Leftover carbon inside cases does not act like a lubricant

+14

chopper

jglenn21

blindshooter

Rodger Barthlow

BE Mike

tovaert

fc60

james r chapman

DA/SA

CR10X

Wobbley

Pinetree

Merick

Chase Turner

18 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Leftover carbon inside cases does not act like a lubricant

Leftover carbon inside cases does not act like a lubricant

Chemistry is the discipline that describes large quantities of small items as "moles," which ought to give everyone a bit of pause. Why not call these things platypuses? I mean, if you are going to use what, and let's be honest here, is a pretty ugly animal to describe things, then you know, maybe think about the humble platypus. Platypi would be a totally awesome word, and could really shake up chemistry labs everywhere!

Sorry- wrong start.

Organic chemistry, generally, is concerned with carbon. It's no surprise that something so abundant in the universe would have a sub-discipline devoted to it. From the lead in your pencil to the dust on a grinding flap, carbon takes many shapes and forms- notably graphite, which is electrically conductive and soft, to a diamond, which is not such a good conductor and the hardest natural substance. Carbon is one of the byproducts of the chemical reaction that takes place when smokeless powder is consumed in the firing process of launching a bullet from a gun- and this isn't even considering the role carbon plays in black powder combustion.

"But," you ask, "why are we talking about carbon? Specifically, why are you talking about it Chase? I have things to do like organize my sock drawer instead of read your crazytalk..."

Well, you know how you get a new toy and you want to use it to test things to see if what people have said before was true, when you believed yourself that it wasn't, or at least, hadn't been demonstrated? Yeah. This is one of those things.

Dillon Precision routinely advises against wet tumbling because it gets the cases too clean, which can lead to cases sticking on the powder die (and also, it's probably not out of the realm of possibility to imagine them recommending this because they sell dry media tumblers and would prefer to continue doing so). The idea here is that some amount of leftover carbon in the case will ease the reloading process by its mere presence, which acts as a lube of sorts for the powder funnel and cases. But is that what is really happening?

You also will routinely read folks all across the internet who say that they, "don't clean brass," like our own Chris Miceli. I imagine there are many folks here who also don't routinely clean their brass. Perhaps they are of limited means and time; hell, there are plenty of people here who also just don't like to reload, and so they don't care if the cases are clean or not.

Lastly, there are those who, like Dillon Precision, believe that what is leftover from the combustion process inside the case is carbon, and as such, acts as a lubricant, like our own noylj, who claims that "Soot is a very good dry lube and that is that."

Well, like Todd from Project Farm says- we're going to test that!

---

I recently picked up an AMP Press from the Annealing Made Perfect bunch from New Zealand. I plan to use it to answer some other questions I have, which will be the subject of future posts. For purposes here, I thought the best first experiment I could conduct would be to see what differences in seating pressure exist between clean, new brass, and brass that has been fired multiple times, but not cleaned. If the remaining smokeless powder residue, or carbon as we call it, was in fact a lubricant, then my hypothesis was that we'd see similar, perhaps slightly lower, seating pressure results for unclean brass than we would see with new brass. In fact, it could also be the case that we'd see even significantly less seating force- if it was a lube, after all, wouldn't it at least be reasonable to see reduced seating pressures? This seemed like a good first test to see if the equipment I purchased was working and producing expected results, but also something that might help confirm my suspicion that leftover smokeless powder residue wasn't a lubricant, as has been commonly thought and spoken as knowledge in reloading circles.

Here I should point out- I'm not an engineer. I don't know the ins and outs of what it means for something to technically be a lubricant. However, what I do know is that for something to be a lubricant, it basically needs to reduce friction; and this friction between bullet and case wall is what force is ultimately being measured by the AMP Press (which is better thought of as a comparator, and not a traceable lbs/force gauge).

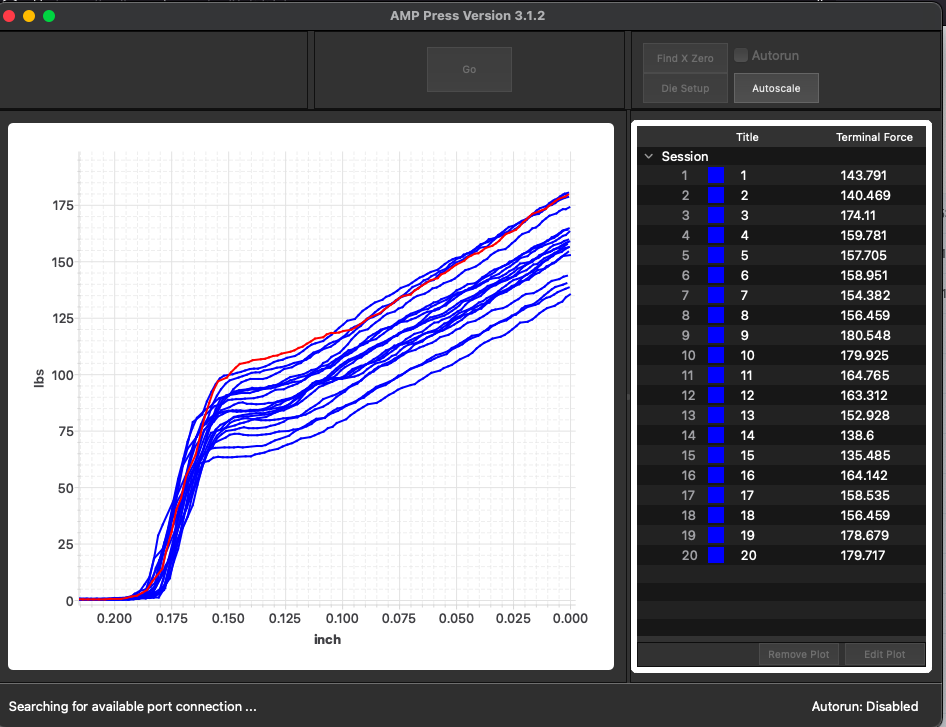

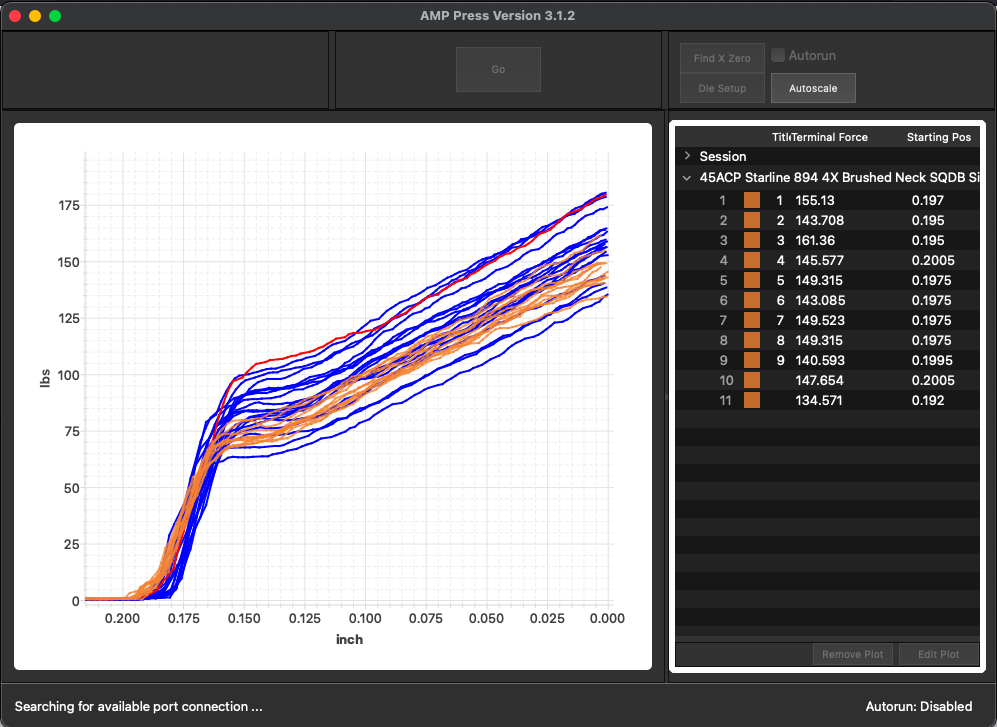

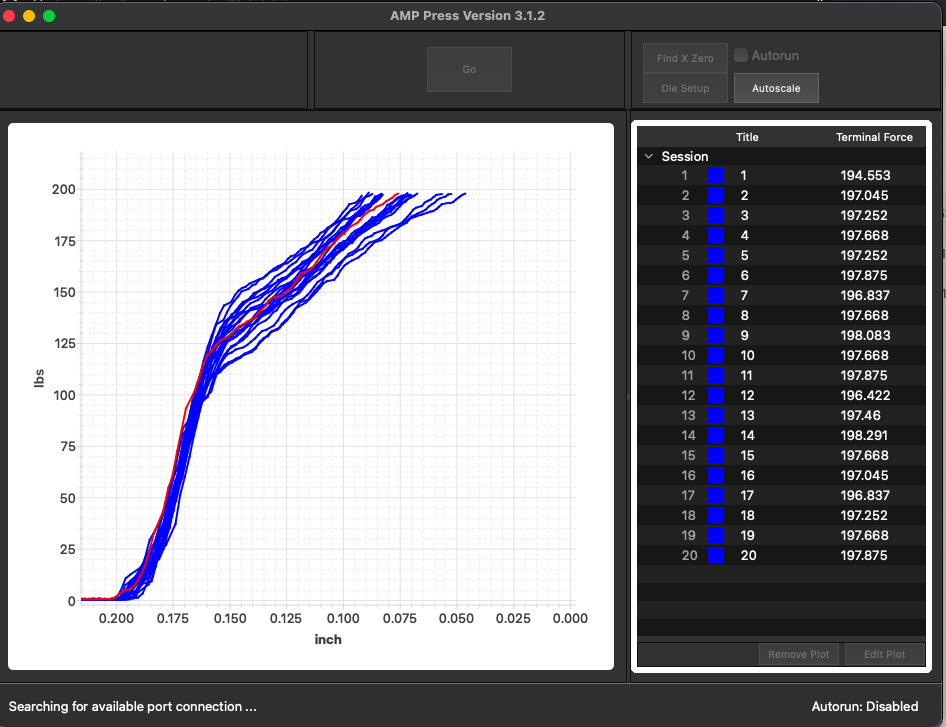

So, I grabbed a bunch of new 45ACP Starline cases, measuring .894" in length and took some seating measurements. The Zero 185 JHP bullet was used.

We have to remember that Starline does send their new cases out of the door with some sort of protective coating on them, so that the brass is super shiney when you get it. Nothing was done to the brass to clean it- I just took the measured cases and ran them through the press. Before bullet seating on the press, the primed & charged case was removed and seated using the AMP press. The AMP seating process completed, the bullet was returned to its station to complete the loading cycle.

So, then I got to do the fun part- shoot them! I brought the cases home, and ran them through the press like many probably do after league night or maybe an 1800 or 2700. No cleaning of any kind- just reload and go.

Well, it turns out the AMP press wasn't able to completely seat the bullets. The AMP press features a pressure lockout so that you don't damage the motor or load cell when seating bullets. This means that the pressure required to seat these bullets was in excess of 200 lbs, or about a 1/4 or 1/3rd more than net new brass. It's also clear that there is some variance here- the bullets don't all behave the same during seating. My guess on this is that the phenomenon observed is a result of an uneven distribution of smokeless residue from the first firing.

So, after loading these up, it was again time for some boom boom. Which brought me these measurements for 2X fired brass, unclean:

Well, now we are cooking! Great trace, every case is pretty much acting like the others. Just one problem- why is it taking so much force to not even completely seat the bullet? The press actually had to finish seating these bullets as the AMP Press does not have enough juice to do so.

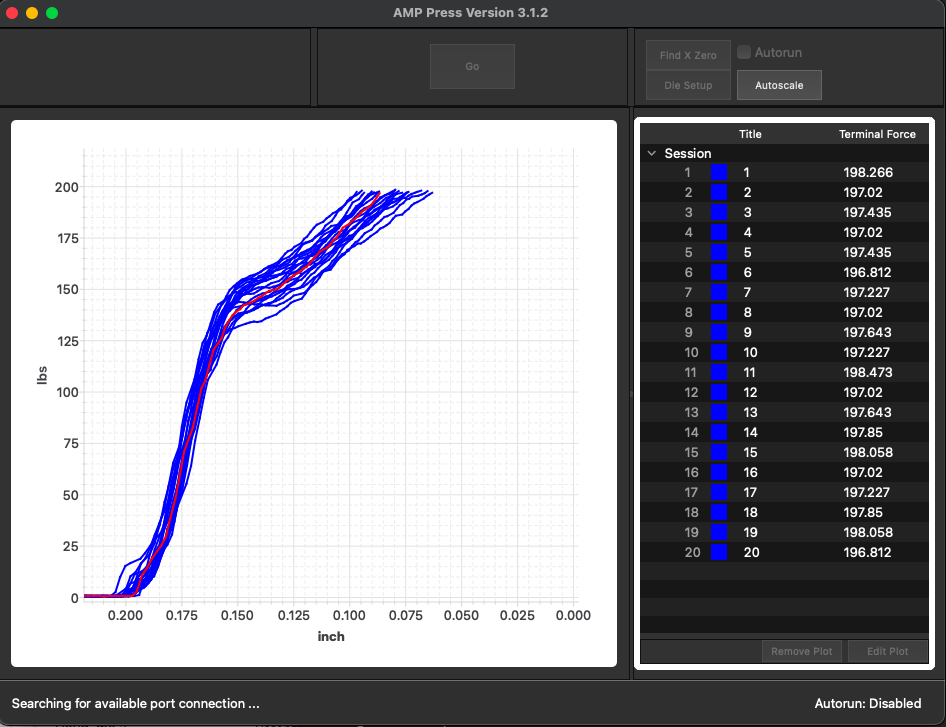

But- let's try once more. I know it is a chore, but lets go make a joyful noise and see what happens! 3X fired cases:

Well, the cases are starting to seat the bullet a little more, but really, it's not looking like carbon is much of a lubricant here, unless maybe you have to fire brass 3 times in order to have enough to generate enough to actually coat enough to move the needle back to what we saw with new brass. Here again, the press was required to seat the bullets completely, as the AMP press isn't able to do so due to the force required.

That seems to have finally put the nail in that particular coffin- the remaining residue from firing isn't a lubricant, at least when it comes to seating the bullet in the case. If it was a lubricant, we'd see different results.

"But Chase," you say, "maybe you aren't accounting for brass hardening from all that work- firing, sizing, and so what about that?" I hear you ask. It's a good question. Brass does indeed harden with work, just like many metals. But here's the problem- even if it is the brass that is somehow distorting and requiring increased force to seat the bullet- isn't that what the carbon is supposed to be helping with? It's clear that the carbon canard is now dead- if anything, it seems to make bullet seating harder, not easier.

I know what you're thinking. That can't quite be the end of it, because the explanation to this point doesn't really address the brass work hardening question other than to dismiss it away under the guise of "well, carbon isn't a lube because it doesn't help with seating pressure." And I want you to know- I admire you for thinking that. Some folks are probably still holding on to their beliefs on this issue. Can't say I blame them- it is difficult to change your mind because you have to tacitly realize and admit you believed something wrong in order for the change to take place and be successfully adopted.

So, for everyone still not convinced, I did think of a way to demonstrate that brass hardness itself probably plays little part in this story.

The way to see if brass hardness alone was at issue was to take our new case measurements, and then test them against 4X fired cases, but in this instance, to actually clean the 4X cases without putting in any sort of lubricant, which you find in walnut and corn cob media, or the particular soap you use in wet tumbling. This means using a mechanical means to remove the carbon, and so I picked a nylon brush to do the deed and brush out the necks (I only did this as to be able to eliminate using any sort of media by which a claim could be made that said media may additionally harden the brass, or add lubrication to the brass, and potentially invalidate the test results to this point- I'm not suggesting that you brush pistol brass necks, nor do I think it is beneficial to brass; just use your usual cleaning method without worry).

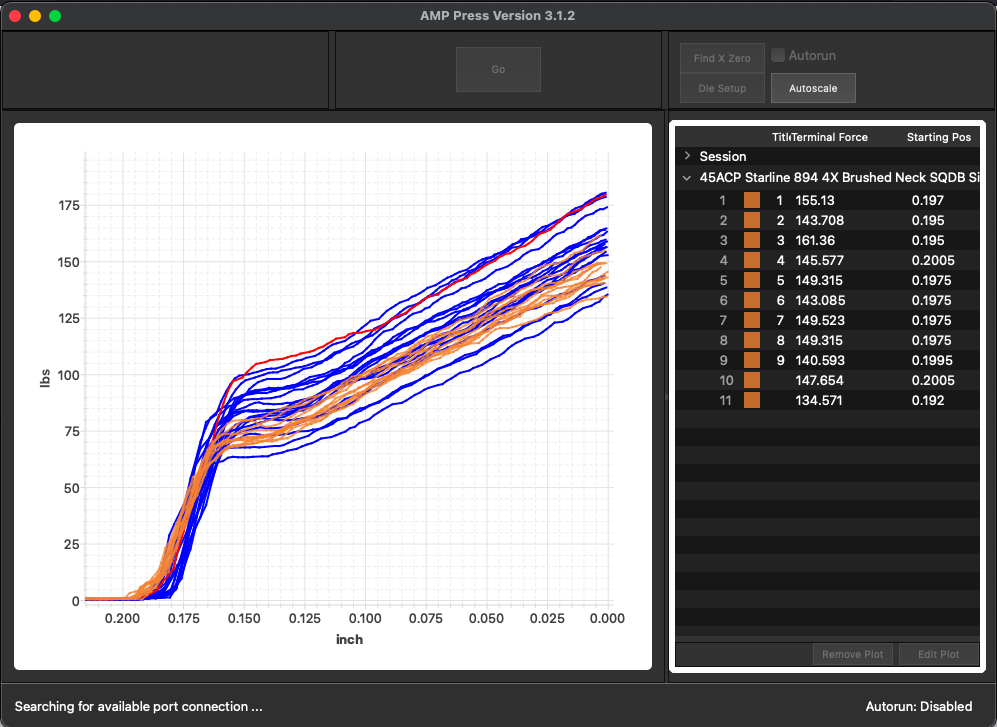

So, here is the overlay of new brass and 4X brass with brushed necks:

(Blue Traces are New Starline brass, same as first graph above. Orange traces are 4X fired Starline cases with necks brushed with a nylon brush mounted in a drill)

If anything, it looks like work hardening relieves some of the tension in the brass and therefore it doesn't grip the bullet as well.

---

So, the next time someone tells you that carbon in a case acts as a lubricant, don't believe them. It isn't true.

Does any of this matter? Other than requiring more seating force in a press to use dirty brass, it isn't yet clear. The work to date on whether or not seating pressure matters for long range rifle shooting is still undecided. It probably does not matter for our application. However, I'm big on actually testing things to see what really obtains; remember- it isn't the big changes you make the higher up you go in this sport, it is the minor, small items you correct for that push you forward, and perhaps past the person next to you on the line.

Hope this reaches you well,

Chase

Sorry- wrong start.

Organic chemistry, generally, is concerned with carbon. It's no surprise that something so abundant in the universe would have a sub-discipline devoted to it. From the lead in your pencil to the dust on a grinding flap, carbon takes many shapes and forms- notably graphite, which is electrically conductive and soft, to a diamond, which is not such a good conductor and the hardest natural substance. Carbon is one of the byproducts of the chemical reaction that takes place when smokeless powder is consumed in the firing process of launching a bullet from a gun- and this isn't even considering the role carbon plays in black powder combustion.

"But," you ask, "why are we talking about carbon? Specifically, why are you talking about it Chase? I have things to do like organize my sock drawer instead of read your crazytalk..."

Well, you know how you get a new toy and you want to use it to test things to see if what people have said before was true, when you believed yourself that it wasn't, or at least, hadn't been demonstrated? Yeah. This is one of those things.

Dillon Precision routinely advises against wet tumbling because it gets the cases too clean, which can lead to cases sticking on the powder die (and also, it's probably not out of the realm of possibility to imagine them recommending this because they sell dry media tumblers and would prefer to continue doing so). The idea here is that some amount of leftover carbon in the case will ease the reloading process by its mere presence, which acts as a lube of sorts for the powder funnel and cases. But is that what is really happening?

You also will routinely read folks all across the internet who say that they, "don't clean brass," like our own Chris Miceli. I imagine there are many folks here who also don't routinely clean their brass. Perhaps they are of limited means and time; hell, there are plenty of people here who also just don't like to reload, and so they don't care if the cases are clean or not.

Lastly, there are those who, like Dillon Precision, believe that what is leftover from the combustion process inside the case is carbon, and as such, acts as a lubricant, like our own noylj, who claims that "Soot is a very good dry lube and that is that."

Well, like Todd from Project Farm says- we're going to test that!

---

I recently picked up an AMP Press from the Annealing Made Perfect bunch from New Zealand. I plan to use it to answer some other questions I have, which will be the subject of future posts. For purposes here, I thought the best first experiment I could conduct would be to see what differences in seating pressure exist between clean, new brass, and brass that has been fired multiple times, but not cleaned. If the remaining smokeless powder residue, or carbon as we call it, was in fact a lubricant, then my hypothesis was that we'd see similar, perhaps slightly lower, seating pressure results for unclean brass than we would see with new brass. In fact, it could also be the case that we'd see even significantly less seating force- if it was a lube, after all, wouldn't it at least be reasonable to see reduced seating pressures? This seemed like a good first test to see if the equipment I purchased was working and producing expected results, but also something that might help confirm my suspicion that leftover smokeless powder residue wasn't a lubricant, as has been commonly thought and spoken as knowledge in reloading circles.

Here I should point out- I'm not an engineer. I don't know the ins and outs of what it means for something to technically be a lubricant. However, what I do know is that for something to be a lubricant, it basically needs to reduce friction; and this friction between bullet and case wall is what force is ultimately being measured by the AMP Press (which is better thought of as a comparator, and not a traceable lbs/force gauge).

So, I grabbed a bunch of new 45ACP Starline cases, measuring .894" in length and took some seating measurements. The Zero 185 JHP bullet was used.

We have to remember that Starline does send their new cases out of the door with some sort of protective coating on them, so that the brass is super shiney when you get it. Nothing was done to the brass to clean it- I just took the measured cases and ran them through the press. Before bullet seating on the press, the primed & charged case was removed and seated using the AMP press. The AMP seating process completed, the bullet was returned to its station to complete the loading cycle.

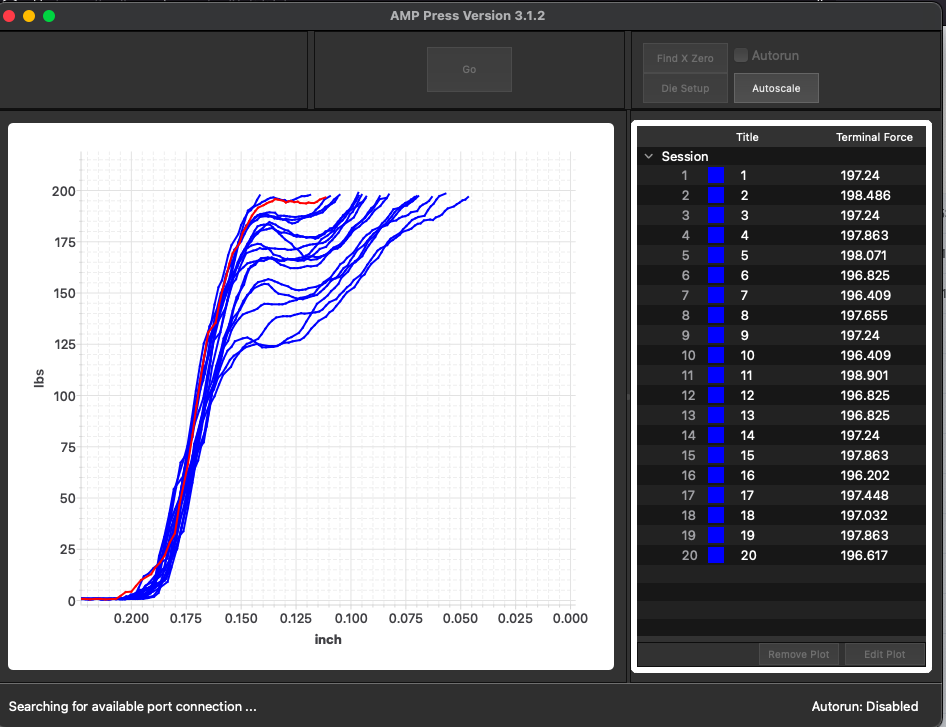

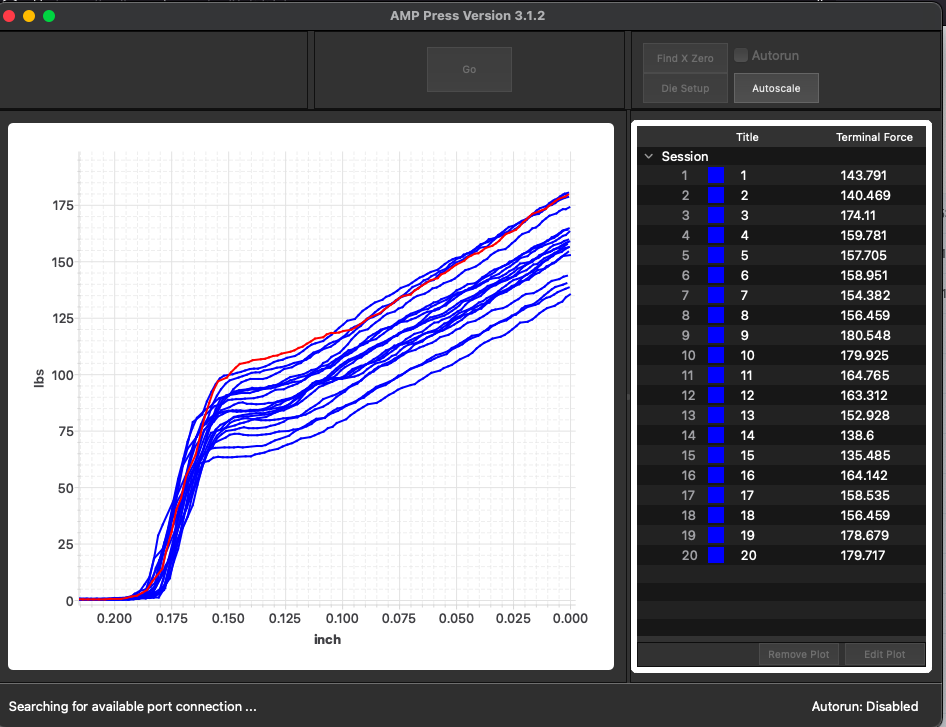

So, then I got to do the fun part- shoot them! I brought the cases home, and ran them through the press like many probably do after league night or maybe an 1800 or 2700. No cleaning of any kind- just reload and go.

Well, it turns out the AMP press wasn't able to completely seat the bullets. The AMP press features a pressure lockout so that you don't damage the motor or load cell when seating bullets. This means that the pressure required to seat these bullets was in excess of 200 lbs, or about a 1/4 or 1/3rd more than net new brass. It's also clear that there is some variance here- the bullets don't all behave the same during seating. My guess on this is that the phenomenon observed is a result of an uneven distribution of smokeless residue from the first firing.

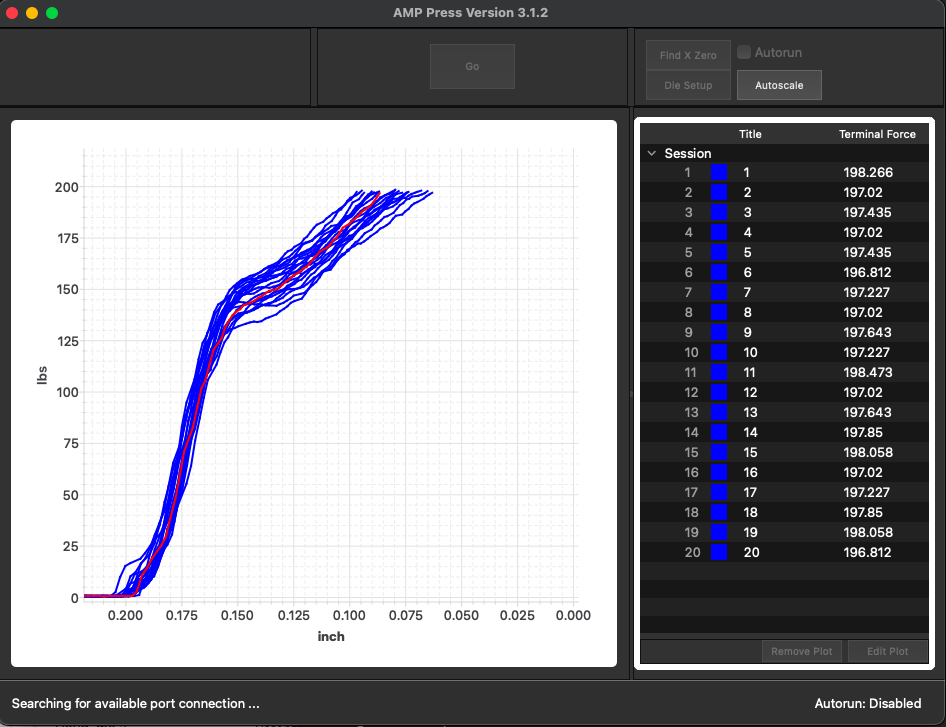

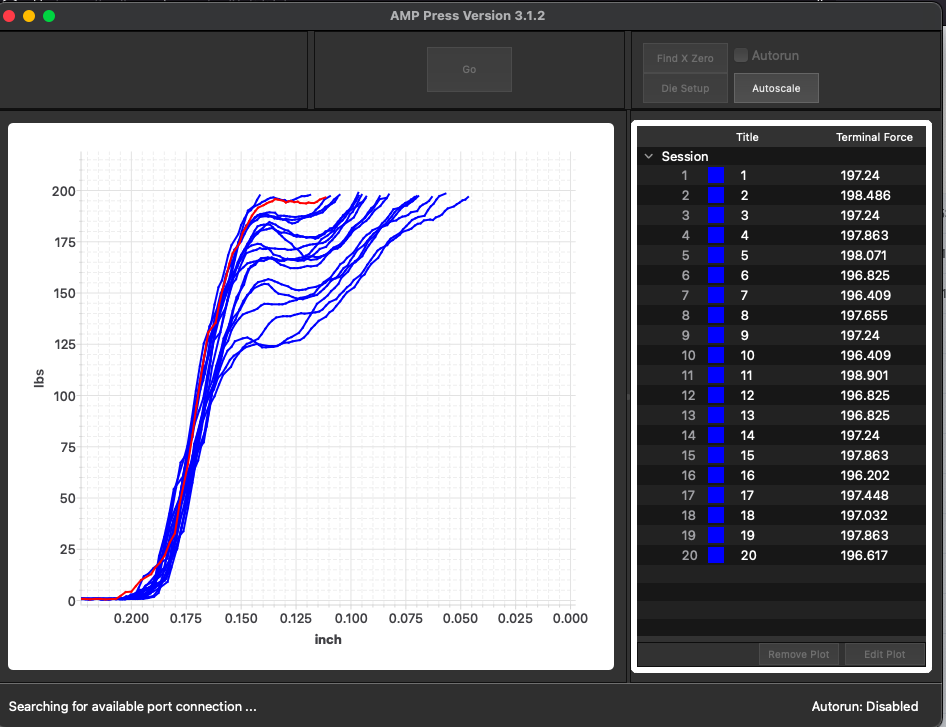

So, after loading these up, it was again time for some boom boom. Which brought me these measurements for 2X fired brass, unclean:

Well, now we are cooking! Great trace, every case is pretty much acting like the others. Just one problem- why is it taking so much force to not even completely seat the bullet? The press actually had to finish seating these bullets as the AMP Press does not have enough juice to do so.

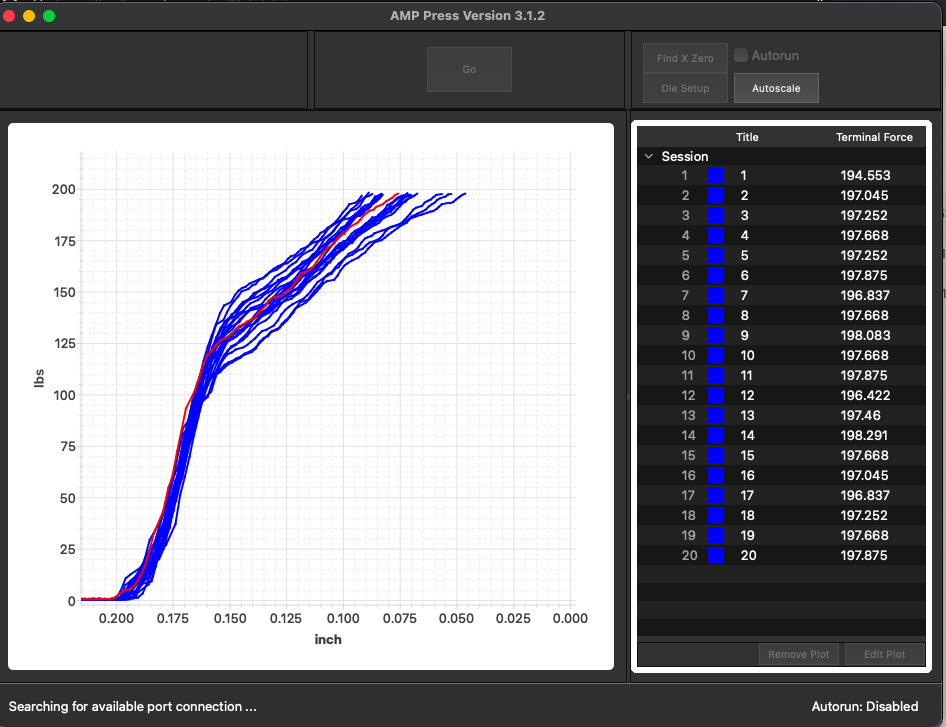

But- let's try once more. I know it is a chore, but lets go make a joyful noise and see what happens! 3X fired cases:

Well, the cases are starting to seat the bullet a little more, but really, it's not looking like carbon is much of a lubricant here, unless maybe you have to fire brass 3 times in order to have enough to generate enough to actually coat enough to move the needle back to what we saw with new brass. Here again, the press was required to seat the bullets completely, as the AMP press isn't able to do so due to the force required.

That seems to have finally put the nail in that particular coffin- the remaining residue from firing isn't a lubricant, at least when it comes to seating the bullet in the case. If it was a lubricant, we'd see different results.

"But Chase," you say, "maybe you aren't accounting for brass hardening from all that work- firing, sizing, and so what about that?" I hear you ask. It's a good question. Brass does indeed harden with work, just like many metals. But here's the problem- even if it is the brass that is somehow distorting and requiring increased force to seat the bullet- isn't that what the carbon is supposed to be helping with? It's clear that the carbon canard is now dead- if anything, it seems to make bullet seating harder, not easier.

I know what you're thinking. That can't quite be the end of it, because the explanation to this point doesn't really address the brass work hardening question other than to dismiss it away under the guise of "well, carbon isn't a lube because it doesn't help with seating pressure." And I want you to know- I admire you for thinking that. Some folks are probably still holding on to their beliefs on this issue. Can't say I blame them- it is difficult to change your mind because you have to tacitly realize and admit you believed something wrong in order for the change to take place and be successfully adopted.

So, for everyone still not convinced, I did think of a way to demonstrate that brass hardness itself probably plays little part in this story.

The way to see if brass hardness alone was at issue was to take our new case measurements, and then test them against 4X fired cases, but in this instance, to actually clean the 4X cases without putting in any sort of lubricant, which you find in walnut and corn cob media, or the particular soap you use in wet tumbling. This means using a mechanical means to remove the carbon, and so I picked a nylon brush to do the deed and brush out the necks (I only did this as to be able to eliminate using any sort of media by which a claim could be made that said media may additionally harden the brass, or add lubrication to the brass, and potentially invalidate the test results to this point- I'm not suggesting that you brush pistol brass necks, nor do I think it is beneficial to brass; just use your usual cleaning method without worry).

So, here is the overlay of new brass and 4X brass with brushed necks:

(Blue Traces are New Starline brass, same as first graph above. Orange traces are 4X fired Starline cases with necks brushed with a nylon brush mounted in a drill)

If anything, it looks like work hardening relieves some of the tension in the brass and therefore it doesn't grip the bullet as well.

---

So, the next time someone tells you that carbon in a case acts as a lubricant, don't believe them. It isn't true.

Does any of this matter? Other than requiring more seating force in a press to use dirty brass, it isn't yet clear. The work to date on whether or not seating pressure matters for long range rifle shooting is still undecided. It probably does not matter for our application. However, I'm big on actually testing things to see what really obtains; remember- it isn't the big changes you make the higher up you go in this sport, it is the minor, small items you correct for that push you forward, and perhaps past the person next to you on the line.

Hope this reaches you well,

Chase

Last edited by Chase Turner on 12/9/2022, 7:35 pm; edited 1 time in total

Chase Turner- Posts : 385

Join date : 2019-11-15

mhayford45, Merick, tomj44, OldGaGuy and samtoast like this post

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

In that seating force is actually a proxy for bullet release during firing, I would hypothesize that there are countervailing forces of a springy new case grips the bullet better but may absorb a percentage of the powder impulse around the rest of the chamber, vs a work hardened case may not grip as well but also is less absorptive, netting out very nearly the same.

Merick- Posts : 453

Join date : 2015-08-13

Location : Kansas

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

I've always been under the impression that Bullseye powder contained Graphite.. just my observation after years of watching the powder bar on my SDB.

Any truth to this?

Any truth to this?

Pinetree- Posts : 271

Join date : 2017-05-13

Age : 65

Location : NWPA

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

I really don’t think that seating force has any connection to bullet release force. Long before the bullets moves much at all the case expands. During firing, the bullet will move to where it contacts the rifling, then essentially stops while the bullet is engraved. While that happens the case has lost all grip from tension on the bullet. Meanwhile pressure builds very quickly and those forces engrave the bullet and sends it on its merry way. The variances from neck tension are so small in the scheme of things to be lost in the variances of powder burn variances generating pressure differentials.Merick wrote:In that seating force is actually a proxy for bullet release during firing, I would hypothesize that there are countervailing forces of a springy new case grips the bullet better but may absorb a percentage of the powder impulse around the rest of the chamber, vs a work hardened case may not grip as well but also is less absorptive, netting out very nearly the same.

While neck tension and or crimping may have some effect on ignition of the powder, this only affects the overall dynamics of the gun and shooter interface. Put the “badly loaded” ammo in a barrel tester and the results will be different that that fired in a functional firearm. With the super-light loads we shoot for bullseye, ignition becomes a bit marginal and that influences gun dynamics. Some guys here have shot very good groups using brass with the odd cracked case.

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

Thanks for all the testing. I do have one question. Are you measuring the "seating force" after the normal process of resizing, expanding and then measuring during the seating process?

If so, then my suggestion would be that you use a set up that will measure the "upstroke" or or the extraction of the expanding die rather than the seating force. Those two conditions are similar, but not the same.

Aside, I don't really understand the significant issue with the bullet seating after 1X firing in your test process. That is a real question unless there was only resizing and no expansion die used or it was not adjusted properly. Curious and strange, and I think that deserves more thought about the process.

Anyway, the significant difference that I have seen between new brass / wet cleaned brass and regular tumbled brass after 1x firing is not in the seating force for the bullet, but the extraction force after the expansion die is fully inserted. And it is sometimes significant.

My assumption is that when the expansion / flair die is used after resizing, there is a larger amount of expansion taking place on / in the case and therefore any difference between new / wet cleaned versus fired and tumbled cases is more noticeable during the expanding process.

After the expander die is used, the case is somewhat larger, slightly cleaned or smoothed by the expander plug and there for the actual "seating force" is similar for new / wet cleaned versus fired and tumbled cased is similar (which matches what I feel when reloading).

Using my press the "extraction" force need to remove the expander die is much larger than the force needed to seat a bullet. So the order of magnitude of the forces (lesser for just seating bullet (with properly adjusted expansion die) and more for extracting the expansion plug in new / wet cleaned cases) may be masking the overall "lube" effect when we are just measuring seating force.

Just my thoughts and ponderings. I'm interested in any further testing and results. Thank you very much for the testing and posting.

CR

If so, then my suggestion would be that you use a set up that will measure the "upstroke" or or the extraction of the expanding die rather than the seating force. Those two conditions are similar, but not the same.

Aside, I don't really understand the significant issue with the bullet seating after 1X firing in your test process. That is a real question unless there was only resizing and no expansion die used or it was not adjusted properly. Curious and strange, and I think that deserves more thought about the process.

Anyway, the significant difference that I have seen between new brass / wet cleaned brass and regular tumbled brass after 1x firing is not in the seating force for the bullet, but the extraction force after the expansion die is fully inserted. And it is sometimes significant.

My assumption is that when the expansion / flair die is used after resizing, there is a larger amount of expansion taking place on / in the case and therefore any difference between new / wet cleaned versus fired and tumbled cases is more noticeable during the expanding process.

After the expander die is used, the case is somewhat larger, slightly cleaned or smoothed by the expander plug and there for the actual "seating force" is similar for new / wet cleaned versus fired and tumbled cased is similar (which matches what I feel when reloading).

Using my press the "extraction" force need to remove the expander die is much larger than the force needed to seat a bullet. So the order of magnitude of the forces (lesser for just seating bullet (with properly adjusted expansion die) and more for extracting the expansion plug in new / wet cleaned cases) may be masking the overall "lube" effect when we are just measuring seating force.

Just my thoughts and ponderings. I'm interested in any further testing and results. Thank you very much for the testing and posting.

CR

Last edited by CR10X on 12/10/2022, 6:07 am; edited 1 time in total

CR10X- Posts : 1777

Join date : 2011-06-17

Location : NC

R*P*DR*, OldGaGuy and SingleActionAndrew like this post

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

This is what I have found as well. I tried wet tumbling with pins once and went right back to dry tumbling in corn cob for the reason CR speaks of.CR10X wrote:

Anyway, the significant difference that I have seen between new brass / wet cleaned brass and regular tumbled brass after 1x firing is not in the seating force for the bullet, but the extraction force after the expansion die is fully inserted. And it is sometimes significant.

You will also find references to people that wet tumble with pins or load new cases having to use case lube on the inside of the cases.

DA/SA- Posts : 1506

Join date : 2017-10-09

Age : 68

Location : Southeast Florida

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

I miss when messages had 256 character limits.

james r chapman- Admin

- Posts : 6370

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

farmboy, 10sandxs, donp and Allgoodhits like this post

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

CR10X wrote:Thanks for all the testing. I do have one question. Are you measuring the "seating force" after the normal process of resizing, expanding and then measuring during the seating process?

Yes. Using a progressive press, I took the new, 1X, 2X, 3X, etc. brass loaded them all the same way. The brass is deprimed, resized, primed, then powder charged and case mouth belled. The case is then ready for a bullet, and so I remove the case from this station, place it and the Zero 185 JHP inside the Wilson inline seating die I had chambered for 45ACP, and place it on the AMP Press to record the seating force measurement. Once that information is collected, I take the case with seated bullet (or not completely seated as happened with 2X/3X brass) and place it back into the press for the bullet seating operation. Then the round is crimped and knocked out.

CR10X wrote:If so, then my suggestion would be that you use a set up that will measure the "upstroke" or or the extraction of the expanding die rather than the seating force. Those two conditions are similar, but not the same.

Could you expound on this a little bit? I can appreciate that there is a difference in what I'm ignorantly going to call compressive force vs sheer force (?), but I'm not sure how that is relevant here. And I also have no idea of what sort of mechanism one would use to test just such a thing- can I get a hint?

CR10X wrote:Aside, I don't really understand the significant issue with the bullet seating after 1X firing in your test process. That is a real question unless there was only resizing and no expansion die used or it was not adjusted properly. Curious and strange, and I think that deserves more thought about the process.

I'm going to tip my hand a little bit here.

I once asked my mentor, Art Rozier, what he thought about brass life- was it real, fake, myth or truth? My question was something along the lines of, "how many times should you use brass for 50 yards?" And his answer was once or twice. On the other hand, there are many people who believe that the amount of times fired a piece of brass is has little bearing on it's accuracy potential at 50 yards. Now, I do realize that for many many shooters, this sort of minutiae isn't going to help them. But for people who are able to take mechanical advantage of their equipment, this might just be the thing that pushes a High Expert to Master, or Master to High Master (among all sorts of other prep/training activities).

I happen to fall into JIMPGOVs camp- that virgin brass delivers the very best platform for 50 yard accuracy. Why do I believe that, other than from his experimental results? Well, can anyone show me any sort of mechanical object that actually gets better with use? I don't know of any. Brass cases can't cheat the reaper anymore than I can- they probably do have an accuracy lifecycle of sorts. It may not be very large in terms of smallest to largest, but I am willing to bet there is a pretty good answer for my original question; but I want to prove it, as best as I can.

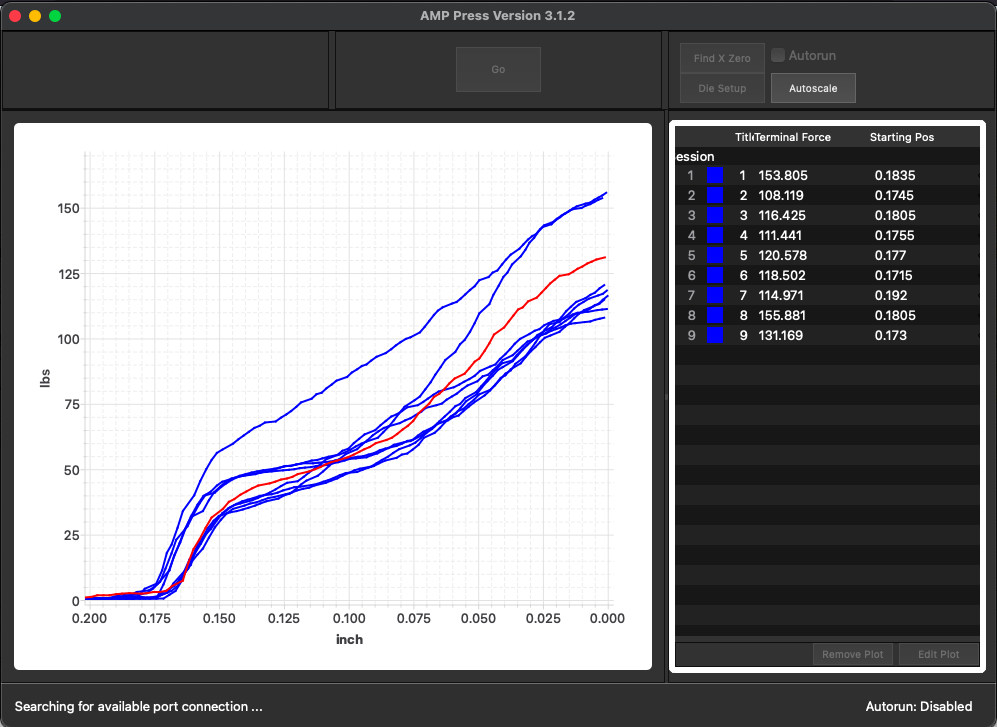

Additionally, not all of us have access to, or can create various sizing dies, custom crimp dies, etc., or other gizmos that can help with turning out great ammo from cases that are well used. So whether you have a Lee turret or a Dillon RL1100, the one thing you can control is the brass case. Because brass work hardens from sizing, expanding, seating and shooting, it will loose tension over time. Here's an some brief testing I did with some Zero 185 Swaged and American Mystery brass- no idea how many times it has been fired:

Lots of variation, and a much lower amount of force required for seating. There isn't yet a good way to get averages out of the software, but the AMP guys are working on that.

This stuff keeps me out of bars, I guess.

CR10X wrote:Anyway, the significant difference that I have seen between new brass / wet cleaned brass and regular tumbled brass after 1x firing is not in the seating force for the bullet, but the extraction force after the expansion die is fully inserted. And it is sometimes significant.

My assumption is that when the expansion / flair die is used after resizing, there is a larger amount of expansion taking place on / in the case and therefore any difference between new / wet cleaned versus fired and tumbled cases is more noticeable during the expanding process.

After the expander die is used, the case is somewhat larger, slightly cleaned or smoothed by the expander plug and there for the actual "seating force" is similar for new / wet cleaned versus fired and tumbled cased is similar (which matches what I feel when reloading).

Using my press the "extraction" force need to remove the expander die is much larger than the force needed to seat a bullet. So the order of magnitude of the forces (lesser for just seating bullet (with properly adjusted expansion die) and more for extracting the expansion plug in new / wet cleaned cases) may be masking the overall "lube" effect when we are just measuring seating force.

Just my thoughts and ponderings. I'm interested in any further testing and results. Thank you very much for the testing and posting.

Ah, OK- I think I see where you are headed.

I think what the expander die does when there is a coating of carbon on the case- here again, presuming it hasn't been cleaned and just dumped in the loading hopper- is that it acts as a coating (not a lubricant) and keeps the "grabby" brass from touching the steel plug/expander die. If anything, I imagine that the carbon is forced into brass surface from the steel plug/expander, which again acts like a coating, and not a lubricant (maybe I'm using the words the wrong way here- but hopefully you understand my meaning; maybe it is correct to say the coating itself is behaving like a lubricant?).

It could be insightful to understand how much force the sizing and expanding plugs impart to the brass. But, as I mentioned above, I have no idea how to measure that without designing and then having some fixture built to test it. If there is an easier way than what I described- I'm all ears.

However, what I am uncertain of is how much this additional work matters to the accuracy potential of the case. It seems obvious to say the less work, the seemingly longer an accuracy plateau could be maintained. But whether that obtains on the target is a whole other story (need to send the ammo to Dave to test- and we ought to start to get a good picture of what's happening and whether or not the measuring I'm doing actually corresponds to something on the target).

Food for thought- appreciate the comments.

Thanks,

Chase

Chase Turner- Posts : 385

Join date : 2019-11-15

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

All this is just personal preference and feelings. So here goes.

My take on it is from a consistency (which to me is proportional to accuracy potential) when using a progressive press is highly desirable. Consistent motion and forces seem to lead to more consistent rounds being produced. The "grabbing" of the expander produces some additional variances that just doesn't feel as consistent for me. And creates extra effort (work) per round. It's the same reason I lube cases even with carbide dies, everything just works smoother and with more consistency.

I can generally tell how the reloading is going by the feel of the process. If anything feels substantially different, those five rounds go in the "special" box, usually TF /RF training, sight ins, firing a newly cleaned gun, etc. And there's just not that many of them these days.

Consistent feeling rounds go in the training / match boxes.

For me, there is no difference between training and match rounds. (Why, because its very important to have confidence and known reliability for match rounds and the only way to do that is to shoot a lot of them in training. Never go to a match with "special) brass, bullets, powder charges, etc., unless you've shot thousands of them already in training. That way you know they work.)

Again, thanks for the testing. As we all know setting up to objective, limiting the variables, measuring and documenting are the hardest part of any testing process. And it keeps us from going over the same old ground and hopefully helps to point us in productive directions.

CR

CR

My take on it is from a consistency (which to me is proportional to accuracy potential) when using a progressive press is highly desirable. Consistent motion and forces seem to lead to more consistent rounds being produced. The "grabbing" of the expander produces some additional variances that just doesn't feel as consistent for me. And creates extra effort (work) per round. It's the same reason I lube cases even with carbide dies, everything just works smoother and with more consistency.

I can generally tell how the reloading is going by the feel of the process. If anything feels substantially different, those five rounds go in the "special" box, usually TF /RF training, sight ins, firing a newly cleaned gun, etc. And there's just not that many of them these days.

Consistent feeling rounds go in the training / match boxes.

For me, there is no difference between training and match rounds. (Why, because its very important to have confidence and known reliability for match rounds and the only way to do that is to shoot a lot of them in training. Never go to a match with "special) brass, bullets, powder charges, etc., unless you've shot thousands of them already in training. That way you know they work.)

Again, thanks for the testing. As we all know setting up to objective, limiting the variables, measuring and documenting are the hardest part of any testing process. And it keeps us from going over the same old ground and hopefully helps to point us in productive directions.

CR

CR

CR10X- Posts : 1777

Join date : 2011-06-17

Location : NC

chopper and JRV like this post

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

Greetings,

Over the years, I have bought/traded/sold many Star loaders.

It seems that the expander plug on a used machine had a nasty looking scuffed surface from expanding thousands of cases.

Usually, they clean up well with a drill motor and ScotchBrite. Some did not as they were scored deeply.

The expander plugs are case hardened and ground/polished to size. Most case hardened parts are about 67 HRC.

My point? The repeated action of expanding the soot/Carbon lined cases led to physical wear.

If the soot/Carbon was a lubricant, the plug would show the benefit.

Cheers,

Dave

Over the years, I have bought/traded/sold many Star loaders.

It seems that the expander plug on a used machine had a nasty looking scuffed surface from expanding thousands of cases.

Usually, they clean up well with a drill motor and ScotchBrite. Some did not as they were scored deeply.

The expander plugs are case hardened and ground/polished to size. Most case hardened parts are about 67 HRC.

My point? The repeated action of expanding the soot/Carbon lined cases led to physical wear.

If the soot/Carbon was a lubricant, the plug would show the benefit.

Cheers,

Dave

fc60- Posts : 1458

Join date : 2011-06-11

Location : South Prairie, WA 98385

mhayford45, LCWELL, R*P*DR* and RoyDean like this post

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

Dave: Even Graphite is an abrasive….

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

Dan Webb likes this post

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

Yep...what Wobbley said. Carbon is complicated. In pure graphite form, remove humidity and the basal planes now act like diamond (abrasive powder). This was the reason why high-altitude bombers experienced severe wear on hinges during WWII (they were lubricated with a graphite paste). Along comes MoS2 and others to fix that (no water vapor necessary).

A recent field of drug delivery research centers around the creation and use of nano diamonds ("spherical-like" w/diameter in the nm range). They were first produced in small quantities by igniting propellants (aka, what we use)! So they are also potentially a part of the coating inside a fired case.

If you've ever heard of "DLC" (diamond-like carbon)...it's a plasma vapor deposited form of carbon derived from methane, that has both graphitic and diamond-like characteristics (hard and somewhat slippery). Certainly enough energy during ignition to form some of that (likely much more graphitic though).

What is a lubricant? IMHO something that prevents clean metal-to-metal contact and galling and is essentially a "contaminant" between two moving surfaces. A very clean jacket OD against a very clean case ID will have a friction coefficient of 0.4 to 0.5. A "carbon" film inside a case will cut that in half. Thus, it is a lubricant, though not as effective as grease or oil which shears much more easily.

The variations in seating force data could be the result of variation in dimensions in the "press-fit" process. There are equations that can be used (as an estimate) to determine this. Small changes in interference can have a very large effect on the force necessary to cause expansion/contraction and sliding. Add in asymmetric distorted cases, surface roughness, variation in case elastic modulus, and things can vary even more.

A recent field of drug delivery research centers around the creation and use of nano diamonds ("spherical-like" w/diameter in the nm range). They were first produced in small quantities by igniting propellants (aka, what we use)! So they are also potentially a part of the coating inside a fired case.

If you've ever heard of "DLC" (diamond-like carbon)...it's a plasma vapor deposited form of carbon derived from methane, that has both graphitic and diamond-like characteristics (hard and somewhat slippery). Certainly enough energy during ignition to form some of that (likely much more graphitic though).

What is a lubricant? IMHO something that prevents clean metal-to-metal contact and galling and is essentially a "contaminant" between two moving surfaces. A very clean jacket OD against a very clean case ID will have a friction coefficient of 0.4 to 0.5. A "carbon" film inside a case will cut that in half. Thus, it is a lubricant, though not as effective as grease or oil which shears much more easily.

The variations in seating force data could be the result of variation in dimensions in the "press-fit" process. There are equations that can be used (as an estimate) to determine this. Small changes in interference can have a very large effect on the force necessary to cause expansion/contraction and sliding. Add in asymmetric distorted cases, surface roughness, variation in case elastic modulus, and things can vary even more.

tovaert- Posts : 455

Join date : 2018-11-28

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

So what lube should we use on our belling (expander) dies to keep the cases from sticking?

BE Mike- Posts : 2585

Join date : 2011-07-29

Location : Indiana

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

Basically none…. Or….

Reload in two steps…. Process your brass with one trip through…resize, swage pockets (if necessary), expand and flare. Then case wash. Then run through again with prime, powder, bullet seat and crimp.

There are some very good advantages to this two step approach. First is better consistency in operation. Doing all the mechanical steps in conjunction with loading means more interruptions to fix issues. An issue with sizing or expanding will stop the process or give a hesitation and loading consistency isn’t there. Second is that automation can be incorporated if your machine can be automated. That can take a LOT of the drudgery out of loading.

Reload in two steps…. Process your brass with one trip through…resize, swage pockets (if necessary), expand and flare. Then case wash. Then run through again with prime, powder, bullet seat and crimp.

There are some very good advantages to this two step approach. First is better consistency in operation. Doing all the mechanical steps in conjunction with loading means more interruptions to fix issues. An issue with sizing or expanding will stop the process or give a hesitation and loading consistency isn’t there. Second is that automation can be incorporated if your machine can be automated. That can take a LOT of the drudgery out of loading.

Wobbley- Admin

- Posts : 4803

Join date : 2015-02-12

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

I guess I've been doing it right all along then, but I tumble my cases with ground walnut shells and liquid Flitz instead of washing them.Wobbley wrote:Basically none…. Or….

Reload in two steps…. Process your brass with one trip through…resize, swage pockets (if necessary), expand and flare. Then case wash. Then run through again with prime, powder, bullet seat and crimp.

There are some very good advantages to this two step approach. First is better consistency in operation. Doing all the mechanical steps in conjunction with loading means more interruptions to fix issues. An issue with sizing or expanding will stop the process or give a hesitation and loading consistency isn’t there. Second is that automation can be incorporated if your machine can be automated. That can take a LOT of the drudgery out of loading.

BE Mike- Posts : 2585

Join date : 2011-07-29

Location : Indiana

Wobbley likes this post

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

An ultra-smooth pure diamond coating applied to the belling die where it's needed, remaining adherent for many thousands of cycles...I think that would reduce the friction force. That would also require some experimentation on optimal cone angle(s), with prescribed limits on the extent of expansion. DLC could also work. The major issue is getting proper adhesion to the base material, which is softer. I've never looked into it but I would be surprised if the more expensive die manufacturers haven't investigated this. A belling die made from diamond coated silicon nitride would also be an excellent candidate. Since that die is in a state of compression, ceramics could work.

tovaert- Posts : 455

Join date : 2018-11-28

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

I have used molybdenum in a puffer bottle to lube the insides of rifle case mouths that worked for a smooth release and tried it with pistol cases which didn't seem to change the hard release of the expander. I also have Reading rifle dies with carbide case neck expanders that works great. Maybe Dillon will see the need and make one for their reloading machines but for now I'm using an expander powder funnel from Photo E Scape and let it break in with use.

Rodger Barthlow- Posts : 392

Join date : 2013-08-10

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

I don't have the ability or means to test anything to any kind of certainty.

Having said that, I use Hornady spray case lube. Shake them around until a good portion of the cases are mouth up then give them a spritz. Shake around and repeat. Let them dry and load. Brass is tumbled in cob treated with car wax first.

The press operation is so much smoother and the effort needed to run the press greatly reduced.

I can''t tell any difference in accuracy at all. (see my first sentence)

Reliability has been 100%.

Most of my loading is with a D1050, non Dillon powder through expander and modified case hold down at swage station.

Having said that, I use Hornady spray case lube. Shake them around until a good portion of the cases are mouth up then give them a spritz. Shake around and repeat. Let them dry and load. Brass is tumbled in cob treated with car wax first.

The press operation is so much smoother and the effort needed to run the press greatly reduced.

I can''t tell any difference in accuracy at all. (see my first sentence)

Reliability has been 100%.

Most of my loading is with a D1050, non Dillon powder through expander and modified case hold down at swage station.

blindshooter- Posts : 122

Join date : 2016-03-15

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

I literally dump my used cases into my tumbler from my catch net most times. Add a cap full of NuFinish. Turn it on and go do more productive things in the shop. Might run the tumbler several times during the week before emptying the brass. I do the same for new brass. The coating of NuFinish resolves the sticking issue on my 750. I prefer corncob media. Just my lazy self

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

BE Mike likes this post

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

Jlm, you use corn cob media in a tumbler? Would walnut media be good enough, I have a big box left from my RCBS vibrating cleaner days?jglenn21 wrote:I literally dump my used cases into my tumbler from my catch net most times. Add a cap full of NuFinish. Turn it on and go do more productive things in the shop. Might run the tumbler several times during the week before emptying the brass. I do the same for new brass. The coating of NuFinish resolves the sticking issue on my 750. I prefer corncob media. Just my lazy self

Stan

chopper- Posts : 820

Join date : 2013-10-29

Age : 72

Location : Western Iowa

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

lots of folks run walnut with excellent results. probably what you get used to.. I used the term tumbler but it's a vibrating cleaner...

jglenn21- Posts : 2620

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

I believe there are some misconceptions here, and some other things at work.

It has been years since I've had access to metallurgical equipment where I could zap something with an electron beam and find out what it was. I read somewhere a post by someone who had tested such fouling, and posted that there was very little carbon in it, being mostly Lead and Copper. Reading the above posts, I did an internet search and found answers that indicate there's a lot of metals there, and more or less carbon.

https://ncfs.ucf.edu/research/chemical-evidence/gun-shot-residue/

https://en.wikipedia.org/wiki/Gunshot_residue

https://pubmed.ncbi.nlm.nih.gov/20158597/

I remember (45+ years ago) talking with one of my Metallurgy professors about seeing a brass wash on steel expanders while reloading new cases, and my professor told me he believed what I was describing a very microscopic heating of the brass such that small amounts of the brass brazed itself to the expander or size die on insertion, and breaking that very small braze added significantly to the force necessary to withdraw the case from the die.

I did a lot of microscopy in the Lab. When I looked at a cross section of a part, surface conditions were always different from what was a few thousandths below, except when I polished off that original surface. I would expect the un-disturbed inside or the outside of a fired case to have at least some copper oxide, in addition to the fouling. Vibratory cleaning such as I do removes a little brass, and I believe the stainless pins removes a lot more.

I am trying to remember whether the copper oxides have higher or lower melting points than copper, and I seem to remember them being higher. I did a quick internet search, and while cartridge brass has a melting point of about 916 C, copper oxide has a melt temperature of about 1235 C.

So, the fouling probably can't be described as a lubricant, but the surface conditions new/fired/steel-pin-cleaned are quite different.

It has been years since I've had access to metallurgical equipment where I could zap something with an electron beam and find out what it was. I read somewhere a post by someone who had tested such fouling, and posted that there was very little carbon in it, being mostly Lead and Copper. Reading the above posts, I did an internet search and found answers that indicate there's a lot of metals there, and more or less carbon.

https://ncfs.ucf.edu/research/chemical-evidence/gun-shot-residue/

https://en.wikipedia.org/wiki/Gunshot_residue

https://pubmed.ncbi.nlm.nih.gov/20158597/

I remember (45+ years ago) talking with one of my Metallurgy professors about seeing a brass wash on steel expanders while reloading new cases, and my professor told me he believed what I was describing a very microscopic heating of the brass such that small amounts of the brass brazed itself to the expander or size die on insertion, and breaking that very small braze added significantly to the force necessary to withdraw the case from the die.

I did a lot of microscopy in the Lab. When I looked at a cross section of a part, surface conditions were always different from what was a few thousandths below, except when I polished off that original surface. I would expect the un-disturbed inside or the outside of a fired case to have at least some copper oxide, in addition to the fouling. Vibratory cleaning such as I do removes a little brass, and I believe the stainless pins removes a lot more.

I am trying to remember whether the copper oxides have higher or lower melting points than copper, and I seem to remember them being higher. I did a quick internet search, and while cartridge brass has a melting point of about 916 C, copper oxide has a melt temperature of about 1235 C.

So, the fouling probably can't be described as a lubricant, but the surface conditions new/fired/steel-pin-cleaned are quite different.

NuJudge- Posts : 263

Join date : 2011-09-22

Age : 67

Location : SE Michigan

OldGaGuy and Chase Turner like this post

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

I can add that carbon dirty rifle cases take a lot more force to extract over the expander button in the size die. Back in my benchrest and hunting days, we used all sorts of loading tricks to make the best ammo.

If we were talking rifle cases, here is the gospel....

https://www.forsterproducts.com/product-category/case-sizing-lubricating/sizing-lubricants/

And I saw this via the Forster site

https://www.youtube.com/watch?v=GRJZPSew4DA

If we were talking rifle cases, here is the gospel....

https://www.forsterproducts.com/product-category/case-sizing-lubricating/sizing-lubricants/

And I saw this via the Forster site

https://www.youtube.com/watch?v=GRJZPSew4DA

Jack H- Posts : 2698

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

I haven’t yet slogged through all of the posts, but please note: all graphite is carbon, but not all carbon is graphite.

GrumpyOldMan- Posts : 482

Join date : 2013-03-08

Location : High Desert Southwest Red Rock Country

Re: Leftover carbon inside cases does not act like a lubricant

Re: Leftover carbon inside cases does not act like a lubricant

After reading most if this in detail. I think this is a "tin floats to the top of the molten lead" discussion.

Argument 1: tin is soluble in lead so it "cant" float, just like sugar or salt don't float_sink in water.

Argument 2: the dross has more tin than the lead so it must be floating.

The reality is both were right and both were wrong as neither were seeing the whole story. Tin oxidizes faster than lead so tin oxides form at the surface faster. Tin oxides are not soluble so they float. The melt is constantly in motion for one reason or another (ladle, convection currents etc) so ner tin is always being brought to the surface to oxidize and be removed.

Point is its a very complex system.

That said, DLC is an excellent wear surface and reduces the coefficient of friction dramatically. I send gun parts out for DLC coating occasionally. Perhaps I'll send an expandernout with the next batch. I'd like to send my cri.p die out as well as that's where I have.theost issues, but the vapor deposition processes don't do well on deep holes.

Argument 1: tin is soluble in lead so it "cant" float, just like sugar or salt don't float_sink in water.

Argument 2: the dross has more tin than the lead so it must be floating.

The reality is both were right and both were wrong as neither were seeing the whole story. Tin oxidizes faster than lead so tin oxides form at the surface faster. Tin oxides are not soluble so they float. The melt is constantly in motion for one reason or another (ladle, convection currents etc) so ner tin is always being brought to the surface to oxidize and be removed.

Point is its a very complex system.

That said, DLC is an excellent wear surface and reduces the coefficient of friction dramatically. I send gun parts out for DLC coating occasionally. Perhaps I'll send an expandernout with the next batch. I'd like to send my cri.p die out as well as that's where I have.theost issues, but the vapor deposition processes don't do well on deep holes.

10sandxs- Posts : 972

Join date : 2016-01-29

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Carbon Coated Cases

» What case lubricant do you use.

» Corrosion goes inside too

» lubricant for barrels

» Hammer & Seier Lubricant

» What case lubricant do you use.

» Corrosion goes inside too

» lubricant for barrels

» Hammer & Seier Lubricant

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum