Purpose of Hard Cast Hollow Base Wadcutters?

+6

WesG

javaduke

8eightring

Wobbley

fc60

lmyer

10 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Purpose of Hard Cast Hollow Base Wadcutters?

Purpose of Hard Cast Hollow Base Wadcutters?

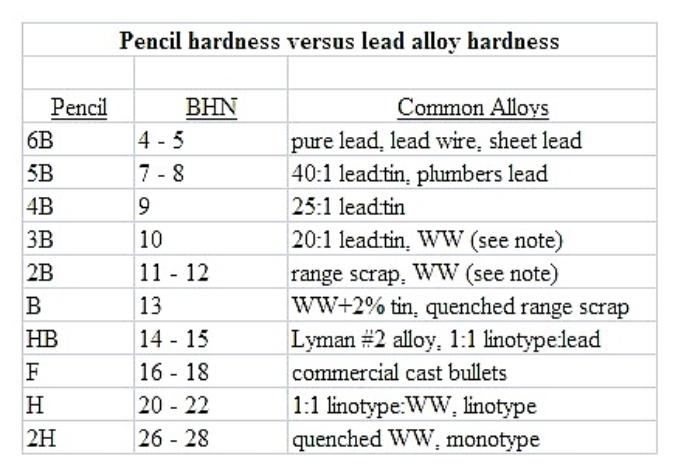

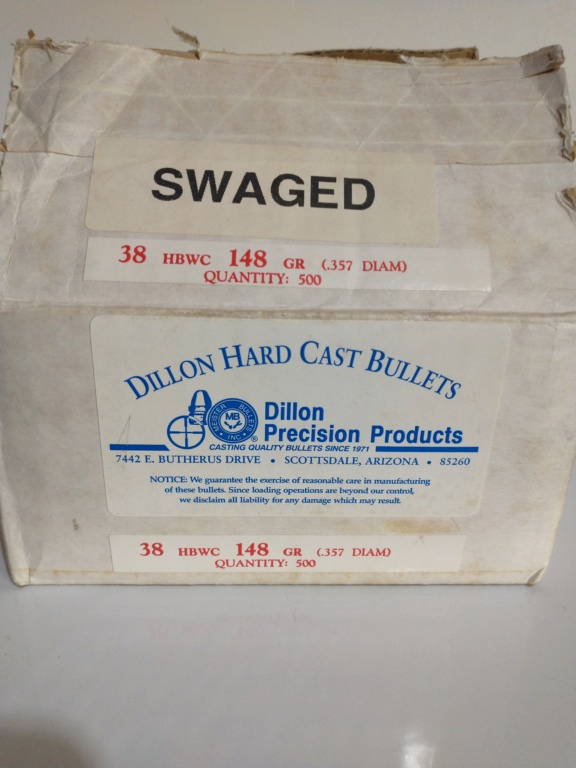

I have come into some older 0.357" Dillon Hard Cast HBWC. Test as BHN=16 using an artist's pencil set to scratch the lead.

Thought there was chance of the base breaking off if you push HBWC too fast and the purpose of the hollow base was to expand to seal the barrel better at lower pressures. So what is the purpose of casting them BHN=16? Should these be pushed faster than soft lead?

The Hornady HBWC I typically use are 0.358" and much softer lead and go 725fps in my Colt Officers 2nd issue (7.5" barrel) using 2.8gr. Bullseye. Really don't want to push the old revolver any more than that. I suppose I could shoot them faster in my S&W 586, but I already have a 158gr SWC load and 2000 bullets for it. Big question is what to do with these Dillon bullets?? I already have plenty of Hornady HBWCs on hand.

Thought there was chance of the base breaking off if you push HBWC too fast and the purpose of the hollow base was to expand to seal the barrel better at lower pressures. So what is the purpose of casting them BHN=16? Should these be pushed faster than soft lead?

The Hornady HBWC I typically use are 0.358" and much softer lead and go 725fps in my Colt Officers 2nd issue (7.5" barrel) using 2.8gr. Bullseye. Really don't want to push the old revolver any more than that. I suppose I could shoot them faster in my S&W 586, but I already have a 158gr SWC load and 2000 bullets for it. Big question is what to do with these Dillon bullets?? I already have plenty of Hornady HBWCs on hand.

lmyer- Posts : 18

Join date : 2021-01-18

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Greetings,

I hear that Dillon offer excellent Customer Service.

Telephone them and ask their loading suggestions.

Cheers,

Dave

I hear that Dillon offer excellent Customer Service.

Telephone them and ask their loading suggestions.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

I’ve had SOME experience with PLATED HBWC in my 52. Now a 52 barrel,isn’t a revolver nor is a plated bullet as hard as a 16 BHN. But they did shoot about what was expected from a plated bullet. I had uncalled flyers. In the 8 ring. I no longer shoot plated unless indoor range regs require it. Most are ok with coated so that’s what I shoot.

These hard cast HBWC may just shoot ok. I don’t think they were “barn burners” when they were made, but they’d be good practice ammo.

These hard cast HBWC may just shoot ok. I don’t think they were “barn burners” when they were made, but they’d be good practice ammo.

Wobbley- Admin

- Posts : 4808

Join date : 2015-02-12

Powder charge adjustment.

Powder charge adjustment.

Did you have to adjust the powder charge from the swaged HBWC when shooting the plated bullets? I have some of the plated HBWC bullets and didn't know if I should use the same 2.7 Bullseye or adjust up or down.Wobbley wrote:I’ve had SOME experience with PLATED HBWC in my 52. Now a 52 barrel,isn’t a revolver nor is a plated bullet as hard as a 16 BHN. But they did shoot about what was expected from a plated bullet. I had uncalled flyers. In the 8 ring. I no longer shoot plated unless indoor range regs require it. Most are ok with coated so that’s what I shoot.

These hard cast HBWC may just shoot ok. I don’t think they were “barn burners” when they were made, but they’d be good practice ammo.

8eightring- Posts : 193

Join date : 2011-06-16

Location : Ohio

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Hi Dave,fc60 wrote:Greetings,

I hear that Dillon offer excellent Customer Service.

Telephone them and ask their loading suggestions.

Cheers,

Dave

I tried calling their customer service for info some time ago. Guy really didn't understand the product I was taking about. Dillon doesn't sell them any more and apparently the Dillon name was just a re-label thing.

lmyer- Posts : 18

Join date : 2021-01-18

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

FWIW I don't think you should push them any faster than any swaged HBWCs, try loading the same 2.7-2.8gr BE and see how they group at 50 yards.

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Try 2.7 and see. I tent to “fluctuate” between 2.8 and 2.6 depending on whim, it seems as there’s no rhyme or reason but I’ve not seen any appreciable change in zero at 25yds. I wouldn’t exceed 2.9.8eightring wrote:Did you have to adjust the powder charge from the swaged HBWC when shooting the plated bullets? I have some of the plated HBWC bullets and didn't know if I should use the same 2.7 Bullseye or adjust up or down.Wobbley wrote:I’ve had SOME experience with PLATED HBWC in my 52. Now a 52 barrel,isn’t a revolver nor is a plated bullet as hard as a 16 BHN. But they did shoot about what was expected from a plated bullet. I had uncalled flyers. In the 8 ring. I no longer shoot plated unless indoor range regs require it. Most are ok with coated so that’s what I shoot.

These hard cast HBWC may just shoot ok. I don’t think they were “barn burners” when they were made, but they’d be good practice ammo.

Wobbley- Admin

- Posts : 4808

Join date : 2015-02-12

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Honestly, these were emergency bullets from a year ago when I couldn't get the Hornady or Speer bullets I normally used. I did find some Hornadys within days after buying these, so I never have shot them. I'm mostly curious why a manufacturer would cast HBWC out of such hard lead - in what case do these make sense? Doesn't harder lead defeat the purpose of the hollow base at lower pressures/velocities. Wouldn't a DEWC be safer to shoot if one is to take advantage of harder lead and higher pressure/velocities.

Someone said they thought these were re-branded zero bullets, but I'm not seeing it. Zero bullets have lube in all three grooves and they claim they are swaged. Anyone know the hardness of Zero bullets?

lmyer- Posts : 18

Join date : 2021-01-18

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Those aren’t cast, IMO. They may be “hard” but I don’t think they’re cast. Reason: there’s no sprue. They were likely swaged, perhaps from cast “slugs”.

Try to indent the side of a bullet with a thumbnail, at 16 BHN it won’t be deep. I’m not sure the amount of lube is sufficient, to be honest. You may have to apply a coating of Lee liquid Alox, which is easy to do.

Try to indent the side of a bullet with a thumbnail, at 16 BHN it won’t be deep. I’m not sure the amount of lube is sufficient, to be honest. You may have to apply a coating of Lee liquid Alox, which is easy to do.

Wobbley- Admin

- Posts : 4808

Join date : 2015-02-12

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

I can scratch the bullet if I really try with my fingernail, and draw it across with lots of pressure. Pressing hard on the side without drawing across really doesn't do much of anything.Wobbley wrote:Those aren’t cast, IMO. They may be “hard” but I don’t think they’re cast. Reason: there’s no sprue. They were likely swaged, perhaps from cast “slugs”.

Try to indent the side of a bullet with a thumbnail, at 16 BHN it won’t be deep. I’m not sure the amount of lube is sufficient, to be honest. You may have to apply a coating of Lee liquid Alox, which is easy to do.

I used a set of Artist's pencils when I checked it originally. Took an "F" pencil to scratch the Dillon. The Hornady HBWC scratched with a 3B, as expected. So chart and method appears to be reasonably accurate.

lmyer- Posts : 18

Join date : 2021-01-18

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

The unlubed groove is knurled. So I'm thinking Wobbley is right in them being swaged.

WesG- Posts : 715

Join date : 2018-09-21

Location : Cedar Park, TX - N CA

chopper and Chase Turner like this post

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

That unlubed groove actually looks like a cannelure . Which would make that a revolver round . The skirt looks massive too . I'm thinking it's a self defence training/ inexpensive round . That's my WAG .

LenV- Posts : 4770

Join date : 2014-01-24

Age : 74

Location : Oregon

Chase Turner likes this post

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

If those are what I think they are, that bullet was made back when Meister Cast was local to Dillon in AZ, long before the move to MO. You could call Meister and see what they say- I don't know if they have the same ownership today as they did back @ 2000, which is about when I remember seeing these in a Blue Press. Of course, my memory could be wrong, but these are probably close to 20 years old.

I'm not sure why you're worried about shooting them. Try loading them with 2.8 of WST or BE and see how they do? I don't believe you'd hurt anything in trying that, I really don't.

Alternatively, if you would like to sell them, I'd be happy to purchase them from you. Feel free to send me a PM.

I'm not sure why you're worried about shooting them. Try loading them with 2.8 of WST or BE and see how they do? I don't believe you'd hurt anything in trying that, I really don't.

Alternatively, if you would like to sell them, I'd be happy to purchase them from you. Feel free to send me a PM.

Chase Turner- Posts : 385

Join date : 2019-11-15

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

lmyer wrote:

Honestly, these were emergency bullets from a year ago when I couldn't get the Hornady or Speer bullets I normally used. I did find some Hornadys within days after buying these, so I never have shot them. I'm mostly curious why a manufacturer would cast HBWC out of such hard lead - in what case do these make sense? Doesn't harder lead defeat the purpose of the hollow base at lower pressures/velocities. Wouldn't a DEWC be safer to shoot if one is to take advantage of harder lead and higher pressure/velocities.

Someone said they thought these were re-branded zero bullets, but I'm not seeing it. Zero bullets have lube in all three grooves and they claim they are swaged. Anyone know the hardness of Zero bullets?

Those aren't Zero bullets; Zeros have two lube grooves, not three. Additionally, Zero has a greenish tint to their lube- it is not red.

Also, Zero is a swaged bullet. It isn't a claim. They are swaged. No idea about hardness, but they are quite soft.

Chase Turner- Posts : 385

Join date : 2019-11-15

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

To follow up on these mystery bullets: I spoke with my contact at Dillon about them, and he went and found a long tenured employee, who as it happens, still also happens to have some of these about his reloading bench. It turns out, these were in fact cast first (which explains the alloy hardness) and then swaged for uniformity (which seems like you'd want a not so hard alloy; no idea what kind of machinery was involved; also don't know the rationale behind the seemingly additional step) of size.

So, they are indeed both. A modern Frankenstein of a bullet, if there is one.

Thanks,

Chase

So, they are indeed both. A modern Frankenstein of a bullet, if there is one.

Thanks,

Chase

Chase Turner- Posts : 385

Join date : 2019-11-15

troystaten and Slamfire like this post

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Chase,

We call it sizing, not swaging, a cast bullet. It is done all the time.

Don

We call it sizing, not swaging, a cast bullet. It is done all the time.

Don

USSR- Posts : 352

Join date : 2017-07-14

Age : 74

Location : Finger Lakes Region of NY

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Has to be swaged in some way. No way to get it out of a mold with both ends being 'hollow'.

I'm still thinking cast slug, swaged to shape, lube grooves rolled in.

I'm still thinking cast slug, swaged to shape, lube grooves rolled in.

WesG- Posts : 715

Join date : 2018-09-21

Location : Cedar Park, TX - N CA

Chase Turner likes this post

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

USSR wrote:Chase,

We call it sizing, not swaging, a cast bullet. It is done all the time.

Don

Don,

I'm merely relating what Dillon told me. If you don't like the way they explained it, or what they were doing 20 years ago with a third party caster, by all means, take it up with them. I guess they just put "swaged" on the box in the photo for fun. People do that all the time.

-Chase

Last edited by Chase Turner on 11/14/2021, 4:09 pm; edited 1 time in total (Reason for editing : photo uploaded)

Chase Turner- Posts : 385

Join date : 2019-11-15

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Chase,

I question the old guy at Dillon's memory. Simply does not make sense to swage cast bullets. And, to swage bullets that hard would be EXTREMELY hard on the machinery.

Don

I question the old guy at Dillon's memory. Simply does not make sense to swage cast bullets. And, to swage bullets that hard would be EXTREMELY hard on the machinery.

Don

USSR- Posts : 352

Join date : 2017-07-14

Age : 74

Location : Finger Lakes Region of NY

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

You can get “cold header” machines that will cold forge a hex head on a 3/8 stainless steel bolt at 200 per minute. Swaging a hard lead alloy is easy, with only concern being keeping the cold flow under control.

Wobbley- Admin

- Posts : 4808

Join date : 2015-02-12

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Actually, it's not that easy, and that's why swaging lead is relatively soft lead. And commercial swagers use lead wire and not individual bullets. Again, this makes no sense.

Don

Don

USSR- Posts : 352

Join date : 2017-07-14

Age : 74

Location : Finger Lakes Region of NY

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Greetings,

Measure the hardness of some commercial "swaged" bullets.

They are not made of Pure Lead, 5 HBN.

The Remington I have measure 6 HBN.

I swage my bullets out of Lead alloy that measures 6 HBN. I first cast little cylinders prior to swaging.

I suspect the "hard cast" swaged bullets were to appeal to those that drink the "hard cast" KoolAid.

"Hard Cast" is not necessarily your friend.

Cheers,

Dave

Measure the hardness of some commercial "swaged" bullets.

They are not made of Pure Lead, 5 HBN.

The Remington I have measure 6 HBN.

I swage my bullets out of Lead alloy that measures 6 HBN. I first cast little cylinders prior to swaging.

I suspect the "hard cast" swaged bullets were to appeal to those that drink the "hard cast" KoolAid.

"Hard Cast" is not necessarily your friend.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

fc60 wrote:Greetings,

Measure the hardness of some commercial "swaged" bullets.

They are not made of Pure Lead, 5 HBN.

The Remington I have measure 6 HBN.

I swage my bullets out of Lead alloy that measures 6 HBN. I first cast little cylinders prior to swaging.

I suspect the "hard cast" swaged bullets were to appeal to those that drink the "hard cast" KoolAid.

"Hard Cast" is not necessarily your friend.

Cheers,

Dave

Dave,

You got me to thinking about the hardness of these bullets. I think they are probably pretty hard; but I'm not sure they are as hard as OP tested. I'm able to scratch them with a 2B Mitsubishi 9800 pencil. I don't have any 3B pencils to use to test, but these probably are at least 2B or maybe even 3B to scratch.

For reference, the Zero's I have also scratch with a 2B, but it is much easier to do with them. This indicates these are harder than the Zero's, but not by how much.

Also, do you happen to know of, or heard of any hollow base molds that would be used in a commercial casting operation? The only cast 38 wadcutter production molds I'm familiar with are solids- either DEWC or BNDEWC.

Thanks,

Chase

Chase Turner- Posts : 385

Join date : 2019-11-15

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

WesG wrote:Has to be swaged in some way. No way to get it out of a mold with both ends being 'hollow'.

I'm still thinking cast slug, swaged to shape, lube grooves rolled in.

I agree- even if we wanted to believe that these bullets were cast on their side, and sizing mostly removed the sprue, there'd still be evidence of these being cast. There isn't any evidence of such.

Also agree on the problem of the two concave ends. How does the automated casting machine mold fill these both out in one pass?

Believe that is a reasonable guess on construction, and certainly fits the evidence we have.

Chase Turner- Posts : 385

Join date : 2019-11-15

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Re: Purpose of Hard Cast Hollow Base Wadcutters?

Greetings Chase,

No knowledge of commercial moulds for casting HBWC. Due to the design of the casting machines, I would think ejecting a hollow base bullet would be difficult due to the hollow base pins.

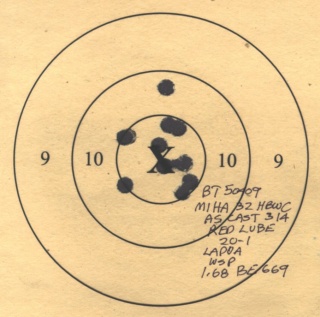

I have owned two HBWC moulds (32 and 38) they were difficult to fill out the hollow base well. Rejection rate was very high. I was using 20:1 alloy which flows very well.

The good ones did shoot rather well at 50 yards.

Cheers,

Dave

No knowledge of commercial moulds for casting HBWC. Due to the design of the casting machines, I would think ejecting a hollow base bullet would be difficult due to the hollow base pins.

I have owned two HBWC moulds (32 and 38) they were difficult to fill out the hollow base well. Rejection rate was very high. I was using 20:1 alloy which flows very well.

The good ones did shoot rather well at 50 yards.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Wadcutters vs. hollow point

» Rem hollow base wc, 38 spl..........

» hollow base wad cutters 38 cal ?

» Any experience with Berry's Hollow Base bullets?

» berrys 83gn plated hollow base double stamped

» Rem hollow base wc, 38 spl..........

» hollow base wad cutters 38 cal ?

» Any experience with Berry's Hollow Base bullets?

» berrys 83gn plated hollow base double stamped

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum