Seating lead bullets on a progressive press

+9

Dcforman

Steve B

Jack H

DA/SA

SingleActionAndrew

james r chapman

CR10X

jjfitch

mikemyers

13 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Seating lead bullets on a progressive press

Seating lead bullets on a progressive press

I've mostly got my reloading press changed over to 38 Special, but I've got some new dies on the way. I'm puzzled by something that's been going on, wondering if someone here can suggest what the problem might be.

If I load 50 rounds, using my old Remington cases (I thought I would start with those, before I use my new Starline cases), one or two rounds ends up with some lead on the outside of the case. My best guess is that some lead is being scraped off the lead bullet (Magnus #514) as it is being seated.

I've re-adjusted the belling, so there's just enough to start the bullet going in straight. As a test, I increased the amount of belling, which made things worse, so I put the expander back to the way Jay at Redding told me to do it - just enough bell to allow the lead bullet to get started.

(I have a feeling that I should expand the bullet even more, so the case can't contact the side of the bullet and scrape off lead....... but that's not what Jay suggests I do, when I get the new dies. The current seater die is RCBS, with the "pusher" reduced slightly in diameter where it touches the bullet. I don't think it's right that the seater is pushing on the tiny "bump" on the end of the bullet - doesn't sound right to me.....)

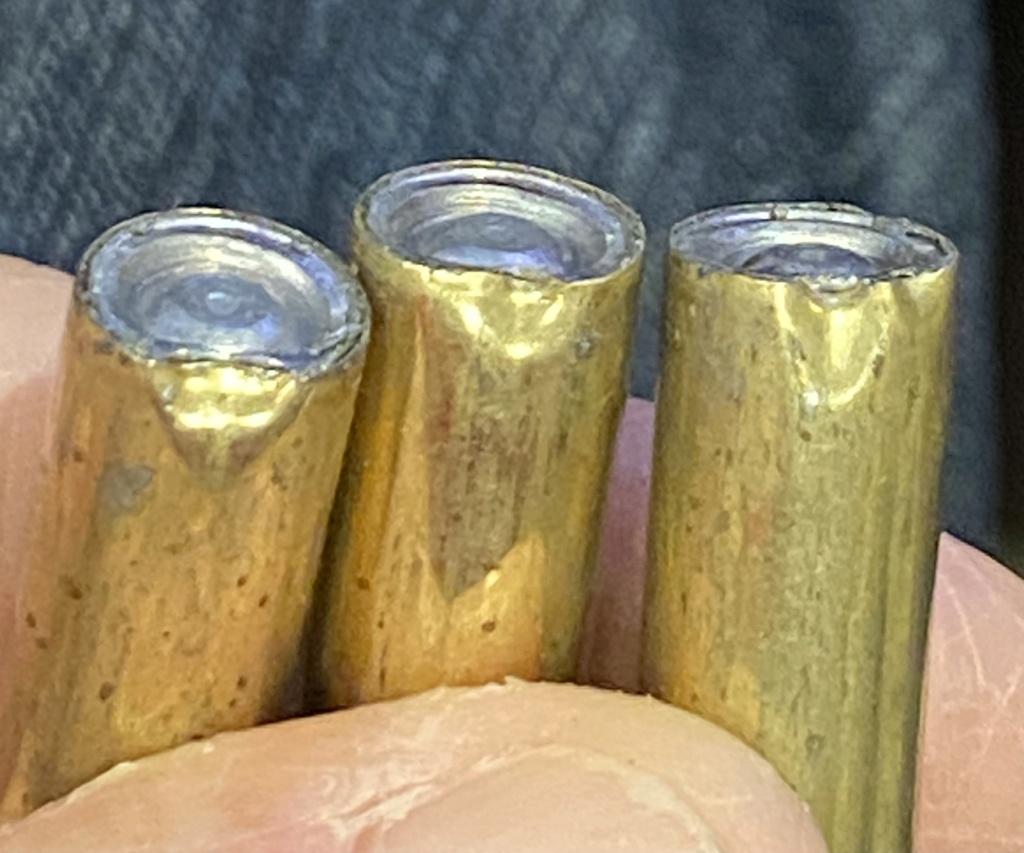

It may or may not be a clue, but when I scrape off the lead on the outside of the cartridge, it's obvious that the brass case has been pushed inward. Here's a photo of three cases, after I removed the lead that covered the "dent":

Jay, at Redding, told me part of my problem is the custom "seater" that RCBS made for me isn't right, as it flattens the small "bump" in the middle of the end of the #514 bullet. Jay says by doing this, it is forcing lead outwards, where it eventually can hit the upper edge of the brass case, causing the problem. By this time next week, my new die will arrive, and Jay also tells me if I send him a few sample #514 bullets, he can machine a "pusher" designed specifically for this bullet.

The problem is more "annoying" than anything else. If I load 50 rounds, three of them are damaged. The others shoot fine. I occasionally had a similar problem three years ago, when I was loading 38 Special. I figured the problem was me, not placing the bullet perfectly vertical on the 38 Special case, so I've been much more careful. I plan to test some rounds to load using Case Lube, and see if that makes a difference.

(I seated the bullet slightly deeper than needed, as I was planning on using a Profile roll crimp die. Since then I've read that I should use a Taper Crimp Die.

If I load 50 rounds, using my old Remington cases (I thought I would start with those, before I use my new Starline cases), one or two rounds ends up with some lead on the outside of the case. My best guess is that some lead is being scraped off the lead bullet (Magnus #514) as it is being seated.

I've re-adjusted the belling, so there's just enough to start the bullet going in straight. As a test, I increased the amount of belling, which made things worse, so I put the expander back to the way Jay at Redding told me to do it - just enough bell to allow the lead bullet to get started.

(I have a feeling that I should expand the bullet even more, so the case can't contact the side of the bullet and scrape off lead....... but that's not what Jay suggests I do, when I get the new dies. The current seater die is RCBS, with the "pusher" reduced slightly in diameter where it touches the bullet. I don't think it's right that the seater is pushing on the tiny "bump" on the end of the bullet - doesn't sound right to me.....)

It may or may not be a clue, but when I scrape off the lead on the outside of the cartridge, it's obvious that the brass case has been pushed inward. Here's a photo of three cases, after I removed the lead that covered the "dent":

Jay, at Redding, told me part of my problem is the custom "seater" that RCBS made for me isn't right, as it flattens the small "bump" in the middle of the end of the #514 bullet. Jay says by doing this, it is forcing lead outwards, where it eventually can hit the upper edge of the brass case, causing the problem. By this time next week, my new die will arrive, and Jay also tells me if I send him a few sample #514 bullets, he can machine a "pusher" designed specifically for this bullet.

The problem is more "annoying" than anything else. If I load 50 rounds, three of them are damaged. The others shoot fine. I occasionally had a similar problem three years ago, when I was loading 38 Special. I figured the problem was me, not placing the bullet perfectly vertical on the 38 Special case, so I've been much more careful. I plan to test some rounds to load using Case Lube, and see if that makes a difference.

(I seated the bullet slightly deeper than needed, as I was planning on using a Profile roll crimp die. Since then I've read that I should use a Taper Crimp Die.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Are you slightly spinning the bullet as it is entering the case?

I find this helps with tilting and shaving!

Smiles,

I find this helps with tilting and shaving!

Smiles,

jjfitch- Posts : 142

Join date : 2012-08-31

Age : 77

Location : The Beautiful Pacific Northwest

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

No - never knew about that. Sure, will try tomorrow. Thanks!

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Bell the case enough to really get the wadcutter bullet started (more is better usually) and then make sure you press into the case some by finger pressure so it has some support. If you don't, you've got a great long bullet sitting on top of the case and no support when it's being started by that flat ended seater plug. Since you didn't press the bullet into the case enough to get it started and some support; giving it more bell before just exacerbated the problem since it allowed more tipping at the start.

Starting WC or HBWC bullets is slightly different that starting other bullets, mostly due to their length and the softer lead.

Starting WC or HBWC bullets is slightly different that starting other bullets, mostly due to their length and the softer lead.

Last edited by CR10X on 10/9/2020, 7:02 am; edited 3 times in total

CR10X- Posts : 1777

Join date : 2011-06-17

Location : NC

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

I believe Keefer would allow 1/2-3/4 the bullet to enter the case before seating.

I’ve always found that worked best.

I’ve always found that worked best.

james r chapman- Admin

- Posts : 6373

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

8eightring likes this post

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Mike your mention of Jay at Redding and custom bullet "pushers" has me intrigued/concerned.

I have their competition seating die for 45acp and was going to set it up this weekend. I have a couple thousand of both Hornady XTP jacketed and Zero SWC lead. I assume the seater die is intended for the JHP. Does Redding already make a different "pusher" for SWC? I haven't seen such a thing in the catalog but I could be in the wrong section. I have the shouldered + truncated cone profile on the Zero SWCs. Or since it has the cone already, might the standard "pusher" in the redding seating die be appropriate for both bullets?

If I should order a custom "pusher" how do we reach Jay? I have to imagine this is a path well trodden ...

I have their competition seating die for 45acp and was going to set it up this weekend. I have a couple thousand of both Hornady XTP jacketed and Zero SWC lead. I assume the seater die is intended for the JHP. Does Redding already make a different "pusher" for SWC? I haven't seen such a thing in the catalog but I could be in the wrong section. I have the shouldered + truncated cone profile on the Zero SWCs. Or since it has the cone already, might the standard "pusher" in the redding seating die be appropriate for both bullets?

If I should order a custom "pusher" how do we reach Jay? I have to imagine this is a path well trodden ...

SingleActionAndrew- Admin

- Posts : 675

Join date : 2019-11-19

Location : IL, USA

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

You might measure the expander diameter and then the projectile diameter and see what the difference is.

Your expander may be a bit small.

A properly sized (and proper length) expander makes placing the projectile and seating it squarely much easier.

Your expander may be a bit small.

A properly sized (and proper length) expander makes placing the projectile and seating it squarely much easier.

DA/SA- Posts : 1508

Join date : 2017-10-09

Age : 68

Location : Southeast Florida

Steve B likes this post

Jack H- Posts : 2700

Join date : 2011-06-10

Age : 75

Location : Oregon

Steve B likes this post

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

So much to reply to - I'll start with Jim's post. (Nothing that I write is "supposed to be an answer" - all it is, is what I can observe.)james r chapman wrote:I believe Keefer would allow 1/2-3/4 the bullet to enter the case before seating.

I’ve always found that worked best.

I suspect I'm using the wrong die(s) for what I'm trying to do.

To start, this is the "Redding Premium Expander Die" that I use for 45, and now for 38. I bought one of each two years ago.

I assumed the lower part of the die is supposed to expand the case just a little, allowing the bullet to easily drop down into the case, and the upper part of the die has a taper, that bells out the top of the case. Both Jay and Don at Redding have told me to go just deep enough into the case to get the bullet started. If the lower part of the die was large enough for the bullet to drop in that far, it would be just like what Jim wrote, and I wouldn't be having this issue.

What I sort of expected, is I could then push the bullet down into the case using just finger pressure, and eventually a smaller diameter lower down in the case would "lock onto" the bullet as it was seated. The way I read everything, that is what is supposed to happen.

Jim, if you look at this photo, you'll see that once the upper "taper" part reaches the case as I'm lowering the expander die into the case, it expands the case MUCH more than what is needed. You can tell that just by looking at this die.

As I see it, the die doesn't do much of anything with my bullets - maybe the lead bullets we use are larger in diameter than what the die was designed to be used with?

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Jack, do you know the part number? Maybe THIS is what I need to buy.Jack H wrote:RCBS makes a longer expander plug just for HBWC......

Maybe it will do what I thought the Redding die would do?

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Cecil, what you wrote is exactly what I think I should be able to do, but with the Redding die I'm using, I'm starting to think this is impossible.CR10X wrote:Bell the case enough to really get the wadcutter bullet started (more is better usually) and then make sure you press into the case some by finger pressure so it has some support. If you don't, you've got a great long bullet sitting on top of the case and no support when it's being started by that flat ended seater plug. Since you didn't press the bullet into the case enough to get it started and some support; giving it more bell before just exacerbated the problem since it allowed more tipping at the start.

Starting WC or HBWC bullets is slightly different that starting other bullets, mostly due to their length and the softer lead.

I can't push the bullet into the case using finger pressure - it takes a good amount of force from my press to do that.

If my bullet and case behaved as you describe, I think everything would be fine.

Which expansion die and seating die are you using? Are the "standard" dies that should work in my RCBS press?

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Great idea - I will do this later this evening. The dimensions might be shown on the Redding catalog/manual.DA/SA wrote:You might measure the expander diameter and then the projectile diameter and see what the difference is.

Your expander may be a bit small.

A properly sized (and proper length) expander makes placing the projectile and seating it squarely much easier.

Maybe the die I'm using is NOT intended to be used with lead bullets?

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Too early to answer your question - Jay wants me to mail him some of my bullets, and he will make me a custom "pusher" if needed.SingleActionAndrew wrote:Mike your mention of Jay at Redding and custom bullet "pushers" has me intrigued/concerned.

I have their competition seating die for 45acp and was going to set it up this weekend. I have a couple thousand of both Hornady XTP jacketed and Zero SWC lead. I assume the seater die is intended for the JHP. Does Redding already make a different "pusher" for SWC? I haven't seen such a thing in the catalog but I could be in the wrong section. I have the shouldered + truncated cone profile on the Zero SWCs. Or since it has the cone already, might the standard "pusher" in the redding seating die be appropriate for both bullets?

If I should order a custom "pusher" how do we reach Jay? I have to imagine this is a path well trodden ...

What I have now can't be right - the pusher is squishing the little raised plug in the middle of the #514 Magnus bullet.

(Which also shows how much force I am using!!)

I should probably send Jay a dozen or so bullets, so he can figure things out.

If the expander die worked the way I assumed it did, maybe all the other problems would vanish.........

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Mike, it looks like that is a 2 diameter expander with a taper at the top for expanding

You should be able to go up over both diameters and just barely touch the taper for bell.

Mike the diameters, maybe too small!

You should be able to go up over both diameters and just barely touch the taper for bell.

Mike the diameters, maybe too small!

james r chapman- Admin

- Posts : 6373

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

I called RCBS and got the long expander plug direct. I already had the standard expand die.

For seating HBWC, I use and highly recommend the Dillon die with a seat plug that is made or modified to push at the perimeter. Like the shoulder seater for SWC. Also the take apart and clean feature of Dillon die is one of my favorite things in life. Same with the crimp Dillon die.

When there is no lead and lube to clean, I will use the Redding micrometer dies only for jacketed bullets.

For seating HBWC, I use and highly recommend the Dillon die with a seat plug that is made or modified to push at the perimeter. Like the shoulder seater for SWC. Also the take apart and clean feature of Dillon die is one of my favorite things in life. Same with the crimp Dillon die.

When there is no lead and lube to clean, I will use the Redding micrometer dies only for jacketed bullets.

Jack H- Posts : 2700

Join date : 2011-06-10

Age : 75

Location : Oregon

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Jim, the lower part of the expander die measures 0.3525" diameter.james r chapman wrote:Mike, it looks like that is a 2 diameter expander with a taper at the top for expanding

You should be able to go up over both diameters and just barely touch the taper for bell.

Mike the diameters, maybe too small!

Just as advertised, I can take the expanded case in my hand, and push the die into the shell smoothly and easily - up to the point where the expander die gets a little larger. That's as far as the case can go over the die, although if I add the bell, that gets larger.

The Magnus #514 bullet I just measured has an OD of 0.3575".

The box for the Magnus #514 bullets says the bullets are: 0.357" diameter.

When I use my calipers to try to measure the inside diameter of the case, I get readings from 0.35" to 0.353".

The reality is that the bullet only goes into the "expanded" bell, and no further.

Seems to me that to accomplish what you guys are suggesting, either the bullet needs to be smaller in diameter, or the expander plug needs to be larger.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

I went through all my boxes of dies. The RCBS expander die that I used before looks like your photo.

The diameter of the "plug" towards the bottom measures 0.3545" to 0.3550".

That's larger than the Redding diameter.

Time to put it on the press and see if it works better....... Back soon......

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Everything seems much better. I lowered the "plug" until it just started to bell the case. I can't see the bell, but I can barely feel it. Here's a photo of the case and one of my #514 bullets - the red line shows how far the bullet goes into the case reasonably easily - going that far in, the bullet also seems much more "stable".

Jim, with finger pressure, I can't push it much further.

Not sure what to do next - unless one of you has further advice, I'll leave it like this for now, and see I loading goes more easily, and eliminates the lead shaving.

This is what I expected the Redding die to do, but to allow the bullet to go much further into the case.......

I still think my die is too "tight", or the bullet is too "big".

Jim, with finger pressure, I can't push it much further.

Not sure what to do next - unless one of you has further advice, I'll leave it like this for now, and see I loading goes more easily, and eliminates the lead shaving.

This is what I expected the Redding die to do, but to allow the bullet to go much further into the case.......

I still think my die is too "tight", or the bullet is too "big".

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Steve B- Posts : 627

Join date : 2011-06-16

Location : Elkhart, IN

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

I'm surprised no one has mentioned PhotoEscape's expander. It honestly works better than any of the above mentioned expanders. Designed for Dillons, but you can purchase his universal die for the expander that will fit most presses. Cured basically all my problems.

For a seater, I just use the flat seater that came with my RCBS die and fixed a small piece of jb weld to the end. Pressed a hbwc bullet into it, made sure it was straight, and let it cure. I think I just used gun oil as a release compound. Works a treat.

Dave

For a seater, I just use the flat seater that came with my RCBS die and fixed a small piece of jb weld to the end. Pressed a hbwc bullet into it, made sure it was straight, and let it cure. I think I just used gun oil as a release compound. Works a treat.

Dave

Dcforman- Posts : 928

Join date : 2017-11-18

Age : 43

Location : Ohio

Steve B and valbern67 like this post

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

I should note that with his expander, I can press a bullet 90% of the way in with finger pressure, which is what Jerry Keefer recommended.

Dave

Dave

Dcforman- Posts : 928

Join date : 2017-11-18

Age : 43

Location : Ohio

Steve B likes this post

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Correction, my RCBS die is similar to your photo, but the expander plug is much longer in your die.

I'll see what I can find on the RCBS website, and if they have a part number for it so I can order one.

Thanks for the photo.

Things are improving!

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Here's what I would do having been through this exercise very recently.

-Measure the diameters of 3 bulllets.

-Run a few through your press, without adding powder and without crimping.

-Pull those bullets and see if they're still the same diameter.

-If the bullets are no longer the same diameter that has to be fixed. Several above mentioned what is needed.

-Buy a correctly dimensioned expander, length and diameter to match your projectile. Actually the diameter should be slightly larger, .0005-.001". It will need to be mirror polished so it doesn't stick inside your cases.

-Correctly expanded cases will allow you to push 3/4 of the bullet with your thumb easily into the case.

I purchased my expanders from PhotoEscape Inc, he's got an ad at the top of our home page. His DEWC 38 cal expander works perfectly with the Zero 148 HBWC bullet, if that's what youre using.

I've been working on this same issue for a while until recently finding a properly dimensioned expander.

-Measure the diameters of 3 bulllets.

-Run a few through your press, without adding powder and without crimping.

-Pull those bullets and see if they're still the same diameter.

-If the bullets are no longer the same diameter that has to be fixed. Several above mentioned what is needed.

-Buy a correctly dimensioned expander, length and diameter to match your projectile. Actually the diameter should be slightly larger, .0005-.001". It will need to be mirror polished so it doesn't stick inside your cases.

-Correctly expanded cases will allow you to push 3/4 of the bullet with your thumb easily into the case.

I purchased my expanders from PhotoEscape Inc, he's got an ad at the top of our home page. His DEWC 38 cal expander works perfectly with the Zero 148 HBWC bullet, if that's what youre using.

I've been working on this same issue for a while until recently finding a properly dimensioned expander.

Steve B- Posts : 627

Join date : 2011-06-16

Location : Elkhart, IN

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

I found a Bullseye Forum page about this: https://www.bullseyeforum.net/t6413-148-hbwc-and-expander-diesSteve B wrote:Here's what I would do having been through this exercise very recently.

-Measure the diameters of 3 bulllets.

-Run a few through your press, without adding powder and without crimping.

-Pull those bullets and see if they're still the same diameter.

-If the bullets are no longer the same diameter that has to be fixed. Several above mentioned what is needed.

-Buy a correctly dimensioned expander, length and diameter to match your projectile. Actually the diameter should be slightly larger, .0005-.001". It will need to be mirror polished so it doesn't stick inside your cases.

-Correctly expanded cases will allow you to push 3/4 of the bullet with your thumb easily into the case.

I purchased my expanders from PhotoEscape Inc, he's got an ad at the top of our home page. His DEWC 38 cal expander works perfectly with the Zero 148 HBWC bullet, if that's what youre using.

I've been working on this same issue for a while until recently finding a properly dimensioned expander.

I also left a message for Terry Labbe at Magnus Bullets.

I can also check with PhotoEscape if their die works with the Magnus #514 bullet.

What you describe, is what I expected to happen with the Redding die.... more questions for Jay, on Monday.

Thanks!!

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Took me a minute to find this...

"One of the secrets to lead, is to form the brass to accept 90% of the bullet with only mild finger pressure.. The long 38 Hollow base wad cutters are approx. .580 long..Here I am loading PENN double end solids, which are approx .525 All but about .050 should slide into the case with ease.. No force..to prevent sizing the bullet down below bore diameter. The only dies I ever saw designed specifically for the long 38 wad cutters were the now extinct CH Auto Champ. This Dillion punch is custom ground.." Jerry Keefer

Of course, Jerry passed before AP released his version.

Dave

"One of the secrets to lead, is to form the brass to accept 90% of the bullet with only mild finger pressure.. The long 38 Hollow base wad cutters are approx. .580 long..Here I am loading PENN double end solids, which are approx .525 All but about .050 should slide into the case with ease.. No force..to prevent sizing the bullet down below bore diameter. The only dies I ever saw designed specifically for the long 38 wad cutters were the now extinct CH Auto Champ. This Dillion punch is custom ground.." Jerry Keefer

Of course, Jerry passed before AP released his version.

Dave

Dcforman- Posts : 928

Join date : 2017-11-18

Age : 43

Location : Ohio

8eightring likes this post

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Primer Seating in Progressive Press

» Seating die for lead bullets

» Lead SWC Bullets: Case belling and seating question

» Progressive press due order

» Progressive press suggestion?

» Seating die for lead bullets

» Lead SWC Bullets: Case belling and seating question

» Progressive press due order

» Progressive press suggestion?

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum