 extractor. Note the contact between the claw edge and the case as well as the gap between the tensioning wall and the case rim.

The picture on the right is how your .45 extractor should be fit. Note the only contact between the extractor and the case is at the tensioning wall and the case rim. There is no contact between the claw edge and the case.

The pictures below show good and bad .45 frame feed ramps.

#1 and "C" are bad. Too shallow and incorrect angle.

#2, "A", and "B" are good. Note how far down the frame they extend and the angle is dead on at 31.5 degrees.

Here are some critical dimensions that you can show to your 'smith.

There is much more at the LINK I provided in my previous post above.

The picture on the left is the common method of fitting a smaller than .45 extractor. Note the contact between the claw edge and the case as well as the gap between the tensioning wall and the case rim.

The picture on the right is how your .45 extractor should be fit. Note the only contact between the extractor and the case is at the tensioning wall and the case rim. There is no contact between the claw edge and the case.

The pictures below show good and bad .45 frame feed ramps.

#1 and "C" are bad. Too shallow and incorrect angle.

#2, "A", and "B" are good. Note how far down the frame they extend and the angle is dead on at 31.5 degrees.

Here are some critical dimensions that you can show to your 'smith.

There is much more at the LINK I provided in my previous post above.

Steve in Allentown- Posts : 49

Join date : 2020-04-24

Location : Allentown, PA

Re: Reliability test protocol

Re: Reliability test protocol

To answer my own question; the extractor function test is to limp wrist a number of shots without the magazine present. 5 per Weigand, or 8 both hands and 8 strong hand per Hilton Yam. Normal ejection = pass, jams and abnormal ejection = fail.

Also for those who feel random shaking is an unsceintific measure of tension; weigand states in the information supplied with their pull gauge it should take between 25-28 ounces to dislodge their gauge downward when extractor tenstion is correct.

Also for those who feel random shaking is an unsceintific measure of tension; weigand states in the information supplied with their pull gauge it should take between 25-28 ounces to dislodge their gauge downward when extractor tenstion is correct.

Merick- Posts : 453

Join date : 2015-08-13

Location : Kansas

Similar topics

Similar topics» Hammerli 208s reliability

» .32 ACP Pardini reliability

» 22 Pistol Reliability

» Improving the reliability of the Arrow JT-21M

» Larry's Guns/Red Feather Hammerli Scope Mount Reliability issues

» .32 ACP Pardini reliability

» 22 Pistol Reliability

» Improving the reliability of the Arrow JT-21M

» Larry's Guns/Red Feather Hammerli Scope Mount Reliability issues

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum