Oops, good thing for the LYMAN Case Gage

+12

Virgil Kane

weber1b

bruce martindale

Dr.Don

243winxb

JIMPGOV

chopper

LenV

zanemoseley

dronning

STEVE SAMELAK

mikemyers

16 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Oops, good thing for the LYMAN Case Gage

Oops, good thing for the LYMAN Case Gage

Maybe this is a once in a decade problem, or maybe it's much more frequent, and I've just been lucky enough to not have experienced it before. I throw away cases that "look funny", but I've never found a cracked case until today.

I was loading 45ACP, Terry's Magnus #801 bullets into what is supposed to be my own cases, and while checking them one by one in my Lyman case gage, something felt funny. First time I've seen something like this. I guess I need to continue to re-examine my cases when I clean them, and also while loading, and to run each case through the Lyman gage before placing them in my ammo box.

Was also wondering, for so many reloaders going through a zillion rounds an hour, with semi-automated machines, how do they find problem cases like this? ......and how do the remanufactures check every case to catch a problem like this?

I learned not to pick up "range brass", and I try to pick up all the rounds I fired, but sometimes I'm not sure if what I'm picking up is/was really mine. That's where color marking my cases will help. You can still see some of the blue stripe I marked this case with, but most of it is gone from wiping down the case to examine the crack.

I was loading 45ACP, Terry's Magnus #801 bullets into what is supposed to be my own cases, and while checking them one by one in my Lyman case gage, something felt funny. First time I've seen something like this. I guess I need to continue to re-examine my cases when I clean them, and also while loading, and to run each case through the Lyman gage before placing them in my ammo box.

Was also wondering, for so many reloaders going through a zillion rounds an hour, with semi-automated machines, how do they find problem cases like this? ......and how do the remanufactures check every case to catch a problem like this?

I learned not to pick up "range brass", and I try to pick up all the rounds I fired, but sometimes I'm not sure if what I'm picking up is/was really mine. That's where color marking my cases will help. You can still see some of the blue stripe I marked this case with, but most of it is gone from wiping down the case to examine the crack.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

If you grab a handful of brass and give a good shake a cracked case in the bunch will let you know it's there. Cracked cases usually ring like a bell. Pull that bullet & give it a try.

STEVE SAMELAK- Posts : 958

Join date : 2011-06-10

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

$100 says it will hit the X ring if you do your job. We tested some cracked cases using a Ransom Rest and they pretty much stayed in the group, surprised the heck out of us.

- Dave

- Dave

dronning- Posts : 2581

Join date : 2013-03-20

Age : 71

Location : Lakeville, MN

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

I find cracked cases all the time. If you shoot 5,000+ rounds a year it happens. I've also read where a cracked case will still shoot. I also shake the cases in my hand to weed out the cracked cases after they get stainless pin tumbled.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

I find that a lot of my cases that are cracked were fine before resizing. When I loaded one at a time I could feel it happen. Now I find them when I'm done.

Len

Len

LenV- Posts : 4770

Join date : 2014-01-24

Age : 74

Location : Oregon

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Mike,I get them too, that case has some mileage looks on it. If your shooting them out of your Salyer, I'd say this case wasn't one of your new or original cases, it has extractor scuff on the bevel part of case. Dave would have taken care of that when he tunes an extractor. Usually I find them after I load them also. I mark them and shoot them at practice, then put them in my scrap bucket.

Stan

Stan

chopper- Posts : 820

Join date : 2013-10-29

Age : 72

Location : Western Iowa

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

mikemyers wrote:

Was also wondering, for so many reloaders going through a zillion rounds an hour, with semi-automated machines, how do they find problem cases like this? ......and how do the remanufactures check every case to catch a problem like this?

https://www.shockbottle.com/products

JIMPGOV- Posts : 657

Join date : 2011-09-27

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Had a split in very old, well used brass. Not common to me. Using standard RCBS dies.

I checked neck tension on 5 different 45 acp head stamps. Some brass gets work hardened more the others from sizing and expanding.

I wonder if this die would work brass less? Redding Duel ring die.

WRA69 vintage. Reloaded many times. Was new surplus ammo, 50 rounds $3. 230 gr hard ball. The good old days.

I checked neck tension on 5 different 45 acp head stamps. Some brass gets work hardened more the others from sizing and expanding.

I wonder if this die would work brass less? Redding Duel ring die.

WRA69 vintage. Reloaded many times. Was new surplus ammo, 50 rounds $3. 230 gr hard ball. The good old days.

- Attachments

243winxb- Posts : 344

Join date : 2013-12-01

Age : 80

Location : USA

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Stan, I gave away all my old brass, which dated back to the 1980's.chopper wrote:Mike,I get them too, that case has some mileage looks on it. If your shooting them out of your Salyer, I'd say this case wasn't one of your new or original cases, it has extractor scuff on the bevel part of case. Dave would have taken care of that when he tunes an extractor. Usually I find them after I load them also. I mark them and shoot them at practice, then put them in my scrap bucket.

Stan

When I got my Les Baer PII, I bought lots of boxes of Winchester White Box ammo, 230 grain. But for any brass I picked up by mistake, all my 45 brass should be Winchester, from one of those boxes. I've been reloading that brass for Bullseye ever since, and that's what I'm using now in the two Salyer guns I currently own, the Springfield, and the Caspian.

Can you point out what you mean by "extractor score on the bevel part of the case"? I will stare at this photo, and my other brass, for a while, and see if I can recognize what you are referring to. Maybe it's the right time to just buy some new brass for my Bullseye reloads. Starline???

From what you guys are saying, it is safe to shoot brass with a crack like what I found? I assumed it should go into the scrap bin, but now I plan to take the round apart, and see if I can recognize the sound it's supposed to make when mixed in with other brass. Maybe later today....

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Hmm, the picture or link doesn't load for me, and I can't tell what product you are referring to???JIMPGOV wrote:

https://www.shockbottle.com/products

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Look at the Ben Stoeger website. Search "shockbottle".

I just ordered one, exactly what I needed. Thanks JIMPGOV

I just ordered one, exactly what I needed. Thanks JIMPGOV

Guest- Guest

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

I find most of the split cases at the sizing die. Even in a progressive press they feel different...they size with no effort because of the split.

Dr.Don- Posts : 816

Join date : 2012-10-31

Location : Cedar Park, TX

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Cracked cases are fine, for practice then to scrap as they may not always feed. Ed Masaki had no issues with them for long line but the bullet pull force is nonexistent.

Regards

Regards

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

I do the shake test (I think of the sound the good cases make as a bell and the bad one a clang but they are definitely different) and then discard the split ones into my scrap bin. I figure not worth dealing with going forward. But if I did let one slip through, I unload in through the barrel.

weber1b- Posts : 574

Join date : 2015-10-03

Location : Ballwin, MO

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Mike, in your picture go to the right where the case bevels. Then on that bevel is a scuff, not the circumferential rings, it's towards the top of photo. It just means the extractor could be a bit long and not making strong contact on the rim. If it extracts and ejects your loads good, I wouldn't worry about it.

chopper- Posts : 820

Join date : 2013-10-29

Age : 72

Location : Western Iowa

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Time to put away the iPhone and get out my Nikon D750.chopper wrote:Mike, in your picture go to the right where the case bevels. Then on that bevel is a scuff, not the circumferential rings, it's towards the top of photo. It just means the extractor could be a bit long and not making strong contact on the rim. If it extracts and ejects your loads good, I wouldn't worry about it.

Do you mean this (where I focused the camera)?

I never would have known what that is, and without using my camera (or a magnifier) I doubt I'd have noticed it at all.

I'm learning.

Click on the image to view the larger version from my Nikon....

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Is anyone else here using Magnus #801 bullets in 45 ACP cases?

I've been having an issue. I seated the bullets to the specified OAL, but that left some lead from the bullet sticking out right next to the brass case at the opening, effectively making the round too long. Many rounds were not loading properly. As a test, I pressed the bullet in a little deeper, and they worked better, but not 100%. I didn't know enough to understand what was happening, but I assumed the lead was making the case too long, so it wasn't seating properly in the chamber.

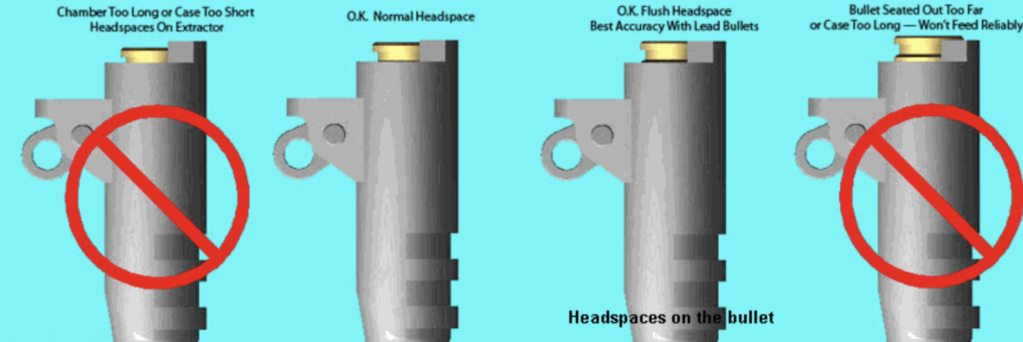

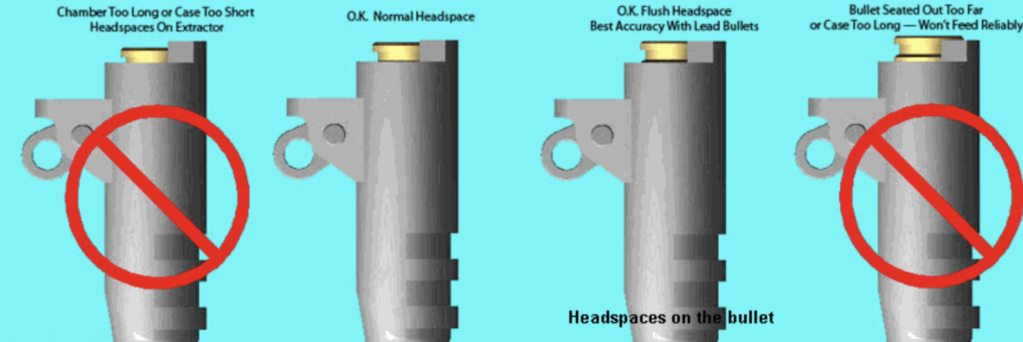

After discussing with Terry at Magnus and Dave Salyer, I had a crash course in how to do a "plunk test". The example at the far right shows what is happening with my reloads. My plan is to seat the bullet, so the lead at the outside edge will be no higher than the brass. That should solve all my current problems.

But, doing this is going to reduce the OAL of the round. Do I need to worry about this?

I've been having an issue. I seated the bullets to the specified OAL, but that left some lead from the bullet sticking out right next to the brass case at the opening, effectively making the round too long. Many rounds were not loading properly. As a test, I pressed the bullet in a little deeper, and they worked better, but not 100%. I didn't know enough to understand what was happening, but I assumed the lead was making the case too long, so it wasn't seating properly in the chamber.

After discussing with Terry at Magnus and Dave Salyer, I had a crash course in how to do a "plunk test". The example at the far right shows what is happening with my reloads. My plan is to seat the bullet, so the lead at the outside edge will be no higher than the brass. That should solve all my current problems.

But, doing this is going to reduce the OAL of the round. Do I need to worry about this?

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Are you sure you chamber is clean and there isn't a hunk of lead, brass or maybe carbon built up?mikemyers wrote: I didn't know enough to understand what was happening, but I assumed the lead was making the case too long, so it wasn't seating properly in the chamber. The lead does NOT make the case longer

But, doing this is going to reduce the OAL of the round. Do I need to worry about this?

What OAL?, when posting issues please give as much info as possible. Are you using the correct OAL for that bullet? I seat the bullet via it's shoulder so about the same amount of the bullet is above the case for all my SWC 45acp bullets, which is a shoulder to rim dimension of about .926.

- Dave

dronning- Posts : 2581

Join date : 2013-03-20

Age : 71

Location : Lakeville, MN

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Do you mean this (where I focused the camera)?

Yes Mike, right on that bevel towards the smaller area.

Yes Mike, right on that bevel towards the smaller area.

chopper- Posts : 820

Join date : 2013-10-29

Age : 72

Location : Western Iowa

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

This primer looks to be proud of the case - be sure it is flush or below the base - could just be the focus.mikemyers wrote:Time to put away the iPhone and get out my Nikon D750.chopper wrote:Mike, in your picture go to the right where the case bevels. Then on that bevel is a scuff, not the circumferential rings, it's towards the top of photo. It just means the extractor could be a bit long and not making strong contact on the rim. If it extracts and ejects your loads good, I wouldn't worry about it.

Do you mean this (where I focused the camera)?

I never would have known what that is, and without using my camera (or a magnifier) I doubt I'd have noticed it at all.

I'm learning.

Click on the image to view the larger version from my Nikon....

sharkdoctor- Posts : 180

Join date : 2014-10-16

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Get out your calipers and check the 801 diameter. I have some older 801s which measure .453” - they are an older mold.

If yours are the current .452” then I wonder if you are getting a build up of lead which the case is cutting off the bullet. Build a dummy round and see how it chambers. Use an impact hammer to knock out the bullet. If there is a sliver of lead on the bullet, let us know and we can suggest the next steps.

If yours are the current .452” then I wonder if you are getting a build up of lead which the case is cutting off the bullet. Build a dummy round and see how it chambers. Use an impact hammer to knock out the bullet. If there is a sliver of lead on the bullet, let us know and we can suggest the next steps.

Aprilian- Posts : 987

Join date : 2016-05-13

Location : Minnesota

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

I'm not "sure" of anything.dronning wrote:Are you sure you chamber is clean and there isn't a hunk of lead, brass or maybe carbon built up?mikemyers wrote: I didn't know enough to understand what was happening, but I assumed the lead was making the case too long, so it wasn't seating properly in the chamber. The lead does NOT make the case longer

But, doing this is going to reduce the OAL of the round. Do I need to worry about this?

What OAL?, when posting issues please give as much info as possible. Are you using the correct OAL for that bullet? I seat the bullet via it's shoulder so about the same amount of the bullet is above the case for all my SWC 45acp bullets, which is a shoulder to rim dimension of about .926.

- Dave

If you look at the reloads, there is what appears to be a ring of lead in front of the case, perhaps the same diameter as the case, which may or may not be the reason the reloads don't go in properly.

I think the chamber is clean - I know resized brass fits in there perfectly, and after what I did to "fix" it, now my reloads drop in fine as well, with a nice "plunk".

I gave up on the fancy Redding expander die, and put the same RCBS expander die in its place.

I changed the seater/crimper die, so all it does now is seat.

I adjusted it so the lead flows smoothly into the end of the cae, with the lead at the same "height" as the edge of the case.

I cleaned off my RCBS Big Max, and set it up for crimping.

The test rounds I made, everything the same but no primer and no powder, fit into my Lyman gage perfectly.

They also drop into the barrel perfectly, with a nice audible 'plunk'.

Bullets are Magnus #801, to be loaded with 4.2 grains of Bullseye (soon to be WST).

OAL is: 1.137". Crimp measures: 0.470" on the case in my hand - was slightly less on the previous case I measured.

According to Terry from Magnus bullets, for the #801 the OAL should be 1.126", with a crimp of 0.468".

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

This is my last box of #801 bullets, a couple of years old. I have new boxes on the way.Aprilian wrote:Get out your calipers and check the 801 diameter. I have some older 801s which measure .453” - they are an older mold.

If yours are the current .452” then I wonder if you are getting a build up of lead which the case is cutting off the bullet. Build a dummy round and see how it chambers. Use an impact hammer to knock out the bullet. If there is a sliver of lead on the bullet, let us know and we can suggest the next steps.

The diameter measures 0.452"

I made three or four "dummy rounds", then when everything was put away, made the round in the photo above. It fits in the chamber with a nice "plunk".

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

That crimp looks awfully loose. Of course I'm a tight crimper now at .463" but when I was at .469" I remember it looking tighter.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Page 1 of 2 • 1, 2

Similar topics

Similar topics» 45 ACP rounds sometimes not dropping in all the way into a Lyman check gage.

» It's A Pardini Thing - You wouldn't understand!

» Wheeler Trigger Pull Gage - anybody try this yet?

» Gage for brass

» Walther GSP or not to Walther GSP

» It's A Pardini Thing - You wouldn't understand!

» Wheeler Trigger Pull Gage - anybody try this yet?

» Gage for brass

» Walther GSP or not to Walther GSP

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum