Measuring..

+9

Rob Kovach

expendable

jmdavis

rich.tullo

james r chapman

Wobbley

Froneck

Axehandle

Jerry Keefer

13 posters

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Measuring..

Measuring..

First topic message reminder :

Relating to the two topics of measuring . Perfection does not exist..We can only strive for perfection. We can zero a part with a .001 displacement indicator to no perceptible motion of the needle.. Remove that indicator and put a 5 digit Tesatast in its place. We will again have very noticeable amount of motion. Or we could go to electron displacement..and still never be perfect.. When starting from scratch, or doing a refurb, I am firm believer in taking the time to do a complete lay out of all the dimensions and transfer those to what I call a mapping document.. It's essential to frame and slide fitting and or doing an acu rail job. It assists in plotting the course so to speak.

The slide bore is a point of issue and topic recently.. I start by lapping the entire bore to true it and get a consistent end to end dimension..The muzzle end ID for the purpose of a bushing or cone then becomes an automatically known. But the main reason is to have an exact radius of the upper lug area. This dimension is then transferred to the upper lug radius of the barrel.. Now we have two matching radii that mate over a larger surface area, than the small 10/2 spots normally found on barrel fits. Think barrel tester.. The barrel always shoots better in the tester than the gun.. Why..? It is supported better.. So any all effort directed to more barrel support within the gun is beneficial to accuracy.. I like Z class minus gauge pins. I have sets starting at .010 thru .800 That covers just about all imaginable possibilities for the 1911 and most other guns. As I have said numerous times.. You must know where you are, to know where you need to go, when it comes to measuring/dimensions.

Lapping to true and size

Assotment of mapping documents.. As you can see anything pertaining to the job can be written in or added

Assorted gauge pin being used to bring a dimension to size.. The "GO/NO GO " process is very accurate. The reason I like minus pins..

In an effort to have maximum contact at lock up, I do not relieve, egg or oblong the bushing bore to accommodate barrel tilt. No need to do that..Clearance in the area of tenths can be run.

Ground radii to match the slide radii and matching the lug shoulders to the slide .

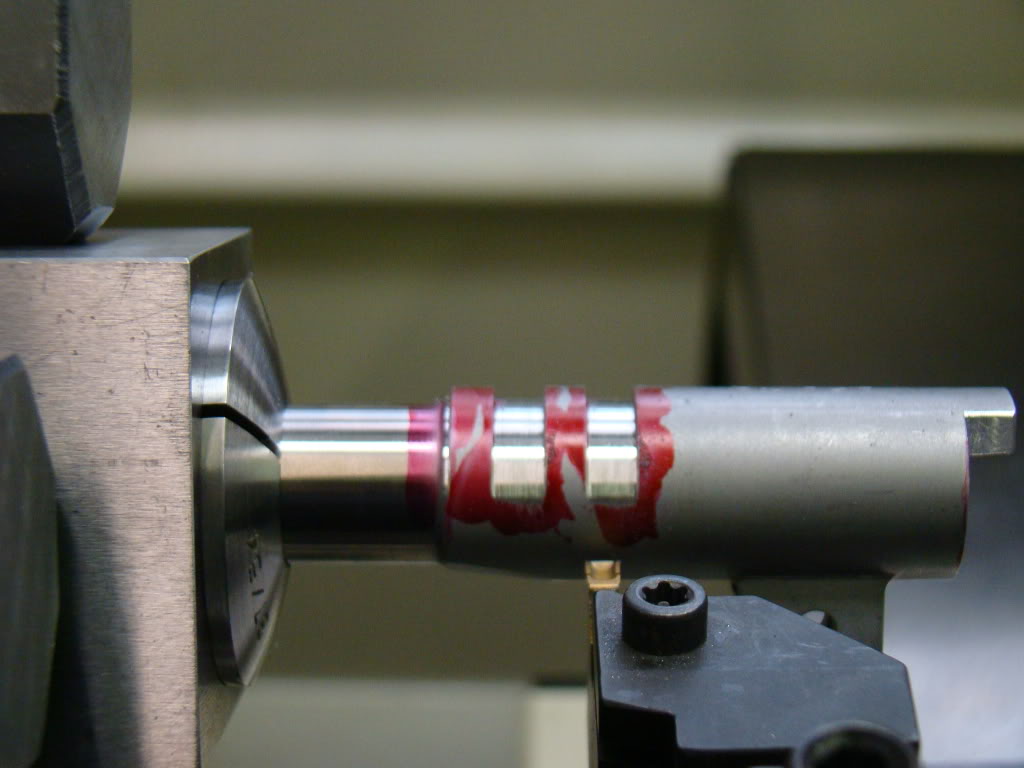

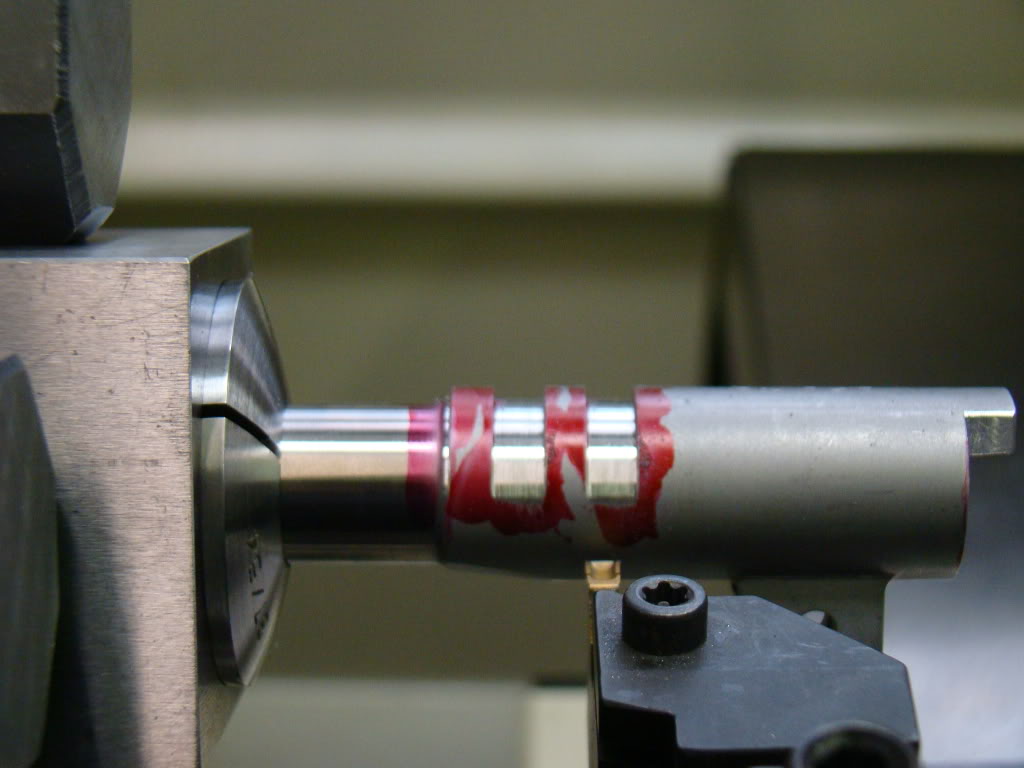

Barrel in the Master Grind lug radius being trued, shoulder locations being adjusted..

Can also be done quite accurately in the lathe..

Relating to the two topics of measuring . Perfection does not exist..We can only strive for perfection. We can zero a part with a .001 displacement indicator to no perceptible motion of the needle.. Remove that indicator and put a 5 digit Tesatast in its place. We will again have very noticeable amount of motion. Or we could go to electron displacement..and still never be perfect.. When starting from scratch, or doing a refurb, I am firm believer in taking the time to do a complete lay out of all the dimensions and transfer those to what I call a mapping document.. It's essential to frame and slide fitting and or doing an acu rail job. It assists in plotting the course so to speak.

The slide bore is a point of issue and topic recently.. I start by lapping the entire bore to true it and get a consistent end to end dimension..The muzzle end ID for the purpose of a bushing or cone then becomes an automatically known. But the main reason is to have an exact radius of the upper lug area. This dimension is then transferred to the upper lug radius of the barrel.. Now we have two matching radii that mate over a larger surface area, than the small 10/2 spots normally found on barrel fits. Think barrel tester.. The barrel always shoots better in the tester than the gun.. Why..? It is supported better.. So any all effort directed to more barrel support within the gun is beneficial to accuracy.. I like Z class minus gauge pins. I have sets starting at .010 thru .800 That covers just about all imaginable possibilities for the 1911 and most other guns. As I have said numerous times.. You must know where you are, to know where you need to go, when it comes to measuring/dimensions.

Lapping to true and size

Assotment of mapping documents.. As you can see anything pertaining to the job can be written in or added

Assorted gauge pin being used to bring a dimension to size.. The "GO/NO GO " process is very accurate. The reason I like minus pins..

In an effort to have maximum contact at lock up, I do not relieve, egg or oblong the bushing bore to accommodate barrel tilt. No need to do that..Clearance in the area of tenths can be run.

Ground radii to match the slide radii and matching the lug shoulders to the slide .

Barrel in the Master Grind lug radius being trued, shoulder locations being adjusted..

Can also be done quite accurately in the lathe..

Jerry Keefer- Posts : 1001

Join date : 2012-01-02

Location : Maidens, VA

Re: Measuring..

Re: Measuring..

troystaten wrote:I'm not a gunsmith and never will be one, but I find this information very interesting and I think it is great to see it posted because the knowledge you guys have is very extensive and it is great that your sharing it especially for future use by other gunsmiths.

Absolutely. At this stage of my life, I would not have the patience to learn everything about milling, lathe work, problem solving that's involved in just 1911 issues. Let alone, all the other stuff that comes your way when word gets out you do gunsmithing.

Like "Hey, Ive got a 6.5 Carcano. Can you put a 30-378 barrel on it so I can shoot an elk at 2000 yards?" kind of questions. I wouldn't have the tact to deal with stuff like that.

Jerry, its such a pleasure seeing your works in action. Surgically clean is the phrase that comes to mind. Here I am, couldn't sleep last night so at 1-4 am, I'm loading short line stuff & getting ready for perry, and I had to clean off a spot to set my bullets down (that's in 22 feet of bench space.) My Dad always said "You don't need a workbench longer than 3', there's never any more clean room than that anyway." I have become my father (and I'm very satisfied with that).

Al

Al- Posts : 650

Join date : 2011-06-10

Age : 69

Location : Bismarck, ND

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Measuring crimp.

» Cheap .22 ammo test

» 45acp case length

» Measuring for new bushing

» Measuring Recoil Springs

» Cheap .22 ammo test

» 45acp case length

» Measuring for new bushing

» Measuring Recoil Springs

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum