Leftover carbon inside cases does not act like a lubricant

+14

chopper

jglenn21

blindshooter

Rodger Barthlow

BE Mike

tovaert

fc60

james r chapman

DA/SA

CR10X

Wobbley

Pinetree

Merick

Chase Turner

18 posters

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Leftover carbon inside cases does not act like a lubricant

Leftover carbon inside cases does not act like a lubricant

First topic message reminder :

Chemistry is the discipline that describes large quantities of small items as "moles," which ought to give everyone a bit of pause. Why not call these things platypuses? I mean, if you are going to use what, and let's be honest here, is a pretty ugly animal to describe things, then you know, maybe think about the humble platypus. Platypi would be a totally awesome word, and could really shake up chemistry labs everywhere!

Sorry- wrong start.

Organic chemistry, generally, is concerned with carbon. It's no surprise that something so abundant in the universe would have a sub-discipline devoted to it. From the lead in your pencil to the dust on a grinding flap, carbon takes many shapes and forms- notably graphite, which is electrically conductive and soft, to a diamond, which is not such a good conductor and the hardest natural substance. Carbon is one of the byproducts of the chemical reaction that takes place when smokeless powder is consumed in the firing process of launching a bullet from a gun- and this isn't even considering the role carbon plays in black powder combustion.

"But," you ask, "why are we talking about carbon? Specifically, why are you talking about it Chase? I have things to do like organize my sock drawer instead of read your crazytalk..."

Well, you know how you get a new toy and you want to use it to test things to see if what people have said before was true, when you believed yourself that it wasn't, or at least, hadn't been demonstrated? Yeah. This is one of those things.

Dillon Precision routinely advises against wet tumbling because it gets the cases too clean, which can lead to cases sticking on the powder die (and also, it's probably not out of the realm of possibility to imagine them recommending this because they sell dry media tumblers and would prefer to continue doing so). The idea here is that some amount of leftover carbon in the case will ease the reloading process by its mere presence, which acts as a lube of sorts for the powder funnel and cases. But is that what is really happening?

You also will routinely read folks all across the internet who say that they, "don't clean brass," like our own Chris Miceli. I imagine there are many folks here who also don't routinely clean their brass. Perhaps they are of limited means and time; hell, there are plenty of people here who also just don't like to reload, and so they don't care if the cases are clean or not.

Lastly, there are those who, like Dillon Precision, believe that what is leftover from the combustion process inside the case is carbon, and as such, acts as a lubricant, like our own noylj, who claims that "Soot is a very good dry lube and that is that."

Well, like Todd from Project Farm says- we're going to test that!

---

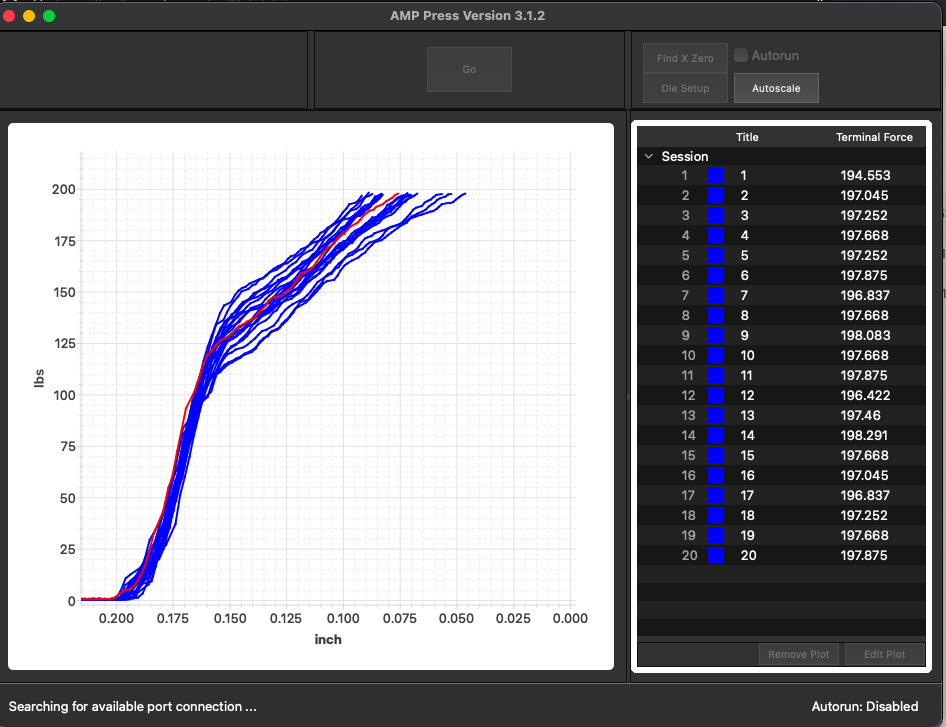

I recently picked up an AMP Press from the Annealing Made Perfect bunch from New Zealand. I plan to use it to answer some other questions I have, which will be the subject of future posts. For purposes here, I thought the best first experiment I could conduct would be to see what differences in seating pressure exist between clean, new brass, and brass that has been fired multiple times, but not cleaned. If the remaining smokeless powder residue, or carbon as we call it, was in fact a lubricant, then my hypothesis was that we'd see similar, perhaps slightly lower, seating pressure results for unclean brass than we would see with new brass. In fact, it could also be the case that we'd see even significantly less seating force- if it was a lube, after all, wouldn't it at least be reasonable to see reduced seating pressures? This seemed like a good first test to see if the equipment I purchased was working and producing expected results, but also something that might help confirm my suspicion that leftover smokeless powder residue wasn't a lubricant, as has been commonly thought and spoken as knowledge in reloading circles.

Here I should point out- I'm not an engineer. I don't know the ins and outs of what it means for something to technically be a lubricant. However, what I do know is that for something to be a lubricant, it basically needs to reduce friction; and this friction between bullet and case wall is what force is ultimately being measured by the AMP Press (which is better thought of as a comparator, and not a traceable lbs/force gauge).

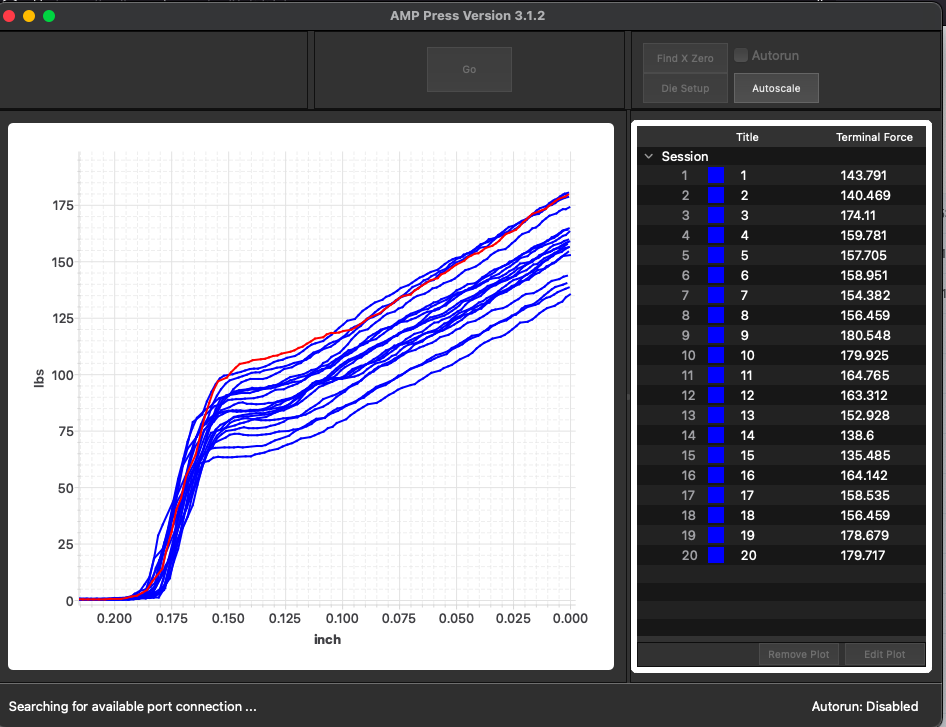

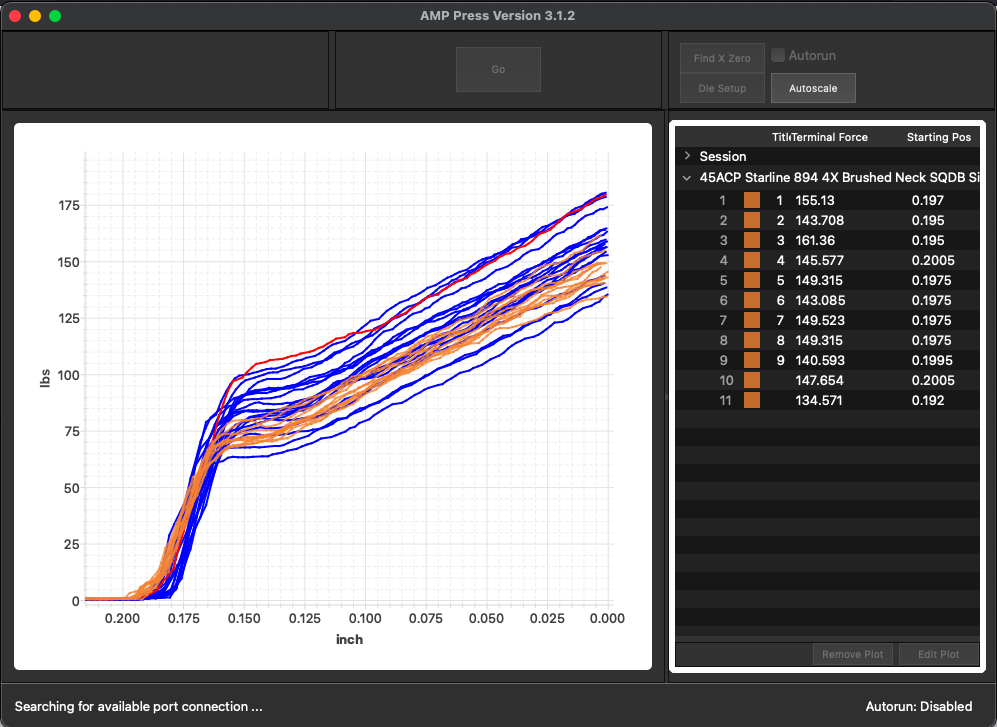

So, I grabbed a bunch of new 45ACP Starline cases, measuring .894" in length and took some seating measurements. The Zero 185 JHP bullet was used.

We have to remember that Starline does send their new cases out of the door with some sort of protective coating on them, so that the brass is super shiney when you get it. Nothing was done to the brass to clean it- I just took the measured cases and ran them through the press. Before bullet seating on the press, the primed & charged case was removed and seated using the AMP press. The AMP seating process completed, the bullet was returned to its station to complete the loading cycle.

So, then I got to do the fun part- shoot them! I brought the cases home, and ran them through the press like many probably do after league night or maybe an 1800 or 2700. No cleaning of any kind- just reload and go.

Well, it turns out the AMP press wasn't able to completely seat the bullets. The AMP press features a pressure lockout so that you don't damage the motor or load cell when seating bullets. This means that the pressure required to seat these bullets was in excess of 200 lbs, or about a 1/4 or 1/3rd more than net new brass. It's also clear that there is some variance here- the bullets don't all behave the same during seating. My guess on this is that the phenomenon observed is a result of an uneven distribution of smokeless residue from the first firing.

So, after loading these up, it was again time for some boom boom. Which brought me these measurements for 2X fired brass, unclean:

Well, now we are cooking! Great trace, every case is pretty much acting like the others. Just one problem- why is it taking so much force to not even completely seat the bullet? The press actually had to finish seating these bullets as the AMP Press does not have enough juice to do so.

But- let's try once more. I know it is a chore, but lets go make a joyful noise and see what happens! 3X fired cases:

Well, the cases are starting to seat the bullet a little more, but really, it's not looking like carbon is much of a lubricant here, unless maybe you have to fire brass 3 times in order to have enough to generate enough to actually coat enough to move the needle back to what we saw with new brass. Here again, the press was required to seat the bullets completely, as the AMP press isn't able to do so due to the force required.

That seems to have finally put the nail in that particular coffin- the remaining residue from firing isn't a lubricant, at least when it comes to seating the bullet in the case. If it was a lubricant, we'd see different results.

"But Chase," you say, "maybe you aren't accounting for brass hardening from all that work- firing, sizing, and so what about that?" I hear you ask. It's a good question. Brass does indeed harden with work, just like many metals. But here's the problem- even if it is the brass that is somehow distorting and requiring increased force to seat the bullet- isn't that what the carbon is supposed to be helping with? It's clear that the carbon canard is now dead- if anything, it seems to make bullet seating harder, not easier.

I know what you're thinking. That can't quite be the end of it, because the explanation to this point doesn't really address the brass work hardening question other than to dismiss it away under the guise of "well, carbon isn't a lube because it doesn't help with seating pressure." And I want you to know- I admire you for thinking that. Some folks are probably still holding on to their beliefs on this issue. Can't say I blame them- it is difficult to change your mind because you have to tacitly realize and admit you believed something wrong in order for the change to take place and be successfully adopted.

So, for everyone still not convinced, I did think of a way to demonstrate that brass hardness itself probably plays little part in this story.

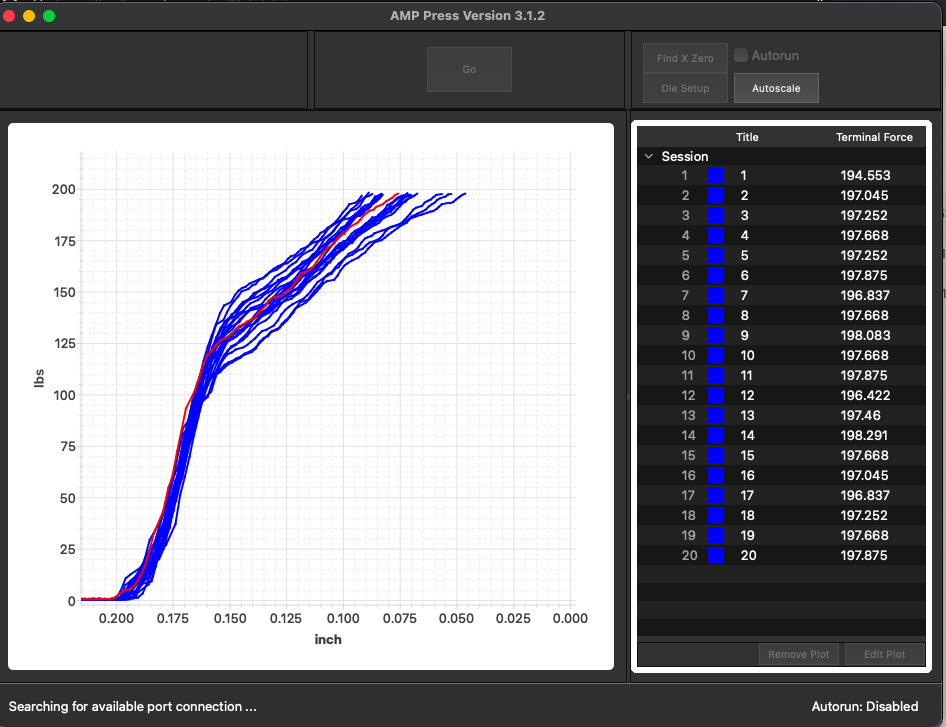

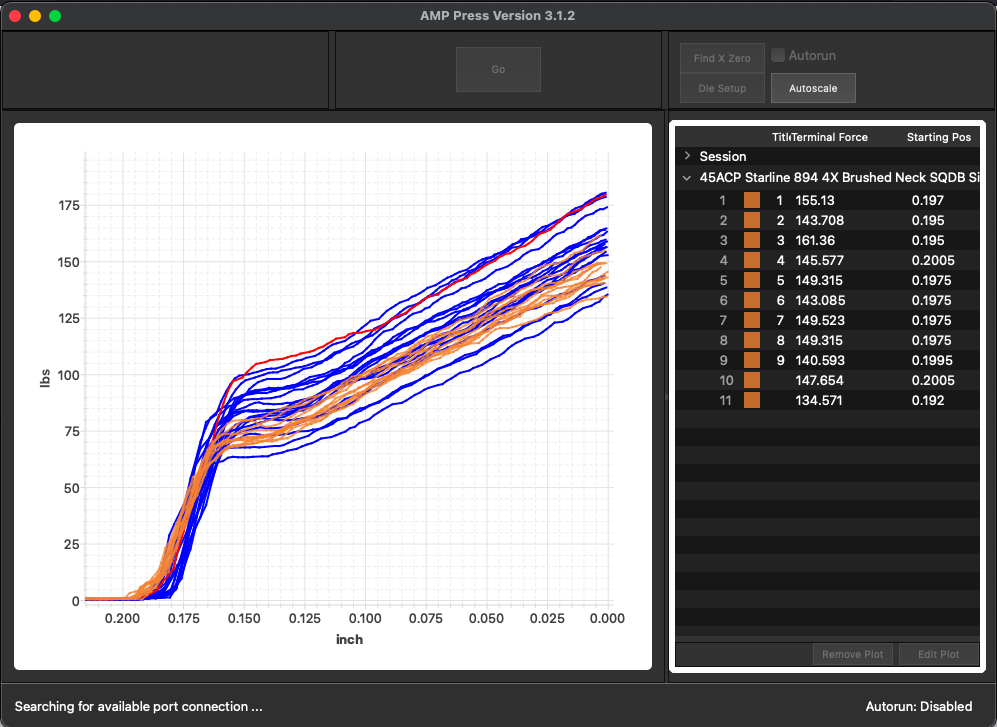

The way to see if brass hardness alone was at issue was to take our new case measurements, and then test them against 4X fired cases, but in this instance, to actually clean the 4X cases without putting in any sort of lubricant, which you find in walnut and corn cob media, or the particular soap you use in wet tumbling. This means using a mechanical means to remove the carbon, and so I picked a nylon brush to do the deed and brush out the necks (I only did this as to be able to eliminate using any sort of media by which a claim could be made that said media may additionally harden the brass, or add lubrication to the brass, and potentially invalidate the test results to this point- I'm not suggesting that you brush pistol brass necks, nor do I think it is beneficial to brass; just use your usual cleaning method without worry).

So, here is the overlay of new brass and 4X brass with brushed necks:

(Blue Traces are New Starline brass, same as first graph above. Orange traces are 4X fired Starline cases with necks brushed with a nylon brush mounted in a drill)

If anything, it looks like work hardening relieves some of the tension in the brass and therefore it doesn't grip the bullet as well.

---

So, the next time someone tells you that carbon in a case acts as a lubricant, don't believe them. It isn't true.

Does any of this matter? Other than requiring more seating force in a press to use dirty brass, it isn't yet clear. The work to date on whether or not seating pressure matters for long range rifle shooting is still undecided. It probably does not matter for our application. However, I'm big on actually testing things to see what really obtains; remember- it isn't the big changes you make the higher up you go in this sport, it is the minor, small items you correct for that push you forward, and perhaps past the person next to you on the line.

Hope this reaches you well,

Chase

Chemistry is the discipline that describes large quantities of small items as "moles," which ought to give everyone a bit of pause. Why not call these things platypuses? I mean, if you are going to use what, and let's be honest here, is a pretty ugly animal to describe things, then you know, maybe think about the humble platypus. Platypi would be a totally awesome word, and could really shake up chemistry labs everywhere!

Sorry- wrong start.

Organic chemistry, generally, is concerned with carbon. It's no surprise that something so abundant in the universe would have a sub-discipline devoted to it. From the lead in your pencil to the dust on a grinding flap, carbon takes many shapes and forms- notably graphite, which is electrically conductive and soft, to a diamond, which is not such a good conductor and the hardest natural substance. Carbon is one of the byproducts of the chemical reaction that takes place when smokeless powder is consumed in the firing process of launching a bullet from a gun- and this isn't even considering the role carbon plays in black powder combustion.

"But," you ask, "why are we talking about carbon? Specifically, why are you talking about it Chase? I have things to do like organize my sock drawer instead of read your crazytalk..."

Well, you know how you get a new toy and you want to use it to test things to see if what people have said before was true, when you believed yourself that it wasn't, or at least, hadn't been demonstrated? Yeah. This is one of those things.

Dillon Precision routinely advises against wet tumbling because it gets the cases too clean, which can lead to cases sticking on the powder die (and also, it's probably not out of the realm of possibility to imagine them recommending this because they sell dry media tumblers and would prefer to continue doing so). The idea here is that some amount of leftover carbon in the case will ease the reloading process by its mere presence, which acts as a lube of sorts for the powder funnel and cases. But is that what is really happening?

You also will routinely read folks all across the internet who say that they, "don't clean brass," like our own Chris Miceli. I imagine there are many folks here who also don't routinely clean their brass. Perhaps they are of limited means and time; hell, there are plenty of people here who also just don't like to reload, and so they don't care if the cases are clean or not.

Lastly, there are those who, like Dillon Precision, believe that what is leftover from the combustion process inside the case is carbon, and as such, acts as a lubricant, like our own noylj, who claims that "Soot is a very good dry lube and that is that."

Well, like Todd from Project Farm says- we're going to test that!

---

I recently picked up an AMP Press from the Annealing Made Perfect bunch from New Zealand. I plan to use it to answer some other questions I have, which will be the subject of future posts. For purposes here, I thought the best first experiment I could conduct would be to see what differences in seating pressure exist between clean, new brass, and brass that has been fired multiple times, but not cleaned. If the remaining smokeless powder residue, or carbon as we call it, was in fact a lubricant, then my hypothesis was that we'd see similar, perhaps slightly lower, seating pressure results for unclean brass than we would see with new brass. In fact, it could also be the case that we'd see even significantly less seating force- if it was a lube, after all, wouldn't it at least be reasonable to see reduced seating pressures? This seemed like a good first test to see if the equipment I purchased was working and producing expected results, but also something that might help confirm my suspicion that leftover smokeless powder residue wasn't a lubricant, as has been commonly thought and spoken as knowledge in reloading circles.

Here I should point out- I'm not an engineer. I don't know the ins and outs of what it means for something to technically be a lubricant. However, what I do know is that for something to be a lubricant, it basically needs to reduce friction; and this friction between bullet and case wall is what force is ultimately being measured by the AMP Press (which is better thought of as a comparator, and not a traceable lbs/force gauge).

So, I grabbed a bunch of new 45ACP Starline cases, measuring .894" in length and took some seating measurements. The Zero 185 JHP bullet was used.

We have to remember that Starline does send their new cases out of the door with some sort of protective coating on them, so that the brass is super shiney when you get it. Nothing was done to the brass to clean it- I just took the measured cases and ran them through the press. Before bullet seating on the press, the primed & charged case was removed and seated using the AMP press. The AMP seating process completed, the bullet was returned to its station to complete the loading cycle.

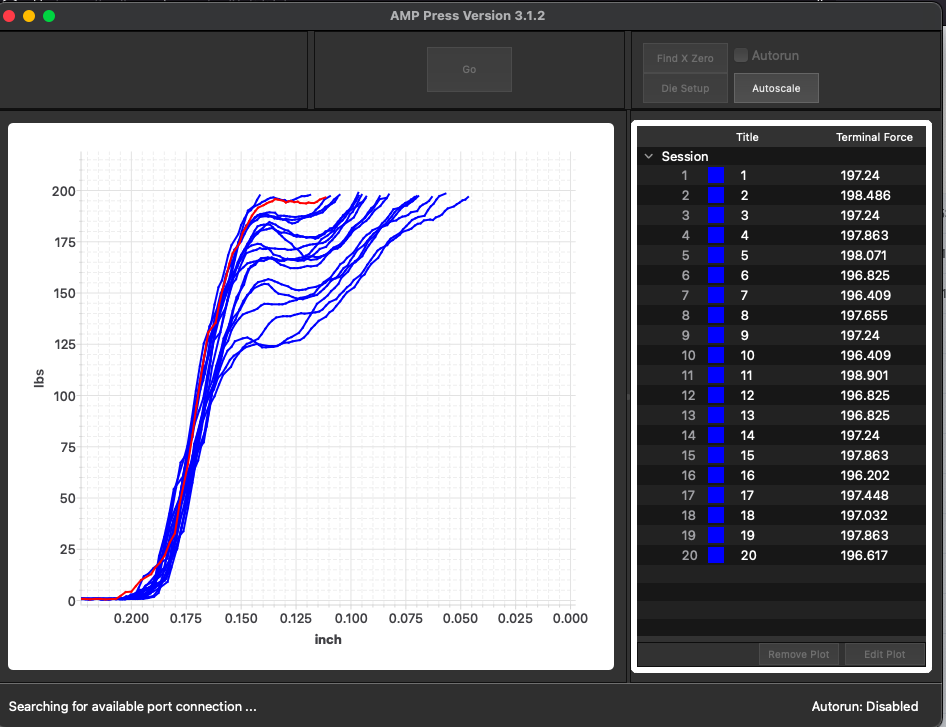

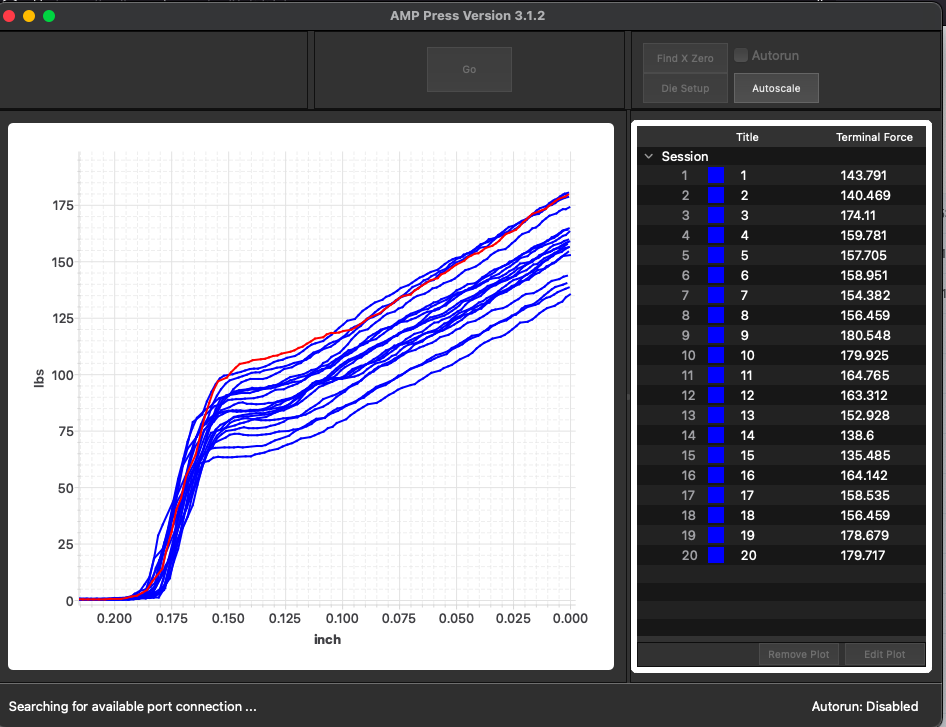

So, then I got to do the fun part- shoot them! I brought the cases home, and ran them through the press like many probably do after league night or maybe an 1800 or 2700. No cleaning of any kind- just reload and go.

Well, it turns out the AMP press wasn't able to completely seat the bullets. The AMP press features a pressure lockout so that you don't damage the motor or load cell when seating bullets. This means that the pressure required to seat these bullets was in excess of 200 lbs, or about a 1/4 or 1/3rd more than net new brass. It's also clear that there is some variance here- the bullets don't all behave the same during seating. My guess on this is that the phenomenon observed is a result of an uneven distribution of smokeless residue from the first firing.

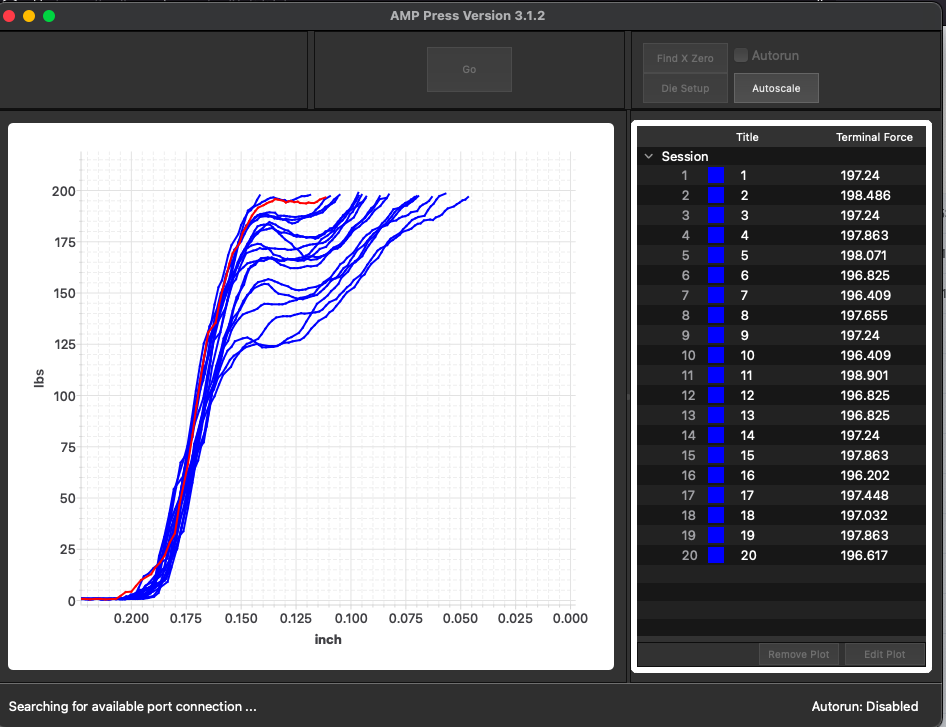

So, after loading these up, it was again time for some boom boom. Which brought me these measurements for 2X fired brass, unclean:

Well, now we are cooking! Great trace, every case is pretty much acting like the others. Just one problem- why is it taking so much force to not even completely seat the bullet? The press actually had to finish seating these bullets as the AMP Press does not have enough juice to do so.

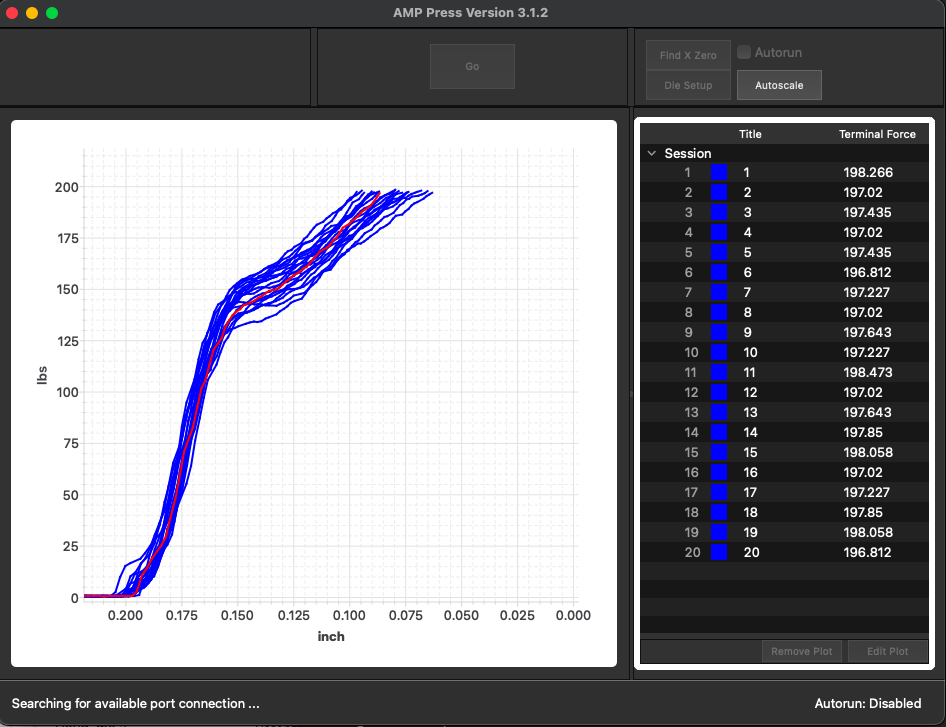

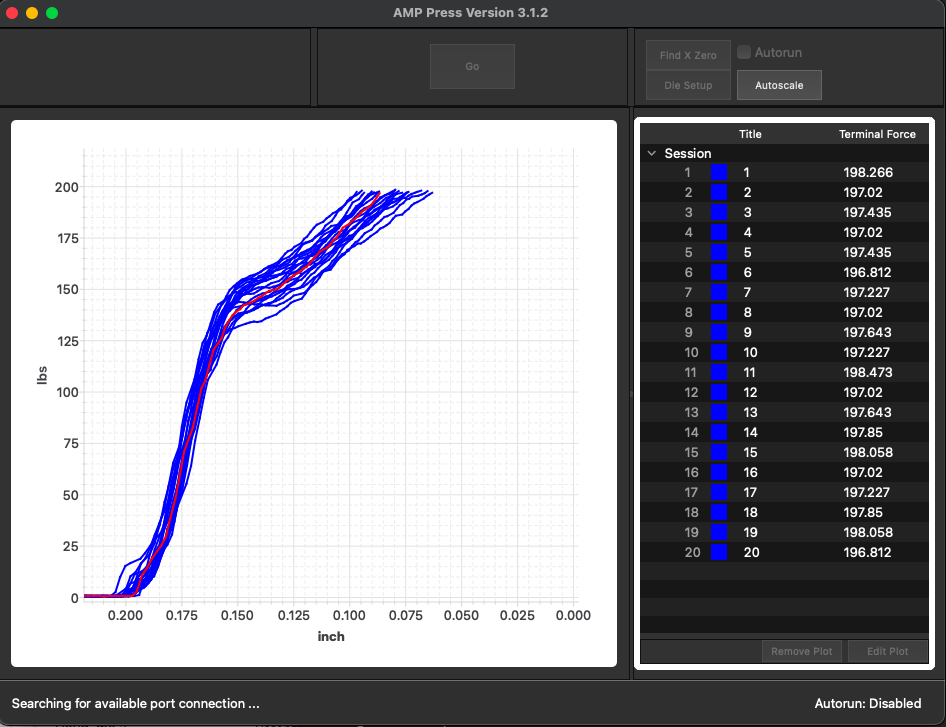

But- let's try once more. I know it is a chore, but lets go make a joyful noise and see what happens! 3X fired cases:

Well, the cases are starting to seat the bullet a little more, but really, it's not looking like carbon is much of a lubricant here, unless maybe you have to fire brass 3 times in order to have enough to generate enough to actually coat enough to move the needle back to what we saw with new brass. Here again, the press was required to seat the bullets completely, as the AMP press isn't able to do so due to the force required.

That seems to have finally put the nail in that particular coffin- the remaining residue from firing isn't a lubricant, at least when it comes to seating the bullet in the case. If it was a lubricant, we'd see different results.

"But Chase," you say, "maybe you aren't accounting for brass hardening from all that work- firing, sizing, and so what about that?" I hear you ask. It's a good question. Brass does indeed harden with work, just like many metals. But here's the problem- even if it is the brass that is somehow distorting and requiring increased force to seat the bullet- isn't that what the carbon is supposed to be helping with? It's clear that the carbon canard is now dead- if anything, it seems to make bullet seating harder, not easier.

I know what you're thinking. That can't quite be the end of it, because the explanation to this point doesn't really address the brass work hardening question other than to dismiss it away under the guise of "well, carbon isn't a lube because it doesn't help with seating pressure." And I want you to know- I admire you for thinking that. Some folks are probably still holding on to their beliefs on this issue. Can't say I blame them- it is difficult to change your mind because you have to tacitly realize and admit you believed something wrong in order for the change to take place and be successfully adopted.

So, for everyone still not convinced, I did think of a way to demonstrate that brass hardness itself probably plays little part in this story.

The way to see if brass hardness alone was at issue was to take our new case measurements, and then test them against 4X fired cases, but in this instance, to actually clean the 4X cases without putting in any sort of lubricant, which you find in walnut and corn cob media, or the particular soap you use in wet tumbling. This means using a mechanical means to remove the carbon, and so I picked a nylon brush to do the deed and brush out the necks (I only did this as to be able to eliminate using any sort of media by which a claim could be made that said media may additionally harden the brass, or add lubrication to the brass, and potentially invalidate the test results to this point- I'm not suggesting that you brush pistol brass necks, nor do I think it is beneficial to brass; just use your usual cleaning method without worry).

So, here is the overlay of new brass and 4X brass with brushed necks:

(Blue Traces are New Starline brass, same as first graph above. Orange traces are 4X fired Starline cases with necks brushed with a nylon brush mounted in a drill)

If anything, it looks like work hardening relieves some of the tension in the brass and therefore it doesn't grip the bullet as well.

---

So, the next time someone tells you that carbon in a case acts as a lubricant, don't believe them. It isn't true.

Does any of this matter? Other than requiring more seating force in a press to use dirty brass, it isn't yet clear. The work to date on whether or not seating pressure matters for long range rifle shooting is still undecided. It probably does not matter for our application. However, I'm big on actually testing things to see what really obtains; remember- it isn't the big changes you make the higher up you go in this sport, it is the minor, small items you correct for that push you forward, and perhaps past the person next to you on the line.

Hope this reaches you well,

Chase

Last edited by Chase Turner on 12/9/2022, 7:35 pm; edited 1 time in total

Chase Turner- Posts : 385

Join date : 2019-11-15

mhayford45, Merick, tomj44, OldGaGuy and samtoast like this post

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

NuJudge wrote:[snip]

…, I did an internet search and found answers that indicate there's a lot of metals there, and more or less carbon.

https://ncfs.ucf.edu/research/chemical-evidence/gun-shot-residue/

https://en.wikipedia.org/wiki/Gunshot_residue

https://pubmed.ncbi.nlm.nih.gov/20158597/

[snip]

I remember reading DiMao’s treatise on GSWs and seeing that identifying ammo type from GSR was primarily looking at the chemical profile of the primer portion of the residue.

GrumpyOldMan- Posts : 482

Join date : 2013-03-08

Location : High Desert Southwest Red Rock Country

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Carbon Coated Cases

» What case lubricant do you use.

» Corrosion goes inside too

» lubricant for barrels

» An inside look at Precision Delta

» What case lubricant do you use.

» Corrosion goes inside too

» lubricant for barrels

» An inside look at Precision Delta

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum