Home Swaged 38 HBWC

+11

Schaumannk

DA/SA

inthebeech

chopper

Black_Talon

Wobbley

RodJ

Steve B

Greg Walloch

Jon Eulette

fc60

15 posters

Page 1 of 1

Home Swaged 38 HBWC

Home Swaged 38 HBWC

Greetings,

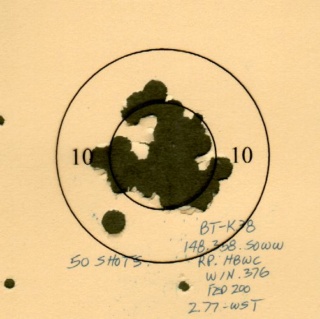

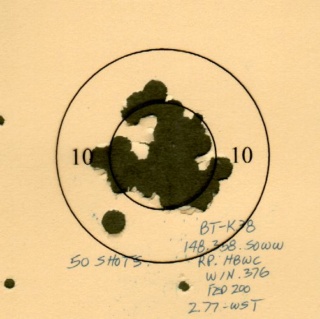

Tested some home swaged 38 HBWC yesterday.

Test parameters...

Cheers,

Dave

Tested some home swaged 38 HBWC yesterday.

Test parameters...

- K38 barrel machined round to fit the barrel tester.

- Chambered with a SAAMI 38 WadCutter ream.

- Bullets first cast into slugs from Stick On Wheel Weights.

- The hollow base is a copy of the Remington Bullet.

- Final swaged bullets lubed lightly with Lee Liquid Alox.

- 2.77 grains of WST.

- Winchester cases sized to 0.376" with no cannelure.

- Federal 200 primer.

- Taper Crimped to 0.370".

- 50 shots fired at 50 yards.

Cheers,

Dave

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

bruce martindale, ric1911a1, chopper, ak41, Fotomaniac, TonyH, chiz1180 and like this post

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

OUTSTANDING Dave!

Jon Eulette- Posts : 4399

Join date : 2013-04-15

Location : Southern Kalifornia

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

It’s always a very interesting post when you bring in your bullet-making! Fascinating stuff!

Greg Walloch- Posts : 183

Join date : 2011-06-11

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

What was the finished bullet diameter?

Steve B- Posts : 627

Join date : 2011-06-16

Location : Elkhart, IN

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Crazy - 50 rounds! What scale do you use to measure into the hundredths of grains?

RodJ- Posts : 921

Join date : 2021-06-26

Location : TX

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Did you get a velocity reading per chance?

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Greetings,

Final swaged diameter is 0.358".

I weigh ten charges and divide by ten. i.e. Ten charges weighed 27.7 grains, repeatedly.

Velocity Averaged 740 FPS twenty feet from the muzzle.

The more I swage, the better I get. Still have a ways to go...

Cheers,

Dave

Final swaged diameter is 0.358".

I weigh ten charges and divide by ten. i.e. Ten charges weighed 27.7 grains, repeatedly.

Velocity Averaged 740 FPS twenty feet from the muzzle.

The more I swage, the better I get. Still have a ways to go...

Cheers,

Dave

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

chopper likes this post

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

I noticed the lack of “characteristic “ scuffing even though you used an old S&W barrel.

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

I'd sure love to see some detailed pics of the finished bullets, before lubing.

Black_Talon- Posts : 214

Join date : 2011-06-10

Location : SoCal

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Dave are you going to test with Bullseye powder also, not that you'd improve on such a nice grouping. Great job swagging, I'm curious if you've barrel tested any .358" cast bullets also. I really like following your posts, they're so good.

Stan

Stan

chopper- Posts : 820

Join date : 2013-10-29

Age : 72

Location : Western Iowa

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

I want to see the barrel tester.

inthebeech- Posts : 657

Join date : 2012-03-17

Age : 59

Location : Harleysville, Pennsylvania

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

It would be interesting to see the results of re-swaging the commercially available HBWC's such as Zero, Precision Delta, Speer, Hornady, etc.

DA/SA- Posts : 1506

Join date : 2017-10-09

Age : 68

Location : Southeast Florida

jglenn21 likes this post

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Greetings,DA/SA wrote:It would be interesting to see the results of re-swaging the commercially available HBWC's such as Zero, Precision Delta, Speer, Hornady, etc.

We have had excellent results swaging the 32 caliber Speer 98 grain HBWC up to 0.314".

The current Speer bullet is lubed with a Moly-like material and actually helps the swage process by acting as a lubricant.

The bullets swaged and lubed with "sticky" lube gum up the swage dies and make the process futile.

I did swage the 38 caliber Speer 148 HBWC and results were not that exciting. Perhaps I could revisit it one day.

The primary reason for swaging my own bullets is that any day, the commercial vendors can stop production. Such as Remington and Winchester.

Cheers,

Dave

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Thanks Dave!

I was just curious if the results would be worth the effort for those that do not cast their own.

I was just curious if the results would be worth the effort for those that do not cast their own.

Last edited by DA/SA on Mon Oct 04, 2021 8:21 am; edited 1 time in total

DA/SA- Posts : 1506

Join date : 2017-10-09

Age : 68

Location : Southeast Florida

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Greetings,Wobbley wrote:I noticed the lack of “characteristic “ scuffing even though you used an old S&W barrel.

I went back and looked at the individual ten shot groups. There is still evidence of "yaw/scuffing" on some of the holes.

The target I posted initially was the backer I started with.

When I was finished and cleaning up, the backer was too nice to toss in the bin.

Cheers,

Dave

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

I have had very good luck swaging the powder coated bullets. All the bullet manufacturers are using a slightly different coating, and it seems to stand up well to going through the swager, although some coatings are superior to others.

So far the best coating appears to be whatever Bob Palermo at Penn bullets is using. I lose the coating in the hollow base, but the rest of the bullet, and the part that contacts the sides of the barrel remains intact, going through the swager. The swaging dies remain clean, and no gunk build up.

So far the best coating appears to be whatever Bob Palermo at Penn bullets is using. I lose the coating in the hollow base, but the rest of the bullet, and the part that contacts the sides of the barrel remains intact, going through the swager. The swaging dies remain clean, and no gunk build up.

Schaumannk- Posts : 615

Join date : 2011-06-11

Location : Cheyenne, WY

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Greetings,chopper wrote:Dave are you going to test with Bullseye powder also, not that you'd improve on such a nice grouping. Great job swagging, I'm curious if you've barrel tested any .358" cast bullets also. I really like following your posts, they're so good.

Stan

Past experiments show that one can get X-ring groups with a variety of powders, providing they meter well in the dispenser.

I have tested many cast bullets and the results are "okay" (ten-ring @ 50 yards). Casting is a chore for me as I reject roughly 60% of them due to defects. A lot of work.

Swaging produces a much higher percentage of "keepers".

Looking in my archive, I found no targets of cast wad cutters using the K38 barrel.

(I modified the K-38 barrel due to the 1:18.75" twist, which is common to the Model 52. The K-38 is 0.3575" groove diameter and the M-52 is 0.3545". I did not want to ruin a good M-52 barrel for the barrel tester.)

Cheers,

Dave

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Dave,

If you wanted to cast your own slugs for the 32 and 38, which molds and lead mix should we be looking for best possible success?

Thanks,

Chase

If you wanted to cast your own slugs for the 32 and 38, which molds and lead mix should we be looking for best possible success?

Thanks,

Chase

Chase Turner- Posts : 385

Join date : 2019-11-15

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Impressive, a bullseye smith I know has said that a 148 grain HBWC in 38 special is one of the most accurate pistol cartridges around.

troystaten- Posts : 824

Join date : 2012-04-18

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Greetings Chase,Chase Turner wrote:Dave,

If you wanted to cast your own slugs for the 32 and 38, which molds and lead mix should we be looking for best possible success?

Thanks,

Chase

Hardness is key. I try to use alloys of about 6 HBN.

Currently, I have been using Stick On Wheel Weights (SOWW), 5.7 HBN, and they swage okay. Problem is the actual alloy is a mystery. I do have the tools to measure hardness.

Another friend, that drank the swaging Kool-Aid, uses 20 Lead : 1 Tin (20:1) alloy with good results. This was purchased from RotoMetals and is a known alloy.

We have also played with 30:1 alloy.

The Lead:Tin alloys are nice as Tin helps the metal flow better. SOWW possibly has Antimony and it takes two swages to produce a nice clean well filled out bullet.

I bought some Lee Six Cavity Blank Moulds and machined cylindrical cavities in them. This way, you can change alloys readily.

Swaging is not for everyone. I enjoy it despite the great amount of labor involved. Good news is that I no longer rely on the availability of factory made bullets.

Cheers,

Dave

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Dave,fc60 wrote:

Swaging is not for everyone. I enjoy it despite the great amount of labor involved. Good news is that I no longer rely on the availability of factory made bullets.

Cheers,

Dave

The ability to produce your own is no small thing these days and considering your quality that is an understatement!

BUT were I to shoot 10 of 'em I would flinch on that 7 o'clock hit for an 8?!?

Compliments on your craftmanship!

Ron Habegger

Colt711- Posts : 641

Join date : 2012-06-07

Age : 82

Location : Hudson, Florida

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

fc60 wrote:Greetings,

The more I swage, the better I get. Still have a ways to go...

Cheers,

Dave

Dave,

What do you think might be possible re: group size?

Ron

Colt711- Posts : 641

Join date : 2012-06-07

Age : 82

Location : Hudson, Florida

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Greetings,

I would like to see groups at 50 yards inside the X-ring. That is all ten shots and none of them touching the X-ring.

After a bit more thought, I have been very pleased to equal/exceed the group size of commercial loaded ammo.

Considering the HBWC is a dynamically unstable projectile, X-ring groups at 50 yards with either the 32 or 38 HBWC is a job well done.

Cheers,

Dave

I would like to see groups at 50 yards inside the X-ring. That is all ten shots and none of them touching the X-ring.

After a bit more thought, I have been very pleased to equal/exceed the group size of commercial loaded ammo.

Considering the HBWC is a dynamically unstable projectile, X-ring groups at 50 yards with either the 32 or 38 HBWC is a job well done.

Cheers,

Dave

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Home Swaged 38 HBWC

Re: Home Swaged 38 HBWC

Dave,

Impressed with your results. I cast 148gr HBWC's, and am curious as to how they would compare to your home swaged results. If you are up for a another test, I would happily send you some.

Don

Impressed with your results. I cast 148gr HBWC's, and am curious as to how they would compare to your home swaged results. If you are up for a another test, I would happily send you some.

Don

USSR- Posts : 352

Join date : 2017-07-14

Age : 74

Location : Finger Lakes Region of NY

Similar topics

Similar topics» Precision Delta has HBWC 38 SPL Swaged in stock

» How do I keep my swaged bullets from getting swaged during reloading?

» swaged LSWCHP vs swaged LSWC vs JHP

» Whats your .32 S&W Long load using H&N .314 wadcutters or bumped Speer clones...

» Swaged vs. Cast....

» How do I keep my swaged bullets from getting swaged during reloading?

» swaged LSWCHP vs swaged LSWC vs JHP

» Whats your .32 S&W Long load using H&N .314 wadcutters or bumped Speer clones...

» Swaged vs. Cast....

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum