Measuring..

+9

Rob Kovach

expendable

jmdavis

rich.tullo

james r chapman

Wobbley

Froneck

Axehandle

Jerry Keefer

13 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Measuring..

Measuring..

Relating to the two topics of measuring . Perfection does not exist..We can only strive for perfection. We can zero a part with a .001 displacement indicator to no perceptible motion of the needle.. Remove that indicator and put a 5 digit Tesatast in its place. We will again have very noticeable amount of motion. Or we could go to electron displacement..and still never be perfect.. When starting from scratch, or doing a refurb, I am firm believer in taking the time to do a complete lay out of all the dimensions and transfer those to what I call a mapping document.. It's essential to frame and slide fitting and or doing an acu rail job. It assists in plotting the course so to speak.

The slide bore is a point of issue and topic recently.. I start by lapping the entire bore to true it and get a consistent end to end dimension..The muzzle end ID for the purpose of a bushing or cone then becomes an automatically known. But the main reason is to have an exact radius of the upper lug area. This dimension is then transferred to the upper lug radius of the barrel.. Now we have two matching radii that mate over a larger surface area, than the small 10/2 spots normally found on barrel fits. Think barrel tester.. The barrel always shoots better in the tester than the gun.. Why..? It is supported better.. So any all effort directed to more barrel support within the gun is beneficial to accuracy.. I like Z class minus gauge pins. I have sets starting at .010 thru .800 That covers just about all imaginable possibilities for the 1911 and most other guns. As I have said numerous times.. You must know where you are, to know where you need to go, when it comes to measuring/dimensions.

Lapping to true and size

Assotment of mapping documents.. As you can see anything pertaining to the job can be written in or added

Assorted gauge pin being used to bring a dimension to size.. The "GO/NO GO " process is very accurate. The reason I like minus pins..

In an effort to have maximum contact at lock up, I do not relieve, egg or oblong the bushing bore to accommodate barrel tilt. No need to do that..Clearance in the area of tenths can be run.

Ground radii to match the slide radii and matching the lug shoulders to the slide .

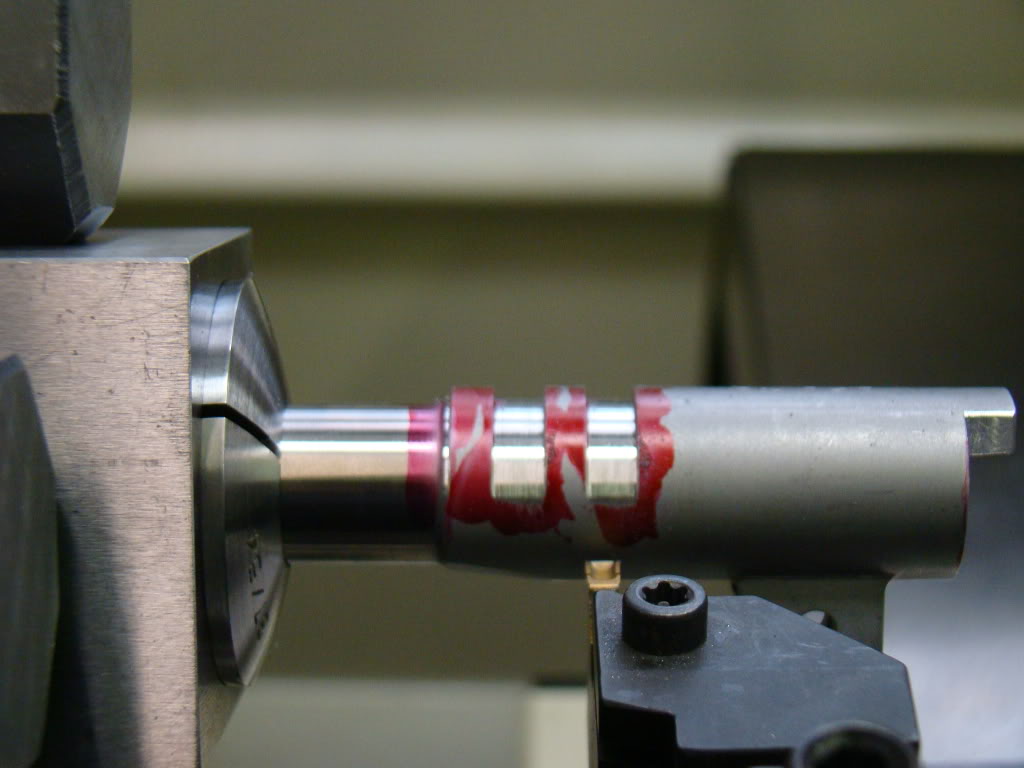

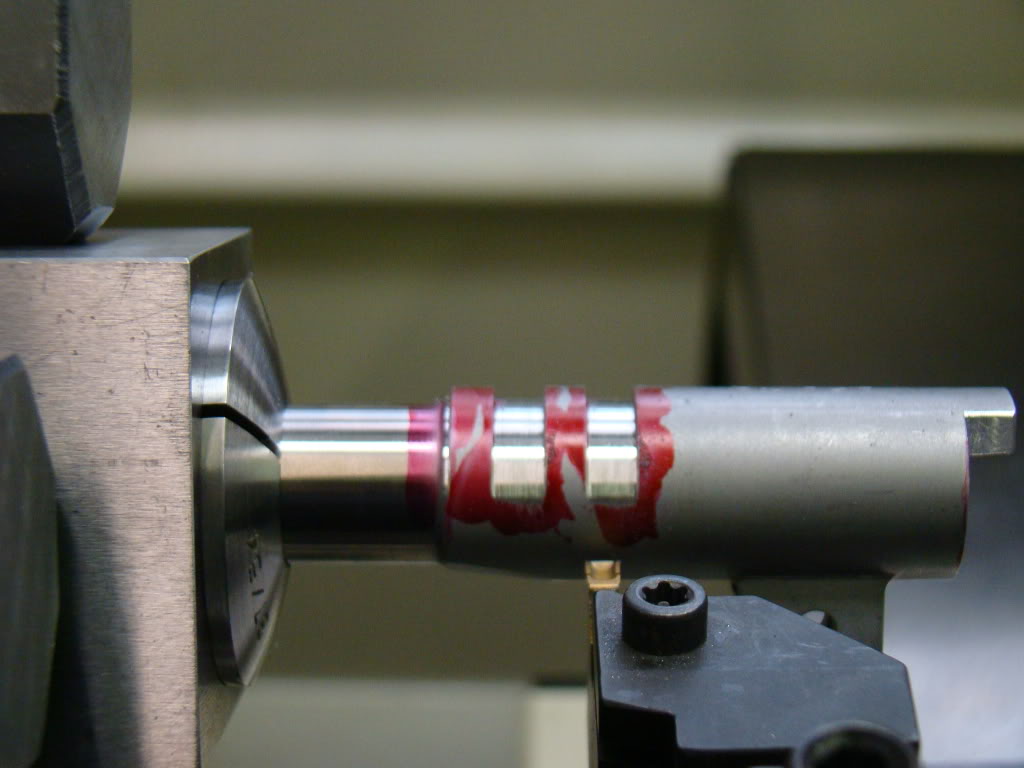

Barrel in the Master Grind lug radius being trued, shoulder locations being adjusted..

Can also be done quite accurately in the lathe..

The slide bore is a point of issue and topic recently.. I start by lapping the entire bore to true it and get a consistent end to end dimension..The muzzle end ID for the purpose of a bushing or cone then becomes an automatically known. But the main reason is to have an exact radius of the upper lug area. This dimension is then transferred to the upper lug radius of the barrel.. Now we have two matching radii that mate over a larger surface area, than the small 10/2 spots normally found on barrel fits. Think barrel tester.. The barrel always shoots better in the tester than the gun.. Why..? It is supported better.. So any all effort directed to more barrel support within the gun is beneficial to accuracy.. I like Z class minus gauge pins. I have sets starting at .010 thru .800 That covers just about all imaginable possibilities for the 1911 and most other guns. As I have said numerous times.. You must know where you are, to know where you need to go, when it comes to measuring/dimensions.

Lapping to true and size

Assotment of mapping documents.. As you can see anything pertaining to the job can be written in or added

Assorted gauge pin being used to bring a dimension to size.. The "GO/NO GO " process is very accurate. The reason I like minus pins..

In an effort to have maximum contact at lock up, I do not relieve, egg or oblong the bushing bore to accommodate barrel tilt. No need to do that..Clearance in the area of tenths can be run.

Ground radii to match the slide radii and matching the lug shoulders to the slide .

Barrel in the Master Grind lug radius being trued, shoulder locations being adjusted..

Can also be done quite accurately in the lathe..

Jerry Keefer- Posts : 1001

Join date : 2012-01-02

Location : Maidens, VA

Re: Measuring..

Re: Measuring..

Axehandle- Posts : 879

Join date : 2013-09-17

Location : Alabama

Re: Measuring..

Re: Measuring..

When building a gun either new or re-build I do just about the same. Though I like using Service Hard Chrome plating on the wear areas. I'm a bushing guy so I double bore the bushing and the start bore is as the barrel is when locked-up then just enough second bore to allow the barrel to drop. That way at lock-up I get half a hole on the top of the barrel and half on the bottom. Lot of engagement with no wear since when the barrel drops to unlock there is no contact with the lockup area. As soon as I get my Jig Grinder running I plan to Hard Chrome the bushing and diamond grind it.

I also plot my movements as Jerry but do it on AutoCad. I draw every gun I do in real time so that I can layer the components. By turning the layers on and off I can assemble the components an see how they fit. Using zoom I can make .0001 look like an inch. Might be a bit of over kill but if I decide to make a change I can modify the drawing and see how that effects everything else. Easier that way than machine the change an find it don't work after trying to assemble the gun.

I also plot my movements as Jerry but do it on AutoCad. I draw every gun I do in real time so that I can layer the components. By turning the layers on and off I can assemble the components an see how they fit. Using zoom I can make .0001 look like an inch. Might be a bit of over kill but if I decide to make a change I can modify the drawing and see how that effects everything else. Easier that way than machine the change an find it don't work after trying to assemble the gun.

Froneck- Posts : 1761

Join date : 2014-04-05

Age : 77

Re: Measuring..

Re: Measuring..

You don't need diamond wheels to grind hard chrome. Good quality carborundum wheels will do. But you do need to use coolant as the heat buildup will cause the underlying steel to turn to martensite and become brittle even with diamond.

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

Re: Measuring..

Re: Measuring..

Like Earl Scheib, I can get all this for $29.95?

james r chapman- Admin

- Posts : 6372

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

Re: Measuring..

Re: Measuring..

Jig Grinder I purchased came with quite a few mounted diamond wheels plus they don't have to be dressed as often as Silicon Carbide (Carborundum) I usually do grind with coolant because it keeps the "dust" down, I don't like breathing that stuff.Wobbley wrote:You don't need diamond wheels to grind hard chrome. Good quality carborundum wheels will do. But you do need to use coolant as the heat buildup will cause the underlying steel to turn to martensite and become brittle even with diamond.

Froneck- Posts : 1761

Join date : 2014-04-05

Age : 77

Re: Measuring..

Re: Measuring..

You can make a space shuttle in that machine shop.

rich.tullo- Posts : 2006

Join date : 2015-03-27

Re: Measuring..

Re: Measuring..

Hmmmm... That's a thought..rich.tullo wrote:You can make a space shuttle in that machine shop.

Jerry Keefer- Posts : 1001

Join date : 2012-01-02

Location : Maidens, VA

Re: Measuring..

Re: Measuring..

I made the infrared assemblies that goes goes into the nose cone of the Red Eye Missile, does that count?

Froneck- Posts : 1761

Join date : 2014-04-05

Age : 77

Re: Measuring..

Re: Measuring..

This was posted recently on another gunsmithing forum.. I hesitate to post this stuff here, because this forum is focused on shooting and not smithing.

But, it is Bullseye smithing and maybe some DIYers can benefit and foster some ideas.. My days of smithing are running out, and it is the Guild goal is to promote the profession and educate.

Forming the lower lug on a S&W 52 barrel

Early model Weigand fixture modified for the surface grinder. Fully adjustable for repeatability and zero.

Using an ACU-PRO truing block to fit the hood.. The sides can be very accurately done in one set up..

Set up on gauge blocks to adjust the length and angle.

1911 barrel in the fixture

But, it is Bullseye smithing and maybe some DIYers can benefit and foster some ideas.. My days of smithing are running out, and it is the Guild goal is to promote the profession and educate.

Forming the lower lug on a S&W 52 barrel

Early model Weigand fixture modified for the surface grinder. Fully adjustable for repeatability and zero.

Using an ACU-PRO truing block to fit the hood.. The sides can be very accurately done in one set up..

Set up on gauge blocks to adjust the length and angle.

1911 barrel in the fixture

Jerry Keefer- Posts : 1001

Join date : 2012-01-02

Location : Maidens, VA

Re: Measuring..

Re: Measuring..

Jerry,

It may be a dumb question, but I am wondering why the surface grinder over the milling machine? Is it the precision required or something else?

It may be a dumb question, but I am wondering why the surface grinder over the milling machine? Is it the precision required or something else?

jmdavis- Posts : 1409

Join date : 2012-03-23

Location : Virginia

Re: Measuring..

Re: Measuring..

Control...An endmill requires more force to cut than a grinding wheel.. The grinder can easily work in tenths or less, the mill cannot..jmdavis wrote:Jerry,

It may be a dumb question, but I am wondering why the surface grinder over the milling machine? Is it the precision required or something else?

Jerry Keefer- Posts : 1001

Join date : 2012-01-02

Location : Maidens, VA

Re: Measuring..

Re: Measuring..

It may or may not be Bullseye related, but I love it when you post this stuff.

Kurt

Kurt

expendable- Posts : 90

Join date : 2011-10-01

Re: Measuring..

Re: Measuring..

Thanks, I can understand that. And this is excellent stuff. It makes a 51 year old man want to go and learn about machining.

Mike

Mike

jmdavis- Posts : 1409

Join date : 2012-03-23

Location : Virginia

Re: Measuring..

Re: Measuring..

It's definitely authorized for you to share all of this knowledge about bullseye guns and the accurizing of them.

Rob Kovach- Admin

- Posts : 2692

Join date : 2011-06-13

Age : 51

Location : Brooklyn, WI

Re: Measuring..

Re: Measuring..

I did post in another thread and thought it would be a good idea to mention it here too. In wandering the net looking for information I came upon this site that showed how to make a accurate 1911 type 45. Didn't show much and I think they were selling a course but they mentioned using a drill press with an X-Y tables as a milling machine., NEVER do that! You will ruin a good slide and frame. Yes there are some Mill/Drills but they have radial bearing in the spindle a drill press has only trust bearings. Have the X-Y table built in not a flat type drill press type table! The mill/drills will work but have issues.

Furthermore As Jerry said the grinder requires less cutting force but the grinding machine is built much better than a standard mill. They are designed to do more accurate work but are limited to particular operations whereas a mill is more universal but less accurate.

Furthermore As Jerry said the grinder requires less cutting force but the grinding machine is built much better than a standard mill. They are designed to do more accurate work but are limited to particular operations whereas a mill is more universal but less accurate.

Froneck- Posts : 1761

Join date : 2014-04-05

Age : 77

Re: Measuring..

Re: Measuring..

To Jerry and other gunsmiths and machinists ; this forum is dedicated to "All things bullseye" there would be no sport if not for the gunsmiths and machinists who figured out how to build the guns and the parts that make our guns shoot so good. Please share any of your knowledge and skills you would like too. Its very interesting and informative. Just yesterday at a match I told a friend who gunsmiths to come to the forum to see this topic and others that have been posted. He was very interested in the cut jerry did to the mags for the trigger bow if sometime you can elaborate on that some more.

DavidR- Admin

- Posts : 3032

Join date : 2011-06-10

Age : 70

Location : NRA:Expert, Georgia

Re: Measuring..

Re: Measuring..

I'm told the the AMU cuts the trigger so it does not touch the frame and uses the bow as the guide. I made 2 triggers for Adam and sent them Saturday so I have no results yet, probably will not until after Perry. One I fitted to a Caspian Frame I have and length exposed as Adam requested .248" wide and just enough in height to slide easy, .725" finger radius. Nice fit, no play only the take-up. The other was .248" wide and .910 top to bottom and 9/16 long to be fitted by their smith. The trigger was Aluminum Bronze with Steel bow. The one I fitted felt great and I'm making one for my gun and will add the shoe to increase width

Froneck- Posts : 1761

Join date : 2014-04-05

Age : 77

Re: Measuring..

Re: Measuring..

OK ..The magazine is about 15 degrees off the trigger bow/track.

I simply use a pencil and protractor to draw a 15 degree line on the chuck. Set a parallel on the line for blocking and line the magazine against the parallel.. Add a parallel to the opposite side of the mag for more security, and make the cut as shown. .005/.008 deep usually cleans up nicely and about .350 wide. On the right side the cut will just kiss the upper edge of the mag catch slot. Most magazines will have a witness mark from the bow rubbing the side wall of the magazine..The mag wall is quite thin.. Heat will build up, make the metal expand quickly, and possibly grab the wheel.. use coolant.

I simply use a pencil and protractor to draw a 15 degree line on the chuck. Set a parallel on the line for blocking and line the magazine against the parallel.. Add a parallel to the opposite side of the mag for more security, and make the cut as shown. .005/.008 deep usually cleans up nicely and about .350 wide. On the right side the cut will just kiss the upper edge of the mag catch slot. Most magazines will have a witness mark from the bow rubbing the side wall of the magazine..The mag wall is quite thin.. Heat will build up, make the metal expand quickly, and possibly grab the wheel.. use coolant.

Jerry Keefer- Posts : 1001

Join date : 2012-01-02

Location : Maidens, VA

Re: Measuring..

Re: Measuring..

The trigger bow is /can be a source of trouble if it has a lot of free play within the track.

Nearly all are to narrow. I swage the bow in several areas to increase the width and then grind the raised metal down to get the perfect fit.. Usually front and rear as shown in the pics.. It keeps the bow from moving up or down as it makes contact with the disconnector. Consistent feel, is the result. I Place a small dot of tig on the front of the bow and grind it down to get the free play I want. The last pic shows the shoe radius being moved to suit the shooter's likes/dislikes

Nearly all are to narrow. I swage the bow in several areas to increase the width and then grind the raised metal down to get the perfect fit.. Usually front and rear as shown in the pics.. It keeps the bow from moving up or down as it makes contact with the disconnector. Consistent feel, is the result. I Place a small dot of tig on the front of the bow and grind it down to get the free play I want. The last pic shows the shoe radius being moved to suit the shooter's likes/dislikes

Jerry Keefer- Posts : 1001

Join date : 2012-01-02

Location : Maidens, VA

Re: Measuring..

Re: Measuring..

Your work is quite amazing, Jerry. Thank you for sharing.

Rob Kovach- Admin

- Posts : 2692

Join date : 2011-06-13

Age : 51

Location : Brooklyn, WI

Re: Measuring..

Re: Measuring..

very cool stuff! thank you

DavidR- Admin

- Posts : 3032

Join date : 2011-06-10

Age : 70

Location : NRA:Expert, Georgia

Re: Measuring..

Re: Measuring..

I love this.

Please keep it up.

Thanks for sharing this.

Please keep it up.

Thanks for sharing this.

HenryA- Posts : 94

Join date : 2013-08-24

Extractors

Extractors

Extractors are nearly always too long

This shows where the extractor needs to be to have the hook free of the rebate angle, as the second picture shows.

A small piece of metal is silver soldered into the slot and machined to pull the hook back. This allows smoother feeding, and relieves the pressure exerted against the base of the cartridge when in lock up.. Being free in lock up aids in accuracy, as the cartridge is not pushed to one side by pressure exerted from the extractor.

This shows where the extractor needs to be to have the hook free of the rebate angle, as the second picture shows.

A small piece of metal is silver soldered into the slot and machined to pull the hook back. This allows smoother feeding, and relieves the pressure exerted against the base of the cartridge when in lock up.. Being free in lock up aids in accuracy, as the cartridge is not pushed to one side by pressure exerted from the extractor.

Jerry Keefer- Posts : 1001

Join date : 2012-01-02

Location : Maidens, VA

Re: Measuring..

Re: Measuring..

I'm not a gunsmith and never will be one, but I find this information very interesting and I think it is great to see it posted because the knowledge you guys have is very extensive and it is great that your sharing it especially for future use by other gunsmiths.

troystaten- Posts : 824

Join date : 2012-04-18

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Measuring Recoil Springs

» Cheap .22 ammo test

» 45acp case length

» Measuring for new bushing

» Measuring recoil spring rate

» Cheap .22 ammo test

» 45acp case length

» Measuring for new bushing

» Measuring recoil spring rate

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum