Need to replace broken extractor on Springfield 1911 A1 made in Brazil

+16

Wobbley

Sa-tevp

Al

orpheoet

bruce martindale

blindshooter

jglenn21

troystaten

Aprilian

spursnguns

-TT-

David R

STEVE SAMELAK

dronning

rreid

mikemyers

20 posters

Page 3 of 3

Page 3 of 3 •  1, 2, 3

1, 2, 3

Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Need to replace broken extractor on Springfield 1911 A1 made in Brazil

First topic message reminder :

Half way through this morning's shooting, my Salyer Springfield stopped ejecting cases.

This gun started life as a Springfield 1911 A1 made in Brazil.

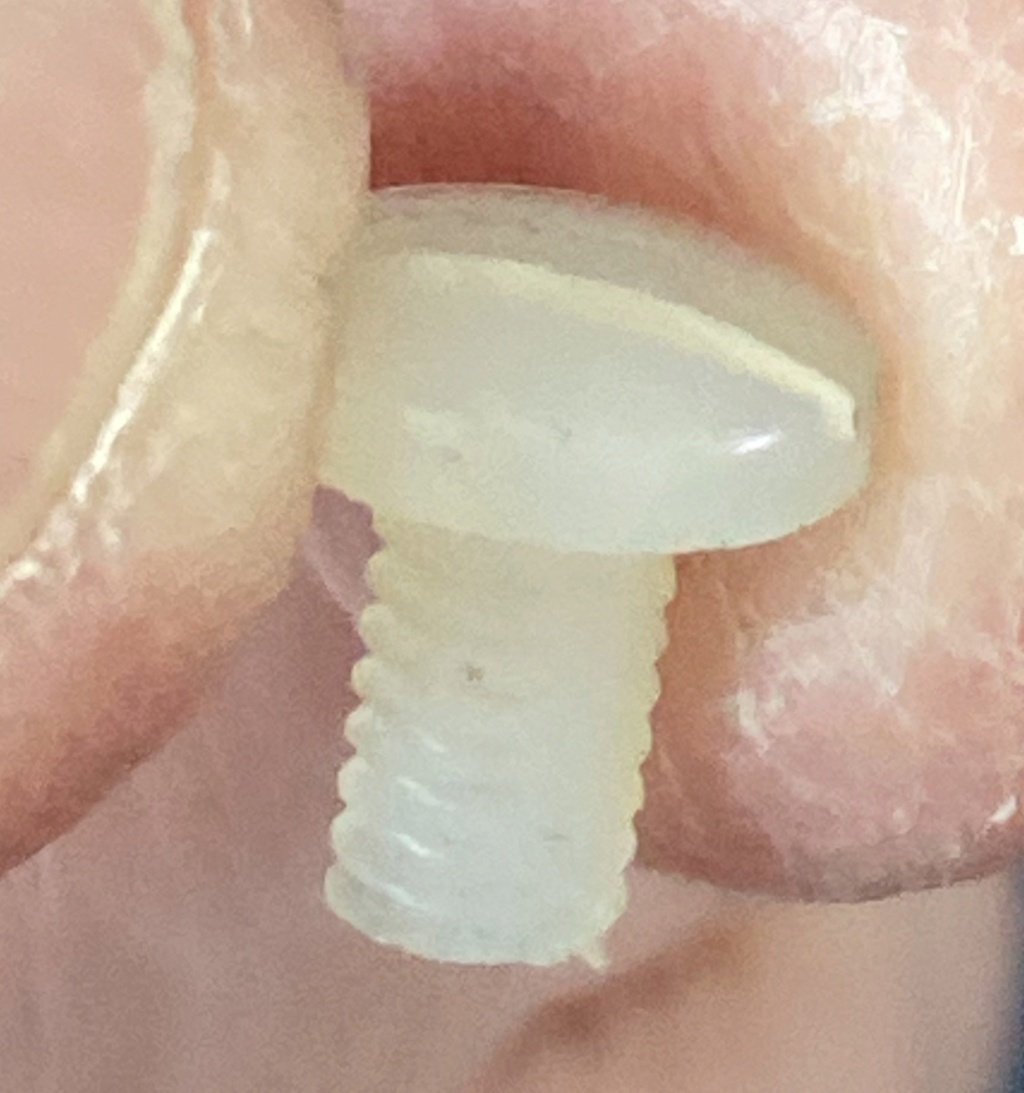

I brought it home, disassembled, and found out why it's no longer extracting - see photo below.

I found replacement extractors on Brownell's, such as:

https://www.brownells.com/handgun-parts/action-parts/extractor-parts/extractors/1911-match-extractor-prod1318.aspx

For those of you who have gone through this already, is this likely to be a good choice, or would you recommend something else?

If paying a little more gets me an e extractor that performs better, that's fine with me.

I've watched the Wilson video on Extractor Tuning - I'm not anxious to do any of this extra work unless it's required.

https://www.youtube.com/watch?v=dorzFGvYj40

I have a feeling the "Aftek Extractor" is more than I need to deal with. It's $85. https://dawsonprecision.com/extractors-1911-by-aftec/

Oh yeah, one more photo - I guess I need to clean my extractor much more frequently.....

Half way through this morning's shooting, my Salyer Springfield stopped ejecting cases.

This gun started life as a Springfield 1911 A1 made in Brazil.

I brought it home, disassembled, and found out why it's no longer extracting - see photo below.

I found replacement extractors on Brownell's, such as:

https://www.brownells.com/handgun-parts/action-parts/extractor-parts/extractors/1911-match-extractor-prod1318.aspx

For those of you who have gone through this already, is this likely to be a good choice, or would you recommend something else?

If paying a little more gets me an e extractor that performs better, that's fine with me.

I've watched the Wilson video on Extractor Tuning - I'm not anxious to do any of this extra work unless it's required.

https://www.youtube.com/watch?v=dorzFGvYj40

I have a feeling the "Aftek Extractor" is more than I need to deal with. It's $85. https://dawsonprecision.com/extractors-1911-by-aftec/

Oh yeah, one more photo - I guess I need to clean my extractor much more frequently.....

You guys are likely going to take one look at this photo, and banish me from bullseye shooting......

Lesson Learned.

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

mikemyers wrote:I think your goal here is setting how far into the slide the extractor should go, so it's at the correct location 0.075" away from the breech face.

That is correct. That gap allows the cartridge to rotate up from the initial feeding angle to horizontal as it enters the chamber. The gap is specific for each caliber based on rim diameter. A .45 requires a gap of no less than .075". It can be more but not less.

A listing of hook-to-breechface distances by caliber can be found here: https://forums.1911forum.com/showthread.php?t=829865

Last edited by Steve in Allentown on Sun Jul 19, 2020 6:57 pm; edited 1 time in total

Steve in Allentown- Posts : 49

Join date : 2020-04-24

Location : Allentown, PA

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

From what I think I've learned here so far, this will tell the ideal location for the extractor hook, 0.075" in front of the breech face.

But, the position of the extractor is mostly determined by the notch at the other end, where the firing pin plate positions the extractor.

So, if the extractor hook is not where it really ought to be, what way is there for this to be adjusted?

Or, in more practical terms, once I get the gun apart again, and if I can measure that distance on my gun, how would this ditance be adjusted? And to go along with that, is there an acceptable range of this dimension? I guess before I post anything more, or ask any questions, I need to study and understand this page:

https://www.brownells.com/aspx/learn/learndetail.aspx?lid=10261

But, the position of the extractor is mostly determined by the notch at the other end, where the firing pin plate positions the extractor.

So, if the extractor hook is not where it really ought to be, what way is there for this to be adjusted?

Or, in more practical terms, once I get the gun apart again, and if I can measure that distance on my gun, how would this ditance be adjusted? And to go along with that, is there an acceptable range of this dimension? I guess before I post anything more, or ask any questions, I need to study and understand this page:

https://www.brownells.com/aspx/learn/learndetail.aspx?lid=10261

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

mikemyers wrote:

But, the position of the extractor is mostly determined by the notch at the other end, where the firing pin plate positions the extractor.

So, if the extractor hook is not where it really ought to be, what way is there for this to be adjusted?

You are correct. The position of the extractor is determined by the position of the firing pin stop slot.

There are several ways to get the precise hook-to-breechface distance wanted.

- Buy an EGW or Harrison extractor that has no firing pin stop slot then cut the slot where needed. Harrison also sells a machining fixture for use in cutting the slot. These items are best utilized by those with the correct machining tools.

- Determine if the existing slot needs to be widened to move the extractor rearward or forward and by how much. Cut a steel spacer to fill in the excess space created by widening the slot. Silver solder the steel spacer in the slot. Technically, the spacer doesn't have to be soldered, It can simply fit in the slot.

- You could also use an epoxy glue such as JB Weld to fill in the excess space. Glop some in the slot then file to shape. That area doesn't experience enough stress to compromise the epoxy but care must be taken when inserting the firing pin stop to avoid damaging the epoxy.

I've not had to resort to any of the above methods often. Using EGW extractors I've been able to get hook-to-breechface distances of between .075" and .079" through filing the appropriate slot wall while maintaining solid contact between the firing pin stop and all three walls of the extractor slot.

Steve in Allentown- Posts : 49

Join date : 2020-04-24

Location : Allentown, PA

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

The range is .075" - .085" but you'll want to get as close as possible to .075" without going any less. Personally, I get very good results using EGW extractors and hook-to-breechface distances as great as .080".mikemyers wrote:And to go along with that, is there an acceptable range of this dimension?

The confounding thing is that dimensional compromises must be made based on the fact that mass produced parts are manufactured within certain tolerances. Sometimes the tolerance stacking of various parts dictates that you can't always achieve a perfect hook-to-breechface distance. As long as it's not less than .075" all should be well.

Steve in Allentown- Posts : 49

Join date : 2020-04-24

Location : Allentown, PA

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Jack is a 1911 icon and his article presents lots of good information. However, he does not cover all aspects of extractor fitting and I caution you not to jump into the fitting process after reading only his well written article. I suggest you also read the material at the link I provided in one of my posts above.mikemyers wrote:I guess before I post anything more, or ask any questions, I need to study and understand this page:

https://www.brownells.com/aspx/learn/learndetail.aspx?lid=10261

Steve in Allentown- Posts : 49

Join date : 2020-04-24

Location : Allentown, PA

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Yep, I have your link open in another window, and will read everything from top to bottom in half an hour or so, including another page that I think you link to in that thread.

I have two concerns:

a) I want to understand as much as possible

b) I want the gun to work

I have two concerns:

a) I want to understand as much as possible

b) I want the gun to work

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Jim, to someone less stubborn, and probably smarter than I, that is absolutely the best possible answer/advice.james r chapman wrote:I once took a tvin for service.

Kid asked what was wrong. I said picture went out.

He said $36 diagnostic fee, I said ok.

A voice from the back said what model?

“GE”

Did you see a glow in the earphone plug hole when it went out?

“Yes”

Voice from the back says GE tube #xxxx will fix it.

Kid puts tube in, tv comes to life.

Says $12 bulb +$36 diagnostic charge.

Says I, what! You never tested it!

Booming voice in back “KNOWLEDGE”

Sometimes it pays to have someone with knowledge do things for you.

I would have my gun fixed and back in my hands in a short time, working perfectly.

On the other hand, I have my Caspian 45, so there's no urgency in getting this repair done.

Also, where should I draw the line? Should I buy ammo, rather than reload?

Should I take the gun to a gunsmith every time something needs to be adjusted?

How will I ever learn about the gun, if I don't at least try to do things on my own?

.....although there are things WAY beyond my ability, and potentially dangerous, such as the sear, which I won't get involved in. I've got my own limits. With the extractor, if I didn't learn to remove it, the extractor and firing pin would never get cleaned.

Still, if I understood what I was getting into, I think I'd have just had an expert do it for me. (Although even there, I'm in Miami, and I'm trying real hard to stay away from everyone because of the virus, so I might not have even driven up to see that gunsmith, two trips.

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

troystaten likes this post

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Before doing anything else, I assembled the gun with no extractor, and no recoil spring. Cycling the gun manually, everything seemed to work fine. Cases had to be ejected manually, but all the parts seemed to work together properly.

Wilson extractor went in, had too much force gripping the case, and was too long.

The lower part of the extractor was filed away to reduce tension.

When things seemed good, the gun was assembled.

The end of the extractor was hitting the angled part of the brass, so I filed it down until it no longer touches the brass.

As of this writing, with a Wilson magazine (stiff spring) rounds cycle through the gun fine. No dents on the brass, and no jams. With my other magazines (all with noticeably softer springs) out of six dummy rounds, one round typically "jams" like before. At least it is better than it used to be, when every round jammed.

The plan, following advice from friends and Wilson, is to bend the extractor slightly, as per these directions from Wilson:

https://shopwilsoncombat.com/images/415-70-extractor-instructions.pdf

There are other changes I need to make to the gun. The sight, Matchdot II with a heavy duty mounting system, is probably too heavy for the gun. With any luck it will change to a one inch Matchdot sight, that everyone seems to prefer. That, or an Aimpoint.

It mostly shot pretty well today - FAR better than before. Next try is Friday.

More later.

I guess I could have avoided all this by just following Jim's advice.....

Wilson extractor went in, had too much force gripping the case, and was too long.

The lower part of the extractor was filed away to reduce tension.

When things seemed good, the gun was assembled.

The end of the extractor was hitting the angled part of the brass, so I filed it down until it no longer touches the brass.

As of this writing, with a Wilson magazine (stiff spring) rounds cycle through the gun fine. No dents on the brass, and no jams. With my other magazines (all with noticeably softer springs) out of six dummy rounds, one round typically "jams" like before. At least it is better than it used to be, when every round jammed.

The plan, following advice from friends and Wilson, is to bend the extractor slightly, as per these directions from Wilson:

https://shopwilsoncombat.com/images/415-70-extractor-instructions.pdf

There are other changes I need to make to the gun. The sight, Matchdot II with a heavy duty mounting system, is probably too heavy for the gun. With any luck it will change to a one inch Matchdot sight, that everyone seems to prefer. That, or an Aimpoint.

It mostly shot pretty well today - FAR better than before. Next try is Friday.

More later.

I guess I could have avoided all this by just following Jim's advice.....

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Re: Need to replace broken extractor on Springfield 1911 A1 made in Brazil

Finished!

I tried to follow Wilson's instructions to bend the extractor.

Thanks to you guys, thanks to Dave Salyer, thanks to my friends on the 1911 forum, and thanks to the lady at Wilson who sent me the instructions as to HOW to bend their extractor.

I tried to follow Wilson's instructions to bend the extractor.

- I traced out the extractor on a piece of paper, so I could see if I was bending it.

- I tried bending, as instructed. No effect.

- I tried again, bending much harder - no effect.

- I used some more leverage to bend the extractor - better.

- I finally measured off half an inch on the extractor as per Wilson’s instructions, pushed the extractor only that far into the hole, then put a small hex-socket over the other end of the extractor, and used a socket driver to allow me to get some leverage for more bending force, and on the third try at this, I thought it changed just a little.

- Re-assembled slide, and checked that the extractor will still hold a round in place. Yes!

- Went to an empty room for testing, and with two sets of dummy rounds, and different magazines, the gun cycled fine, no jams.

Thanks to you guys, thanks to Dave Salyer, thanks to my friends on the 1911 forum, and thanks to the lady at Wilson who sent me the instructions as to HOW to bend their extractor.

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

mikemyers- Posts : 4236

Join date : 2016-07-27

Age : 80

Location : South Florida, and India

Page 3 of 3 •  1, 2, 3

1, 2, 3

Similar topics

Similar topics» Brazil Springfield

» Broken extractor

» How to replace the extractor on a Hämmerli X-esse Sport?

» Springfield Range Office - need to replace grip safety...

» For my BAIKAL IZH35M I need extractor, extractor plunger, extractor spring. Please help!!

» Broken extractor

» How to replace the extractor on a Hämmerli X-esse Sport?

» Springfield Range Office - need to replace grip safety...

» For my BAIKAL IZH35M I need extractor, extractor plunger, extractor spring. Please help!!

Page 3 of 3

Permissions in this forum:

You cannot reply to topics in this forum