Oops, good thing for the LYMAN Case Gage

+12

Virgil Kane

weber1b

bruce martindale

Dr.Don

243winxb

JIMPGOV

chopper

LenV

zanemoseley

dronning

STEVE SAMELAK

mikemyers

16 posters

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Oops, good thing for the LYMAN Case Gage

Oops, good thing for the LYMAN Case Gage

First topic message reminder :

Maybe this is a once in a decade problem, or maybe it's much more frequent, and I've just been lucky enough to not have experienced it before. I throw away cases that "look funny", but I've never found a cracked case until today.

I was loading 45ACP, Terry's Magnus #801 bullets into what is supposed to be my own cases, and while checking them one by one in my Lyman case gage, something felt funny. First time I've seen something like this. I guess I need to continue to re-examine my cases when I clean them, and also while loading, and to run each case through the Lyman gage before placing them in my ammo box.

Was also wondering, for so many reloaders going through a zillion rounds an hour, with semi-automated machines, how do they find problem cases like this? ......and how do the remanufactures check every case to catch a problem like this?

I learned not to pick up "range brass", and I try to pick up all the rounds I fired, but sometimes I'm not sure if what I'm picking up is/was really mine. That's where color marking my cases will help. You can still see some of the blue stripe I marked this case with, but most of it is gone from wiping down the case to examine the crack.

Maybe this is a once in a decade problem, or maybe it's much more frequent, and I've just been lucky enough to not have experienced it before. I throw away cases that "look funny", but I've never found a cracked case until today.

I was loading 45ACP, Terry's Magnus #801 bullets into what is supposed to be my own cases, and while checking them one by one in my Lyman case gage, something felt funny. First time I've seen something like this. I guess I need to continue to re-examine my cases when I clean them, and also while loading, and to run each case through the Lyman gage before placing them in my ammo box.

Was also wondering, for so many reloaders going through a zillion rounds an hour, with semi-automated machines, how do they find problem cases like this? ......and how do the remanufactures check every case to catch a problem like this?

I learned not to pick up "range brass", and I try to pick up all the rounds I fired, but sometimes I'm not sure if what I'm picking up is/was really mine. That's where color marking my cases will help. You can still see some of the blue stripe I marked this case with, but most of it is gone from wiping down the case to examine the crack.

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

PhotoEscape- Admin

- Posts : 1543

Join date : 2018-05-15

Location : Northern Illinois, USA

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

+1 Mike I agree with PhotoEscape it looks like you still have bell in it. You stated you adjusted your seater/crimper die so all it does is seat, so are crimping with a separate die? (that's what I do). You are a little long at 1.137" I'm at 1.1265". I crimp extra tight .465.

dronning- Posts : 2581

Join date : 2013-03-20

Age : 71

Location : Lakeville, MN

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Terry Labbe from Magnus and I had a long discussion last night. I’ve got lots of things to think about, but decided to do the crimping in my single station press as a separate operation after the progressive press has finished.

For reasons I don’t understand, when the bullet was seated in a way that looks good to me, for whatever that’s worth, as pointed out in the previous post by PhotoEscape, the OAL ended up at 1.137”, which is TOO LONG. So, if I’m using both presses, I can seat it a little deeper so it ends up at the correct OAL.

As for crimping, looking closely at my test round, agreed, it doesn’t look like I crimped it at all. So, in the Big Max single station press, with an RCBS taper crimp die in place, I will fix the crimp so it’s correct.

What puzzles me the most, is that what has allowed all this to happen, was switching to separate seat and crimp dies. Terry suggested I call RCBS and see if I can get a seater/crimper die that is made for lead bullets, and allows the bullet to be seated first, and then in the last little bit of movement, crimps the brass. Terry called it a “cowboy die”.

In the meantime, using two presses, I expect I’ll be able to get the OAL and the Crimp to the correct dimensions, something that seemed impossible yesterday.

I could solve lots of issues if I bought one of the new RCBS presses with many more stations. Unfortunately, they use what I still call a pipe bomb setup for primers. On the other hand, I’m retired, I’m rarely in a hurry, I rarely load more than 100 rounds at a time, and using two separate presses isn’t that big a deal, especially if the rounds come out better. By this afternoon everything should be coming out at the proper dimensions.

My crimper die is a standard RCBS taper crimp die from many years ago. Do any of you know of a better crimper die designed for lead bullets? Terry thinks that would work better for me.

For reasons I don’t understand, when the bullet was seated in a way that looks good to me, for whatever that’s worth, as pointed out in the previous post by PhotoEscape, the OAL ended up at 1.137”, which is TOO LONG. So, if I’m using both presses, I can seat it a little deeper so it ends up at the correct OAL.

As for crimping, looking closely at my test round, agreed, it doesn’t look like I crimped it at all. So, in the Big Max single station press, with an RCBS taper crimp die in place, I will fix the crimp so it’s correct.

What puzzles me the most, is that what has allowed all this to happen, was switching to separate seat and crimp dies. Terry suggested I call RCBS and see if I can get a seater/crimper die that is made for lead bullets, and allows the bullet to be seated first, and then in the last little bit of movement, crimps the brass. Terry called it a “cowboy die”.

In the meantime, using two presses, I expect I’ll be able to get the OAL and the Crimp to the correct dimensions, something that seemed impossible yesterday.

I could solve lots of issues if I bought one of the new RCBS presses with many more stations. Unfortunately, they use what I still call a pipe bomb setup for primers. On the other hand, I’m retired, I’m rarely in a hurry, I rarely load more than 100 rounds at a time, and using two separate presses isn’t that big a deal, especially if the rounds come out better. By this afternoon everything should be coming out at the proper dimensions.

My crimper die is a standard RCBS taper crimp die from many years ago. Do any of you know of a better crimper die designed for lead bullets? Terry thinks that would work better for me.

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Here's my loaded Magnus 801 round. Again, I crimp tight, I shoot for .463". I've heard of people going as tight as .460 but most target .463"-.469". It is hard to measure.

As far as multiple presses I don't see why. If you're loading on a single station just buy the Hornady LNL bushing system so you can swap the dies out in seconds. Also I like the Dillon dies. Their crimp die is very straight forward and easy to clean. I would not try and use a combo seater/crimp die.

As far as multiple presses I don't see why. If you're loading on a single station just buy the Hornady LNL bushing system so you can swap the dies out in seconds. Also I like the Dillon dies. Their crimp die is very straight forward and easy to clean. I would not try and use a combo seater/crimp die.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

What is the length of your round?zanemoseley wrote:Here's my loaded Magnus 801 round. Again, I crimp tight, I shoot for .463". I've heard of people going as tight as .460 but most target .463"-.469". It is hard to measure.

As far as multiple presses I don't see why. If you're loading on a single station just buy the Hornady LNL bushing system so you can swap the dies out in seconds. Also I like the Dillon dies. Their crimp die is very straight forward and easy to clean. I would not try and use a combo seater/crimp die.

As to multiple presses, I've had the second press mounted in place for years. I don't see any gain in using the Hornady LNL, as either way, I'm going to need to do a separate crimping process after everything else is done.

I like your photo - very clean.

About the crimp, I mentioned something about a .463 crimp to Terry, and he said no way, it distorts the lead too much. He and Dave prefer I set the crimp to .468. I don't know enough to comment either way, I'll just follow the advice from Dave, Terry, and this forum. Thanks!

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

It all depends on who you ask. I've seen old post (Roddy Toyota comes to mind) about going as tight as .460". I've been crimping like this for a while, with my new 160 grain bullets I sand bagged a .700" group at 25 yards with just a red dot, it would probably be a quarter size hole with a ransom rest. You've got to weight your options and pick for yourself because you will get no consensus if you ask here. I'll measure my OAL when I get home. The LNL bushing just makes it much more convenient to swap dies.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Jack H- Posts : 2700

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Because you changed your process from the first one, it might be hard to prove what was going on. I zoomed in on the first picture and can see smudges of lead on the case mouth. Two possible causes. 1) insufficient expansion 2) combo seating and crimping die is not backed out far enough and that it is still crimping and doing so before the bullet is fully seated.

Aprilian- Posts : 987

Join date : 2016-05-13

Location : Minnesota

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Dave sent me what seems like a simple procedure to seat and crimp in the same station, and get good rounds. I'm changing gears, and will try this out. If it works for me, I'll post it here.

Dave also sent me a photo to check the crimp instantly - take two crimped shells, or one crimped and one straight, stand them up next to each other, and look for a gap near the top. If I can see any gap at all, I'm done.

Dave also sent me a photo to check the crimp instantly - take two crimped shells, or one crimped and one straight, stand them up next to each other, and look for a gap near the top. If I can see any gap at all, I'm done.

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

I would spend the $70 on a set of Dillon dies. Seating and crimping at the same time doesn't sound like a good idea, it's a compromise at some level. I also would measure your crimp with calipers not just eyeball gaps.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

I've been following this thread with great interest because I've only recently begun loading 45ACP and am also having to learn the foibles of a new Dillon XL650. I have been having a few failures to eject and other niggles.

I'm now concentrating on Nosler 185 JHP rather than the lead SWC's in this thread, with Winchester white box brass, COAL 1.200". But the important relevance to me is the crimp. Having read the recommendation for a tight crimp I adjusted my Lee "factory size & crimp" die and found that in order to achieve the recommended 0.463" crimp my die creates a nice bright shiny ring:-

I've not yet shot any of these, but I just re-ran a hundred through the crimp station and will test them tomorrow.

I'm now concentrating on Nosler 185 JHP rather than the lead SWC's in this thread, with Winchester white box brass, COAL 1.200". But the important relevance to me is the crimp. Having read the recommendation for a tight crimp I adjusted my Lee "factory size & crimp" die and found that in order to achieve the recommended 0.463" crimp my die creates a nice bright shiny ring:-

I've not yet shot any of these, but I just re-ran a hundred through the crimp station and will test them tomorrow.

Guest- Guest

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

That shiney I believe is from surfaces inside beyond the crimp area that Lee intended.

I don't think the Lee FC dies are designed to crimp to that tight. Each one I tried abrades and roughs the brass if the crimp is set too tight. Brass is even removed.

I much prefer the Dillon, Redding or Rcbs dies.

Especially nice is the RCBS seat & taper crimp combo used for crimp only. This give a nice smoothe crimp

The Lee die I always think is a solution looking for a problem. If there is a problem, it is better to fix it at the source.

I don't think the Lee FC dies are designed to crimp to that tight. Each one I tried abrades and roughs the brass if the crimp is set too tight. Brass is even removed.

I much prefer the Dillon, Redding or Rcbs dies.

Especially nice is the RCBS seat & taper crimp combo used for crimp only. This give a nice smoothe crimp

The Lee die I always think is a solution looking for a problem. If there is a problem, it is better to fix it at the source.

Jack H- Posts : 2700

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Radjag, I'm not an expert in JHP as I've never loaded any but I'm pretty sure you're only supposed to crimp JHP down to .469" - .470". Maybe someone that shoots JHP will chime in. Lead bullets are what I crimp down to .463".

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

+++++1zanemoseley wrote:Radjag, I'm not an expert in JHP as I've never loaded any but I'm pretty sure you're only supposed to crimp JHP down to .469" - .470". Maybe someone that shoots JHP will chime in. Lead bullets are what I crimp down to .463".

JACKETED bullets .469-.471 maybe .468 with thin walled brass

LEAD you can crimp much tighter - I crimp .465 I just loaded up some @ .463 to try.

- Dave

dronning- Posts : 2581

Join date : 2013-03-20

Age : 71

Location : Lakeville, MN

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Dave Salyer sent me some information on how to load my Magnus #801 bullets:

Followed those instructions, but lowered the crimping die until I got the "space" at the top, showing that they both were crimped (slightly), and here's what I got:

Left Cartridge is 1.132” OAL, with a crimped diameter of 0.466” diameter

Right Cartridge is 1.138” OAL, with a crimped diameter of 0.467” diameter

They both work in my LYMAN gage, but I haven't yet tried the "plunk test" in the barrel.

I will load 50 more rounds, and take measurements before shooting them.

- Back your seating die out one turn.

- Run your seating punch down until you get an OAL of 1.13.

- Back your crimp die out one turn.

- Turn it down until you feel slight resistance.

- Then turn it down one eighth turn.

- Do a second round without changing anything.

- Hold the two rounds together toward light. If you see the brass parting any at the very top of the case you are done.

- If not, turn the crimp die down another eighth turn on both rounds. Take a close look at the top of the case for the slightest parting. Any is enough.

Followed those instructions, but lowered the crimping die until I got the "space" at the top, showing that they both were crimped (slightly), and here's what I got:

Left Cartridge is 1.132” OAL, with a crimped diameter of 0.466” diameter

Right Cartridge is 1.138” OAL, with a crimped diameter of 0.467” diameter

They both work in my LYMAN gage, but I haven't yet tried the "plunk test" in the barrel.

I will load 50 more rounds, and take measurements before shooting them.

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Looking at the lead above the case they even look long to me. For that round my OAL is 1.126. I expose about a fingernail width above the case for 45 SWC.

Another topic

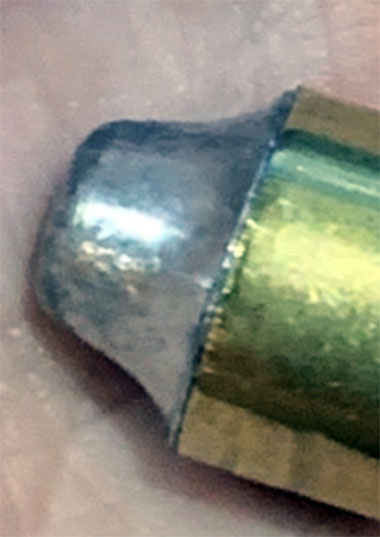

==>Look at the base of your brass the bevel cut is very different (could be camera angle) BUT the one on the right definitely has an extractor "dent" right by that black smudge. The extractor slamming into the case could cause it to break.

- Dave

Another topic

==>Look at the base of your brass the bevel cut is very different (could be camera angle) BUT the one on the right definitely has an extractor "dent" right by that black smudge. The extractor slamming into the case could cause it to break.

- Dave

dronning- Posts : 2581

Join date : 2013-03-20

Age : 71

Location : Lakeville, MN

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Dave, when I look at my rounds, and look at the image I copied above, it looks to me like I have the right amount of lead showing up above the brass.

I don't have any other reloads to compare mine with - yet - but Terry is sending me some example cases.

Dave wanted an OAL of 1.13 - both of my rounds are slightly longer, and yours is slightly shorter. How critical is this dimension?

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

The following was done as a test - I wanted to see what would happen if I got the edge of the lead even with the edge of the brass case. No problem doing so, but from left to right, the OAL measured 1.1185, 1.1175, 1.1205, and 1.1175, all too short. So, I'm stuck with some lead showing up above the case.

Another silly mistake I made - I was wondering why some rounds felt "tight" in my LYMAN gage, until I cleaned it again. Problem solved.

Another silly mistake I made - I was wondering why some rounds felt "tight" in my LYMAN gage, until I cleaned it again. Problem solved.

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Now that I know what to look for, I'm seeing that a lot. Never knew to even look for it until now. There are four of my guns that have shot my ammo, an old Colt Combat Commander, my Les Baer, and my two wad guns, the Springfield and the Caspian.dronning wrote:Another topic

==>Look at the base of your brass the bevel cut is very different (could be camera angle) BUT the one on the right definitely has an extractor "dent" right by that black smudge. The extractor slamming into the case could cause it to break. - Dave

If I cycle un-fired brass through each gun, will that be enough to show if the extractor is causing a problem?

If I need to fire the brass for it to show up, what is the best place to purchase new brass cases? I can use my new marking system to show which gun which cases came from, to see if one of my guns has a problem.

........and if so, how is this corrected? Do I need to get a new extractor? Is this something I can do, or does the gun need to go to a gunsmith.

Thanks, Dave - you're adding to my list of potential problems, that I never knew about before. :-)

(I suppose what I can also do, is go through all my cases, one at a time, using a good light and a magnifier, and throw out any that have this mark on the beveled area near the bottom....)

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

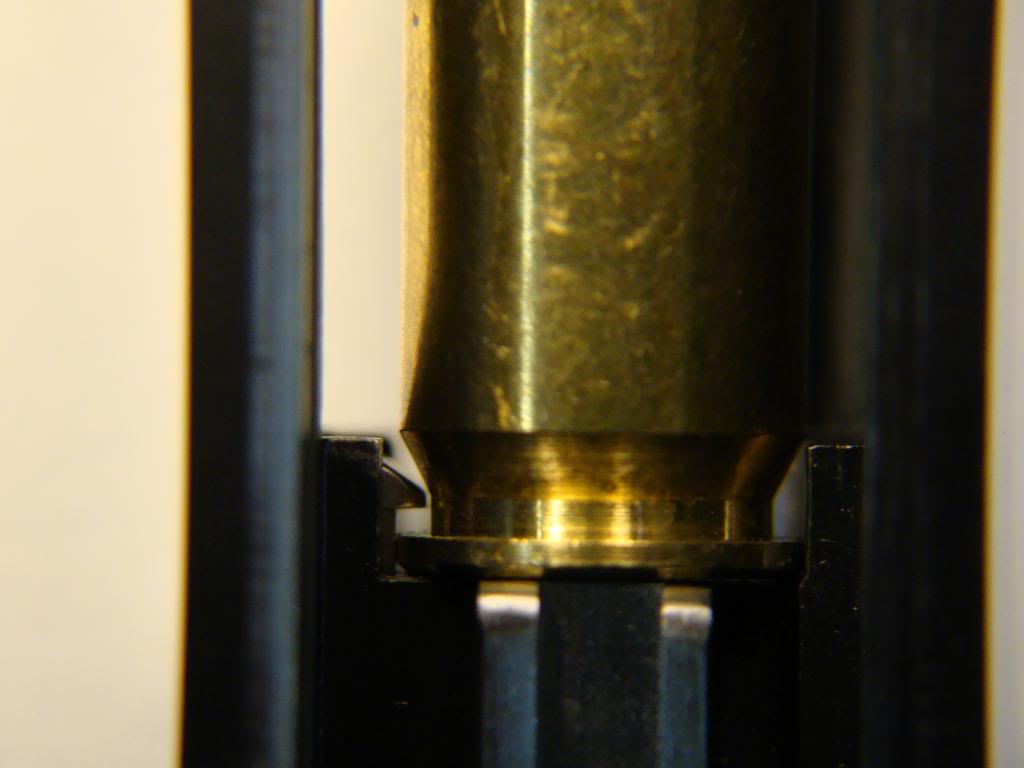

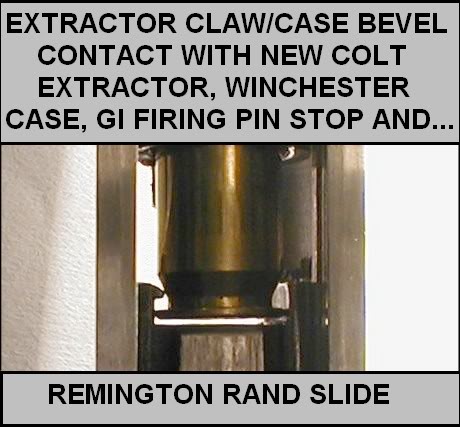

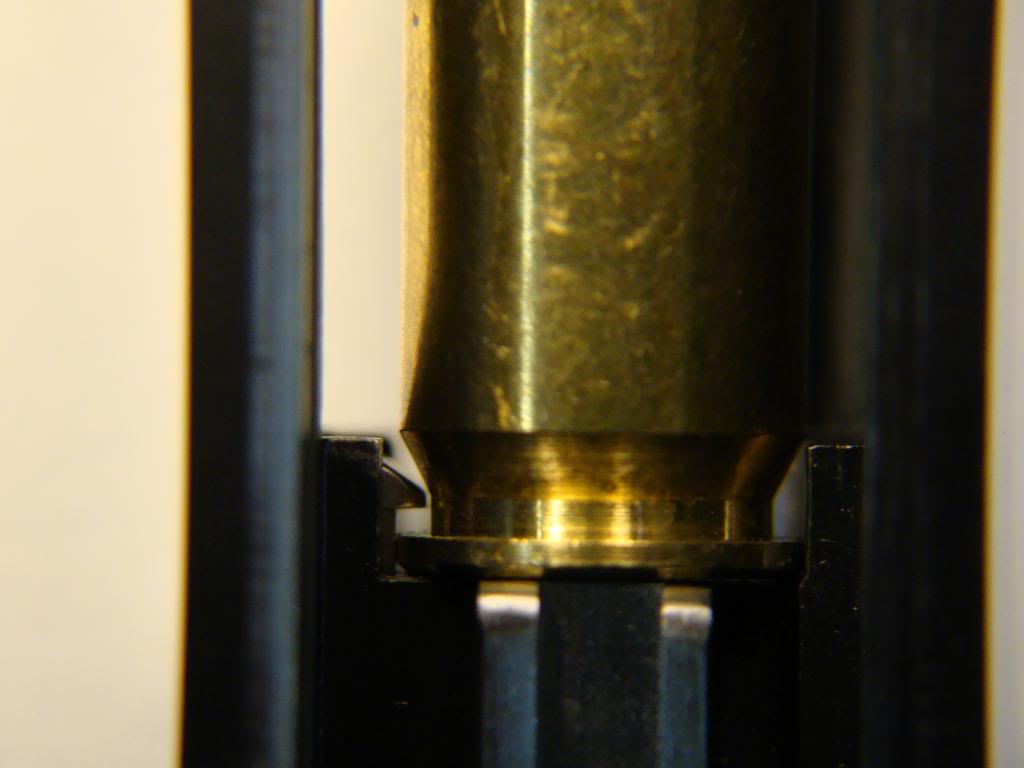

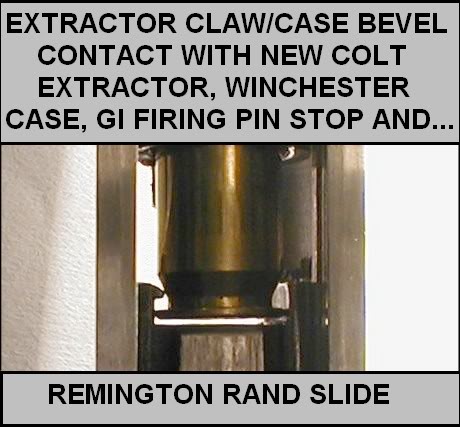

1st check to see if the only cases that have that mark are the same Mfg.. that would point to the brass.

To check your guns, remove the slide then the barrel, flip the slide upside down and slide an empty case making sure the case is against the breachface check the extractor clearance.

The EZ fix if the contact is light and if you are comfortable doing it, is to take a little metal off the extractor. This should have been done when the extractor was fit to the gun.

- Dave

Good

Bad, notice the case isn't even flush with the breachface and the extractor is hitting the case.

Simple fix:

To check your guns, remove the slide then the barrel, flip the slide upside down and slide an empty case making sure the case is against the breachface check the extractor clearance.

The EZ fix if the contact is light and if you are comfortable doing it, is to take a little metal off the extractor. This should have been done when the extractor was fit to the gun.

- Dave

Good

Bad, notice the case isn't even flush with the breachface and the extractor is hitting the case.

Simple fix:

dronning- Posts : 2581

Join date : 2013-03-20

Age : 71

Location : Lakeville, MN

Re: Oops, good thing for the LYMAN Case Gage

Re: Oops, good thing for the LYMAN Case Gage

Excellent - reminds me of the saying "one picture is worth 1,000 words"!!!

I inspected my remaining 53 empty cases - the only ones that had marks were Winchester, but other than for three other off-brand cases, which I threw out, they were all Winchester. About half the cases had marks on them, but I've been reloading the same 250 or so cases over and over for four or five years. Any of my 45 guns could be "at fault".

Thanks to you, I now know how to check for this condition from now on, starting tomorrow.

There are 50 rounds loaded and ready for tomorrow. Will find out if this change fixed it, using the Springfield.

Instead of using RCBS case lube, I used the One Shot Case Lube, as recommended in this forum. If anything, the press was even easier to operate, and now that I'm done, the cases look and feel clean and smooth and shiny. They're no longer sticky and gooey, as cases I've been loading since the 1980's. Thanks, guys, for the recommendation..

I inspected my remaining 53 empty cases - the only ones that had marks were Winchester, but other than for three other off-brand cases, which I threw out, they were all Winchester. About half the cases had marks on them, but I've been reloading the same 250 or so cases over and over for four or five years. Any of my 45 guns could be "at fault".

- I doubt the Colt is the problem, as that was fully gone through by the tech people at Colt.

- Ditto about the Les Baer - I assume they would have caught this.

- My Caspian came from Dave Salyer, and I'm sure he does this right.

- The Springfield went through several owners after Dave built it, before I eventually got it from Dan here on the forum. It's the most likely culprit, but I don't know anything for sure. Yet.

Thanks to you, I now know how to check for this condition from now on, starting tomorrow.

There are 50 rounds loaded and ready for tomorrow. Will find out if this change fixed it, using the Springfield.

Instead of using RCBS case lube, I used the One Shot Case Lube, as recommended in this forum. If anything, the press was even easier to operate, and now that I'm done, the cases look and feel clean and smooth and shiny. They're no longer sticky and gooey, as cases I've been loading since the 1980's. Thanks, guys, for the recommendation..

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» 45 ACP rounds sometimes not dropping in all the way into a Lyman check gage.

» It's A Pardini Thing - You wouldn't understand!

» Wheeler Trigger Pull Gage - anybody try this yet?

» Gage for brass

» Walther GSP or not to Walther GSP

» It's A Pardini Thing - You wouldn't understand!

» Wheeler Trigger Pull Gage - anybody try this yet?

» Gage for brass

» Walther GSP or not to Walther GSP

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum