Lyman 452389

+2

troystaten

fc60

6 posters

Page 1 of 1

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

troystaten, Hawkja and shanneba like this post

Re: Lyman 452389

Re: Lyman 452389

That is pretty impressive. Just goes to show you, until you try it you don't always know how something will work.

troystaten- Posts : 824

Join date : 2012-04-18

Re: Lyman 452389

Re: Lyman 452389

I have a mold for that bullet and have been thinking about casting some and trying them out!

onlylead- Posts : 100

Join date : 2016-12-31

Age : 60

Location : Amarillo tx

Re: Lyman 452389

Re: Lyman 452389

Greetings,

It is good to document your process.

Sadly, I have no clue as to the exact composition of the bullet alloy. The SAECO hardness tester translated to 22 Brinell; so, I suspect I cast them out of LinoType.

For some reason I sold the mould. Oh well, I have done sillier things in my years....

Cheers,

Dave

It is good to document your process.

Sadly, I have no clue as to the exact composition of the bullet alloy. The SAECO hardness tester translated to 22 Brinell; so, I suspect I cast them out of LinoType.

For some reason I sold the mould. Oh well, I have done sillier things in my years....

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Lyman 452389

Re: Lyman 452389

I have some of those and they did work well for some reason but I didn't spend a lot of time with them. Maybe b/c it was a 2cavity mould. They're better than the #130 Or #163 H&G moulds

4.1 of TG? Zippy?

4.1 of TG? Zippy?

Re: Lyman 452389

Re: Lyman 452389

Greetings,

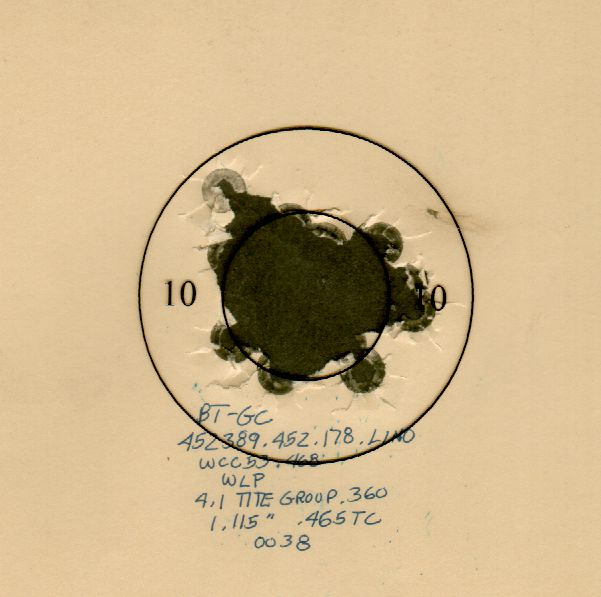

Technical data for the test group.

Cheers,

Dave

Technical data for the test group.

Cheers,

Dave

- Attachments

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

troystaten and SingleActionAndrew like this post

Re: Lyman 452389

Re: Lyman 452389

Thanks Dave, do you think you could maintain accuracy at a lower velocity?

Thanks

Thanks

troystaten- Posts : 824

Join date : 2012-04-18

Re: Lyman 452389

Re: Lyman 452389

I found that the #130 had to go fast to work well too.

Thanks

Thanks

troystaten likes this post

Re: Lyman 452389

Re: Lyman 452389

Back in the day, Ellis Lea (former Army Pistol Team Captain) used to use this bullet in his S&W 1955 in an Auto-Rim case with 3.3gr of Bullseye at 25 and 3.5gr at 50. His alloy was 85% lead, 10% antimony and 5% tin.

NukeMMC- Posts : 564

Join date : 2018-10-12

SingleActionAndrew likes this post

Re: Lyman 452389

Re: Lyman 452389

Greetings,

Testing is the only way to find out if the bullet will stay stable at different velocities.

I sold the mould, so no more testing on my end.

Regarding the H&G 130, I had the best group loading 3.9 Bullseye with a LinoType bullet @ 730 FPS.

COL Ellis Lea, my Father-in-Law shot with him in the 1950's. They, the Army team, won the Hard Ball Team match at Camp Perry and the photo is in an old American Rifleman.

The alloy you quoted (85-10-5) is very close to LinoType.

Thanks for the memory.

Cheers,

Dave

Testing is the only way to find out if the bullet will stay stable at different velocities.

I sold the mould, so no more testing on my end.

Regarding the H&G 130, I had the best group loading 3.9 Bullseye with a LinoType bullet @ 730 FPS.

COL Ellis Lea, my Father-in-Law shot with him in the 1950's. They, the Army team, won the Hard Ball Team match at Camp Perry and the photo is in an old American Rifleman.

The alloy you quoted (85-10-5) is very close to LinoType.

Thanks for the memory.

Cheers,

Dave

fc60- Posts : 1459

Join date : 2011-06-11

Location : South Prairie, WA 98385

Similar topics

Similar topics» LYMAN 452389 185 gr BNWC

» Using a Lyman "M" Die in a Dillon 650

» I forgot to ask Santa for a Lyman Mark 7 Reloading Press

» Lyman M Die Plug for 38 WCHB

» S&W revolver Lyman 358495 WC with HP38/231. Any expearance?

» Using a Lyman "M" Die in a Dillon 650

» I forgot to ask Santa for a Lyman Mark 7 Reloading Press

» Lyman M Die Plug for 38 WCHB

» S&W revolver Lyman 358495 WC with HP38/231. Any expearance?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum