Reloading Machines, and checking powder level before bullet seating

+12

blindshooter

Aprilian

SingleActionAndrew

Wobbley

Sa-tevp

zanemoseley

chopper

noylj

james r chapman

David R

Jack H

mikemyers

16 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Reloading Machines, and checking powder level before bullet seating

Reloading Machines, and checking powder level before bullet seating

I used to use an RCBS Big Max single station press - still have it, still like it, but I decided to move to a Progressive press, and bought the RCBS Pro2000 a few years ago. Later I added the auto-index kit. I enjoyed it back then, and still enjoy it. Primers go in plastic strips, not tubes, which is important to me. I see tubes of primers, and my brain sees a "pipe bomb". The biggest "negative" is that the Pro2000 is "only" a 5-station press.

For two or three years now, I've only been using the press for 45acp. Little by little, so many things were improved from feedback here, from Terry at Magnus Bullets, and from Dave Salyer. I grudgingly gave up on the RCBS "LockOut Die", as all of you convinced me that seating and crimping needed to be done in separate stations. So, instead of the LockOut Die, I set up a mirror so I can look down into the shell casing and verify that it has the right amount of powder, not too much or too little. I've used it like this for the past year, and my finished rounds look like they came out of a factory box. But during all this time, I stopped reloading 38 Special for my Model 52 and revolvers.

Yesterday I switched over to 38, disassembling all the dies and cleaning, and re-setting everything. Apparently I used to use a re-sizer die, an expander die, then the powder load, then my Lockout Die, then a seater die. It's from years ago, but there was no empty station on my die plate for a crimp die. So, I removed the LockOut die, moved the seater die to that now empty station, and was left with one empty station. I ordered a Redding Profile Crimp Die last night, which will arrive in a day or so.

My "problem" is that there is no way for me to look down into the 38 Special case to see the powder. The case is to long and too small, and there is no way to get a light that shines down to the bottom, and no way to get my eyeball where it needs to be. What I need is a dental mirror with a light. It's possible - for about $300 or so:

Not very practical.

To me this means I have two choices:

There is no way I know of to get a "double-charge" on the Pro2000 because after powder is loaded, the round is automatically moved to the next station. As for an "empty" round, I'm loading in an air conditioned closet, so there shouldn't be enough moisture for the powder to "clump" and clog. In all these years that has never happened.

With the experience you guys have had, what would you advise? Trust the press to load powder correctly, or use the LockOut die, and crimp in my second press.

RCBS now makes a 7-station press - I was curious about it, checked it out on the internet, and I wouldn't use it if someone offered it to me for free. The reviews are awful. I'm not a fan of Dillon, and while a Star Press sounds fantastic, that's not an option. If I was buying a new press, this video I watched last night was very persuasive, and the reviews were equally persuasive. I don't like the idea of a primer tube, and I have no plans to switch, but I like what I see here:

https://www.youtube.com/watch?v=72MTiuEBzak

Just dreaming out loud...........but it's still "only" a 5-station press.

For two or three years now, I've only been using the press for 45acp. Little by little, so many things were improved from feedback here, from Terry at Magnus Bullets, and from Dave Salyer. I grudgingly gave up on the RCBS "LockOut Die", as all of you convinced me that seating and crimping needed to be done in separate stations. So, instead of the LockOut Die, I set up a mirror so I can look down into the shell casing and verify that it has the right amount of powder, not too much or too little. I've used it like this for the past year, and my finished rounds look like they came out of a factory box. But during all this time, I stopped reloading 38 Special for my Model 52 and revolvers.

Yesterday I switched over to 38, disassembling all the dies and cleaning, and re-setting everything. Apparently I used to use a re-sizer die, an expander die, then the powder load, then my Lockout Die, then a seater die. It's from years ago, but there was no empty station on my die plate for a crimp die. So, I removed the LockOut die, moved the seater die to that now empty station, and was left with one empty station. I ordered a Redding Profile Crimp Die last night, which will arrive in a day or so.

- As a temporary measure, I installed my 38 taper crimp die in that last station, and used it to remove the expansion, bringing the brass diameter at the end down to 0.3755" did (+/1 0.0005). That's the best I can measure it with my calipers.

My "problem" is that there is no way for me to look down into the 38 Special case to see the powder. The case is to long and too small, and there is no way to get a light that shines down to the bottom, and no way to get my eyeball where it needs to be. What I need is a dental mirror with a light. It's possible - for about $300 or so:

- https://www.practicon.com/microlux-lighted-mirror/p/7078332?src=1000069&gclid=Cj0KCQjw5eX7BRDQARIsAMhYLP-Q_kMNAMQxla78sFUtBDGoNJvuCDA6PsDxdgOcoWOjb0fRtc1PT8kaAiy8EALw_wcB

Not very practical.

To me this means I have two choices:

- I can either avoid checking the powder level completely, or remove the case with powder and look into it.

- Or, I can re-install the LockOut Die, seat the bullet in the next station, and crimp all the rounds in my single-station Big Max press.

There is no way I know of to get a "double-charge" on the Pro2000 because after powder is loaded, the round is automatically moved to the next station. As for an "empty" round, I'm loading in an air conditioned closet, so there shouldn't be enough moisture for the powder to "clump" and clog. In all these years that has never happened.

With the experience you guys have had, what would you advise? Trust the press to load powder correctly, or use the LockOut die, and crimp in my second press.

RCBS now makes a 7-station press - I was curious about it, checked it out on the internet, and I wouldn't use it if someone offered it to me for free. The reviews are awful. I'm not a fan of Dillon, and while a Star Press sounds fantastic, that's not an option. If I was buying a new press, this video I watched last night was very persuasive, and the reviews were equally persuasive. I don't like the idea of a primer tube, and I have no plans to switch, but I like what I see here:

https://www.youtube.com/watch?v=72MTiuEBzak

Just dreaming out loud...........but it's still "only" a 5-station press.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

If you want to break up your process into two passes in two presses.....

1. I would see if your powder measure can go in any position. It probably can if it is totally case activated.

2. Set up a first die head for sizing and priming, and maybe expanding depending on your powder measure funnel.

3. Set up a second die head with your measure in position one. Then powder check, seat, crimp in that order.

It all depends if your measure can go into different positions.

I think this wound work on a Hornady LNL. Not sure on the RCBS.

I will admit that the my first batch of 45 years ago from my new 550 Dillon had a no-powder load. I found it in slowfire so I had plenty of time to discover and fix the situation. Someone here will no doubt ask 'where was the double charge?' It didn't show up so I guess I was lucky. Lesson learned. I do set up a simple light on the 550 to see down into the case before I set a bullet. For any rifle loading, I do use the above two step press method except I charge cases in a loading block and visually check every case.

I'd like to hear what you dislike about Dillon. I have two 550, and one Hornady LNL. Also a LNL single press. I think I got an old RCBS single around here somewhere. Back in my rifle days I used a RCBS A2 press. Way back in the 1950s Dad had a cast iron brown Herters "C" press. That's what I learned on.

1. I would see if your powder measure can go in any position. It probably can if it is totally case activated.

2. Set up a first die head for sizing and priming, and maybe expanding depending on your powder measure funnel.

3. Set up a second die head with your measure in position one. Then powder check, seat, crimp in that order.

It all depends if your measure can go into different positions.

I think this wound work on a Hornady LNL. Not sure on the RCBS.

I will admit that the my first batch of 45 years ago from my new 550 Dillon had a no-powder load. I found it in slowfire so I had plenty of time to discover and fix the situation. Someone here will no doubt ask 'where was the double charge?' It didn't show up so I guess I was lucky. Lesson learned. I do set up a simple light on the 550 to see down into the case before I set a bullet. For any rifle loading, I do use the above two step press method except I charge cases in a loading block and visually check every case.

I'd like to hear what you dislike about Dillon. I have two 550, and one Hornady LNL. Also a LNL single press. I think I got an old RCBS single around here somewhere. Back in my rifle days I used a RCBS A2 press. Way back in the 1950s Dad had a cast iron brown Herters "C" press. That's what I learned on.

Jack H- Posts : 2699

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

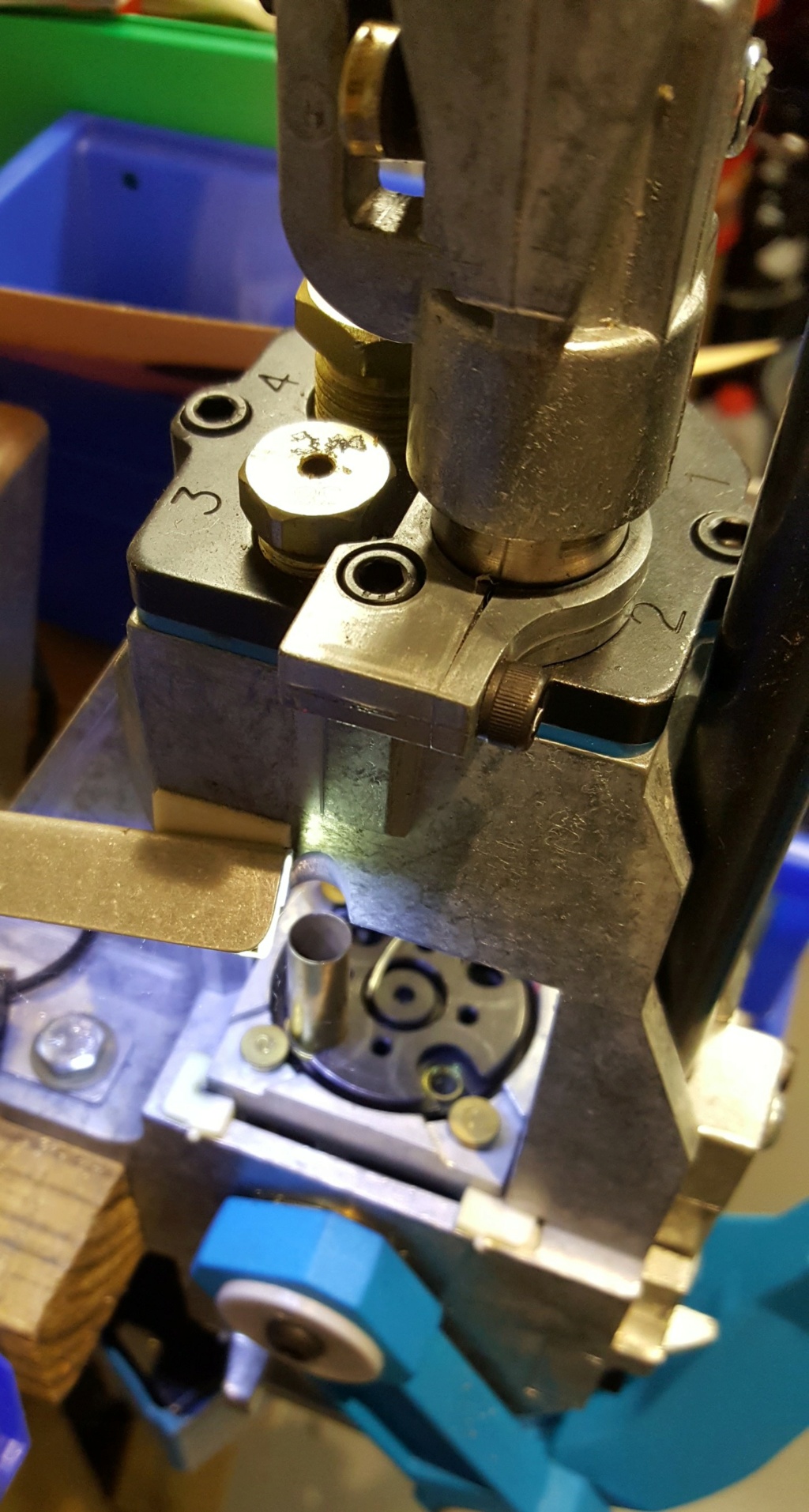

Jack, without major changes, the powder measure goes like what's shown in the photo below, attaching to the frame. The dies go into an easily replaceable die plate, the pulls out to the left. Once you realize this photo was taken from the left, facing the side of the press, it will be obvious.

Are you saying on the 550 that you can look down into a 38 Special case, and see the powder? If so, that will be good news to my relative who has one, but because the case is so tall, I can't do that. With 45, it's no problem.

Did you figure out why you got the empty case? I don't remember how the Dillon works, but that shouldn't be possible - were you just setting up the press? Was it one of a series of rounds? Could it have been the first round, and the powder hadn't yet reached the dispensing mechanism?

I ran round after round, one at a time, first with no powder just checking, and then with powder for 12 or so rounds, then ran the rest to complete 25 rounds that I'll try tomorrow. I'm tempted to load more now, but I'd like to try these first.

Photo:

Are you saying on the 550 that you can look down into a 38 Special case, and see the powder? If so, that will be good news to my relative who has one, but because the case is so tall, I can't do that. With 45, it's no problem.

Did you figure out why you got the empty case? I don't remember how the Dillon works, but that shouldn't be possible - were you just setting up the press? Was it one of a series of rounds? Could it have been the first round, and the powder hadn't yet reached the dispensing mechanism?

I ran round after round, one at a time, first with no powder just checking, and then with powder for 12 or so rounds, then ran the rest to complete 25 rounds that I'll try tomorrow. I'm tempted to load more now, but I'd like to try these first.

Photo:

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

I use a Dillon 450 up graded to a 550. I have a reading light that is on the end of a wand, I shine it in the 38 special case. I can see the charge. Shiny cases inside helps.

The Dillon flares and charges the case at the same time. SO size, deprime and prime on the first step. Charge and flare on the second. Case is closest to my eyes.

I can't see how you could do it with out moving the powder measure, unless you seat and crimp at the same time. It might be ok with 38 special.

Or could you charge and flare at the same time and get rid of the flaring die and use a powder check?

David

The Dillon flares and charges the case at the same time. SO size, deprime and prime on the first step. Charge and flare on the second. Case is closest to my eyes.

I can't see how you could do it with out moving the powder measure, unless you seat and crimp at the same time. It might be ok with 38 special.

Or could you charge and flare at the same time and get rid of the flaring die and use a powder check?

David

David R- Posts : 408

Join date : 2018-12-10

Age : 64

Location : Hamlin NY

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Maybe simpler for

Mike to size, prime, bell, powder then pull cartridge into a loading block to visually check powder level.

Then place bullets into cases, transfer back to press for seating and separate crimping.

Mike to size, prime, bell, powder then pull cartridge into a loading block to visually check powder level.

Then place bullets into cases, transfer back to press for seating and separate crimping.

james r chapman- Admin

- Posts : 6372

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

More detail - If the measure can be relocated.

Two heads:

Positions head one -

1. Size-prime

2. Expand

3-5 empty

Positions head two - priming station is empty

1. Powder, look inside ( I stand when reloading on 550. Also press is on strong stand)

2. powder cop

3. empty

4. seat

5. crimp

Two heads:

Positions head one -

1. Size-prime

2. Expand

3-5 empty

Positions head two - priming station is empty

1. Powder, look inside ( I stand when reloading on 550. Also press is on strong stand)

2. powder cop

3. empty

4. seat

5. crimp

Jack H- Posts : 2699

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Set up for five station press:

Sizing/decapping

Expand/flare case mouth/charge with powder

RCBS Lock-Out die

Seating die

Redding Profile Crimp die

Set up for four station press:

Sell press

Buy five station press

Sizing/decapping

Expand/flare case mouth/charge with powder

RCBS Lock-Out die

Seating die

Redding Profile Crimp die

Set up for four station press:

Sell press

Buy five station press

noylj- Posts : 433

Join date : 2012-03-09

Age : 75

Location : SW USA

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Mike, like Dave says shiny cases help, but I don't clean mine every load. I found using a wooden dowel with a pen mark on the side indicating how far down the case your powder load is accurate enough. 2.5 or 3 grs. is tough to see sometimes.

Stan

Stan

chopper- Posts : 820

Join date : 2013-10-29

Age : 72

Location : Western Iowa

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Thanks; nobody is suggesting to not check that the powder was loaded into the case, which is what I sort of expected you guys to suggest. (In all the years I've had this press, an empty case has never, ever, happened.)

Based on what you're telling me now, I'll move my seater die back to the last station, and put my RCBS LockOut Die back where it used to be, between the powder drop and the seater die.

Problem solved, and I get a bin full of semi-finished rounds, which I will then crimp in my manual press one at a time.

Since I suspect very few people here have a 7-station press, how do you guys verify that the case as it leaves the powder drop is neither empty nor double loaded? .......does anyone other than RCBS even make a 7-station press?

Based on what you're telling me now, I'll move my seater die back to the last station, and put my RCBS LockOut Die back where it used to be, between the powder drop and the seater die.

Problem solved, and I get a bin full of semi-finished rounds, which I will then crimp in my manual press one at a time.

Since I suspect very few people here have a 7-station press, how do you guys verify that the case as it leaves the powder drop is neither empty nor double loaded? .......does anyone other than RCBS even make a 7-station press?

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

'noylj' .....cute, but check the press layout. The powder drop is normally mounted to the press frame, not the die holder. RCBS does make parts to sort of do what you suggest, and I bought them, but I would rather keep things simple.

If all I had to do was buy the Hornady to solve my problem, I'd be seriously considering it, but it's also a 5-station press.

If all I had to do was buy the Hornady to solve my problem, I'd be seriously considering it, but it's also a 5-station press.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Stan, I never thought of that. Nice idea!!! Just use a dowel, which will tell me if the case is empty, or it has powder, or it has too much powder. I'm going to use the LockOut die, but what you suggested might be a good way for my relative to check, with his 4-station 550. Thanks!!

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Get a Hornady LNL already. It great, I've got 2. You should be able to do all you need in 5 stages.

1 - Resize

1.5 - Prime

2 - Charge and Bell simultaneously

3 - Powder Check

4 - Seat

5 - Crimp

1 - Resize

1.5 - Prime

2 - Charge and Bell simultaneously

3 - Powder Check

4 - Seat

5 - Crimp

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

For anyone who does't know how the RCBS LockOut die works:

https://www.youtube.com/watch?v=3N944W_qhVQ

https://www.youtube.com/watch?v=3N944W_qhVQ

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Zane, I didn't know anything about the Hornady until last night, and I sort of fell in love with it. After reading all the reviews, I expect it will cost me maybe $700ish or so, getting all the basic things that the reviewers suggested. It only has one negative for me, so I've got a lot of thinking to do...... and although I like everything else about it, do I need it.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Kneedtospeed likes this post

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Mike 38 special is the hardest one to visually inspect every time, tall and skinny, hard to look down in. I have a 550b and if I give the case a thump with my finger the powder will show it"s self. Not an accurate way to tell you how much is in there, but I know there's something in there. I've never had a bad load yet. I guess the quickest visual method would be to fabricate a light and mirror system.

Stan

Stan

chopper- Posts : 820

Join date : 2013-10-29

Age : 72

Location : Western Iowa

Sa-tevp- Posts : 964

Join date : 2013-07-20

Location : Georgia

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

zanemoseley wrote:Get a Hornady LNL already. It great, I've got 2. You should be able to do all you need in 5 stages.

1 - Resize

1.5 - Prime

2 - Charge and Bell simultaneously

3 - Powder Check

4 - Seat

5 - Crimp

On mine for lead bullets:

1 - Resize with Hornady 454 Casull carbide die

1.5 - Prime

2 - NOE M profile expander .456 x .452 (.457 x .453 was not available when I purchased this)

3 - Charge with 45 Auto powder drop

--- Visually inspect powder and place bullet in case

4 - Seat

5 - Crimp

Sa-tevp- Posts : 964

Join date : 2013-07-20

Location : Georgia

Kneedtospeed likes this post

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

After churning around in my brain for hours, I thought of a small mechanic's mirror I had from ages ago, for looking inside engines or whatever. Found it, and sure, if I hold it in just the right position, it does what I need. If I can make a stand for it, it's another option.

Mirror:

I just need to build something that holds the mirror, so I can slide it into position from the side, then move it away....

Maybe someone creative will jump on this idea, create such an adjustable stand, and sell them to everyone who can use one.

Jon?

Mirror:

The view of the inside of a 38 Special case:

I just need to build something that holds the mirror, so I can slide it into position from the side, then move it away....

Maybe someone creative will jump on this idea, create such an adjustable stand, and sell them to everyone who can use one.

Jon?

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

j_d619 and SingleActionAndrew like this post

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Hey, how do you do all this for 38 Special with only 4 stations?Sa-tevp wrote:I like using wet tumbled brass so I can easily see the powder charge in the case before manually placing a bullet in. I use a Hornady LNL for 45 and a Dillon SDB for 38 Spl Wadcutter......

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

mikemyers wrote:Hey, how do you do all this for 38 Special with only 4 stations?Sa-tevp wrote:I like using wet tumbled brass so I can easily see the powder charge in the case before manually placing a bullet in. I use a Hornady LNL for 45 and a Dillon SDB for 38 Spl Wadcutter......

1- Size 38 Auto

1.5 -Seat primer

2- Expand and powder drop

3 - Check powder load, place bullet and then seat bullet

4 - Crimp cartridge

Sa-tevp- Posts : 964

Join date : 2013-07-20

Location : Georgia

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

The secret it to powder and expand at the same time. rCBS has expander that allow you to do that.

https://www.midwayusa.com/product/1012925582?pid=339587

You might need to adjust your powder measure linkage kit as I don’t know how it compares with the current configuration.

With this setup you’d be Size, Prime, powder and expand, powder check, seat, crimp.

https://www.midwayusa.com/product/1012925582?pid=339587

You might need to adjust your powder measure linkage kit as I don’t know how it compares with the current configuration.

With this setup you’d be Size, Prime, powder and expand, powder check, seat, crimp.

Wobbley- Admin

- Posts : 4805

Join date : 2015-02-12

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

I'm curious - since my relative has one of these. This is Dillon's video of how to use the 550:Sa-tevp wrote:mikemyers wrote:Hey, how do you do all this for 38 Special with only 4 stations?

1- Size 38 Auto

1.5 -Seat primer

2- Expand and powder drop

3 - Check powder load, place bullet and then seat bullet

4 - Crimp cartridge

https://www.youtube.com/watch?v=k0__OViMcaA&feature=emb_logo.

Can you see the shell casing and powder with your bare eye, or if not, where would you mount a mirror, and probably a light, so you can see into the case?

If you've figured out a way, can you please send me a PM or an email, that I can send to him?

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

mikemyers wrote:I'm curious - since my relative has one of these. This is Dillon's video of how to use the 550:Sa-tevp wrote:mikemyers wrote:Hey, how do you do all this for 38 Special with only 4 stations?

1- Size 38 Auto

1.5 -Seat primer

2- Expand and powder drop

3 - Check powder load, place bullet and then seat bullet

4 - Crimp cartridge

https://www.youtube.com/watch?v=k0__OViMcaA&feature=emb_logo.

Can you see the shell casing and powder with your bare eye, or if not, where would you mount a mirror, and probably a light, so you can see into the case?

If you've figured out a way, can you please send me a PM or an email, that I can send to him?

I use a Hornady LNL and a Dillon SDB as noted up thread. I don't have anything to add for a Dillon 550, Others will have to comment.

Sa-tevp- Posts : 964

Join date : 2013-07-20

Location : Georgia

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Everything is a trade-off. Yep, I bought all those parts, only to realize that I would need to move my powder dispenser to the die mounting plate. That makes things a mess if I'm switching back and forth between 38 and 45, unless I buy a second powder dispenser.Wobbley wrote:The secret it to powder and expand at the same time. rCBS has expander that allow you to do that.

https://www.midwayusa.com/product/1012925582?pid=339587

You might need to adjust your powder measure linkage kit as I don’t know how it compares with the current configuration.

With this setup you’d be Size, Prime, powder and expand, powder check, seat, crimp.

It will be easier to just use my LockOut Die and Profile crimp the loaded 38 special rounds in my manual press.

This is only for 38 Special. Loading 45, I can easily see the powder in the case before placing a bullet on top.

Thank you for the idea - you're right, that could work fine.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

mikemyers wrote:

Since I suspect very few people here have a 7-station press, how do you guys verify that the case as it leaves the powder drop is neither empty nor double loaded? .......does anyone other than RCBS even make a 7-station press?

Redding T-7, but still on the honeymoon with it. Not as time efficient for 45 as a progressive of course (assuming the progressive makes rounds correctly on the first go-around) but can easily swap turret heads to other calibers that do call for more precision. Using the RCBS auto trickle and scale system (chargemaster combo) with a powder funnel die, the next cartridge's charge begins to measure when the last charge was emptied from the pan. Together with a flashlight die after the funnel die this is my attempt to solve for the same conditions as your lockout die - the state of the auto trickle powder measure of work is not interrupted makes the previous few operations apparent . And can easily swap to my other turret heads - non-bullseye pistol (10mm and 5.7x28mm on one head) and rifle (30-06, 6.0x51mm on one head).

Now of course with the manually indexing turret head there are less out-of-the-box options for powder measure + drop unit.

Currently experimenting with ...

Tool 1 Lee full size carbide die with deprime pin removed (deprime off-peak before ultrasonic case clean) and Redding autoprime system

Tool 2 Redding premium expander die

Tool 3 Hormady powder funnel die (for auto trickled charge transfer from measuring pan to the case without removing from shell holder)

Tool 4 reloadernetwork flashlight die (~$12 and with so many tool positions it's with the experiment)

Tool 5 Redding competition seating die

Tool 6 Lee carbide factory crimp die

SingleActionAndrew- Admin

- Posts : 674

Join date : 2019-11-19

Location : IL, USA

Page 1 of 2 • 1, 2

Similar topics

Similar topics» 45 reloading question - checking reloads before I buy them.

» Bullet seating for the .45acp

» 38 super bullet seating

» New Reloader - Bullet Seating Question

» Bullet Seating Plug Leading

» Bullet seating for the .45acp

» 38 super bullet seating

» New Reloader - Bullet Seating Question

» Bullet Seating Plug Leading

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum