Seating lead bullets on a progressive press

+9

Dcforman

Steve B

Jack H

DA/SA

SingleActionAndrew

james r chapman

CR10X

jjfitch

mikemyers

13 posters

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Seating lead bullets on a progressive press

Seating lead bullets on a progressive press

First topic message reminder :

I've mostly got my reloading press changed over to 38 Special, but I've got some new dies on the way. I'm puzzled by something that's been going on, wondering if someone here can suggest what the problem might be.

If I load 50 rounds, using my old Remington cases (I thought I would start with those, before I use my new Starline cases), one or two rounds ends up with some lead on the outside of the case. My best guess is that some lead is being scraped off the lead bullet (Magnus #514) as it is being seated.

I've re-adjusted the belling, so there's just enough to start the bullet going in straight. As a test, I increased the amount of belling, which made things worse, so I put the expander back to the way Jay at Redding told me to do it - just enough bell to allow the lead bullet to get started.

(I have a feeling that I should expand the bullet even more, so the case can't contact the side of the bullet and scrape off lead....... but that's not what Jay suggests I do, when I get the new dies. The current seater die is RCBS, with the "pusher" reduced slightly in diameter where it touches the bullet. I don't think it's right that the seater is pushing on the tiny "bump" on the end of the bullet - doesn't sound right to me.....)

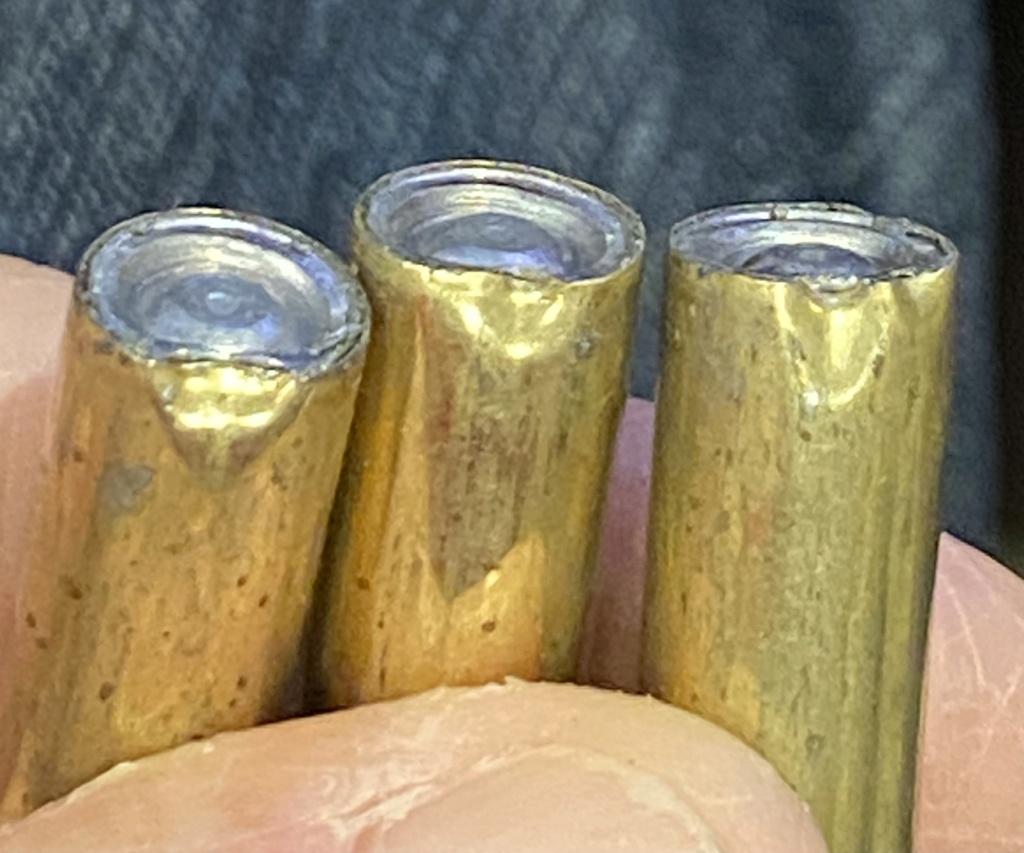

It may or may not be a clue, but when I scrape off the lead on the outside of the cartridge, it's obvious that the brass case has been pushed inward. Here's a photo of three cases, after I removed the lead that covered the "dent":

Jay, at Redding, told me part of my problem is the custom "seater" that RCBS made for me isn't right, as it flattens the small "bump" in the middle of the end of the #514 bullet. Jay says by doing this, it is forcing lead outwards, where it eventually can hit the upper edge of the brass case, causing the problem. By this time next week, my new die will arrive, and Jay also tells me if I send him a few sample #514 bullets, he can machine a "pusher" designed specifically for this bullet.

The problem is more "annoying" than anything else. If I load 50 rounds, three of them are damaged. The others shoot fine. I occasionally had a similar problem three years ago, when I was loading 38 Special. I figured the problem was me, not placing the bullet perfectly vertical on the 38 Special case, so I've been much more careful. I plan to test some rounds to load using Case Lube, and see if that makes a difference.

(I seated the bullet slightly deeper than needed, as I was planning on using a Profile roll crimp die. Since then I've read that I should use a Taper Crimp Die.

I've mostly got my reloading press changed over to 38 Special, but I've got some new dies on the way. I'm puzzled by something that's been going on, wondering if someone here can suggest what the problem might be.

If I load 50 rounds, using my old Remington cases (I thought I would start with those, before I use my new Starline cases), one or two rounds ends up with some lead on the outside of the case. My best guess is that some lead is being scraped off the lead bullet (Magnus #514) as it is being seated.

I've re-adjusted the belling, so there's just enough to start the bullet going in straight. As a test, I increased the amount of belling, which made things worse, so I put the expander back to the way Jay at Redding told me to do it - just enough bell to allow the lead bullet to get started.

(I have a feeling that I should expand the bullet even more, so the case can't contact the side of the bullet and scrape off lead....... but that's not what Jay suggests I do, when I get the new dies. The current seater die is RCBS, with the "pusher" reduced slightly in diameter where it touches the bullet. I don't think it's right that the seater is pushing on the tiny "bump" on the end of the bullet - doesn't sound right to me.....)

It may or may not be a clue, but when I scrape off the lead on the outside of the cartridge, it's obvious that the brass case has been pushed inward. Here's a photo of three cases, after I removed the lead that covered the "dent":

Jay, at Redding, told me part of my problem is the custom "seater" that RCBS made for me isn't right, as it flattens the small "bump" in the middle of the end of the #514 bullet. Jay says by doing this, it is forcing lead outwards, where it eventually can hit the upper edge of the brass case, causing the problem. By this time next week, my new die will arrive, and Jay also tells me if I send him a few sample #514 bullets, he can machine a "pusher" designed specifically for this bullet.

The problem is more "annoying" than anything else. If I load 50 rounds, three of them are damaged. The others shoot fine. I occasionally had a similar problem three years ago, when I was loading 38 Special. I figured the problem was me, not placing the bullet perfectly vertical on the 38 Special case, so I've been much more careful. I plan to test some rounds to load using Case Lube, and see if that makes a difference.

(I seated the bullet slightly deeper than needed, as I was planning on using a Profile roll crimp die. Since then I've read that I should use a Taper Crimp Die.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

'dcforman', do you have a link to where I can find this die on his website?Dcforman wrote:I'm surprised no one has mentioned PhotoEscape's expander. It honestly works better than any of the above mentioned expanders. Designed for Dillons, but you can purchase his universal die for the expander that will fit most presses.........

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Thank you for posting the above - nice to know the reason for this. Now that I read your post, it almost feels "obvious" - but it sure wan't five minutes ago!Dcforman wrote:Took me a minute to find this...

"One of the secrets to lead, is to form the brass to accept 90% of the bullet with only mild finger pressure.. The long 38 Hollow base wad cutters are approx. .580 long..Here I am loading PENN double end solids, which are approx .525 All but about .050 should slide into the case with ease.. No force..to prevent sizing the bullet down below bore diameter. The only dies I ever saw designed specifically for the long 38 wad cutters were the now extinct CH Auto Champ. This Dillion punch is custom ground.." Jerry Keefer

Of course, Jerry passed before AP released his version.

Dave

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

https://www.photoescapeinc.com/products/powder-funnel-wadcutter38.html

If you aren't using a Dillon, you'll probably need this:

https://www.photoescapeinc.com/products/single-stage-powder-die-kit.html

If you aren't using a Dillon, you'll probably need this:

https://www.photoescapeinc.com/products/single-stage-powder-die-kit.html

Dcforman- Posts : 928

Join date : 2017-11-18

Age : 43

Location : Ohio

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Note that I run a Hornady LNL, and just use the above combo as a straight expander die.

Dcforman- Posts : 928

Join date : 2017-11-18

Age : 43

Location : Ohio

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Side note:

When I first posted this thread, it was because I was shaving lead and bending the end of the brass case while using the Redding expander die I bought.

I think all of you have convinced me that the reason for the problem is that either my 38 Special case is not being expanded enough, or that my Redding die is not appropriate for what I'm trying to do.

The RCBS die that I photographed has been used on my various presses for 30 years or so. I can now see it will work better for me than the Redding. (I'll call Jay at Redding to discuss this, and I'll call RCBS to get the longer version of the expander.). In the meantime, I'm going back to the reloading room and will re-install my RCBS die for now.

My problems were shaving lead, and damaging the brass. If the RCBS die fixes this, great. .....and it will be even better when I get the longer version, which I will order as soon as I find out a part number for it, so I can order it.

This discussion has now gone way beyond that. I'm beginning to understand that I may get better accuracy if I avoid squishing the bullet, making it too small for my bore. I would prefer to accomplish that too, but it's not my main goal as of right now.

Finally, whatever I do, the rounds I make need to fit in both my Model 52 and in my Colt and SW revolvers. I don't want to make a change that makes my cartridges more accurate for the Model 52, at the expense of not working in my revolvers. This was brought up in one of the discussions.

When I first posted this thread, it was because I was shaving lead and bending the end of the brass case while using the Redding expander die I bought.

I think all of you have convinced me that the reason for the problem is that either my 38 Special case is not being expanded enough, or that my Redding die is not appropriate for what I'm trying to do.

The RCBS die that I photographed has been used on my various presses for 30 years or so. I can now see it will work better for me than the Redding. (I'll call Jay at Redding to discuss this, and I'll call RCBS to get the longer version of the expander.). In the meantime, I'm going back to the reloading room and will re-install my RCBS die for now.

My problems were shaving lead, and damaging the brass. If the RCBS die fixes this, great. .....and it will be even better when I get the longer version, which I will order as soon as I find out a part number for it, so I can order it.

This discussion has now gone way beyond that. I'm beginning to understand that I may get better accuracy if I avoid squishing the bullet, making it too small for my bore. I would prefer to accomplish that too, but it's not my main goal as of right now.

Finally, whatever I do, the rounds I make need to fit in both my Model 52 and in my Colt and SW revolvers. I don't want to make a change that makes my cartridges more accurate for the Model 52, at the expense of not working in my revolvers. This was brought up in one of the discussions.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Follow-up on this thread.

The press is back together, with the RCBS expander die in place, just barely belling out the top of the case. I loaded 25 rounds, of which 23 went through the press smoothly and came out perfect. Two of them took more pressure to seat - if I was smarter, I'd have pulled those off to the side, to deal with them later. All the others were easy to do.

Those two rounds were shaving off lead - that explains the extra pressure. I don't know how well the case length is controlled on Federal ammo. That's the first thing (really, the only thing) I could think of, as to why those two rounds didn't seat down into the seating die as easily as the others - not enough bell for them. I guess I can measure all the Federal case lengths. Or, I could put them all off to the side, and switch to my new Starline cases. I was going to wait on that until everything was going perfectly.

Thanks to all of you, things are going infinitely better than just 24 hours ago! Time for bed.

The press is back together, with the RCBS expander die in place, just barely belling out the top of the case. I loaded 25 rounds, of which 23 went through the press smoothly and came out perfect. Two of them took more pressure to seat - if I was smarter, I'd have pulled those off to the side, to deal with them later. All the others were easy to do.

Those two rounds were shaving off lead - that explains the extra pressure. I don't know how well the case length is controlled on Federal ammo. That's the first thing (really, the only thing) I could think of, as to why those two rounds didn't seat down into the seating die as easily as the others - not enough bell for them. I guess I can measure all the Federal case lengths. Or, I could put them all off to the side, and switch to my new Starline cases. I was going to wait on that until everything was going perfectly.

Thanks to all of you, things are going infinitely better than just 24 hours ago! Time for bed.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Apology - I must be a very slow learner - I can't think of a better "excuse". I asked about this same topic back in 2015:

https://www.thehighroad.org/index.php?threads/expanding-38-special-cases.776285/

There's an obvious answer, which was suggested back then - if lead is being scraped off the bullet, just open the bell a little more until that stops. For me, that's now two cases out of 50. Maybe 1/8 turn of the "plug", and it that's not enough, another.

I'll still try to get some of the better parts recommended here, but I no longer feel frustrated, like I did just a few days ago.

https://www.thehighroad.org/index.php?threads/expanding-38-special-cases.776285/

There's an obvious answer, which was suggested back then - if lead is being scraped off the bullet, just open the bell a little more until that stops. For me, that's now two cases out of 50. Maybe 1/8 turn of the "plug", and it that's not enough, another.

I'll still try to get some of the better parts recommended here, but I no longer feel frustrated, like I did just a few days ago.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Jay suggested I buy things, that just arrived today.SingleActionAndrew wrote:Mike your mention of Jay at Redding and custom bullet "pushers" has me intrigued/concerned.

I have their competition seating die for 45acp and was going to set it up this weekend. I have a couple thousand of both Hornady XTP jacketed and Zero SWC lead. I assume the seater die is intended for the JHP. Does Redding already make a different "pusher" for SWC? I haven't seen such a thing in the catalog but I could be in the wrong section. I have the shouldered + truncated cone profile on the Zero SWCs. Or since it has the cone already, might the standard "pusher" in the redding seating die be appropriate for both bullets?

If I should order a custom "pusher" how do we reach Jay? I have to imagine this is a path well trodden ...

First was the "Competition Pro Die Set" including the micrometer seating die, and then, to avoid damaging the ends of my #514 Magnus Bullets, was the "Redding Part #55092 Comp Handgun Seat Stem. Larry at RCBS made me a special seater to work with those bullets, but it always crushes the small point on the end of the bullet. The Redding seat stem pushes around the circumference - the center area is recessed. (I got the kit because it comes with a better resize/decapper die than the ancient one I've been using.) I bought the 45 version last year, and like it.

Reaching Jay is very easy - just call the main number for Redding Reloading, 607 753-3331 and ask for Tech Support. Jay and Don are both great people to work with, and they have all the right answers, as long as I ask the right questions. I still need to call them because the expansion die I bought seems to be too small for the #514 bullets.

I'd rather they tell you what's what, rather say much more myself. As for seating bullets, they may ask you to send some bullets, so they can advise you on what part to use, or perhaps make a custom pusher as they did for me, for 45.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

SingleActionAndrew likes this post

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

I spoke with Jay - very kind and knowledgeable gentleman. Thanks for his contact info Mike.

For 45acp and for the competition seating die they do not make a specific stem for semi-wadcutters. He instead suggested acquiring an additional 55084 seating stem and filling it with hot glue to seat the flat nose SWCs

For 45acp and for the competition seating die they do not make a specific stem for semi-wadcutters. He instead suggested acquiring an additional 55084 seating stem and filling it with hot glue to seat the flat nose SWCs

SingleActionAndrew- Admin

- Posts : 675

Join date : 2019-11-19

Location : IL, USA

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Great - Larry at RCBS Tech Support and both Jay and Don at Redding are good people to talk to. Gradually, all my dies for 45 became Redding, and the same thing seems to be happening with 38 dies for Model 52 food. I just received this:

https://redding-reloading.com/online-catalog/16-competition-pro-series-die-sets

My new Redding "38 SPL 357 MAG TIC 9U" Titanium Carbide die will be installed later today, as soon as I get it cleaned.

One of its case mates, a "38 SPL / 357 COMP ST 0" micrometer seating die will installed next.

They came with a "38 / 357 MAG PRO CR G0" Profile Crimp Die.

I need to look up all the information, before I install anything. So far what I've been reading about the Model 52 reloading suggests using a taper crimp die, not a profile (roll) crimp die. The die in my crimping station (my other press) is a taper crimp die. I think I'll try both, and see if it makes any difference for me.

https://redding-reloading.com/online-catalog/16-competition-pro-series-die-sets

My new Redding "38 SPL 357 MAG TIC 9U" Titanium Carbide die will be installed later today, as soon as I get it cleaned.

One of its case mates, a "38 SPL / 357 COMP ST 0" micrometer seating die will installed next.

They came with a "38 / 357 MAG PRO CR G0" Profile Crimp Die.

I need to look up all the information, before I install anything. So far what I've been reading about the Model 52 reloading suggests using a taper crimp die, not a profile (roll) crimp die. The die in my crimping station (my other press) is a taper crimp die. I think I'll try both, and see if it makes any difference for me.

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

This is handy for seating wadcutters in a Redding Competition Seating die:

Waductter Seating Stem

Waductter Seating Stem

saread- Posts : 11

Join date : 2011-06-12

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

yes, that will work. just make sure it doesn't contact the case mouth then you've gone too far.

james r chapman- Admin

- Posts : 6372

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Uh oh, this is interesting. With the amount of bell I now make on the case, the #514 bullets drop in easily. As long as the Redding die keeps everything concentric, the pusher will also easily fit into the case bell. If the case, the bullet, the die, and the pusher are not concentric, this could be a problem. I'd like to think they've taken all this into account, and it will work as intended. Maybe that's wishful thinking?james r chapman wrote:yes, that will work. just make sure it doesn't contact the case mouth then you've gone too far.

The bullet can't protrude beyond the case mouth, or it won't feed into the the gun.

Has anyone reading this stuff already done this? Were there any issues?

Maybe that's why they added the micrometer adjustment on top?

mikemyers- Posts : 4236

Join date : 2016-07-26

Age : 80

Location : South Florida, and India

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Dcforman wrote:I'm surprised no one has mentioned PhotoEscape's expander. It honestly works better than any of the above mentioned expanders. Designed for Dillons, but you can purchase his universal die for the expander that will fit most presses. Cured basically all my problems.

For a seater, I just use the flat seater that came with my RCBS die and fixed a small piece of jb weld to the end. Pressed a hbwc bullet into it, made sure it was straight, and let it cure. I think I just used gun oil as a release compound. Works a treat.

Dave

Dave,

What kind of press do you have? I just ordered PhotoEscape's PT expander and his whole powder die, but I don't know how to switch it out on my Hornady LnL. PhotoEscape doesn't have a Hornady press, so he can't be of much help.

Does anyone having a Hormady press use his powder drop die? Can you help me figure out how to install it?

Thanks!

Val

valbern67- Posts : 278

Join date : 2018-09-04

Location : Norman, OK

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Hey Val!

Though it's designed as a powder through expander, I just use it in my Hornady LNL as a straight expander die. So my five stations are:

1. Resizer/deprimer

2. PhotoEscape's expander

3. Powder dropper

4. Seater

5. Crimp

I do not use a powder cop. I just verify the powder amount before placing a bullet.

Hope this helps!

Dave

Though it's designed as a powder through expander, I just use it in my Hornady LNL as a straight expander die. So my five stations are:

1. Resizer/deprimer

2. PhotoEscape's expander

3. Powder dropper

4. Seater

5. Crimp

I do not use a powder cop. I just verify the powder amount before placing a bullet.

Hope this helps!

Dave

Dcforman- Posts : 928

Join date : 2017-11-18

Age : 43

Location : Ohio

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

I should mention that he does have an adapter if you want to use the expander with the stock Hornady powder dispenser!

Dave

Dave

Dcforman- Posts : 928

Join date : 2017-11-18

Age : 43

Location : Ohio

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Dcforman wrote:I should mention that he does have an adapter if you want to use the expander with the stock Hornady powder dispenser!

Dave

Hey Dave,

I bought the entire powder drop die and expander, but need some help in figuring out how to replace the stock Hornady powder die.

Or maybe I'll do it the way you have yours configured....Can you send me a photo of your die setup on your press? What do you have to remove in order to jst drop the powder?

Or if anyone else has a Hornady LnL with PhotoEscape's powder die/expander, please help!

Val

valbern67- Posts : 278

Join date : 2018-09-04

Location : Norman, OK

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Hey Val!

I'll post a photo tomorrow morning!

Dave

I'll post a photo tomorrow morning!

Dave

Dcforman- Posts : 928

Join date : 2017-11-18

Age : 43

Location : Ohio

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

I believe this would solve your problem. https://www.uniquetek.com/product/T1735

38 Special Powder Funnels

I have spoken to Lee many times there and he is awesome!

38 Special Powder Funnels

I have spoken to Lee many times there and he is awesome!

Boston Bill- Posts : 9

Join date : 2020-03-07

Age : 69

Location : Cape Cod

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

Boston Bill wrote:I believe this would solve your problem. https://www.uniquetek.com/product/T1735

38 Special [size=33]Powder Funnels[/size]

I have spoken to Lee many times there and he is awesome!

Those are actually made by PhotoEscape!

Dave

Dcforman- Posts : 928

Join date : 2017-11-18

Age : 43

Location : Ohio

Re: Seating lead bullets on a progressive press

Re: Seating lead bullets on a progressive press

valbern67 wrote:Dcforman wrote:I should mention that he does have an adapter if you want to use the expander with the stock Hornady powder dispenser!

Dave

Hey Dave,

I bought the entire powder drop die and expander, but need some help in figuring out how to replace the stock Hornady powder die.

Or maybe I'll do it the way you have yours configured....Can you send me a photo of your die setup on your press? What do you have to remove in order to jst drop the powder?

I posted some pictures in this thread: https://www.bullseyeforum.net/t15843-hornady-lnl-with-photoescape-powder-die-expander

Note, I was trying to use it as an expander and powder drop, using the threaded top cap as a hard stop for belling. I'm also loading 45 with it, although the original post was for 38.

First step to see if 'you' can do it for 38: Put the adapter in the top cap, and put the expander on the end of it. Line it up eyeball close to straight and measure the distance between the cap and expander. Mine is about .450 (45 HTC).

The measure 'needs' .550 travel to fully cycle. If you don't have that much in the die, you can adjust it all to center the travel of the measure. I don't want to run mine that way, but it's your choice.

Otherwise ... If you put the Hornady clamp on the PE die, the ring in the clamp fits in the groove of the die, the clamp will extend past the top of the die body. The 1/2" tall spacer that came with the adapter is undersize and will drop in there. Using it negates the hard stop for the expander, so you'll have to use the PTX stop linkage instead. Otherwise, I think the setup of it will be just like the Hornady die, adjusting the die up or down until the measure travel works out. And then set the stop for the proper bell. Maybe a tweak here and there after that.

WesG- Posts : 714

Join date : 2018-09-21

Location : Cedar Park, TX - N CA

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Primer Seating in Progressive Press

» Seating die for lead bullets

» Lead SWC Bullets: Case belling and seating question

» Progressive press due order

» Progressive press suggestion?

» Seating die for lead bullets

» Lead SWC Bullets: Case belling and seating question

» Progressive press due order

» Progressive press suggestion?

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum