Reloading Machines, and checking powder level before bullet seating

+12

blindshooter

Aprilian

SingleActionAndrew

Wobbley

Sa-tevp

zanemoseley

chopper

noylj

james r chapman

David R

Jack H

mikemyers

16 posters

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Reloading Machines, and checking powder level before bullet seating

Reloading Machines, and checking powder level before bullet seating

First topic message reminder :

I used to use an RCBS Big Max single station press - still have it, still like it, but I decided to move to a Progressive press, and bought the RCBS Pro2000 a few years ago. Later I added the auto-index kit. I enjoyed it back then, and still enjoy it. Primers go in plastic strips, not tubes, which is important to me. I see tubes of primers, and my brain sees a "pipe bomb". The biggest "negative" is that the Pro2000 is "only" a 5-station press.

For two or three years now, I've only been using the press for 45acp. Little by little, so many things were improved from feedback here, from Terry at Magnus Bullets, and from Dave Salyer. I grudgingly gave up on the RCBS "LockOut Die", as all of you convinced me that seating and crimping needed to be done in separate stations. So, instead of the LockOut Die, I set up a mirror so I can look down into the shell casing and verify that it has the right amount of powder, not too much or too little. I've used it like this for the past year, and my finished rounds look like they came out of a factory box. But during all this time, I stopped reloading 38 Special for my Model 52 and revolvers.

Yesterday I switched over to 38, disassembling all the dies and cleaning, and re-setting everything. Apparently I used to use a re-sizer die, an expander die, then the powder load, then my Lockout Die, then a seater die. It's from years ago, but there was no empty station on my die plate for a crimp die. So, I removed the LockOut die, moved the seater die to that now empty station, and was left with one empty station. I ordered a Redding Profile Crimp Die last night, which will arrive in a day or so.

My "problem" is that there is no way for me to look down into the 38 Special case to see the powder. The case is to long and too small, and there is no way to get a light that shines down to the bottom, and no way to get my eyeball where it needs to be. What I need is a dental mirror with a light. It's possible - for about $300 or so:

Not very practical.

To me this means I have two choices:

There is no way I know of to get a "double-charge" on the Pro2000 because after powder is loaded, the round is automatically moved to the next station. As for an "empty" round, I'm loading in an air conditioned closet, so there shouldn't be enough moisture for the powder to "clump" and clog. In all these years that has never happened.

With the experience you guys have had, what would you advise? Trust the press to load powder correctly, or use the LockOut die, and crimp in my second press.

RCBS now makes a 7-station press - I was curious about it, checked it out on the internet, and I wouldn't use it if someone offered it to me for free. The reviews are awful. I'm not a fan of Dillon, and while a Star Press sounds fantastic, that's not an option. If I was buying a new press, this video I watched last night was very persuasive, and the reviews were equally persuasive. I don't like the idea of a primer tube, and I have no plans to switch, but I like what I see here:

https://www.youtube.com/watch?v=72MTiuEBzak

Just dreaming out loud...........but it's still "only" a 5-station press.

I used to use an RCBS Big Max single station press - still have it, still like it, but I decided to move to a Progressive press, and bought the RCBS Pro2000 a few years ago. Later I added the auto-index kit. I enjoyed it back then, and still enjoy it. Primers go in plastic strips, not tubes, which is important to me. I see tubes of primers, and my brain sees a "pipe bomb". The biggest "negative" is that the Pro2000 is "only" a 5-station press.

For two or three years now, I've only been using the press for 45acp. Little by little, so many things were improved from feedback here, from Terry at Magnus Bullets, and from Dave Salyer. I grudgingly gave up on the RCBS "LockOut Die", as all of you convinced me that seating and crimping needed to be done in separate stations. So, instead of the LockOut Die, I set up a mirror so I can look down into the shell casing and verify that it has the right amount of powder, not too much or too little. I've used it like this for the past year, and my finished rounds look like they came out of a factory box. But during all this time, I stopped reloading 38 Special for my Model 52 and revolvers.

Yesterday I switched over to 38, disassembling all the dies and cleaning, and re-setting everything. Apparently I used to use a re-sizer die, an expander die, then the powder load, then my Lockout Die, then a seater die. It's from years ago, but there was no empty station on my die plate for a crimp die. So, I removed the LockOut die, moved the seater die to that now empty station, and was left with one empty station. I ordered a Redding Profile Crimp Die last night, which will arrive in a day or so.

- As a temporary measure, I installed my 38 taper crimp die in that last station, and used it to remove the expansion, bringing the brass diameter at the end down to 0.3755" did (+/1 0.0005). That's the best I can measure it with my calipers.

My "problem" is that there is no way for me to look down into the 38 Special case to see the powder. The case is to long and too small, and there is no way to get a light that shines down to the bottom, and no way to get my eyeball where it needs to be. What I need is a dental mirror with a light. It's possible - for about $300 or so:

- https://www.practicon.com/microlux-lighted-mirror/p/7078332?src=1000069&gclid=Cj0KCQjw5eX7BRDQARIsAMhYLP-Q_kMNAMQxla78sFUtBDGoNJvuCDA6PsDxdgOcoWOjb0fRtc1PT8kaAiy8EALw_wcB

Not very practical.

To me this means I have two choices:

- I can either avoid checking the powder level completely, or remove the case with powder and look into it.

- Or, I can re-install the LockOut Die, seat the bullet in the next station, and crimp all the rounds in my single-station Big Max press.

There is no way I know of to get a "double-charge" on the Pro2000 because after powder is loaded, the round is automatically moved to the next station. As for an "empty" round, I'm loading in an air conditioned closet, so there shouldn't be enough moisture for the powder to "clump" and clog. In all these years that has never happened.

With the experience you guys have had, what would you advise? Trust the press to load powder correctly, or use the LockOut die, and crimp in my second press.

RCBS now makes a 7-station press - I was curious about it, checked it out on the internet, and I wouldn't use it if someone offered it to me for free. The reviews are awful. I'm not a fan of Dillon, and while a Star Press sounds fantastic, that's not an option. If I was buying a new press, this video I watched last night was very persuasive, and the reviews were equally persuasive. I don't like the idea of a primer tube, and I have no plans to switch, but I like what I see here:

https://www.youtube.com/watch?v=72MTiuEBzak

Just dreaming out loud...........but it's still "only" a 5-station press.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

When I was considering a pro 200, I saw that some people mounted the powder throw in the die plate in order to get the die sequence where the want it.mikemyers wrote:'noylj' .....cute, but check the press layout. The powder drop is normally mounted to the press frame, not the die holder. RCBS does make parts to sort of do what you suggest, and I bought them, but I would rather keep things simple.

If all I had to do was buy the Hornady to solve my problem, I'd be seriously considering it, but it's also a 5-station press.

Aprilian- Posts : 987

Join date : 2016-05-13

Location : Minnesota

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Too many trade-offs....

First, if I use that, I can't use the special Redding expander die that I like so much.

Second, if I use that, I need to move the press back and forth between die plates when I change caliber.

What is least disruptive to my reloading 38 Special, is to put the LockOut die back where it belongs, and let the un-crimped rounds pile up in the bin. Ever 25 or 50 rounds, I'll stop, and one at a time take the seated but uncrimped rounds and crimp them in my Big Max press, then follow Dave's advice and check each one in an old Match Barrel he sent me for this purpose, and them place them in the ammo box.

I spent four hours at the range this morning. 22 went great, better than last time, and after that I tried twelve rounds in the Model 52, which functioned fine. The remaining 13 rounds I shot in my Python, getting a better target than I think I'm capable of. Most of the 10 rounds fired at a B-8 were overlapping. By then it was getting quite warm.

By the way, every place I searched on the internet implied that the 38 Special cases should be crimped with a Profile (roll) crimp. My friend Tony said that the advice "way back when" was to use a taper crimp. He said "The Pistol Shooter's Treasury" had a discussion about this - will read that later today. Can anyone here point out the benefit of using one crimp method vs. the other for shooting in a Model 52 ?

First, if I use that, I can't use the special Redding expander die that I like so much.

Second, if I use that, I need to move the press back and forth between die plates when I change caliber.

What is least disruptive to my reloading 38 Special, is to put the LockOut die back where it belongs, and let the un-crimped rounds pile up in the bin. Ever 25 or 50 rounds, I'll stop, and one at a time take the seated but uncrimped rounds and crimp them in my Big Max press, then follow Dave's advice and check each one in an old Match Barrel he sent me for this purpose, and them place them in the ammo box.

I spent four hours at the range this morning. 22 went great, better than last time, and after that I tried twelve rounds in the Model 52, which functioned fine. The remaining 13 rounds I shot in my Python, getting a better target than I think I'm capable of. Most of the 10 rounds fired at a B-8 were overlapping. By then it was getting quite warm.

By the way, every place I searched on the internet implied that the 38 Special cases should be crimped with a Profile (roll) crimp. My friend Tony said that the advice "way back when" was to use a taper crimp. He said "The Pistol Shooter's Treasury" had a discussion about this - will read that later today. Can anyone here point out the benefit of using one crimp method vs. the other for shooting in a Model 52 ?

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Interesting day, I keep finding I don't know enough.

I took the shell plate apart, and added the lockout die, then the seater die. With the seater die relocated to the new position #5, I found I could clearly see the powder. So I put the mirror and light back on. The Lockout Die catches empty cases and double charges, but it's so easy now I found myself looking at the powder before placing the bullet on top.

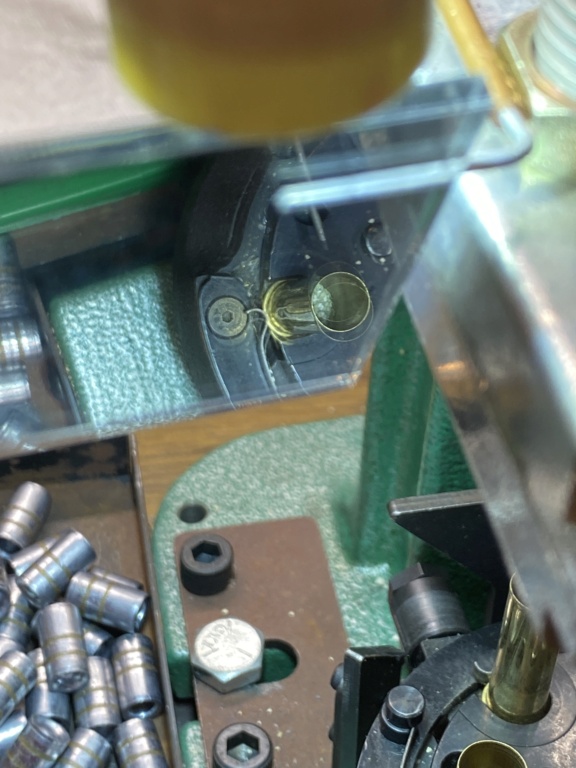

If you see the shell with powder, sort of up near the top of the image below, that's what I see in the mirror. I've got to look there anyway to put the bullet in place, so it worked out fine.

I took the shell plate apart, and added the lockout die, then the seater die. With the seater die relocated to the new position #5, I found I could clearly see the powder. So I put the mirror and light back on. The Lockout Die catches empty cases and double charges, but it's so easy now I found myself looking at the powder before placing the bullet on top.

If you see the shell with powder, sort of up near the top of the image below, that's what I see in the mirror. I've got to look there anyway to put the bullet in place, so it worked out fine.

I temporarily installed the taper crimp die in my other press. Later on, I realized I could just remove the die holder plate, and put in another one with the taper crimp die. Who knows, maybe eventually I'll do that.

BUT.....

At this morning's match, my friend Tony told me the The Pistol Shooter's Treasury had a whole section about loading for the Model 52. I forgot about that. The suggestion in the book is to use a taper crimp die to 0.370" (page #105). Maybe I'll ask this question in a more prominent place, instead of buried here. Since my Profile Crimp Die won't arrive for a week or so, I just adjusted my Taper Crimp Die to 0.370". I hope to try this tomorrow, both in my Model 52, and in whichever revolver I decide to bring with me. How do you guys crimp? Taper Crimp Die, or Profile (Roll) Crimp Die?

I loaded one box of 50 rounds, re-adjusting different parts of the press along the way that didn't work smoothly. The Pro2000 seems happier loading 45 than 38. I remember that from two years ago. In the past two years, it has gotten easier along the way. Now I'm back to things that I never fully understood two years ago.

I was curious what kind of accuracy I might expect from my 38 reloads. I didn't do so well this morning with the Model 52, but that's me, not the gun, needing to get back into shape. I then shot 15 rounds with my Python, and did much better. If nothing else, it's obvious to me both as to the best I can currently shoot the Python, and how my mistakes really mess me up. I'm slowly eliminating those mistakes. If I'm smarter, I'll bring my S&W Model 14 with me tomorrow.

Oh yeah, LenV, check the grips!!! :-) It's your fault that I got hooked on them. Now I'm addicted.

There's hope for the future, once I do everything right every time.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

SingleActionAndrew likes this post

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Mike, did you just get that Python? You were talking about them a week or two ago. Looks too shiny to be a new one. I've considered getting a new one them have it polished so could have a slick looking Python with new parts availability and lower price. Still hoping they'll release a factory polished stainless one or even better nickel and royal blue. But even the base model is selling $300 over MSRP on GB now.

zanemoseley- Posts : 2688

Join date : 2015-07-11

Location : Cookeville, TN

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Zane, I was at the range, and overheard two people discussing a Python - one fellow had a 1980 model for sale. I told him if the first person didn't buy it, to let me know. So he shows up a few days later at the range, tells me the other person didn't have the cash, and was I interested? After just picking up the gun I knew my answer, but we talked about it for half an hour or so, I drove home to raid my piggy bank, and went home with something I've wanted since the late 1970's.

If you look around, especially in the threads in the Colt Forum, you can buy them now for the "official" price, nothing added. Hickock45 has several videos on them, which you probably should watch. Something nobody talks about though, is the new model no longer has the Accro sight that used to come with the gun - to adjust the sight, first you need to loosen a lock screw, then adjust, then tighten the lock screw. I prefer the old sight, and the optional version that was supposedly better for Bullseye - it's the same sight that came on Gold Cup 1911's. The new guns also come with stiff springs - firing my Python feels like firing a S&W target revolver, but like people say, it's "buttery smooth". The stiffer springs seems to be a common complaint on the Colt Forum (maybe it's a liability issue, and they can't sell guns with light springs to the general public?). The other "issues" with the new Python apparently are resolved, and the new guns work properly.

You're right - my gun is nickel plated, and it's shinier than any gun I remember seeing. I wold have been happier with Stainless Steel, but the Nickel sure stands out. To be honest though, I might have been better off buying a brand new 6" SS Python. Regarding price, the $300 gives people an incentive on making easy money, but as a buyer, if you have patience, the more guns are available, the less reason there is to give these guys a free $300 or whatever. People are still posting on the Colt Forum when a dealer is getting guns in stock, to be sold at the official price.

For me, the grips that came on the old Python were just as nice as what comes with a target S&W revolver, but I'm spoiled now - the Nill grips fit my hand so much better. The new Pythons come with "skinnier" grips - not sure if that is better or worse, but it's easy to change.

If you look around, especially in the threads in the Colt Forum, you can buy them now for the "official" price, nothing added. Hickock45 has several videos on them, which you probably should watch. Something nobody talks about though, is the new model no longer has the Accro sight that used to come with the gun - to adjust the sight, first you need to loosen a lock screw, then adjust, then tighten the lock screw. I prefer the old sight, and the optional version that was supposedly better for Bullseye - it's the same sight that came on Gold Cup 1911's. The new guns also come with stiff springs - firing my Python feels like firing a S&W target revolver, but like people say, it's "buttery smooth". The stiffer springs seems to be a common complaint on the Colt Forum (maybe it's a liability issue, and they can't sell guns with light springs to the general public?). The other "issues" with the new Python apparently are resolved, and the new guns work properly.

You're right - my gun is nickel plated, and it's shinier than any gun I remember seeing. I wold have been happier with Stainless Steel, but the Nickel sure stands out. To be honest though, I might have been better off buying a brand new 6" SS Python. Regarding price, the $300 gives people an incentive on making easy money, but as a buyer, if you have patience, the more guns are available, the less reason there is to give these guys a free $300 or whatever. People are still posting on the Colt Forum when a dealer is getting guns in stock, to be sold at the official price.

For me, the grips that came on the old Python were just as nice as what comes with a target S&W revolver, but I'm spoiled now - the Nill grips fit my hand so much better. The new Pythons come with "skinnier" grips - not sure if that is better or worse, but it's easy to change.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Save up for a Dillon 1100 or a used 1050.

Set it up for the round you load the most. Get the powder check die/alarm.

I wish I had two of them. Its so easy on my messed up shoulder.

Currently I have a Projector, a LnL and the 1050. I do have a RCBS RC, but hardly ever mount it.

I leave the 1050 set up for .45acp as thats what I load the most.

Use the LnL and Projector for 9mm and processing/loading .223 and 6.5-08.

Also have a PW Metallic 2 (basically a turret with auto primer feed) used for final loading precision rifle.

Your pics show a small space for machines? You could use a plate and socket system to move different tools on/off the bench and store the unused equipment?

Finally and I may be beat up for this, a squib is not the end of the world as long as the shooter handles it correctly. A double charge not so much. The auto index press almost precludes a double. YMMV

P.S.

If you get tired of it or don't like the 1100/1050 you can sell it for at least 80% of cost. Maybe more in the current environment.

Set it up for the round you load the most. Get the powder check die/alarm.

I wish I had two of them. Its so easy on my messed up shoulder.

Currently I have a Projector, a LnL and the 1050. I do have a RCBS RC, but hardly ever mount it.

I leave the 1050 set up for .45acp as thats what I load the most.

Use the LnL and Projector for 9mm and processing/loading .223 and 6.5-08.

Also have a PW Metallic 2 (basically a turret with auto primer feed) used for final loading precision rifle.

Your pics show a small space for machines? You could use a plate and socket system to move different tools on/off the bench and store the unused equipment?

Finally and I may be beat up for this, a squib is not the end of the world as long as the shooter handles it correctly. A double charge not so much. The auto index press almost precludes a double. YMMV

P.S.

If you get tired of it or don't like the 1100/1050 you can sell it for at least 80% of cost. Maybe more in the current environment.

blindshooter- Posts : 122

Join date : 2016-03-15

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

First post, long time lurker. I saw this post and thought of a usb endoscope camera that you can hook up to your phone or tablet. They are about $20 on Amazon or ebay. The camera is small, has a LIGHT, could be mounted in various locations or on a stand, has a long cord, and is compatible with Android, mac, or pc. The resolution or picture quality is not great but I think it would do what you need.

j_d619- Posts : 1

Join date : 2016-05-22

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Interesting idea - I sort of like the setup I've got now, as I can literally see into the case and verify there's powder there. The only "bad" thing is I need to crimp the rounds one at a time on my other press, but that's not all that bad, as I can check over the rounds which I usually do anyway. If loading time mattered, or if I was in a hurry, I might feel differently.j_d619 wrote:.......a usb endoscope camera that you can hook up to your phone or tablet. They are about $20 on Amazon or ebay. The camera is small, has a LIGHT, could be mounted in various locations or on a stand......

If I did get the endoscope, I's probably put a small screen in front of me, that I could glance at before placing the bullet on the case.

(This is only for 38 - doing 45's, I have no problem seeing the powder level in my mirror.)

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

It's more likely that I'll buy a Yugo car, than a Dillon press.blindshooter wrote:Save up for a Dillon 1100 or a used 1050.

Set it up for the round you load the most. Get the powder check die/alarm.

I wish I had two of them. Its so easy on my messed up shoulder.

Currently I have a Projector, a LnL and the 1050. I do have a RCBS RC, but hardly ever mount it.

I leave the 1050 set up for .45acp as thats what I load the most.

Use the LnL and Projector for 9mm and processing/loading .223 and 6.5-08.

Also have a PW Metallic 2 (basically a turret with auto primer feed) used for final loading precision rifle.

Your pics show a small space for machines? You could use a plate and socket system to move different tools on/off the bench and store the unused equipment?

Finally and I may be beat up for this, a squib is not the end of the world as long as the shooter handles it correctly. A double charge not so much. The auto index press almost precludes a double. YMMV

P.S.

If you get tired of it or don't like the 1100/1050 you can sell it for at least 80% of cost. Maybe more in the current environment.

The ONLY other press I'm interested in right now, is the LnL, and I would prefer to not have a primer tube in front of me. The Pro2000 was/is the perfect (and only) choice for me.

I used to do all my reloading on my single station RCBS Big Max press. That used to be fine for me - now I'm spoiled. :-(

Regarding a squib, I agree. If the gun goes bang, rather than BANG, I would stop and check things out. To get past my press, a bad round would need to get through the LockOut die (I've tested it, and it locks up for no powder, or a double load). Since I'm manually placing the 38 Special bullet onto the case, looking into the case with my mirror is effortless.

(If someone offered me a used LnL press, I'm not sure I could resist.......)

You're correct about the small space, but I live in a tiny one-bedroom condo, and my shop/reloading-area is half of my closet. Things that are not in use mostly go up on shelves.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

I reload pistol on a Pro2000.

I personally would never load pistol on any progressive without a check or cop die to verify powder charges, but others disagree with that opinion.

I put the powder measure on the die plate in station 2.

1 - resize/deprime

2 - prime, dispense powder

3 - RCBS lockout die

4 - bullet feeder die

5 - seater

I don't crimp pistol ammo.

Before I used a lockout die, I used one of the $20 Chinamart USB endoscopes plugged into a laptop next to the press. Works great. Just required a lot of bench real estate.

Also, if you're not spraying your pistol brass with Hornady One-Shot before running it through the sizing die (yes, even carbide ones that don't "need" lube), you're missing out. Hornady 1S is terrible with rifle brass but makes resizing pistol effortless.

I personally would never load pistol on any progressive without a check or cop die to verify powder charges, but others disagree with that opinion.

I put the powder measure on the die plate in station 2.

1 - resize/deprime

2 - prime, dispense powder

3 - RCBS lockout die

4 - bullet feeder die

5 - seater

I don't crimp pistol ammo.

Before I used a lockout die, I used one of the $20 Chinamart USB endoscopes plugged into a laptop next to the press. Works great. Just required a lot of bench real estate.

Also, if you're not spraying your pistol brass with Hornady One-Shot before running it through the sizing die (yes, even carbide ones that don't "need" lube), you're missing out. Hornady 1S is terrible with rifle brass but makes resizing pistol effortless.

pgg- Posts : 198

Join date : 2015-11-21

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

What is a "bullet feeder die" ?

Does it automatically place one bullet in position for the next station?

If so, does it work with more than one caliber, and/or bullet?

How many bullets does it hold? Does it align them automatically?

Is it another accessory from RCBS ?

I'd like to understand, but I don't want to add any more complexity to what I'm already doing.

Does it automatically place one bullet in position for the next station?

If so, does it work with more than one caliber, and/or bullet?

How many bullets does it hold? Does it align them automatically?

Is it another accessory from RCBS ?

I'd like to understand, but I don't want to add any more complexity to what I'm already doing.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

RCBS, Hornady, and Mr Bulket Feeder all make “bullet feeder dies. Hornady and Mr Bullet feeder also make automatic bullet collator that will sort and feed the bullets in correct orientation. These collators only work with jacketed, plated, OR PERHAPS coated bullets only. bulket feeder dies also don’t work with full wadcutters well either. They are caliber specific with perhaps the exception that 9mm and 37/357 are interchangeable.

Wobbley- Admin

- Posts : 4805

Join date : 2015-02-12

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

https://www.midwayusa.com/product/1011879179

This is the RCBS, like the one I use for pistol. I have extra tubes, so I load a few hundred bullets in tubes ahead of time. Works well. I have a second Pro2000 set up for rifle that uses their rifle bullet feeder.

Speeds things up a lot.

This is the RCBS, like the one I use for pistol. I have extra tubes, so I load a few hundred bullets in tubes ahead of time. Works well. I have a second Pro2000 set up for rifle that uses their rifle bullet feeder.

Speeds things up a lot.

pgg- Posts : 198

Join date : 2015-11-21

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

The number of things I'm finding out I don't know is growing much faster than the number of new things I've learned. Based on what. you wrote, I found this ( https://www.youtube.com/watch?v=dWG_8u-1Gfk ) which I guess is similar to what 'pgg' meant. I guess then I need a machine to orient and load the bullets into this device, and maybe something at the other end of the machine to deal with the steady stream of bullets being churned out.....

I always thought that for me, reloading meant going into the reloading room for one or two hours at a time, and carefully turning out 50 or 100 leisurely rounds..........

I always thought that for me, reloading meant going into the reloading room for one or two hours at a time, and carefully turning out 50 or 100 leisurely rounds..........

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Now I'm even more confused than usual.... This is the first Youtube video I went to, about the RCBS: https://www.youtube.com/watch?v=divTwek0Gdspgg wrote:https://www.midwayusa.com/product/1011879179

This is the RCBS, like the one I use for pistol. I have extra tubes, so I load a few hundred bullets in tubes ahead of time. Works well. I have a second Pro2000 set up for rifle that uses their rifle bullet feeder.

Speeds things up a lot.

I didn't watch the whole video. I'll check out the Midway link in a few minutes.

You have two Pro2000's? Lucky guy!!!!

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

I got the second one for a song when RCBS discontinued it. Someone was blowing out all the accessories at the time too, so I got shell plates for about $2 each along with other goodies. Lucky indeed.

pgg- Posts : 198

Join date : 2015-11-21

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

(They really screwed up. Everyone seemed to like the Pro2000. Check the reviews on the newer ProChucker 5 or 7, the replacement. The word "junk" isn't strong enough, based on what I read. Very sad. You made out like a bandit!!!! :-) )

I did also buy a lot of parts at extremely low prices, even if I didn't know if I would ever use them. I've got lots of things I've never even looked at. It's midnight. Time for sleep!

I did also buy a lot of parts at extremely low prices, even if I didn't know if I would ever use them. I've got lots of things I've never even looked at. It's midnight. Time for sleep!

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

How about using a small wireless backup camera? You’ll need to figure out a mount, but I’ve seen it used to monitor the level on presses which run a case feeder & bulletfeeder combo. Live picture is sent to your iPhone.

Last edited by New2BE on 10/22/2020, 9:13 am; edited 1 time in total (Reason for editing : Missed word)

New2BE- Posts : 93

Join date : 2017-04-23

Location : So CAL

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

Technically, I'm sure that could be done. I like the way things are now though, just look into the case before covering it up with a bullet. I can re-assure myself that all is safe by deliberately creating an "empty" or a "double charge", and the RCBS LockOut Die does just that - it "locks" the press, so I can't pull the lever.

If the powder level is too high, I'd like to think that I would notice it with my eye, looking into the case. I don't think I would see it this clearly on my iPhone.

Since my reloader is producing rounds that just need crimping, I check over each round before crimping it. No more shaved lead. Every so often a round doesn't look right, so I put it off to the side. Potentially, it can be shot in my revolver, after which I can throw away the case. Most of these were cases that got deformed while scraping lead.

At some point in time, I'll put all these cases away, and switch to my still unused Starline cases.

At some point in the future, I want to load some more 44 Special. I still have 40-year-old bullets and cases. Cases need a good cleaning. Maybe I should add some Napalmolive to the tumbler. :-)

If the powder level is too high, I'd like to think that I would notice it with my eye, looking into the case. I don't think I would see it this clearly on my iPhone.

Since my reloader is producing rounds that just need crimping, I check over each round before crimping it. No more shaved lead. Every so often a round doesn't look right, so I put it off to the side. Potentially, it can be shot in my revolver, after which I can throw away the case. Most of these were cases that got deformed while scraping lead.

At some point in time, I'll put all these cases away, and switch to my still unused Starline cases.

At some point in the future, I want to load some more 44 Special. I still have 40-year-old bullets and cases. Cases need a good cleaning. Maybe I should add some Napalmolive to the tumbler. :-)

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Reloading Machines, and checking powder level before bullet seating

Re: Reloading Machines, and checking powder level before bullet seating

mikemyers wrote:I used to use an RCBS Big Max single station press - still have it, still like it, but I decided to move to a Progressive press, and bought the RCBS Pro2000 a few years ago. Later I added the auto-index kit. I enjoyed it back then, and still enjoy it. Primers go in plastic strips, not tubes, which is important to me. I see tubes of primers, and my brain sees a "pipe bomb". The biggest "negative" is that the Pro2000 is "only" a 5-station press.

For two or three years now, I've only been using the press for 45acp. Little by little, so many things were improved from feedback here, from Terry at Magnus Bullets, and from Dave Salyer. I grudgingly gave up on the RCBS "LockOut Die", as all of you convinced me that seating and crimping needed to be done in separate stations. So, instead of the LockOut Die, I set up a mirror so I can look down into the shell casing and verify that it has the right amount of powder, not too much or too little. I've used it like this for the past year, and my finished rounds look like they came out of a factory box. But during all this time, I stopped reloading 38 Special for my Model 52 and revolvers.

Yesterday I switched over to 38, disassembling all the dies and cleaning, and re-setting everything. Apparently I used to use a re-sizer die, an expander die, then the powder load, then my Lockout Die, then a seater die. It's from years ago, but there was no empty station on my die plate for a crimp die. So, I removed the LockOut die, moved the seater die to that now empty station, and was left with one empty station. I ordered a Redding Profile Crimp Die last night, which will arrive in a day or so.

- As a temporary measure, I installed my 38 taper crimp die in that last station, and used it to remove the expansion, bringing the brass diameter at the end down to 0.3755" did (+/1 0.0005). That's the best I can measure it with my calipers.

My "problem" is that there is no way for me to look down into the 38 Special case to see the powder. The case is to long and too small, and there is no way to get a light that shines down to the bottom, and no way to get my eyeball where it needs to be. What I need is a dental mirror with a light. It's possible - for about $300 or so:

- https://www.practicon.com/microlux-lighted-mirror/p/7078332?src=1000069&gclid=Cj0KCQjw5eX7BRDQARIsAMhYLP-Q_kMNAMQxla78sFUtBDGoNJvuCDA6PsDxdgOcoWOjb0fRtc1PT8kaAiy8EALw_wcB

Not very practical.

To me this means I have two choices:

- I can either avoid checking the powder level completely, or remove the case with powder and look into it.

- Or, I can re-install the LockOut Die, seat the bullet in the next station, and crimp all the rounds in my single-station Big Max press.

There is no way I know of to get a "double-charge" on the Pro2000 because after powder is loaded, the round is automatically moved to the next station. As for an "empty" round, I'm loading in an air conditioned closet, so there shouldn't be enough moisture for the powder to "clump" and clog. In all these years that has never happened.

With the experience you guys have had, what would you advise? Trust the press to load powder correctly, or use the LockOut die, and crimp in my second press.

RCBS now makes a 7-station press - I was curious about it, checked it out on the internet, and I wouldn't use it if someone offered it to me for free. The reviews are awful. I'm not a fan of Dillon, and while a Star Press sounds fantastic, that's not an option. If I was buying a new press, this video I watched last night was very persuasive, and the reviews were equally persuasive. I don't like the idea of a primer tube, and I have no plans to switch, but I like what I see here:

https://www.youtube.com/watch?v=72MTiuEBzak

Just dreaming out loud...........but it's still "only" a 5-station press.

Get this light. I can almost guarantee you will see the powder level! http://kmssquared.com/

Boston Bill- Posts : 9

Join date : 2020-03-07

Age : 69

Location : Cape Cod

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» 45 reloading question - checking reloads before I buy them.

» Bullet seating for the .45acp

» 38 super bullet seating

» New Reloader - Bullet Seating Question

» Bullet Seating Plug Leading

» Bullet seating for the .45acp

» 38 super bullet seating

» New Reloader - Bullet Seating Question

» Bullet Seating Plug Leading

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum